Professional Documents

Culture Documents

ACI 233r - 95 GGBS

Uploaded by

Mahmood MuftiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI 233r - 95 GGBS

Uploaded by

Mahmood MuftiCopyright:

Available Formats

ACI 233R-95

(Reapproved 2000)

Ground Granulated Blast-Furnace Slag as a Cementitious Constituent in Concrete

Reported by ACI Committee 233

Stanley J. Virgalitte Chairman* Leonard W. Bell* Bayard M. Call* Ravindra K. Dhir Mark D. Luther Secretary* Bryce A. Ehmke* R. Douglas Hooton* Gunnar M. Idorn Jere H. Rose Bryant Mather Technical Subcommittee Chairman* Editorial Subcommittee Chairman* Paul Klieger* Donald W. Lewis* V. M. Malhotra* Della M. Roy Mauro J. Scali

* Members of the Subcommittee who prepared this report. The committee also wishes to acknowledge the contributions of Associate Member Graham R. H. Grieve to the development of this report.

The use of iron blast-furnace slag as a constituent of concrete, either as an aggregate or as a cementing material, or both, is well known. The use of ground granulated blast-furnace (GGBF) slag in the production of blended cements began in 1905 in the United States. Recent attention has been given to the use of GGBF slag as a separate cementitious constituent of concrete. This report primarily addresses the use of GGBF slag as a separate cementitious material added along with portland cement in the production of concrete. Other slags derived from the smelting of materials other than iron ores are not discussed in this report. The reader should be aware that the material characteristics described and the recommendations for use pertain solely to ground granulated iron blast-furnace (GGBF) slag. Keywords: blast-furnace slag; concretes; granulated materials; mix proportioning; mortars (material); pelletized; portland cements; specications.

Chapter 2Storage, handling, and batching, p. 233R-5 2.1Storage 2.2Handling 2.3Batching Chapter 3Proportioning concrete containing GGBF slag, p. 233R-5 3.1Proportioning with GGBF slag 3.2Ternary systems 3.3Use with chemical admixtures Chapter 4Effects on properties of fresh concrete, p. 233R-7 4.1Workability 4.2Time of setting 4.3Bleeding 4.4Rate of slump loss Chapter 5Effects on properties of hardened concrete, p. 233R-8 5.1Strength and rate of strength gain 5.2Modulus of elasticity 5.3Creep and shrinkage 5.4Influence of curing on the performance of GGBF slag 5.5Color 5.6Effects on temperature rise in mass concrete

CONTENTS Chapter 1General information, p. 233R-2 1.1History 1.2Scope and objective 1.3Definitions 1.4Origin of blast-furnace slag 1.5Chemical and physical properties 1.6Processing 1.7Specifications 1.8Hydraulic reactivity 1.9Factors determining cementitious properties

ACI Committee Reports, Guides, Standard Practices, and Commentaries are intended for guidance in designing, planning, executing, or inspecting construction and in preparing specifications. Reference to these documents shall not be made in the Project Documents. If items found in these documents are desired to be part of the Project Documents, they should be phrased in mandatory language and incorporated in the Project Documents.

ACI 233R-95 (reapproved 2000) supersedes and replaces ACI 226.1RR-87 and became effective October 1, 1995. Copyright 2000, American Concrete Institute. All rights reserved including rights of reproduction and use in any form or by any means, including the making of copies by any photo process, or by any electronic or mechanical device, printed, written, or oral, or recording for sound or visual reproduction or for use in any knowledge or retrieval system or device, unless permission in writing is obtained from the copyright proprietors.

233R-1

233R-2

ACI COMMITTEE REPORT

5.7Permeability 5.8Resistance to sulfate attack 5.9Reduction of expansion due to alkali-silica reaction (ASR) 5.10Resistance to freezing and thawing 5.11Resistance to deicing chemicals 5.12Resistance to the corrosion of reinforcement Chapter 6Uses of GGBF slag in concrete, p. 233R-15 6.1Introduction 6.2Ready-mixed concrete 6.3Concrete products 6.4Mortars and grouts Chapter 7References, p. 233R-16 7.1Specified and/or recommended references 7.2Cited references CHAPTER 1GENERAL INFORMATION 1.1History The use of ground granulated blast-furnace (GGBF) slag as a cementitious material dates back to 1774 when Loriot made a mortar using GGBF slag in combination with slaked lime (Mather 1957). In 1862, Emil Langen proposed a granulation process to facilitate removal and handling of iron blast-furnace slag leaving the blast furnace. Glassy iron blast-furnace slags were later investigated by Michaelis, Prussing, Tetmayer, Prost, Feret, and Green. Their investigation, along with that of Pasow, who introduced the process of air granulation, played an important part in the development of iron blastfurnace slag as a hydraulic binder (Thomas 1979). This development resulted in the first commercial use of slag-lime cements in Germany in 1865. In France, these slag cements were used as early as 1889 to build the Paris underground metro system (Thomas 1979). The use of GGBF slags in the production of blended cements accounted for nearly 20 percent of the total hydraulic cement produced in Europe (Hogan and Meusel 1981). The first recorded production of portland blast-furnace slag cement was in Germany in 1892; the first United States production was in 1896. Until the 1950s, GGBF slag was used in production of cement or as a cementitious material in two basic ways: as a raw material for the manufacture of portland cement, and as a cementitious material combined with portland cement, hydrated lime, gypsum, or anhydrite (Lewis 1981). Since the late 1950s, use of GGBF slag as a separate cementitious material added at the concrete mixer with portland cement has gained acceptance in South Africa, Australia, the United Kingdom, Japan, Canada, and the United States. Separate grinding of GGBF slag and portland cement, with the materials combined at the mixer, has two advantages over the interground blended cements: 1) each material can be ground to its own optimum fineness and 2) the proportions can be adjusted to suit the particular project needs.

Production capacity for GGBF slag is estimated to be approximately two million metric tons annually in North America. A part of this is used stabilizing mine tailings and industrial waste materials. There are five companies providing GGBF slag in North America. According to the 1991 Bureau of Mines Annual Report, 13,293,000 metric tons of blast-furnace slag were sold or used in the United States during that year (Solomon 1991). Today, much of this material could be used for the production of cementitious material if granulating facilities were available at all furnace locations. Additional sources of GGBF slag may become available for energy and environmental reasons. 1.2Scope and objective This state-of-the-art report presents a detailed discussion of the composition and production of GGBF slag, its use in concrete, and its effects on the properties of concrete and mortar. Other types of slag not produced in the iron-making process, (i.e., those derived from the production of copper, lead, and steel) may differ greatly in composition and performance from GGBF slags, and their performance in concrete cannot be predicted from the information provided in this report. The objective of this report is to compile and present experiences in research and field use of GGBF slag in concrete and mortar, and to offer guidance in its selection, proportioning, and use. 1.3Definitions 1.3.1 ACI definitionsACI 116R contains the following: Blast-furnace slagThe nonmetallic product, consisting essentially of silicates and aluminosilicates of calcium and of other bases, that is developed in a molten condition simultaneously with iron in a blast furnace. 1. Air-cooled blast-furnace slag is the material resulting from solidification of molten blast-furnace slag under atmospheric conditions; subsequent cooling may be accelerated by application of water to the solidified surface. 2. Expanded blast-furnace slag is the lightweight, cellular material obtained by controlled processing of molten blastfurnace slag with water, or water and other agents, such as steam or compressed air, or both. 3. Granulated blast-furnace slag is the glassy granular material formed when molten blast-furnace slag is rapidly chilled, as by immersion in water. Cement, blendedA hydraulic cement consisting essentially of an intimate and uniform blend of granulated blastfurnace slag and hydrated lime; or an intimate and uniform blend of portland cement and granulated blast-furnace slag, portland cement and pozzolan, or portland blast-furnace slag cement and pozzolan, produced by intergrinding portland cement clinker with the other materials or by blending portland cement with the other materials, or a combination of intergrinding and blending. Cement, portland blast-furnace slagA hydraulic cement consisting of an intimately interground mixture of portland-

