Professional Documents

Culture Documents

Omr F Hn12ra02

Uploaded by

Bruna GomesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Omr F Hn12ra02

Uploaded by

Bruna GomesCopyright:

Available Formats

Tech Note

Hydraulic motors with negative brake type OMR F

HN.12.RA.02 is new

Introduction

Danfoss has extended its range of OMR motors to include a version with an integrated holding brake (negative brake) for use in both

open and closed circuits. The brake is a spring-applied, multiple-disc type which is released by hydraulic pressure.

Characteristics

High holding torque Compact unit with maximum brake/motor integration Minimum servicing - the brake is lubricated automatically by drain oil (no separate oil change)

Application

The brake motors are designed for hydrostatic transmissions and for applications where a load must be held in a given position.

Application examples

Road rollers Work platforms Mowing machines Miniloaders Sweepers Winches Machine tools

10-1997

HN.12.RA.02

Book 2 Partition 3

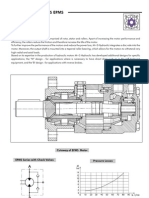

Funktion

In normal condition there is no pressure on the integrated brake in OMR, i.e. the motor is braked. The brake is released when hydraulic pressure of min. 21 bar is applied to the brake release port (1). The pressure forces the piston (2) against the springs (3 and 4) disengaging the outer and

inner discs (5 and 6) from each other so that the cardan shaft (7) and consequently output shaft (8) become free to rotate. If the pressure on the brake release port is reduced to less than 21 bar, the springs force the piston and pressure pad (9) against the brake discs and the cardan shaft/output shaft begin to, be locked.

Code numbers OMR with negative brake, side port version with 2-hole oval mounting flange

Type Cylindrical shaft 25 mm Weight (kg) OMR 80 F 151-6461* 11,5 OMR 100 F 151-6462 * 12,0 OMR 125 F 151-6463 * 12,0 OMR 160 F 151-6464* 12,5 OMR 200 F 151-6465* 12,5 OMR 250 F 151-6466 * 13,0 OMR 315 F 151-6467* 13,5 OMR 375 F 151-6468 * 14,0

* In principle the negative multi-disc brake can be built together with all existing OMR motors (80 - 375 cm3).Please contact the Danfoss Sales Organisation for Hydraulics for further information.

Technical data for OMR F with 25 mm shaft

OMR F 80 80,3 cont. 750 Max. speed (min-1) int.1) 940 cont. 19,5 Max. torque (daNm) int.1) 22 peak 2) 27 cont. 12,5 Max. output (kW) int.1) 15 cont. 175 Max. pressure drop (bar) int.1) 200 peak 2) 225 cont. 60 Max. oil flow (l/min) int.1) 75 Max. starting pressure with unloaded shaft (bar) 10 at max. press.drop cont. 15 Min. starting torque (daNm) at max. press.drop int.1) 17 3) -1 Min. speed (min ) 10 cont. Max. inlet / return pressure int.1) peak 2) Holding torque (daNm) (bar) Min. brake release press.4) Max. pressure in brake line (bar) Motor size Geometric displacement (cm3/rev)

1) 2) 3)

Type

OMR F 100 99,8 600 750 24 28 32 13 15 175 200 225 60 75 10 20 23 10

OMR F 125 125,7 475 600 30 34 37 12,5 14,5 175 200 225 60 75 9 25 28 9

OMR F OMR F 160 200 159,6 199,8 375 300 470 375 30 30 39 39 46 56 10 8 12,5 10 130 110 175 140 225 225 60 60 75 75 7 5 24 26 32 33 7 5 175 200 225 40 21 200

OMR F 250 249,3 240 300 30 38 60 6 8 80 110 200 60 75 5 24 31 5

OMR F 315 315,7 190 240 30 42 61 5 6,5 70 100 150 60 75 5 26 35 5

OMR F 375 372,6 160 200 30 43 60 4 6 55 85 130 60 75 5 24 38 5

Intermittent operation: the permissible values may occur for max. 10% of every minute. Peak load: the permissible values may occur for max. 1% of every minute. Operation at lower speeds may be slightly less smooth. 4) Brake motors must always have a drain line. The brake release pressure is the difference between the pressure in the brake release line and the pressure in the drain line.

