Professional Documents

Culture Documents

HSS Flange Plate Moment Connection - Temporary Steel

Uploaded by

rajedmaglinteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSS Flange Plate Moment Connection - Temporary Steel

Uploaded by

rajedmaglinteCopyright:

Available Formats

1012 - Lyric Opera House Expansion

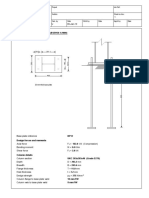

HSS Flange-Plate Moment Connection

Page 1 of 9

UPPER TEMP. ROOF FRAMING PLAN REF: S2.2

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

Lay-out:

3

1/4

W14x68 1/4

6'' HSS10X6X1/4 End offset = 0.5''

4 1/2'' HSS10X6X1/4 End offset = 0.5''

5''

5''

2-L3 1/2 x 3 1/2 x 5/16

PL3/8 - A36 (Top & Bottom Plates)

10''

3/16 8'' 8'' 2'' 1 1/4'' 1 1/4'' 3''

3/16

7''

(4)- 3/4" A325-SC-SSLN Bolts

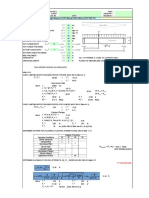

Required Strength: Member 1 Beam Reaction, Ra1 Moment, Ma1 Member 2 Beam Reaction, Ra2 Moment, Ma2

= =

10.0 30.0

kips kip-ft

= =

10.0 30.0

kips kip-ft

Page 2 of 9

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

Material & Geometric Properties: Members 1 & 2: Size: Fy Fu B HT A tdes tdet Member 3: Size: Fy Fu d tw bf tf kdes W14X68 ASTM A992 = ksi 50 = ksi 65 = in 14.00 = in 0.42 = in 10.00 = 0.72 in = in 1.31 ASTM 36 in in ksi ksi HSS10X6X1/4 = 46 = 58 6.00 = 10.00 = 7.10 = 0.233 = 0.250 = ASTM A500 Gr. B ksi ksi in in in in in

Bottom Flange-plate: t B Fy Fu = = = =

0.375 7 36 58

Top Flange-plate: t B Fy Fu Angles: Size: Fy Fu t B A y Calculations: = = = =

ASTM 36 0.375 4.5 36 58 in in ksi ksi

L3-1/2X3-1/2X5/16 36 = ksi 58 = ksi 0.3125 = in 3.50 = in 2.09 = in2 = 0.979 in2

ASTM 36

Double-Angle Connection

Bolt Shear Resistance Rn/ 2 X n x rn/ = where:

Page 3 of 9

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

rn/ = n= Rn/ = 42.4 10.6 2.00 kips kips

>

10.00

kips

(OK)

Bolt Bearing on Angles Exterior Bolts rn/ = 1.2 Lc t Fu < 2.4 d t Fu < 2.4 (0.75)(0.3125)(58) 2.0 16.31 kips

= = Use rn/ = Interior Bolts rn/ =

1.2 (0.84)(0.3125)(58) 2.0 9.18 9.18 kips kips <

1.2 Lc t Fu

<

2.4 d t Fu < 2.4 (0.75)(0.3125)(58) 2.0 16.31 kips

= = Use rn/ =

1.2 (2.19)(0.3125)(58) 2.0 23.79 16.31 kips kips >

Rn/

= = =

Allowable Bearing Resistance of Bolts 2 [ (1 x 9.18 + (2 - 1 ) x 16.31] kips > 50.98 10.00 kips

(OK)

Shear Yield Strength Rn/ = =

( = 1.5 ) Allowable Yield Strength of Angle 2 x 0.6 x Fy x Ag

where: Ag = Rn/ = 49.5 1.719 kips kips > 10.00 kips (OK)

Shear Rupture Strength Rn/ = =

( =2 ) Allowable Rupture Strength of Angle 2 x 0.6 x Fu x An

where:

Page 4 of 9

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

An db L An = tp x [L - n x (db 0.75 = in. 5.50 = in. 1.17 = in + 0.125)]

(Bolt Diameter) (Depth of Plate) (Net Cross-sectional Area)

Rn/

40.8

kips

>

10.00

kips

(OK)

Block Shear Strength Rn/ = = Where: Ubs =

( =2 ) Allowable Block Shear Strength of Angle 2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] 1.0