GROUND GRANULATED BLAST FURNACE SLAG

233R-3

cement clinker and granulated blast-furnace slag or an intimate and uniform blend of portland cement and fine granulated blast-furnace slag in which the amount of the slag constituent is within specified limits. Cement, slagA hydraulic cement consisting mostly of an intimate and uniform blend of granulated blast-furnace slag and hydrated lime in which the slag constituent is more than a specified minimum percentage. 1.3.2 ASTM definition GlassASTM C 162 defines glass as an inorganic product of fusion which has cooled to a rigid condition without crystallization. 1.4Origin of blast-furnace slag In the production of iron, the blast furnace is continuously charged from the top with iron oxide (ore, pellets, sinter, etc.), fluxing stone (limestone and dolomite), and fuel (coke). Two products are obtained from the furnace: molten iron that collects in the bottom of the furnace (hearth) and liquid iron blast-furnace slag floating on the pool of iron. Both are periodically tapped from the furnace at a temperature of about 1500 C. 1.5Chemical and physical properties The composition of blast-furnace slag is determined by that of the ores, fluxing stone, and impurities in the coke charged into the blast furnace. Typically, silicon, calcium, aluminum, magnesium, and oxygen constitute 95 percent or more of the blast-furnace slag. Table 1.1 indicates the chemical analysis range for elements (reported as oxides) in blastfurnace slags produced in the United States and Canada in 1988. The ranges in composition from source to source shown in Table 1.1 are much greater than those from an individual plant. Modern blast-furnace technology produces very low variability in the compositions of both the iron and the slag from a single source. To maximize hydraulic (cementitious) properties, the molten slag must be chilled rapidly as it leaves the blast furnace. Rapid quenching or chilling minimizes crystallization and converts the molten slag into fine-aggregate-sized particles (generally smaller than a 4.75 mm (No. 4) sieve, composed predominantly of glass. This product is referred to as granulated iron blast-furnace slag. The cementitious action of a granulated blast-furnace slag is dependent to a large extent on the glass content, although other factors will also have some influence. Slowly cooled slags are predominately crystalline and therefore do not possess significant cementitious properties. 1.6Processing Quenching with water is the most common process for granulating slags to be used as cementitious materials. Simple immersion of the molten slag in water was often used in the past; more efficient modern granulation systems use high-pressure water jets that impinge on the stream of molten slag at a water-slag ratio of about 10 to 1 by mass. The blast-furnace slag is quenched almost instantaneously to a

Table 1.1Range of chemical composition of blastfurnace slags in the United States and Canada

Chemical constituents (as oxides)* SiO2 Al2O3 CaO MgO S Fe2O3 MnO

* Except for sulfur.

Range of composition percent by mass 32-42 7-16 32-45 5-15 0.7-2.2 0.1-1.5 0.2-1.0

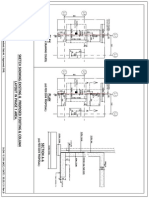

temperature below the boiling point of water, producing particles of highly glassy material (Fig. 1.1). Another process, sometimes referred to as air granulation, involves use of the pelletizer (Cotsworth 1981). In this process, the molten slag passes over a vibrating feed plate, where it is expanded and cooled by water sprays. It then passes onto a rotating, finned drum, which throws it into the air where it rapidly solidifies to spherical pellets. The resulting product may also have high glass content and can be used either as a cementitious material, or in the larger particle sizes, as a lightweight aggregate (Fig. 1.2). Other processes for combining slag with water which are used primarily for the production of lightweight aggregates are also capable of producing a sufficiently glassy slag for successful cementitious use (Robertson 1979). After the granulated blast-furnace slag is formed, it must be dewatered, dried, and ground before it is used as a cementitious material. Magnets are often used before and after grinding to remove residual metallic iron. Typically, the slag is ground to an air-permeability (Blaine) fineness exceeding that of portland cement to obtain increased activity at early ages. As with portland cement and pozzolans, the rate of reaction increases with the fineness.

Fig. 1.1Conguration of GGBF slag water granulator to include steam-condensing tower (Hogan and Meusel 1981)

233R-4

ACI COMMITTEE REPORT

Table 1.2Slag-activity index standards for various grades as prescribed in ASTM C 989

Slag-activity index, minimum percent Average of last ve consecutive samples Any individual sample 7-day index 75 70 95 90 28-day index 75 70 95 90 115 110

Grade 80 100 120 80 100 120

Fig. 1.2GGBF slag pelletization process, using a minimum of water usually applied at the vibrating feed plate (Hogan and Meusel 1981) 1.7Specifications ASTM C 989, first adopted in 1982, provides for three strength grades of GGBF slags, depending on their respective mortar strengths when blended with an equal mass of portland cement. The classifications are Grades 120, 100, and 80,* based on the slag-activity index expressed as: SAI = slag-activity index, percent = (SP/P x 100) SP = average compressive strength of slag-reference cement mortar cubes, psi P = average compressive strength of reference cement mortar cubes, psi Classification is in accordance with Table 1.2 (adapted from ASTM C 989) as follows: The slag-activity index test is influenced by the portland cement used; ASTM C 989 specifies total alkalies and 28day compressive strengths for the reference cement. The precision of this test is such that the coefficient of variation is 4.1 percent for single laboratory testing and 5.7 percent for multilaboratory testing. In addition to requirements on strength performance, the specification limits the residue on a 45-m (No. 325) sieve to 20 percent and the air content of a mortar containing only GGBF slag to a maximum of 12 percent. The specification also includes two chemical requirements: one limiting the sulfide sulfur (S) to a maximum of 2.5 percent and the other limiting the sulfate content (reported as SO3) to a maximum of 4.0 percent. Canadian standards CSA A363 and CSA A23.5 differentiate between GGBF slags that react hydraulically with water and those that require activators to develop their cementitious properties quickly. Blended cements, in which the GGBF slags are combined with portland cement, are covered by ASTM C 595. Three types of such cements are addressed: 1) slag-modified portland cement [Type I (SM)], in which the GGBF slag constituent is less than 25 percent of the total mass; 2) portland blast-furnace slag cement (Type IS), which contains 25 to 70 percent GGBF slag; and 3) slag cement (Type S), containing

* The literature referenced in this report does not always identify the slag by grade because the standard for grade determination was not recognized prior to 1982.

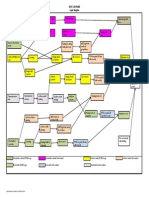

70 percent or more GGBF slag. While the specifications permit the GGBF slag and the other ingredients to be ground either together or separately and blended, most portland blastfurnace slag cements have been interground. Such cements have been used worldwide for almost 100 years, and have excellent service records (Lea 1971). 1.8Hydraulic activity There is general agreement among researchers (Smolczyk 1978), that the principal hydration product that is formed when GGBF slag when it is mixed with portland cement and water is essentially the same as the principal product formed when portland cement hydrates, i.e., calcium-silicate hydrate (CSH). As seen in the ternary diagram in Fig. 1.3, portland cement and GGBF slag lie in the same general field, although portland cement is essentially in the tricalcium silicate (C3S) field whereas GGBF slag is found essentially in the dicalcium silicate (C2S) field of the diagram. GGBF slag hydrates are generally found to be more gellike than the products of hydration of portland cement, and so add denseness to the cement paste. When GGBF slag is mixed with water, initial hydration is much slower than portland cement mixed with water; therefore, portland cement or alkali salts or lime are used to increase the reaction rate. Hydration of GGBF slag in the presence of portland cement depends largely upon breakdown and dissolution of the glassy slag structure by hydroxyl ions released during the hydration of the portland cement. In the hydration of GGBF slag, the GGBF slag reacts with alkali and calcium hydroxide (Ca(OH)2) to produce additional CSH. Regourd (1980) showed that a very small immediate reaction also takes place when GGBF slag is mixed with water, preferentially releasing calcium and aluminum ions to solution. The reaction is limited, however, until additional alkali, calcium hydroxide, or sulfates are available for reaction. Research by Regourd (1980), Vanden Bosch (1980), and Roy and Idorn (1982) has suggested that, in general, hydration of GGBF slag in combination with portland cement at normal temperature is a two-stage reaction. Initially and during the early hydration, the predominant reaction is with alkali hydroxide, but subsequent reaction is predominantly with calcium hydroxide. Calorimetric studies of the rate of

GROUND GRANULATED BLAST FURNACE SLAG

233R-5

heat liberation show this two-stage effect, in which the major amount of GGBF slag hydration lags behind that of the portland-cement component (Fig. 1.4). With increasing temperature, the alkali hydroxides from the cement have greater solubility; therefore, they predominate in promoting the early reactions of the GGBF slag. GGBF slag is thus able to chemically bind a larger amount of alkali in the CSH because of the calcium to silica ratio of the CSH formed from GGBF slag is lower than that formed from portland cement (Regourd 1987). Forss (1982) and Voinovitch, Raverdy, and Dron (1980) have shown that alkali hydroxide alone, i.e., without calcium hydroxide from portland cement hydration, can hydrate GGBF slag to form a strong cement paste structure which may be used in special application. 1.9Factors determining cementitious properties The clarification of the basic principles of slag hydration makes it possible to identify the primary factors that in practice will influence the effectiveness of the uses of GGBF slag in hydraulic cement. These factors are: a) chemical composition of the GGBF slag b) alkali concentration of the reacting system c) glass content of the GGBF slag d) fineness of the GGBF slag and portland cement e) temperature during the early phases of the hydration process Due to the complexity of the influencing factors, it is not surprising that earlier attempts to relate the hydration of GGBF slag to simplified chemical moduli failed to provide adequate evaluation criteria for practice (Mather 1957, Hooton and Emery 1980). The complexity of the reacting system suggests that direct performance evaluations of workability, strength characteristics, and durability are the most satisfactory measures of the effectiveness of GGBF slag use. The ASTM C 989 slag-activity index is often used as a basic criterion for evaluating the relative cementitious potential of a GGBF slag. Furthermore, proportioning for particular performance requirements should be based on tests of concrete including the same materials intended to be used in the work. CHAPTER 2STORAGE, HANDLING, AND BATCHING 2.1Storage As is the case with portland cement and most pozzolans, GGBF slag must be stored in bins or silos to provide protection from dampness and contamination. Color and fineness of GGBF slag can be similar to those of portland cement; therefore, necessary precautions should be taken to clearly mark handling and storage equipment. When compartmented bins are used, periodic checks for leaks between adjacent bins should be conducted to avoid contamination of the stored materials. 2.2Handling GGBF slags are handled with the same kinds of equipment Fig. 1.3Ternary diagram indicating composition of portland cement and blast-furnace slag in the system CaO-SiO2Al2O3 [based on Lea (1971) and Bakker (1983)]