HN.12.R-

Max. permissible shaft seal pressure

OMR F motors must always have a drain line

Max. pressure in the drain line

int. operation

Max. permissible radial load for OMR F with 25 mm cylindrical shaft and 2-hole oval mounting flange

Permissible shaft load (PR)

800 n

25000 95 + l

daN*

* n 200 min-1; and l 55 mm l = distance from loading point to mounting flange n = motor speed (min-1) if n < 200 min-1; and l 55 mm PR = max. 800 daN

Shuttle valve

For releasing the brake Danfoss offers a shuttle valve type VTF that can be flanged onto the OMR F motor. Code No.: 158H8003

A: G1/2 - 14 mm deep B: G1/4 - 12 mm deep

HN.12.R-

Dimensions

C D E F Type OMR 80 F OMR 100 F OMR 125 F OMR 160 F OMR 200 F OMR 250 F OMR 315 F OMR 375 F

: : : :

Drain connection G 1/4; 12 mm deep G 1/2; 15 mm deep M8; 13 mm deep Brake release connection G 1/4 L1 14.0 17.4 21.8 27.8 34.8 43.5 54.8 65.0 L2 186.25 189.65 194.05 200.05 207.05 215.75 227.05 237.25 L3 210.25 213.65 218.05 224.05 231.05 239.75 251.05 261.25

Lmax. 238.35 241.75 246.15 252.15 259.15 267.85 279.15 289.35

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DK-6430 Nordborg Denmark 4 HN.12.R-

You might also like

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Omrw NF Dkmhpn120a102Document4 pagesOmrw NF Dkmhpn120a102seaqu3stNo ratings yet

- Omr Na Hn12ka02Document4 pagesOmr Na Hn12ka02seaqu3stNo ratings yet

- Fixed Speed CatalogueDocument26 pagesFixed Speed CatalogueSarfaraz Hoda100% (1)

- TMT Dkmhpn141a102Document4 pagesTMT Dkmhpn141a102seaqu3stNo ratings yet

- Re 15190Document24 pagesRe 15190Ahmed Abd ElhakeemNo ratings yet

- Hydraulic Motors Epms: Cutaway of EPMS MotorDocument16 pagesHydraulic Motors Epms: Cutaway of EPMS MotorDavíð Örn FriðrikssonNo ratings yet

- Chapter5 - Drive CouplingsDocument90 pagesChapter5 - Drive Couplingsvijay219100% (1)

- Technical Specifications For Centrifugal Pumps PDFDocument12 pagesTechnical Specifications For Centrifugal Pumps PDFVicky GautamNo ratings yet

- FuelPurifier WestfaliaDocument193 pagesFuelPurifier WestfaliaHorst100% (2)

- Omt PDFDocument24 pagesOmt PDFIvanStefanovichNo ratings yet

- Catalogo JUMBO InglesDocument8 pagesCatalogo JUMBO InglesDarko BogdanovicNo ratings yet

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDocument4 pagesCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemNo ratings yet

- MANN Filters For LiquidsDocument48 pagesMANN Filters For LiquidsRoccinanteNo ratings yet

- Cryo Pump PDFDocument0 pagesCryo Pump PDFkanchanabalajiNo ratings yet

- Pump Polaris SeriesDocument47 pagesPump Polaris SeriesDANIZACHNo ratings yet

- clfd1292 - 1208Document8 pagesclfd1292 - 1208ggace82No ratings yet

- Axem Disc DC Servo Motor ManualDocument12 pagesAxem Disc DC Servo Motor ManualjohnysonycumNo ratings yet

- RW PDFDocument6 pagesRW PDFnbharath1988No ratings yet

- Brochure - 14.458 DC Spring Apllied BrakesDocument2 pagesBrochure - 14.458 DC Spring Apllied Brakeskpr_02161371No ratings yet

- EIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsDocument17 pagesEIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsPravinPMKoolNo ratings yet

- Gardner Denver Industrial Blowers TF 140L K202Document8 pagesGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićNo ratings yet

- Penta Wet KitDocument44 pagesPenta Wet KitAlexandru Nicu100% (1)

- Miniature Series Designed For Manifold MountingDocument5 pagesMiniature Series Designed For Manifold MountingKenry LimNo ratings yet

- Catálogo General Medidor para Agua WoltmanDocument8 pagesCatálogo General Medidor para Agua WoltmanLuis David LopezNo ratings yet