Agt = Gross Area with Tension Resistance = 1.50 x t 0.47 = in Ant = Net Area with Tension Resistance = Agt - t x (db +0.125)/2 0.33 = in Agv = Gross Area with Shear Resistance = ( L - 1.25 ) x t 1.33 = in Anv = Net Area with Shear Resistance = Agv - (n - 0.5) x (db + 0.125) x t 0.92 = in Rn/ Angle to HSS Weld See attached calcs. = 47.95 kips > 10.00 kips (OK)

Effective flange force

Ff1 Ff1 = = M H + (ttop + tbot)/2 34.70 kips

Bottom Flange Connection

Plate Buckling of Gusset Plate Ap = = = Effective Plate Cross-sectional Area L*t 2.63 in

Page 5 of 9

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

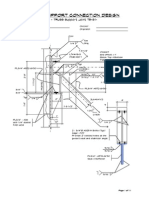

Lcr K = = = = = = = = Plate Unbraced Length of Whitmore Section 0.50 in. Effective Length Factor 0.65 Radius of Gyration t / 3.464 0.108 in. 3.00 < 25 36.00 ksi

K Lcr/r

Thus, Fcr = Fy = Rn/ = = Rn/ =

Allowable Strength in Compression Ap * Fcr 1.67 56.59 kips > 34.70 kips (OK)

Calculate weld size Max weld size that can be develop by the HSS D/16 = D= Fu t

3.09 0.27

4.373 in = = = =

sixteenths

Outside Radius of HSS, R Outside Radius of HSS, R Effective throat thickness, E Effective throat thickness, E

2 x tdes 0.500 (5/16) R 0.156

in

in

The equivalent fillet weld that provides the same throat dimension is w = 2 E in 0.221 w=

in

<

0.27

in.

(OK)

Bottom Plate to HSS weld Electrode Class Fu = = = = = = = = = E70XX

Nominal Tensile Strength of Weld 70 Ksi 0.00 0.000 deg rad

Size of Weld 0.2210 in. Allowable Weld Shear Strength 0.6 Fu / 2

Page 6 of 9

Fv

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

= Pw = = = = = = = = 21 Ksi

Shear Capacity of 1/4" weld per Linear Inch 0.707 * Fv * w * (1.0 + 0.50 sin1.5) (0.707 * 21 * 0.2209703125) * (1) 3.281 Kips/in Length of Weld 8 in. 2 L x Pw 52.49 kips > 34.70 kips (OK)

P P

Top Flange Connection

Tension Yielding of the Top Plate: Rn/ = where: Ag = B x t Ag = 1.69 Rn/ = 36.38 kips Fyp * Ag 1.67

in > 34.70 kips (OK)

Plate to Top Flange Weld: Perpendicular Weld Electrode Class Fu = = = = = = = = = = = = = = = = = E70XX

Nominal Tensile Strength of Weld Ksi 70 90.00 1.571 deg rad

Size of Weld 0.2500 in. Allowable Weld Shear Strength 0.6 Fu / 2 Ksi 21 Shear Capacity of 1/4" weld per Linear Inch 0.707 * Fv * w * (1.0 + 0.50 sin1.5) (0.707 * 21 * 0.25) * (1.5) Kips/in 5.568 Length of Weld 4.5 in. L x Pw

Page 7 of 9

Fv

Pw

P1

1012 - Lyric Opera House Expansion

HSS Flange-Plate Moment Connection

P1 Parallel Weld Electrode Class Fu = = = = = = = = = = = = = = = = = = E70XX = 25.05 kips

Nominal Tensile Strength of Weld 70 Ksi 0.00 0.000 deg rad

Size of Weld 0.2500 in. Allowable Weld Shear Strength 0.6 Fu / 2 21 Ksi Shear Capacity of 1/4" weld per Linear Inch 0.707 * Fv * w * (1.0 + 0.50 sin1.5) (0.707 * 21 * 0.25) * (1) Kips/in 3.712 Length of Weld in. 5 2 L x Pw 37.12 kips

Fv

Pw

P2 P2 Thus, P P

= =

+ P1 62.17

P2 kips

>

34.70

kips (OK)

Page 8 of 9

1012 - Lyric Opera House Expansion

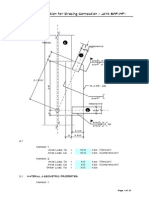

AISC 13th Edition Manual Table 8-8

Coefficients C for Eccentrically Loaded Weld Groups

Input:

kl = l = x = e x = al = = weld size, w = Fexx = C1 = P = Specs = 3 5.5 0.142 3.219 0 3/16 70 1 in in ksi kips xl kl l degrees in in P e x =al