Fig. 1.4Rate of heat liberation of cements with and without GGBF slag at 27 C (80 F) (Roy and Idorn 1982) as portland cement. The most commonly used items of equipment are pneumatic pumps, screw conveyors, air slides, and bucket elevators. Unlike some other finely-divided materials that are extremely fluid when aerated, GGBF slags do not require special gates or feeders. Since GGBF slags are cementitious, periodic emptying and cleaning of the screws, air slides, weigh hoppers, and associated equipment is advised. 2.3Batching GGBF slag should be batched by weight in accordance with the requirements of ACI 304R and ASTM C 94. When GGBF slag is batched cumulatively in the same weighing apparatus with portland cement, the GGBF slag should follow the weighing of portland cement. When the GGBF slag is introduced into the mixer, it is preferable to introduce it along with the other components of the concrete mixture. CHAPTER 3PROPORTIONING CONCRETE CONTAINING GGBF SLAG 3.1Proportioning with GGBF slag In most cases, GGBF slags have been used in proportions of 25 to 70 percent by mass of the total cementitious materi-

233R-6

ACI COMMITTEE REPORT

al. These proportions are in line with those established by ASTM C 595 for the production of portland blast-furnace slag cement. In South Africa, its use has been predominantly at 50 percent replacement of cement due to convenience in proportioning (Wood 1981). The use of GGBF slag in alkali-activated systems where no portland cement is used has been found to provide special properties in the CSIR and several European countries according to Talling and Brandstetr (1989). Mary (1951) described the preparation of slag cement by the Trief wet process and its use in the Bort-les-Orgues Dam. This was done after World War II when the supply of portland cement was limited. The dam involved 660,000 m3 (863,000 yd3) of concrete. The slag was ground wet and charged into the mixer as a thick slurry. A sample of the Trief wet process cement was obtained by the Corps of Engineers in December 1950 and tested at the Waterways Experiment Station (WES 1953). In the WES tests the behavior of the ground slag from Europe was compared with slag ground in the laboratory from expanded slag from Birmingham, Alabama. Each slag was activated with 1.5 percent sodium hydroxide and 1.5 percent sodium chloride by weight, with generally similar results. Such systems are not in commercial use in the U.S.A. The proportion of GGBF slag should be dictated by the purposes for which the concrete is to be used, the curing temperature, the grade (activity) of GGBF slag, and the portland cement or other activator. Where GGBF slags are blended with portland cement, the combination of cementitious material will result in physical properties that are characteristic of the predominant material. For example, as the percentage of GGBF slag increases, a slower rate of strength gain should be expected, particularly at early ages, unless the water content is substantially reduced or accelerators are used or accelerated curing is provided. There appears to be an optimum blend of GGBF slag that produces the greatest strength at 28 days as tested by ASTM C 109. This optimum is usually found to be 50 percent of the total cementitious material, although this relationship varies depending on the grade of GGBF slag (Hogan and Meusel 1981, Fulton 1974). Other considerations that will determine the proportion of GGBF slag to be used will depend on the requirements for temperature rise control, time of setting and finishing, sulfate resistance, and the control of expansion due to the alkali-silica reaction. For example, where high sulfateresistance is required, the GGBF slag content should be a minimum of 50 percent of the total cementitious material, unless previous testing with a particular GGBF slag has indicated that a lower percentage is adequate (Chojnacki 1981; Hogan and Meusel 1981; Fulton 1984; Lea 1971; Hooton and Emery 1983). The proportioning techniques for concretes incorporating GGBF slags are similar to those used in proportioning concretes made with portland cement or blended cements. Methods for proportioning are given in ACI 211.1. However, due to the high proportions of GGBF slag commonly used, allowances should be made for changes in solid volume due to the difference in specific gravity of slags (2.85 to 2.94) and

portland cement (3.15). Concrete with GGBF slag typically has greater placeability and ease of compaction, hence greater volumes of coarse aggregate may be used to reduce water demand. Often an increase in coarse aggregate is desirable, since it often reduces the stickiness of concrete mixtures (Wood 1981; Fulton 1974). This is particularly true when high cement contents are used. GGBF slags are usually substituted for portland cement on a one-to-one basis by mass and are always considered in the determination of the watercementitious material ratio. Water demand for given slump may generally be 3 to 5 percent lower than that found with concrete without GGBF slags (Meusel and Rose 1983). Exceptions can be found and should be accounted for in the trial mixture proportioning studies. 3.2Ternary systems The use of GGBF slag in combination with portland cement and pozzolans such as fly ash and silica fume is not uncommon. Typically the use of a ternary system is for economic reasons, but it may also be used for improving engineering properties. Combinations of GGBF slag, cement and silica fume were used in concrete mixtures in high-strength applications for the Scotia Plaza in Toronto (Bickley et al. 1991) and Society Tower (Engineering News Record 1991) in Cleveland, Ohio. Combinations of GGBF slag, fly ash, and portland cement have all been used as ballast for tunnel sections when low heat generation in mass concrete was desired. In addition, the combination of GGBF slag, fly ash, and portland cement appears to be the most appropriate binding material for the solidification and stabilization of low-level nuclear waste forms (Langton 1989, Spence et al. 1989). As reported by Malhotra (1987), all of these systems can provide concrete properties similar to those found with portland cement with the exception that in freezing and thawing environments, a minimum of 200 kg/m3 (337 lb/yd3) of portland cement and a low water-cementitious materials ratio are desired to provide adequate resistance to freezing-and-thawing environments. Among the effects resulting from adding silica fume to ternary systems are increased strength and reduced permeability. In addition, GGBF slag has been used in combination with portland cement and ground quartz (silica flour) in autoclaved concrete masonry (Hooton and Emery 1980). 3.3Use with chemical admixtures Effects of chemical admixtures on the properties of concrete containing GGBF slags are similar to those for concretes made with portland cement as the only cementitious materials. Information regarding the effect of admixtures on the properties of concrete can be obtained from the report of ACI Committee 212. Small increases in the dosage rate of air-entraining admixtures are sometimes necessary, if the fineness of the GGBF slag is higher than that of the portland cement. The amount of high-range water-reducing admixtures required to produce flowing concrete is usually 25 percent less than that used in concretes not containing GGBF

GROUND GRANULATED BLAST FURNACE SLAG

233R-7

Fig. 4.1Relationship between response to vibration of concrete mixtures made with portland cement and with mixture containing 50 percent GGBF slag

slag (Wu and Roy 1982). A given amount of retarder will have a greater retarding effect as the proportion of GGBF slag in the concrete is increased. CHAPTER 4EFFECTS ON PROPERTIES OF FRESH CONCRETE 4.1Workability Wood (1981) reported that the workability and placeability of concrete containing GGBF slag yielded improved characteristics when compared with concrete not containing GGBF slag. He further stated that this result was due to the surface characteristics of the GGBF slag, which created smooth slip planes in the paste. He also theorized that, due to the smooth, dense surfaces of the GGBF slag particles, little if any water was absorbed by the GGBF slag during initial mixing, unlike portland cement. Fulton (1974) investigated the phenomenon in greater detail and suggested that cementitious matrix containing GGBF slags exhibited greater workability due to the increased paste content and increased cohesiveness of the paste. Wu and Roy (1982) found that pastes containing GGBF slags exhibited different rheological properties compared to paste of portland cements alone. Their results indicate a better particle dispersion and higher fluidity of the pastes and mortars, both with and without water-reducing admixtures. It also appears (Fig. 4.1) that concrete containing GGBF slag is normally consolidated under mechanical compaction more easily than concrete that does not contain GGBF slag. Using conventional test procedures for workability, this phenomenon was never substantiated with any degree of confidence. Fulton (1974) states, practically all standard workability tests involve a measure of the amount of work necessary to remold the concrete from a compacted state to another state. Cohesion is a valuable and important property of a fresh mix, but obviously in such tests, it has an adverse effect

on the particular index measured--an effect which is not related to the compaction of concrete on the construction site. Considering this, Fulton devised a test using the Vebe apparatus, in which uncompacted concrete was molded by vibration and differences in molding time of mixtures with and without slag were compared. In all cases, the placeability of the concrete containing 50 percent GGBF slag was superior to that of mixtures without GGBF slag. Meusel and Rose (1983) found that increased slump was obtained with all GGBF slag blends tested when compared to concrete without GGBF slag at the same water content (Fig. 4.2). Osborne (1989) showed test results of slump, Vebe, and compacting factor for concretes containing 0, 40 and 70 percent GGBF slag. As the percentage of GGBF slag increased, the ratio of water-cementitious materials had to be reduced to maintain workability properties more or less similar to the concrete mix with 0 percent GGBF slag. Wimpenny et al. (1989) found, in concretes with constant water-cementitious ratio and increasing GGBF replacement, that the slump increased significantly with increasing GGBF slag replacement. 4.2Time of setting Usually, an increase in time of setting can be expected when GGBF slag is used as a replacement for part of the portland cement in concrete mixtures. The degree to which the time of setting is affected is dependent on the initial temperature of the concrete, the proportion of the blend used, the water-cementitious materials ratio, and the characteristics of the portland cement (Fulton 1974). Typically, the time of initial setting is extended one-half to one hour at temperatures of 23 C (73 F); little if any change is found at temperatures above 29 C (85 F) (Hogan and Meusel 1981). Although significant retardation has been observed at low temperatures, the additions of conventional accelerators, such as calcium chloride or other accelerating admixtures, can greatly reduce or eliminate this effect. Since the amount of portland cement