- IR LM100A Crawlair Drill PDFDocument8 pagesIR LM100A Crawlair Drill PDFAnonymous 8yIptglHhNo ratings yet

- Eaton Nomenclature 9 10 12 16 13 Speed Transmission PDFDocument13 pagesEaton Nomenclature 9 10 12 16 13 Speed Transmission PDFErick AjvixNo ratings yet

- Catalogo Motores OMT315 DanfosDocument20 pagesCatalogo Motores OMT315 DanfosLeandroNo ratings yet

- 190 e Cr302 en Servomotors-For-steam-turbinesDocument10 pages190 e Cr302 en Servomotors-For-steam-turbinesscribdkhatnNo ratings yet

- ZF Tiratron Catalog Rev 0 PDFDocument28 pagesZF Tiratron Catalog Rev 0 PDFNaracu FabianNo ratings yet

- Calpeda GXR, GXV Submersible Drainage PumpsDocument4 pagesCalpeda GXR, GXV Submersible Drainage PumpsWayne SeamanNo ratings yet

- Omega ES Adatlap 0Document2 pagesOmega ES Adatlap 0Cesar CcmNo ratings yet

- Hydraulic MotorsDocument8 pagesHydraulic MotorsAnonymous OFKjccHONo ratings yet

- Screw Pump Brochure USA LowResDocument12 pagesScrew Pump Brochure USA LowResSandeep LeeNo ratings yet

- 2112f-Brake Motors PATAY 3463c enDocument85 pages2112f-Brake Motors PATAY 3463c enSagacious NItin50% (2)

- 3887bhf Ws - BHF Series (b3887bhf)Document4 pages3887bhf Ws - BHF Series (b3887bhf)Oscar GonzalesNo ratings yet

- HoistDocument4 pagesHoistAnonymous 1qAH6CKCNo ratings yet

- Transtar Converter CatalogDocument0 pagesTranstar Converter CatalogANDWARHLNo ratings yet

- York CompressorsDocument6 pagesYork CompressorsFernando HuarocNo ratings yet

- Roto Rainer 2011Document8 pagesRoto Rainer 2011sunilbholNo ratings yet

- CA Motors Product DetailsDocument25 pagesCA Motors Product DetailsP Venkata Suresh100% (2)

- MMS Product GuideDocument40 pagesMMS Product GuideFelipe VargasNo ratings yet

- Fiac UK CatalogueDocument10 pagesFiac UK Cataloguewhwy99No ratings yet

- Pompa TOYO GR 10-2Document4 pagesPompa TOYO GR 10-2Daniel MocanuNo ratings yet

- Delco Remy 39MT Brochure 3 13Document6 pagesDelco Remy 39MT Brochure 3 13jonfortiNo ratings yet

- Air Motor Motair CatalogueDocument8 pagesAir Motor Motair CatalogueMohd Taufiq IsmailNo ratings yet

- Rotork ManualDocument6 pagesRotork ManualKamlesh DalavadiNo ratings yet

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesNo ratings yet

- Front Mount HF TechdataDocument14 pagesFront Mount HF TechdataAlexandru NicuNo ratings yet

- 681 FF867 D 01Document10 pages681 FF867 D 01nazar750No ratings yet

- Rexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDocument24 pagesRexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDarioNo ratings yet

- SMC 100 SB 2827 2008.10Document2 pagesSMC 100 SB 2827 2008.10rbctdiNo ratings yet

- Agitator SizingDocument4 pagesAgitator SizingArbee AquinoNo ratings yet

- Traxoil OM3 - OM4Document5 pagesTraxoil OM3 - OM4IonutCiobanuNo ratings yet

- Bomba Hidraulica Sp25Document5 pagesBomba Hidraulica Sp25Javier SumozaNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Mitsubishi Forklift Fg50k Service ManualDocument24 pagesMitsubishi Forklift Fg50k Service Manualchristopherwhite101288dxj100% (124)

- Ma & SaDocument20 pagesMa & SasingoNo ratings yet

- Operación de Sistemas: CP-563E, CP-573E, CS-563E, CS-573E and CS-583E Vibratory Soil Compactors Propel SystemDocument3 pagesOperación de Sistemas: CP-563E, CP-573E, CS-563E, CS-573E and CS-583E Vibratory Soil Compactors Propel SystemroqueNo ratings yet