5 ASD

where:

P = D = l = a = ex = C = C1 = required force, P u or P a , kips number of sixteenths-of-an-inch in the fillet weld size characteristic length of weld group, in. e x /l horizontal component of eccentricity of P with respect to centroid of weld group, in. weld group coefficient electrode strength coefficient (1.0 for E70XX electrodes)

Results:

C =

2.64

Available strength of a weld group, Rn/, is determined with C C1 D l Rn/ = (1/) = Setting Rn/ = P, D min = D min = P / C C1 l 0.689 l min = l min = P / C C1 D 1.264 in ( = 2.00)

Conclusion: Since Dmin = 0.689 < 3 (1/16's) Weld is adequate! and l min = 1.264 < 5.5 in.,

Page 9 of 9

You might also like

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNo ratings yet

- Plate GirderDocument15 pagesPlate GirderPriodeep ChowdhuryNo ratings yet

- Monorail 0.5 TonDocument9 pagesMonorail 0.5 TonAndreas HendiNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- 111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24Document7 pages111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24ItsmejanuNo ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- Base Plate For Tension1Document7 pagesBase Plate For Tension1maheshbandhamNo ratings yet

- Design of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Document10 pagesDesign of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Rajib MaharjanNo ratings yet

- Deck Girder - Top GirderDocument3 pagesDeck Girder - Top GirdervibishnanNo ratings yet

- Pin Design AISCDocument3 pagesPin Design AISCFernando SimaNo ratings yet

- 8Document6 pages8Mohan BhalmeNo ratings yet

- Moment Connection Design Hea220Document56 pagesMoment Connection Design Hea220Atul WanodeNo ratings yet

- 3PB Pilecap DesignDocument3 pages3PB Pilecap DesignJONAS NGNo ratings yet

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 pagesFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerNo ratings yet

- Moment Connection - Beam SpliceDocument3 pagesMoment Connection - Beam SpliceSh MNNo ratings yet

- W12x30 Beam To BeamDocument6 pagesW12x30 Beam To BeamWin ThanNo ratings yet

- LRFD Beam Column DesignDocument242 pagesLRFD Beam Column DesignChristian FTNo ratings yet

- Light Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PDocument7 pagesLight Gage Truss Design Based On AISI S100/SI-10 & ESR-3064PShan Adrias100% (1)

- Portal FrameDocument42 pagesPortal Framesurendra_pangaNo ratings yet

- Beam Column - IS 800Document2 pagesBeam Column - IS 800parishith0% (1)

- Welded Splice Connection-R2Document33 pagesWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Gantry Girder DesignDocument6 pagesGantry Girder DesignpandianNo ratings yet

- Base Plate Ver Brace Connection - Column FlangeDocument27 pagesBase Plate Ver Brace Connection - Column FlangeAnıl Berk SağırNo ratings yet

- Footing Sliding Pressure21Document452 pagesFooting Sliding Pressure21ersinNo ratings yet

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7No ratings yet

- Web Flange WeldDocument1 pageWeb Flange Weldakgupta733779No ratings yet

- AISC 360 VerificationBeamDesign PDFDocument7 pagesAISC 360 VerificationBeamDesign PDFCarl Patrick Erni RagasNo ratings yet

- Splice DesignDocument13 pagesSplice Designtitir bagchiNo ratings yet

- Columna de SotanoDocument38 pagesColumna de SotanoLivian TeddyNo ratings yet

- Welded & Pinned Connection Design CalculationDocument14 pagesWelded & Pinned Connection Design CalculationPrakash Singh RawalNo ratings yet

- Welded Moment Connection PDFDocument22 pagesWelded Moment Connection PDFRajasekar MeghanadhNo ratings yet

- Design of Beam To Beam Connection Using Web CleatDocument2 pagesDesign of Beam To Beam Connection Using Web CleatAnonymous UUAriPf8KqNo ratings yet

- HDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Document8 pagesHDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Mohammad Shadab AliNo ratings yet

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- Design of Plate GirderDocument7 pagesDesign of Plate Girderlakshmi1011No ratings yet

- Welded Splice Connection-R2Document16 pagesWelded Splice Connection-R2Nitesh Singh100% (1)

- Knee ConnectionsDocument13 pagesKnee ConnectionsNag RajNo ratings yet

- SteelDesign Composite Fu NewDocument16 pagesSteelDesign Composite Fu Newpresentasi mankonNo ratings yet