233R-8

ACI COMMITTEE REPORT

Fig. 5.1Strength relationship of mortar containing typical GGBF slag meeting ASTM C 989 requirements, compared to portland cement mortar (data originates from Task Group E-38.06.02 report) (1 ksi = 6.89 MPa) rate yielded slump loss equal to that of concrete without GGBF slag. Experiences in the United Kingdom indicate reduced slump loss, particularly when the portland cement used in the blend exhibits rapid slump loss, such as that caused by false-set characteristics of the cement (Lea 1971). CHAPTER 5EFFECTS ON PROPERTIES OF HARDENED CONCRETE AND MORTAR 5.1Strength and rate of strength gain Compressive and flexural strength-gain characteristics of concrete containing GGBF slag can vary over a wide range. When compared to portland cement concrete, use of Grade 120 slag typically results in reduced strength at early ages (1 to 3 days) and increased strength at later ages (7 days and beyond) (Hogan and Meusel 1981). Use of grade 100 results in lower strengths at early ages (1 to 21 days), but equal or greater strength at later ages. Grade 80 gives reduced strength at all ages. The extent to which GGBF slags affect strength is dependent on the slag activity index of the particular GGBF slag, and the ratio in which it is used in the mixture. Fig. 5.1 indicates that the mortar strength potential of 50-percent blends is dependent upon the grade of GGBF slag as defined in ASTM C 989. Consistent and stable long-term strength gain beyond 20 years has been documented for concrete made with portland blast-furnace slag cement (Type 1S) while exposed to moist or air curing (Wood 1992). Other factors that can affect the performance of GGBF slag in concrete are water-cementitious materials ratio, physical and chemical characteristics of the portland cement, and curing conditions. As seen in Fig. 5.2, the percentage of strength gain achieved with a Grade 120 GGBF slag is greater in concrete mixtures which have high water-cementitious materials ratio than in mixtures with a low water-cementitious materials ratio (Fulton 1974; Meusel and Rose 1983). The same trend was also noted by Malhotra (1980).

Fig. 4.2Effect of water content on slump of concrete mixtures with and without GGBF slag (Meusel and Rose 1983) (25.4 mm = 1 in.; 1 kg/m3 = 169 lb/yd3) in a mixture usually determines setting characteristics, changing the GGBF slag proportions may be considered in cold weather. At higher temperatures, the slower rate of setting is desirable in most cases, but care may need to be taken to minimize plastic shrinkage cracking. 4.3Bleeding Bleeding capacity and bleeding rate of concrete are mostly affected by the ratio of the surface area of solids to the unit volume of water. Therefore, when GGBF slags are used, these effects can be estimated depending on the fineness of the GGBF slag as compared to that of the cement and the combined effect of the two cementitious materials. When the GGBF slag is finer than the portland cement and is substituted on an equal-mass basis, bleeding is reduced; conversely, when the GGBF slag is coarser, the rate and amount of bleeding may increase. Cesareni and Frigione (1968) found that in all GGBF slags tested, both total amount and rate of bleeding increased with the addition of slag. No explanation was given for the phenomenon, but since the cement and GGBF slag were ground to the same fineness, the results contradict what is normally found with finely divided materials. Time of setting of the concrete and nonabsorptive qualities of the dense GGBF slag are likely to have contributed to the increased bleeding. 4.4Rate of slump loss Little information is available regarding slump loss when GGBF slags are used. Frigione (1983) reports a reduced rate of slump loss, whereas Meusel and Rose (1983) indicate that concrete containing GGBF slag at 50 percent substitution

GROUND GRANULATED BLAST FURNACE SLAG

233R-9

The temperature at which the concrete is cured will have a great effect on the strength of the concrete, particularly at early ages. Concrete containing GGBF slag is found to respond very well under elevated temperature curing conditions in accordance to the Arrhenius Law reported by Roy and Idorn (1982). In fact, strength exceeding that of portland-cement concrete at 1 day and beyond has been reported for accelerated curing conditions (Hogan and Meusel 1981; Fulton 1974; Lea 1978). Conversely, strength reduction at early ages is expected with concrete containing GGBF slag, when cured at normal or low temperatures. The proportion of the GGBF slag used also affects the strength and rate of strength gain as noted in Fig. 5.3. When highly active GGBF slags have been tested, the greatest 28day strengths are found with blends of 40 to 50 percent (Fulton 1974; Hogan and Meusel 1981; Meusel and Rose 1983). Where early strengths are concerned, the rate of strength gain is generally inversely proportional to the amount of GGBF slag used in the blend. The compressive strength properties of the various blends of GGBF slag and portland cement, as compared to a portland-cement mixture, are shown in Fig. 5.4. Of particular interest is the effect of GGBF slag when concrete is tested for flexural strength (modulus of rupture). When comparisons are made between concrete with and without GGBF slag, where the GGBF slag used is at proportions designed for greatest strength, the blends generally yield increasing modulus of rupture at ages beyond 7 days (Fulton 1974; Malhotra 1980; Hogan and Meusel 1981) (Fig. 5.5). This is believed to be a result of the increased denseness of the paste and improved bond at the aggregate-paste interface. 5.2Modulus of elasticity Most work in this area has been with blended cement containing GGBF slag. Klieger and Isberner (1967) found essentially the same modulus of elasticity in concretes containing portland blast-furnace slag cement as compared with Type I cement concrete. Stutterheim, as quoted by Fulton (1974), also confirmed this, using concrete containing equal amounts of GGBF slag and portland cement and concrete with portland cement only.

Fig 5.2Effect of water-cementitious materials ratio on compressive strength of GGBF slag levels, expressed as a percentage of mixtures made with portland cement (Meusel and Rose 1983)

Fig. 5.3Inuence of GGBF slag replacement on mortar cube compressive strength (Hogan and Meusel 1981) (1 ksi = 6.89 MPa) will reduce the shrinkage much the same as with portland cement (Hogan and Meusel 1981). 5.4Influence of curing on the performance of GGBF slag Regardless of the cement or the blends of cementitious materials used, concrete must be kept in a proper moisture and temperature condition during its early stages if it is to fully develop its strength and durability potential. There has been considerable discussion regarding the effects of curing on concrete containing portland blast-furnace slag cement and concrete containing GGBF slag as a separate constituent. In Mathers 1957 study comparing Type II cement with portland blast-furnace slag cement, he found that both cements suffered strength loss to the same degree when curing was stopped at 3 days. Conversely, Fulton (1974) reports that concrete containing GGBF slag is more susceptible to poor curing conditions than concrete without GGBF slag where the GGBF slag is used in percentages higher than 30

5.3Creep and shrinkage There are few data available on creep and shrinkage of concrete containing GGBF slag, and the limited test data show conflicting results. For example, Klieger and Isberner (1962) found few differences when portland blast-furnace slag cement was compared to portland cement. On the other hand, Fulton (1974) reports generally greater creep and shrinkage where various blends of GGBF slag were used. It is believed that the increased shrinkage may be due to the greater volume of paste in the concrete when GGBF slag is substituted on an equal mass basis. An example of the effects of blends on shrinkage is seen in Fig. 5.6 (Hogan and Meusel 1981). Other investigators indicate that where shrinkage is found to be greater, the addition of gypsum to the GGBF slag

233R-10

ACI COMMITTEE REPORT

Fig. 5.4Compressive strength of concrete containing various blends of GGBF slag, compared to concrete using only portland cement as cementitious material (Hogan and Meusel 1981) (1 ksi = 6.89 MPa)

percent. He attributes this susceptibility to reduced formation of hydrate at early ages leading to increased loss of moisture which would otherwise be available for hydration to continue. There is no doubt that, as with all cementitious materials, the rate and degree of hydration is affected by the loss of moisture at an early age, with a decrease in strength gain. To attain proper strength and durability, curing should follow the procedures prescribed in ACI 308. 5.5Color GGBF slag is considerably lighter in color than most portland cements and will produce a lighter color in concrete after curing. In certain operations, up to 30 percent GGBF slag has been used to replace white portland cements without a noticeable color change in the cured product. There is a unique characteristic of concrete containing GGBF slag, ei-

ther added separately or in blended cements, in that during the second to fourth days after casting, a blue-green coloration may appear, which then diminishes with age as oxidation takes place. This coloration is attributed to a complex reaction of the sulfide sulfur in the GGBF slag with other compounds in the cement. The degree and extent of the coloration depends on the rate of oxidation, the percentage of GGBF slag used, curing conditions, and porosity of the concrete surfaces. Where color is important, correctly timed exposure to air, sunlight, or wetting and drying promotes oxidation of the concrete surface. Concrete containing GGBF slag has been found to yield extended blue coloration when continuously exposed to water or when sealers were applied at early ages. The interior of the concrete will retain a deep blue-green coloration for a considerable time, as observed in normal compressive test specimens when broken.