- BLOWBAGETS: 10 Things To Check Before You Drive: Venus ZoletaDocument4 pagesBLOWBAGETS: 10 Things To Check Before You Drive: Venus Zoletaearl sorianoNo ratings yet

- Art of Design IntegrationDocument26 pagesArt of Design IntegrationML DeshmukhNo ratings yet

- Auto Adjust Clutch Cable Berlingo and Partner Van 96 05Document2 pagesAuto Adjust Clutch Cable Berlingo and Partner Van 96 05lesa33No ratings yet

- Mitsubishi Electric Genuine SolenoidsDocument8 pagesMitsubishi Electric Genuine SolenoidsJessie BechaydaNo ratings yet

- Model Car Builder 1Document40 pagesModel Car Builder 1naruemon khongmiNo ratings yet

- The Ten Forklift Safety RulesDocument10 pagesThe Ten Forklift Safety RulesAlexandra johnNo ratings yet

- 2WH LightDocument36 pages2WH LightJagotta Corp - Pravin BorgudeNo ratings yet

- O NA L: Isuzu Grafter' N35.15O (T) 3.5T GVWDocument2 pagesO NA L: Isuzu Grafter' N35.15O (T) 3.5T GVWtradeplatesNo ratings yet

- Negative Pressure SuperchargingDocument38 pagesNegative Pressure SuperchargingPrakash Chandrasekaran100% (1)

- 333G Compact Track Loader PIN 1T0333G F387881 Replacement Parts GuideDocument3 pages333G Compact Track Loader PIN 1T0333G F387881 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- Abschlussbericht B Agv 1Document126 pagesAbschlussbericht B Agv 1Hậu PhạmNo ratings yet

- Service Manual: Vacuum Cleaner FC8344Document5 pagesService Manual: Vacuum Cleaner FC8344Ana PfefferkornNo ratings yet

- Short Titles Long TitlesDocument2 pagesShort Titles Long TitlesTomyNo ratings yet

- Manual TransaxleDocument128 pagesManual TransaxleEdson Vereau Rosas100% (1)

- Dedham Transcript Feb. 3, 2011 Feeding The Stomach and Soul Through Meals On WheelsDocument1 pageDedham Transcript Feb. 3, 2011 Feeding The Stomach and Soul Through Meals On WheelsAndreaECalvinNo ratings yet

- 3378405M4 en 1200 Massey Ferguson 6400 Series Service Manual Chapter 11 ElectronicsDocument1,200 pages3378405M4 en 1200 Massey Ferguson 6400 Series Service Manual Chapter 11 ElectronicsMartin ZaehNo ratings yet

- CBM Digital SystemDocument238 pagesCBM Digital Systemadm comex bibNo ratings yet

- Aircraft DesigneDocument3 pagesAircraft DesigneNavjeet MeshramNo ratings yet

- Mcculloch Parts List: 530087882 Mac Cat 335, 435 & 440 03/08/00Document3 pagesMcculloch Parts List: 530087882 Mac Cat 335, 435 & 440 03/08/00lulu3232No ratings yet

- DTC P0504 Brake Switch "A" / "B" Correlation: DescriptionDocument4 pagesDTC P0504 Brake Switch "A" / "B" Correlation: Descriptionmike chenNo ratings yet

- TGX 6x2 Midlift Tractor: Chassis SpecificationDocument4 pagesTGX 6x2 Midlift Tractor: Chassis SpecificationDarNo ratings yet

- The Global Alliance of Nissan and Renaultt NBFHDBSJBFCKJSBKCBJSBDocument19 pagesThe Global Alliance of Nissan and Renaultt NBFHDBSJBFCKJSBKCBJSBSunil PatilNo ratings yet

- SCANIA Axle Load CalculationDocument19 pagesSCANIA Axle Load CalculationGuillermo Cordero33% (3)

- XCMG Excavator XE215BRDocument2 pagesXCMG Excavator XE215BRMyrcol Redes100% (1)

- Bike Tire SizeDocument6 pagesBike Tire Sizever_at_workNo ratings yet

- Pre-Placement Class - Mba - Man TrucksDocument34 pagesPre-Placement Class - Mba - Man Trucksrudey18No ratings yet

- ZF AS Tronic ManualDocument51 pagesZF AS Tronic ManualBienvenu Massouangui100% (6)