- Steel Column FOR SCRIBDDocument8 pagesSteel Column FOR SCRIBDdarshika.jaganiNo ratings yet

- TR 6 & 7-K-126Document20 pagesTR 6 & 7-K-126rammohanNo ratings yet

- Column Splice 356 x368x129 Column - WeldDocument4 pagesColumn Splice 356 x368x129 Column - WeldNiraj Shinde100% (1)

- Insert Plate Design - LugsDocument8 pagesInsert Plate Design - Lugsnavneet3bawaNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 1Document9 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 1Ahmad Badsha QuadriNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Standard Isolated Footing f1Document11 pagesStandard Isolated Footing f1Saajan bhathalNo ratings yet

- Bolt Design (Blodget)Document4 pagesBolt Design (Blodget)mayureshNo ratings yet

- Design of Beam Based On ACI 318-99Document5 pagesDesign of Beam Based On ACI 318-99Haris AlamNo ratings yet

- Calculations of Effective Length of Steel Columns: AS PER IS 800: 2007 (Annex D, Cl. 7.2.2)Document4 pagesCalculations of Effective Length of Steel Columns: AS PER IS 800: 2007 (Annex D, Cl. 7.2.2)Zaki SiddiquiNo ratings yet

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasNo ratings yet

- Design of BracingDocument4 pagesDesign of Bracingankkeshmundra1No ratings yet

- Setting Bolt CalculationDocument1 pageSetting Bolt Calculationrina2393No ratings yet

- Precast Rib Beam DesignDocument1 pagePrecast Rib Beam Designanshutomar7915100% (1)

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Rule of Thumb Concrete DesignDocument54 pagesRule of Thumb Concrete DesignrunkirNo ratings yet

- Ltil LRN Eb Ezee.:, Clean. Postholes, in Concre, Le !Document2 pagesLtil LRN Eb Ezee.:, Clean. Postholes, in Concre, Le !rajedmaglinteNo ratings yet

- PCA Rectangular - Tank Design ExampleDocument15 pagesPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- SlabsOnGrade - Ppthandout ACI 360Document7 pagesSlabsOnGrade - Ppthandout ACI 360Ivan Pacompia Calcina50% (2)

- Structural Engineer 2009 Top Performers ListDocument3 pagesStructural Engineer 2009 Top Performers ListrajedmaglinteNo ratings yet

- Piling RequirementsDocument80 pagesPiling Requirementsthusi67% (3)

- Haydon TC Wrench InfoDocument11 pagesHaydon TC Wrench InforajedmaglinteNo ratings yet

- Chap 3-Structural Bolts PDFDocument45 pagesChap 3-Structural Bolts PDFAndang85No ratings yet

- WireRopeRailingEngSection ADocument16 pagesWireRopeRailingEngSection ArajedmaglinteNo ratings yet

- SP Slab PresentationDocument19 pagesSP Slab PresentationrajedmaglinteNo ratings yet

- Spslab Manual PDFDocument251 pagesSpslab Manual PDFrajedmaglinteNo ratings yet

- FootingsDocument2 pagesFootingsrajedmaglinteNo ratings yet

- A325 and Class 8.8Document3 pagesA325 and Class 8.8rajedmaglinte100% (1)

- Brace ConnectionDocument8 pagesBrace ConnectionrajedmaglinteNo ratings yet

- Steel Connection Formulas - Tension CheckDocument1 pageSteel Connection Formulas - Tension CheckrajedmaglinteNo ratings yet

- Wood Armer Equations 553Document2 pagesWood Armer Equations 553Balaji VenkateswaranNo ratings yet

- Twisting Momentsin Two-Way SlabsDocument6 pagesTwisting Momentsin Two-Way SlabsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Corrosion Protection of Steel BridgesDocument0 pagesCorrosion Protection of Steel Bridgesrajedmaglinte100% (1)

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- Beam DesignDocument1 pageBeam DesignrajedmaglinteNo ratings yet

- Column TiesDocument1 pageColumn TiesrajedmaglinteNo ratings yet

- FootingsDocument2 pagesFootingsrajedmaglinteNo ratings yet

- HLC Vs KWIK CON IIDocument2 pagesHLC Vs KWIK CON IIrajedmaglinteNo ratings yet

- Forged Steel Clevis: Caution: Never Exceed The Working Load LimitDocument1 pageForged Steel Clevis: Caution: Never Exceed The Working Load LimitrajedmaglinteNo ratings yet