GROUND GRANULATED BLAST FURNACE SLAG

233R-11

Fig. 5.5Flexural strength (modulus of rupture) of concrete containing various blends of GGBF slag, compared to concrete using only portland cement as cementitious material (Hogan and Meusel 1981) (1 ksi = 6.89 MPa)

Fig. 5.6Drying shrinkage of non-air-entrained concrete for various slag replacements (w/c = 0.55) (Hogan and Meusel 1981) However, when these faces are exposed to the atmosphere, such as split-face concrete block, they will oxidize to a uniform color. 5.6Effects on temperature rise in mass concrete GGBF slags have been used commonly as an ingredient of portland blast-furnace slag cement and as a separate cementitious constituent to reduce the temperature rise in mass concrete (Bamforth 1980; Fulton 1974; Mather 1951; Lea 1971). There are cases where mixtures with and without GGBF slag were tested using the heat of solution method (ASTM C 186) and the mixtures with GGBF slag produced

233R-12

ACI COMMITTEE REPORT

Fig. 5.7Comparison of heat generated in mass concrete with portland cement, portland cement-y ash, and portland cement-slag concrete mixtures (Bamforth 1980)

the greater cumulative heats (Bamforth 1980; Hogan and Meusel 1981; Roy and Idorn 1982). It is important to note that, although the heat-of-solution method indicates the total heat release potential of cement, it does not indicate the rate of heat rise which is also important in mass concrete applications. In all cases the incorporation of GGBF slag reduced the early rate of heat generation; this reduction is directly proportional to the proportion of GGBF slag used. The reduction in peak temperature and rate of heat gain are seen in Fig. 5.7, where in-situ measurements were reported by Bamforth (1980) comparing concrete without GGBF slag to concrete with 30 percent fly ash and concrete with 75 percent GGBF slag. The heat of hydration is dependent on the portland cement used and the activity of the GGBF slag. Roy and Idorn (1982) found a correlation of heat of hydration to strength potential of various blends of GGBF slag and portland cement. Reduced heat of hydration can be expected when GGBF slags are used to replace equal amounts of cement. Studies on heat generation of concrete containing GGBF slab by Kokubu, Takahashi, and Anzai (1989) indicate that blends of 35 to 55 percent GGBF slag produced greater total

heat than the portland cement mixtures, even though the rate of heat rise was less. Where blends of highly active GGBF slags are used, proportions of at least 70 percent GGBF slag may be needed to meet low heat of hydration requirements when evaluated by heat-of-solution method (ASTM C 186). 5.7Permeability The use of GGBF slag in hydraulic structures is well documented. The permeability of mature concrete containing GGBF slag is greatly reduced when compared with concrete not containing GGBF slag (Hooton and Emery 1990; Roy 1989; Rose 1987). As the GGBF slag content is increased, permeability decreases. It is found that the pore structure of the cementitious matrix is changed through the reaction of GGBF slag with the calcium hydroxide and alkalies released during the portland cement hydration (Bakker 1980; Roy and Idorn 1982). Pores in concrete, normally containing calcium hydroxide, are then, in part, filled with calcium silicate hydrates (Bakker 1980; Mehta 1980; Roy and Idorn 1982). As pointed out by Mehta (1980), the permeability of concrete depends on its porosity and pore-size distribution. Reduction in pore size which GGBF slags impart is seen in Fig. 5.8,

GROUND GRANULATED BLAST FURNACE SLAG

233R-13

comparing paste with and without GGBF slags. Where GGBF slags are used, reduction in the pore size has been noted prior to 28 days after mixing (Bakker 1980; Mehta 1980; Roy and Idorn 1981). Another example of the reduced permeability is seen in Fig. 5.9 taken from Smolczyk (1977) where concretes of varying water-cementitious materials ratio and GGBF slag proportions were evaluated for chloride diffusion, over a period of 2 years. 5.8Resistance to sulfate attack Partial replacement of portland cement with GGBF slag is found to improve the sulfate resistance of concrete. High resistance to sulfate attack has been demonstrated when the GGBF slag proportion exceeds 50 percent of the total cementitious material where Type II cements were used (Hogan and Meusel 1981). Additional testing of GGBF slag in Canada showed that 50-percent blends of GGBF slag with Type I portland cement containing up to 12 percent C3A have sulfate resistance equivalent to that of Type V cements. The GGBF slag was reported to have 7 percent Al2O3 (Chojnacki 1981). As reported by Hooton and Emery (1990), a minimum amount of GGBF slag is required to provide high sulfate resisting properties to concrete. Their results, using ASTM C 1012, indicate that this minimum would be 50 percent or greater when used with Type I portland cement having a C3A content up to 12 percent as long as the Al2O3 content of the GGBF slag was lower than 11 percent, Fig. 5.10. Where GGBF slag is used in sufficient quantities, several changes occur which improve resistance to sulfate attack. Those changes include: 1) The C3A content of the mixture is proportionally reduced depending on the percentage of GGBF slag used. However, Lea (1971) reports that increased

sulfate resistance is not only dependent on the C3A content of portland cement alone, but also the alumina content of the GGBF slag. Lea further reports from tests made by Locher that where the alumina content of the GGBF slag is less than 11 percent, increased sulfate resistance was found regardless of the C3A content of the portland cement where blends between 20 and 50 percent GGBF slag were used. 2) Through the reduction of soluble calcium hydroxide in the formation of calcium silicate hydrates, the environment for the formation of calcium sulfoaluminate is reduced. 3) Investigations indicate that resistance to sulfate attack is greatly dependent on the permeability of the concrete or cement paste (Bakker 1983; Mehta 1980; Roy and Idorn 1982). Again, the formation of calcium silicate hydrates in pore spaces, normally occupied by alkalies and calcium hydroxide, reduces the permeability of the paste and prevents the intrusion of the aggressive sulfates. Expansion of mortar bars due to sulfate attack is illustrated in Fig. 5.11 where bars made using GGBF slag blends are compared to bars made using Type II and Type V portland cements (Hogan and Meusel 1981). Buck (1985) reported results of tests by a procedure generally similar to ASTM C 1012 using Type IS cements from Alabama, Michigan, and Pennsylvania, and two cements containing GGBF slag made in Germany. The IS cements contained about 25 percent GGBF slag. The committee believes the test results showed relatively poor sulfate resistance due to too low a proportion of GGBF slag. 5.9Reduction of expansion due to alkali-silica reaction (ASR) Use of GGBF slag as a partial replacement for portland ce-

Fig. 5.8Comparison of pore-size distribution of paste containing portland cement and paste containing 40 percent slag and 60 percent portland cement, tested by mercury intrusion (Roy and Parker 1983)

Fig. 5.9Results of chloride content in 20.3 to 40.6 mm (0.8 to 1.6 in.) deep layers in concrete beams stored in 3.0 molar solution of NaCl (Smolczyk 1977)

233R-14

ACI COMMITTEE REPORT

Fig. 5.10Effect of various slag replacement levels on expansions in 50,000 mg/1 SO4 as Na2SO4 (slag Al2O3 = 8.4 percent)

Fig. 5.11Sulfate resistance of mortar bars, Wolochow test, Type II (Hogan and Meusel 1981) ment is known to reduce the potential expansion of concrete due to alkali-silica reaction (Bakker 1980; Hogan and Meusel 1981). It is reported in the Appendix of ASTM C 989 that where GGBF slags were used in quantities greater than 40 percent of the total cementitious material, reduced expansion due to the alkali-silica reaction is found with cement having alkali contents up to 1.0 percent. It is reported by Hogan and Meusel (1981) (Fig. 5.12) that where slag contents are used in percentages from 40 to 65 percent of total cementitious material, expansion was virtually eliminated when tested in accordance with ASTM C 227. Their test used highly reactive Pyrex glass to obtain maximum expansion. Similar re-

Fig. 5.12ASTM C 227 potential alkali-aggregate reactivity for various slag replacements (Hogan and Meusel 1981) sults were reported by Klieger and Isberner (1967), where portland blast-furnace slag cements were used. Resistance to ASR is attributed to the following influences on the cementitious media: (1) reduced permeability, (2) change of the alkali-silica ratio, (3) dissolution and consumption of the alkali species, (4) direct reduction of available alkali in the system, and (5) reduction of calcium hydroxide needed to support the reaction. Results of tests using GGBF slag as a partial replacement for high-alkali cement with aggregate known to exhibit alkali-silica and alkali-carbonate reactions were reported by