- 3in DeckDocument1 page3in DeckrajedmaglinteNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- STAT4GDocument1 pageSTAT4GjoramiandrisoaNo ratings yet

- ESD PPT HKDocument11 pagesESD PPT HKHarshvardhan MishraNo ratings yet

- Id Based Multicast Secret-Key Management Scheme (SKMS) in ManetsDocument10 pagesId Based Multicast Secret-Key Management Scheme (SKMS) in ManetsSandhya RaniNo ratings yet

- VCSEL Technology v1Document17 pagesVCSEL Technology v1Vaibhav MathurNo ratings yet

- Simplified Management With Hitachi Command Suite Application BriefDocument19 pagesSimplified Management With Hitachi Command Suite Application BriefpankajrudrawarNo ratings yet

- Communication Technology The New Media in Society PDFDocument2 pagesCommunication Technology The New Media in Society PDFElma0% (5)

- The Impact of E-Banking On Customer Satisfaction in NigeriaDocument13 pagesThe Impact of E-Banking On Customer Satisfaction in NigeriaRoni Shikder100% (2)

- CxSuite Scanned Vulnerabilities List 7.14 PDFDocument15 pagesCxSuite Scanned Vulnerabilities List 7.14 PDFFlorino IsletaNo ratings yet

- Electronics 19 PDFDocument25 pagesElectronics 19 PDFgitanjali seciNo ratings yet

- ANDROID Workshop MaheshDocument72 pagesANDROID Workshop MaheshPradeepCool100% (2)

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 page07.4 111 FW ML PF WPS 20mm ENGViktorNo ratings yet

- Proses Manufaktur: Machining Operation and Machine ToolsDocument34 pagesProses Manufaktur: Machining Operation and Machine ToolsLyndaNo ratings yet

- FL FX 1961 1976 Parts Book Harley Davidson OPTDocument239 pagesFL FX 1961 1976 Parts Book Harley Davidson OPTbron nonnamakerNo ratings yet

- Proses Bisnis Otomotif: Zummayroh, S.PDDocument26 pagesProses Bisnis Otomotif: Zummayroh, S.PDHannyka FebrianoNo ratings yet

- 2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.Document3 pages2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.des1982No ratings yet

- Gmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDDocument2 pagesGmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDShresth SanskarNo ratings yet

- The Hydraulic Pumping SystemDocument12 pagesThe Hydraulic Pumping SystemCarlos Lopez DominguezNo ratings yet

- Stm32 Mcu FamilyDocument12 pagesStm32 Mcu FamilyriverajluizNo ratings yet

- Flare Gas Reduction: Recent Global Trends and Policy Considerations by GE Energy, January 2011Document60 pagesFlare Gas Reduction: Recent Global Trends and Policy Considerations by GE Energy, January 2011Randall WestNo ratings yet

- Ee503 - Ic Fabrication and Packaging TechnologyDocument34 pagesEe503 - Ic Fabrication and Packaging TechnologyPrevenaManiamNo ratings yet

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTDocument7 pagesErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- 213078Document38 pages213078Mbade NDONGNo ratings yet

- 120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Document43 pages120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Mazariegôs JJNo ratings yet

- Labtech 20121120 - SS HIRE Bro C 2Document24 pagesLabtech 20121120 - SS HIRE Bro C 2Carlos PereaNo ratings yet

- The Diffusion of Innovation and Adopter CategoriesDocument3 pagesThe Diffusion of Innovation and Adopter CategoriesMark Angelo TitcoNo ratings yet

- Self Priming Water Lifting Booster PumpDocument2 pagesSelf Priming Water Lifting Booster PumpzhelipumpNo ratings yet

- Celsius Scale Thermometer Displays The Ambient Temperature Through A LCD DisplayDocument6 pagesCelsius Scale Thermometer Displays The Ambient Temperature Through A LCD DisplayJaspinder SinghNo ratings yet

- ICBC Motorcycle Handbook (British Columbia)Document212 pagesICBC Motorcycle Handbook (British Columbia)BNo ratings yet

- Fire Risk Assessment ChecklistDocument10 pagesFire Risk Assessment Checklistm. absiyeNo ratings yet

- Seagoing Tug "Mhan Aung-3": Ministry of TransportDocument2 pagesSeagoing Tug "Mhan Aung-3": Ministry of TransportnyaungzinNo ratings yet