GROUND GRANULATED BLAST FURNACE SLAG

233R-15

Soles, Malhotra, and Chen (1989). After two years of observation the GGBF slag blends were found to be effective in reducing expansion, but the reduction was less than that found with the low-alkali cement. When used in combination with high-alkali cement, blends of 40 percent GGBF slag appear to be effective in reducing the potential of alkalicarbonate reactions, and blends of 50 percent GGBF slag appear to be effective in reducing the potential of alkali-silica reactions. 5.10Resistance to freezing and thawing Many studies have been made where GGBF slags were used in concrete as a portion of blended cement. Results of these studies generally indicate that when concrete made with portland blast-furnace slag cement was tested in comparison with Type I and Type II cements, their resistances to freezing and thawing in water were essentially the same (Fulton 1974; Klieger and Isberner 1967; Mather 1957). As with all hydraulic cement concrete, proper air content and bubble spacing are necessary for adequate protection in freezing-and-thawing environments. Most recently, air-entrained concrete containing GGBF slag used as 50 percent of the total cementitious material was found to be frost resistant even though a measurable difference in weight loss was found when compared to the concrete made with Type II portland cement and tested using ASTM C 666 (Hogan and Meusel 1981). Similar results were found by Malhotra (1980) using various percentages of GGBF slag with portland cement. This weight loss does not appear significant and is probably due to comparing concretes of unequal strengths. 5.11Resistance to deicing chemicals Although some laboratory tests with Type IS cement indicate less resistance to deicing salts, many researchers have found, in field exposure, little difference when compared to concrete not containing slag (Klieger and Isberner 1967). Similar results were reported using blends of 50 percent GGBF slag and 50 percent portland cement, by Hogan and Meusel (1981). Most research indicates that scaling is usually found when the concrete has a high water-cementitious materials ratio and high percentages of GGBF slag are used. 5.12Resistance to the corrosion of reinforcement Many investigations have shown that reduced permeability of concrete containing GGBF slag significantly reduces the penetration of chloride to all depths within the concrete (Bakker 1980; Bakker 1983; Fulton 1974; Mehta 1980; Roy 1989; Rose 1987; Mehta 1980; Meusel and Hogan 1981). The reduction in permeability and the resistance to chloride intrusion increases as the level of GGBF slag increases in the concrete mixture of mortar. The use of GGBF slag is found to reduce the permeability of concrete by several orders of magnitude. During the early use of concrete containing portland blastfurnace slag cement, there was considerable concern regarding the potential harmful effects of sulfur in GGBF slag. Since then, many investigations have shown that the use of

GGBF slags has no negative effect on the corrosion of steel (Fulton 1974; Lea 1971; Hogan and Meusel 1981). It has been found that a slight reduction in the pH of pore solution does not have a negative impact on the passivity of reinforcing steel, and that use of GGBF slag in good quality concrete, reduces concrete permeability, thus reducing the penetration of chlorides and carbon dioxide which promote corrosion of steel. CHAPTER 6USES OF GGBF SLAG IN CONCRETE AND MORTAR 6.1Introduction Type IS blended cement is considered equivalent to Type I portland cement. Therefore, Type IS is used in all concrete applications except where high early strengths are required under normal curing conditions. As in its use in blended cement, GGBF slag mixed with portland cement at the concrete mixer may also be used in all applications and processes. The flexibility of using different blends of GGBF slag depends upon the desired qualities of concrete which are most important to the concrete designer and producer. 6.2Ready-mixed concrete Most of the producers of ready-mixed concrete that use GGBF slag do so in proportions of 50 percent of total cementitious material when the weather is warm and the GGBF slag is highly active (Wood 1981). Not only is this blend convenient, but with a highly active GGBF slag this blend usually produces the greatest strength and most favorable cost to benefit ratio. Proportions of GGBF slag as low as 20 to 30 percent have been used with less active GGBF slags or during periods of colder weather. In those jobs requiring special qualities, such as sulfate resistance or low temperature rise, blends containing more than 50 percent GGBF slag are recommended. On the other hand, when early strengths are required to facilitate quick form removal or when thin sections are placed at low temperatures, blends containing less than 50 percent are recommended. Particular advantages in the use of GGBF slag as a separate cementitious material in ready-mixed concrete are: a) increased flexibility to meet individual job requirements; b) reduced cost of cementitious material; c) improved workability; d) reduced strength loss in concrete subject to hot weather application; and e) increased compressive and flexural strength with GGBF slag grade of 100 or better. 6.3Concrete products The use of GGBF slag in precast concrete products is usually restricted by the requirements for early strength (1 day) and the curing cycle used. Under normal curing conditions, 1-day strength is usually lower in concrete containing GGBF slag, particularly when high percentages of GGBF slag are substituted for the portland cement. Therefore, reduced blends of GGBF slag or the use of accelerating admixtures or both are required to achieve the desired stripping and handling strength.

233R-16

ACI COMMITTEE REPORT

Where accelerated curing conditions are used, normal GGBF slag blends of 40 to 60 percent of total cementitious material are applicable in most concrete mixtures and curing cycles. GGBF slags respond favorably to accelerated curing, and increased strength at 1 day may be obtained when Grade 120 slags are used with curing temperatures exceeding 130 F (Hogan and Meusel 1981). The positive response, i.e., improved early strength, of GGBF slag to accelerated curing is an important attribute in the manufacture of precast and prestressed components for marine exposure where high durability is needed. Using GGBF slag is also beneficial in those products made from no-slump concrete mixtures. The increased workability found during mechanical compaction allows for a reduction in water demand, usually resulting in greater density and strength (Fulton 1974). 6.4Mortars and grouts The use of GGBF slags typically improves the strength, permeability, flow, and cohesive characteristics of mortars and grouts. In this application, GGBF slags are used in proportions similar to those used in the production of concrete. Using GGBF slag in the form of blended cements or separately blended with lime and portland cement for masonry mortars is well known. The same general properties found in concrete are also to be expected in mortars and grouts. Special uses of GGBF slag in grouts for the stabilization and solidification of waste materials were reported by Langton (1989). The combination of ultra-fine GGBF slag, having air-permeability finenesses greater than 1000 m2/kg, and portland cement or alkali salts are being used for the grouting of fine cracks in existing dams and the stabilization of fine sands. CHAPTER 7REFERENCES 7.1Specified and/or recommended references The documents of the various standards-producing organizations referred to in this document are listed below with their serial designation. Since some of these documents are revised frequently, generally in minor detail only, the user of this document should check directly with the sponsoring group if it is desired to refer to the latest revision. American Concrete Institute 116R Cement and Concrete Terminology 211.1 Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete 212.2R Guide for Use of Admixtures in Concrete 304R Guide for Measuring, Mixing, Transporting, and Placing Concrete 308 Standard Practice for Curing Concrete ASTM C 94 C 109

C 162

Definition of Terms Relating to Glass and Glass Products C 186 Test Method for Heat of Hydration of Hydraulic Cement C 227 Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method) C 595 Specification for Blended Hydraulic Cements C 666 Test Method for Resistance of Concrete to Rapid Freezing and Thawing C 989 Specification for Ground Iron Blast-Furnace Slag for Use in Concrete and Mortars C 1012 Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution C 1073 Test Method for Hydraulic Activity of Ground Slag by Reaction with Alkali Canadian Standards Association A23.5 Supplemental Cementing Materials and Their Use in Concrete Construction A363 Cementitious Hydraulic Slag These publications may be obtained from the following organizations: American Concrete Institute P. O. Box 9094 Farmington Hills, MI 48333 ASTM 1916 Race Street Philadelphia, PA 19103 Canadian Standards Association 178 Rexdale Blvd. Rexdale, Ontario M9W 1R3 Canada 7.2Cited references Bakker, R. F. M., On the Cause of Increased Resistance of Concrete Made from Blast-Furnace Cement to Alkali Reaction and to Sulfate Corrosion, Thesis RWTH-Aachen, 1980, 118 pp. (Translated from the German, Den s'Hertogenbosch, The Netherlands.) Bakker, Robert F. M., Permeability of Blended Cement Concrete, Fly Ash, Silica Fume, Slag, and Other Mineral By-Products in Concrete, SP-79, American Concrete Institute, Detroit, 1983, pp. 589-605. Bamforth, P. B., In Situ Measurement of the Effect of Partial Portland Cement Replacement Using Either Fly Ash or Ground Granulated Blast-Furnace Slag on the Performance of Mass Concrete, Proceedings, Institution of Civil Engineers (London), Part 2, V. 69, Sept. 1980, pp. 777-800. Bickley, J. A., Ryell, J., Rogers, C., and Hooton, R. D., Some Characteristics of High Strength Structural Concrete, Canadian Journal of Civil Engineering, V. 18, No. 5, 1991, pp. 885-889.

Specification for Ready-Mixed Concrete Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube Specimens)

GROUND GRANULATED BLAST FURNACE SLAG

233R-17

Buck, Alan D., Sulfate Resistance of Hydraulic Cements Containing Blast-Furnace Slag, USAEWES Miscellaneous Paper SL-85-14, Vicksburg, MS, 1985, 15 pp. (Also CTIAC Report No. 72). Cesareni, D., and Frigione, G., A Contribution to the Study of the Physical Properties of Hardened Paste of Portland Cements Containing Granulated Blast-Furnace Slag, Proceedings, 5th International Symposium on the Chemistry of Cement, Cement Association of Japan, Tokyo, V. 4, 1968, pp. 237-247. Chojnacki, B., Sulfate Resistance of Blended (Slag) Cement, Report No. EM-52, Ministry of Transportation and Communications, Downsview, Ontario, Canada, 1981. Cotsworth, R.P., National Slag's Pelletizing Process, Symposium on Slag Cement, University of Alabama, Birmingham, 1981. Engineering News Record, Society Tower, Concrete Today, May 6, 1991, p. C-72. Forss, B., F-Cement, A Low-Porosity Slag Cement for the Precast Industry, International Conference on Slag and Blended Cements, University of Alabama, Birmingham, 1982, 12 pp. Fulton, F. S., The Properties of Portland Cement Containing Milled Granulated Blast-Furnace Slag, Monograph, Portland Cement Institute, Johannesburg, 1974, pp. 4-46. Hogan, F. J., and Meusel, J. W., Evaluation for Durability and Strength Development of a Ground Granulated BlastFurnace Slag, Cement, Concrete, and Aggregates, V. 3, No. 1, Summer, 1981, pp. 40-52. Hooton, R. D., and Emery, J. J., Pelletized Slag Cement: Autoclave Reactivity, Proceedings, 7th International Congress on the Chemistry of Cement, Paris, 1980, V. II, pp. III43-47. Hooton, R. D., and Emery, J. J., Sulfate Resistance of a Canadian Slag, ACI Materials Journal, V. 87, No. 6, Nov.Dec. 1990, pp. 547-555. Hooton, R. D., and Emery J. J., Glass Content Determination and Strength Development Predictions for Vitrified Blast Furnace Slag, Fly Ash, Silica Fume, Slag and Other Mineral By-Products in Concrete, V. M. Malhotra, Ed., V. II, SP-79, American Concrete Institute, Detroit, 1983, pp. 943-962. Klieger, Paul, and Isberner, Albert W., Laboratory Studies of Blended CementPortland Blast-Furnace Slag Cements, Journal, PCA Research and Development Department Laboratories, V. 9, No. 3, Sept. 1967, pp. 2-22. Kokubu, K., Takahashi, S., and Anzai, H., Effect of Curing Temperatures on the Hydration and Adiabatic Temperature Characteristics of Portland Cement-Blast Furnace Slag Concrete, Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, V. M. Malhotra, Ed., SP-114, American Concrete Institute, Detroit, 1989, pp. 1366-1371. Langton, C. A., Slag Based Materials for Toxic Based Metal and Radioactive Waste Stabilization, Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, V. M. Malhotra, Ed., SP-114, American Concrete Institute, Detroit, 1989, pp. 1697-1706.

Lea, F. M., The Chemistry of Cement and Concrete, 3rd edition, Chemical Publishing Co., New York, 1971, pp. 454489. Lewis, D. W., History of Slag Cements, Symposium on Slag Cement, University of Alabama, Birmingham, 1981. Malhotra, V. M., Strength and Durability Characteristics of Concrete Incorporating a Pelletized Blast Furnace Slag, Fly Ash, Silica Fume, Slag, and Other Mineral By-Products in Concrete, V. M. Malhotra, ed., SP-79, V. 2, American Concrete Institute, Detroit, 1980, pp. 891-922. Malhotra, V. M., Strength and Freeze-Thaw Characteristics of Concrete Incorporating Granulated Blast-Furnace Slag, CANMET, I.R. 79-38, Energy, Mines & Resources, Ottawa, Canada, 1980. Malhotra, V. M., Carette, G. G., and Bremner, T. W., Durability of Concrete Containing Supplementary Cementing Materials in Marine Environment, J. Scanlon, Ed., SP-100, American Concrete Institute, Detroit, 1987, pp. 1227-1258. Mary, M., Preparation du Cimeut di Latier par Voie Homide le Proced Trief et Son Aplication au Barrage de Bortles-orgues, Annales de l'institute technique du Batiment et des travaux publiques, No. 200, July-Aug. 1951 (Translation 52-4, Oct. 1952, U.S. Army Engineer Waterways Experiment Station, Vicksburg, MS). Mather, Bryant, Laboratory Tests of Portland Blast-Furnace Slag Cements, ACI Journal, V. 54, No. 3, Sept. 1957, pp. 205-232. Mehta, P. Kumar, Durability of Concrete in Marine EnvironmentA Review, Performance of Concrete in Marine Environment, SP-65, American Concrete Institute, Detroit, 1980, pp. 1-20. Mehta, P. Kumar, Pozzolanic and Cementitious Byproducts as Mineral Admixtures for ConcreteA Critical Review, Fly Ash, Silica Fume, Slag and Other Mineral ByProducts in Concrete, V. M. Malhotra, Ed., SP-79, American Concrete Institute, V. 1, Detroit, 1983, pp. 1-46. Meusel, J. W., and Rose, J. H., Production of Granulated Blast Furnace Slag at Sparrows Point, and the Workability and Strength Potential of Concrete Incorporating the Slag, Fly Ash, Silica Fume, Slag and Other Mineral By-Products in Concrete, SP-79, American Concrete Institute, Detroit, 1983, pp. 867-890. NSA Report 188-1, Slag, The All Purpose Construction Aggregate, National Slag Association, Washington, 1988. Osborne, G. J., Carbonation and Permeability of BlastFurnace Slag Cement Concretes from Field Structures, Fly Ash, Slag and Natural Pozzolans in Concrete, V. M. Malhotra, Ed., SP-114, American Concrete Institute, Detroit, 1989, pp. 1209-1237. Regourd, M., Structure and Behavior of Slag Portland Cement Hydrates, Proceedings, 7th International Congress on the Chemistry of Cements (Paris), Editions Septima, Paris, V. 1, III-2, 1980, pp. 10-18. Regourd, M., Characterization of Thermal Activation of Slag Cements, Proceedings, 7th International Congress on the Chemistry of Cements (Paris), Editions Septima, Paris, V. 2, III-3, 1980, pp. 105-111.

233R-18

ACI COMMITTEE REPORT

Regourd, M., Microanalytical Studies (X-Ray Photo Electron Spectrometry) of Surface Hydration Reactions of Cement Compounds, Philosophical Transactions (London), Series A., V. 310 (No. 1511) R.S., 1980, pp. 85-91. Regourd, M., Slags and Slag Cements, Ch. 3, Cement Replacement Materials, R. N. Swamy, Ed., Surrey University Press, 1987, pp. 73-99. Robertson, J. L., At Submicron Fineness, Expanded Slag is a Cement Replacement, Rock Products, April 1982. Rose, J. H., The Effects of Cementitious Blast-Furnace Slag on Chloride Permeability of Concrete, Corrosion, Concrete, and Chlorides, V. M. Malhotra, Ed., SP-102, American Concrete Institute, Detroit, 1987, pp. 107-125. Roy, D. M., and Idorn, G. M., Hydration, Structure, and Properties of Blast Furnace Slag Cements, Mortars, and Concrete, Proceedings, ACI JOURNAL V. 79, No. 6, Nov.Dec. 1983, pp. 445-457. Roy, D. M., and Parker, K. M., Microstructures and Properties of Granulated Slag-Portland Cement Blends at Normal and Elevated Temperatures, Fly Ash, Silica Fume, Slag and Other Mineral By-Products in Concrete, SP-79, American Concrete Institute, Detroit, 1983, pp. 397-414. Smolczyk, H. G., The Use of Blast-Furnace Slag Cement in Reinforced and Prestressed Concrete, Proceedings, 6th International Steelmaking Day, Paris, 1977. Smolczyk, H. G., The Effect of the Chemistry of Slag on the Strength of Blast-Furnace Cements, Zement-Kalk-Gips (Wiesbaden), V. 31, No. 6, 1978, pp. 294-296. Soles, J. A., Malhotra, V. M., and Chen, H., Supplementary Alkali-Aggregate Reactions, Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, V. M. Malhotra, Ed., SP-114, American Concrete Institute, Detroit, 1989, pp. 1632-1656. Solomon, C., Slag-Iron and Steel, Bureau of Mines, Annual Report, Washington, 1991. Talling, B., and Brandstetr, J., Present State and Future of

Alkali-Activated Slag Concrete, Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, V. M. Malhotra, Ed., SP-114, American Concrete Institute, Detroit, 1989, pp. 1519-1545. Thomas, Anwar, Metallurgical and Slag Cements, the Indispensable Energy Savers, General Practices, IEEE Cement Industry 21 Technical Conference, 1979, 108 pp. Vanden Bosch, V. D., Performance of Mortar Specimens in Chemical and Accelerated Marine Exposure, Performance of Concrete in Marine Environment, SP-65, American Concrete Institute, Detroit, 1980, pp. 487-507. Voinovitch, I., Raverdy, M., and Dron, R., Ciment de laitier granule sand Clinkers, Proceedings, 7th International Congress on the Chemistry of Cement (Paris), Editions Septima, Paris, V. 3, 1980, pp. 122-128. Waterways Experiment Station, Tests of Trief Cement and Laboratory-Ground Water-Quenched, Blast-Furnace Slag Cement, Miscellaneous Paper No. 6-39, 1953, 12 pp. Wimpenny, D. E., Ellis, C. M., and Higgins, D. D., The Development of Strength and Elastic Properties in Slag Cement under Low Temperature Curing Conditions, Proceedings, 3rd International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, V. M. Malhotra, Ed., SP-114, American Concrete Institute, Detroit, V. 2, Trondheim, Norway, June 1989, p. 1288, 1296. Wood, K., Twenty Years of Experience with Slag Cement, Symposium on Slag Cement, University of Alabama, Birmingham, 1981. Wood, S. L., Evaluation of the Long-Term Properties of Concrete, RD102, Portland Cement Association, 1992, pp. 14-15. Wu, X., and Roy, D. M., Zeta Potential Investigation During Hydration of Slag Cement, Proceedings, M.R.S. Symposium, Boston, Research Society, 1982.

ACI 233R-95 was submitted to letter ballot of the committee and was approved in accordance with ACI balloting procedures.

You might also like

- LD Slag ResearchDocument13 pagesLD Slag ResearchShailesh BansalNo ratings yet

- Characteristics and Uses of Steel Slag in Building ConstructionFrom EverandCharacteristics and Uses of Steel Slag in Building ConstructionNo ratings yet

- Blast Furnace Slag B. InggrisDocument8 pagesBlast Furnace Slag B. InggrisBayuPrasetyaPNo ratings yet

- What Is CSA Cement.Document4 pagesWhat Is CSA Cement.Madan Mohan ReddyNo ratings yet

- Steel Slag JSPLDocument43 pagesSteel Slag JSPLKalai SelvanNo ratings yet

- Calcined ClayDocument4 pagesCalcined ClaynaikNo ratings yet

- Nanotechnology in The Cement Industry - A Patent AnalysisDocument9 pagesNanotechnology in The Cement Industry - A Patent AnalysisOscar Santos EstofaneroNo ratings yet

- Kiln OptimizationDocument7 pagesKiln Optimizationneo 87No ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Effects of Clinker Grinding Aids On Flow of Cement Based MaterialsDocument11 pagesEffects of Clinker Grinding Aids On Flow of Cement Based MaterialsJaga JayNo ratings yet

- 2018 Fillers in Cementitious Materials - Experience, Recent Advances and Future PotentialDocument14 pages2018 Fillers in Cementitious Materials - Experience, Recent Advances and Future PotentialTiago BragaNo ratings yet

- Application of Sustainable Cement Alternatives in ConcreteDocument6 pagesApplication of Sustainable Cement Alternatives in ConcreteCARLOS ALTAMIRANO GUPIOCNo ratings yet

- Influence of SO3 On The Hydration HeatDocument10 pagesInfluence of SO3 On The Hydration HeatPaknubkNo ratings yet

- Perillex Bricks PDFDocument3 pagesPerillex Bricks PDFMuntandwe georgeNo ratings yet

- Concrete TechnologyDocument48 pagesConcrete Technologyrfvz6sNo ratings yet

- Distribution of Sulfate Between Phases in Portland Cement ClinkersDocument7 pagesDistribution of Sulfate Between Phases in Portland Cement ClinkersNocifLyesNo ratings yet

- Meq 01 2015 0012Document17 pagesMeq 01 2015 0012Anonymous Ja3jvaXNo ratings yet

- Коротк Нотатки Про Хемiю ЦементiвDocument33 pagesКоротк Нотатки Про Хемiю ЦементiвCementarNo ratings yet

- Portland Cement ChemistryDocument3 pagesPortland Cement ChemistryShaykh AlthamasNo ratings yet

- Cement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Document14 pagesCement - Manufacturing Process & Unit Operations: F:/plant/sranga/general/cement - Doc Page 1 of 14Senthilkumar PragasamNo ratings yet

- JSW Cement PSC BrochureDocument2 pagesJSW Cement PSC BrochureAravind NagarajNo ratings yet

- Quality Assessment of Clay For Limestone Calcined Clay Cement ProductionDocument6 pagesQuality Assessment of Clay For Limestone Calcined Clay Cement ProductionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Seminar On GGBS & Silica FumeDocument10 pagesSeminar On GGBS & Silica FumeawasarevinayakNo ratings yet

- Type of Monolithic Refractories PDFDocument4 pagesType of Monolithic Refractories PDFNaelNo ratings yet

- The Calcination of Kaolin ClayDocument7 pagesThe Calcination of Kaolin ClaytaghdirimNo ratings yet

- 35-Castables With MgO-SiO2-Al2O3 As Bond PhaseDocument11 pages35-Castables With MgO-SiO2-Al2O3 As Bond PhaseAnky FadharaniNo ratings yet

- Lecture 1 CementDocument23 pagesLecture 1 CementJappu KumarNo ratings yet

- Calcined ClayDocument2 pagesCalcined ClayTariq AhmedNo ratings yet

- Hexavalent Chromium in Portland CementDocument5 pagesHexavalent Chromium in Portland Cementyinglv100% (1)

- Cement, Slag, Pozzolan, & Silica FumeDocument60 pagesCement, Slag, Pozzolan, & Silica Fumeog_double8699No ratings yet

- Fluoride Mineralization of Portland Cement Thuan T Tran PhDthesisDocument165 pagesFluoride Mineralization of Portland Cement Thuan T Tran PhDthesismemorphNo ratings yet

- Study On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderDocument4 pagesStudy On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderIJIRST100% (1)

- Portland Cement PDS v6Document2 pagesPortland Cement PDS v6Joseph ChenNo ratings yet

- Cement Plant Simulation and Dynamic Data PDFDocument8 pagesCement Plant Simulation and Dynamic Data PDFUsman HamidNo ratings yet

- Effect of Alkalis and Sulfates On Portland Cement SystemsDocument219 pagesEffect of Alkalis and Sulfates On Portland Cement SystemsmargarethsmNo ratings yet

- Calcination ProcessDocument82 pagesCalcination ProcessMayur ChhagNo ratings yet

- Gbfs SlagDocument2 pagesGbfs SlagchandramohanNo ratings yet

- Grinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent GuillotDocument15 pagesGrinding Systems and Cement Composition Optimisation-Cement Additives Added Value - Laurent Guillotnathaniel villanuevaNo ratings yet

- 3rd International Conference On The Application of Superabsorben 2020Document275 pages3rd International Conference On The Application of Superabsorben 20204919404No ratings yet

- The Effect of Temperature Upon The Setting Behaviour of Refractory Calcium Aluminate CementsDocument10 pagesThe Effect of Temperature Upon The Setting Behaviour of Refractory Calcium Aluminate CementsLenia LuciaNo ratings yet

- Influence of NaOH Concentration On Microstructure and Properties of Cured Alkali-Activated Calcined Clay (Hafid - 2017)Document36 pagesInfluence of NaOH Concentration On Microstructure and Properties of Cured Alkali-Activated Calcined Clay (Hafid - 2017)juan diazNo ratings yet

- High Purity Calcium Aluminate Cements Production and PropertiesDocument6 pagesHigh Purity Calcium Aluminate Cements Production and Propertiesvimalp_20No ratings yet

- RA SiC T CM EC PDFDocument2 pagesRA SiC T CM EC PDFDaniel RicartNo ratings yet

- Chimestry Mechanical Engineering: Group No # 2 REG NO # 16 To 36 Lets StartDocument44 pagesChimestry Mechanical Engineering: Group No # 2 REG NO # 16 To 36 Lets StartarslanNo ratings yet

- Chemical Analysis and Percent CementDocument8 pagesChemical Analysis and Percent CementValeria PerlazaNo ratings yet

- 2022 - CClay Brochure - RevH-finalDocument16 pages2022 - CClay Brochure - RevH-finalJamel Ben AbdelmalekNo ratings yet

- Mgo in Portland CementDocument19 pagesMgo in Portland CementYuniar Luthfia ListyadeviNo ratings yet

- AReviewOnGeopolymerConcrete (214 217)Document4 pagesAReviewOnGeopolymerConcrete (214 217)anupamrcNo ratings yet

- Lab Ball Mill Testing of ClinkerDocument5 pagesLab Ball Mill Testing of ClinkerPrasann R NamannavarNo ratings yet

- Modeling of Cement Clinker ChemistryDocument24 pagesModeling of Cement Clinker ChemistryBitbitter100% (1)

- The Use of Calcium Aluminate Solutions in The Aluminium IndustryDocument7 pagesThe Use of Calcium Aluminate Solutions in The Aluminium IndustryDick ManNo ratings yet

- MonolithicRefractory PDFDocument2 pagesMonolithicRefractory PDFmevaNo ratings yet

- Alkali Activated MetakaolinDocument15 pagesAlkali Activated MetakaolinMadihah Wan RazaliNo ratings yet