Professional Documents

Culture Documents

3495 Part 1 Bricks PDF

Uploaded by

Vb SeriesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3495 Part 1 Bricks PDF

Uploaded by

Vb SeriesCopyright:

Available Formats

IS 3495 ( Parts

1 to 4 ) : 1992

Itldian Standard

METHODS

PART 1

OF TESTS OF BURNT BUILDING BRICKS

OF COMPRESSIVE OF WATER DETERMINATION 3 DETERMINATION 4 ( DETERMINATION ABSORPTION

CLAY

DETERMINATION 2

STRENGTH

PART

PART

OF EFFLORESCENCE OF WARPAGE

PART

Third Revision )

Third Reprint OCTOBER1998

UDC

666 712 * 6201

BIS

1991

BUREAU

MANAK

OF

BHAVAN.

INDIAN

9 BAHADUR DELHI

STANDARDS

SHAH 110002 Price Group 4 ZAFAR MARG

NEW

hfuy 1992

Clay Products

for Buildings

Sectional

Committee,

CED 30

FOREWORD This Indian Standard ( Parts 1 to 4 ) ( Third Revision ) was adopted by the Bureau of Indian Standards, after the draft finalized by the Clay Products for Buildings Sectional Committee had been approved by the Civil Engineering Division Council. This standard covering methods of tests was first published in 1966 and subsequently revised in 1973 and 1976. This revision has been prepared so as to bring in line with the latest Indian Standards on bricks. Opportunity has also been taken to up-to-date the contents. In reporting the results of a test made in accordance with this standard, if the final value, observed or calculated, is to be rounded ofT, it shall be done in accordance with 1S 2 : 1960 Rules for rounding off numerical values ( revised >.

IS 3495 ( Part 1) : 1992

Indian Standard

METHODS OF TESTS OF BURNT CLAY BUILDING BRICKS

PART 1 DETERMINATION ( OF COMPRESSWE STRENGTH

Third Revision )

further increase in the indicator testing machine.

NOTE -

1 SCOPE 1.1 This standard ( Part 1 ) covers the method of determination of compressive strength of burnt clay building bricks. 2 REFERENCE 2.1 The hdian Standard IS 5454 : 1976 Method for sampling of clay building bricks ( firsr revision ) is a necessary adjunct to this standard. 3 GENERAL 3.1 The dimensions nearest 1 mm. shall be measured to the

reading on the

may be

used

In place of plywood sheets plaster of Paris

to ensure of load. a uniform surface for

application

4.1.4 Report

The report shall be as given below: Compressive strength in N/mm2 ( kgf,cm2) = Maximum load at failure in N(kgf) Average area of the bed faces in mm2 ( cm2 ) 4.1.4.1 The average of results shall be reported. 4.2 For Perforated Bricks

4.2.1 Apparatus

3.2 All apparatus and testing equipment calibrated at frequent intervals.

shall be

3.3 The number of specimens for the test shall be selected according to IS 5454 : 1976. 4 METHODS 4.1 For Solid Bricks

4.1.1 Apparatus

See 4.1.1. 4.2.2 Preconditioning Immerse the specimen in water at room temperature for 24 hours. Remove the specimen from water and drain out any surplus water. No mortar shall be filled in perforations and no mortar capping shall be provided. 4.2.3 Procedure Place the perforated faces of the brick between two 3-ply plywood sheets each of 3 mm thickness and carefully centred between the plates of the testing machine. Apply the load axially at uniform rate of 14 N/mm2 ( 140 kgf/cma ) per minute till the failure occurs and note the maximum load at failure. The load at failure shall be the maximum load at which the specimen fails to produce any further increase in the indicator reading on the testing machine.

NOTE - In place of plywood sheets plaster of Pa;:; may be used to ensure a uniform surfac; application of load.

A compression testing machine, the compression plate of which shall have a ball seating in the form of portion of a sphere the centre of which coincides with the centre of the plate, shall be used. 4.1.2 Preconditioning Remove unevenness observed in the bed faces to provide two smooth and parallel faces by grinding. Immerse in water at room temperature for 21 hours. Remove the specimen and drain out any Fill the surplus moisture at room temperature. frog ( where provided ) and all voids in the bed face flush with cement mortar ( 1 cement, clean coarse sand of grade 3 mm and down ). Store under the damp jute bags for 24 hours followed by immersion in clean water for 3 days. Remove, and wipe out any traces of moisture. 4.1.3 Procedure Place the specimen with flat faces horizontal, and mortar filled face facing upwards between two 3-ply plywood sheets each of 3 mm thickness and carefully centred between plates of the testing machine. Apply load axially at a uniform rate of 14 N/mm* ( 140 kgf/cm2 ) per minute till failure occurs and note the maximum load at failure. The load at failure shall be the maximum load at which the specimen fails to produce any 1

4.2.4 Report The report shall be as given below: Comoressive strength in N/mm MaGmum load at failure in N ( kgf) ( kgf/cm2 ) = Average net area of the two faces under compression in mm2 ( cm* ) 4.2.4.1 The average of results shall be reported.

As in the Original Standard, this Page is Intentionally Left Blank

IS 3495 ( Part 2 ) : 1992

Indian Standard

METHODS OF TESTS OF BURNT CLAY BUILDING BRICKS

PART 2 DETERMINATION ( OF WATER ABSORPTION

Tlzird Revision )

4.1.1 Apparatus

1 SCOPE 1.1 This standard ( Part 2 ) covers the method of determination of water absorption of burnt clay building bricks. 2 REFERENCE 2.1 The Indian Standard IS 5454 : 1976 Method for sampling of clay building bricks (first revision ) is a necessary adjunct to this standard. 3 GENERAL

A sensitive balance capable of weighing within 01 percent of the mass of the specimen; and a ventilated oven. 4.1.2 Preconditioning Dry the specimen in a ventilated oven at a temperature of 105 to 115C till it attains substantially constant mass. Cool the specimen to room temperature and obtain its weight ( MI ). Specimen warm to touch shall not be used for the purpose. 4.1.3 Procedure

3.1 The dimension nearest 1 mm.

shall be measured

to

the

3.2 All apparatus and testing equipment calibrated at frequent intervals.

shall be

Immerse completely dried specimen in clean water at a temperature of 27 f 2C for 24 hours. Remove the specimen and wipe out any traces of water with a damp cloth and weigh the specimen. Complete the weighing 3 minutes after the specimen has been removed from water ( Mz ). 4.1.4 Water absorption, percent by mass, after 24-hour immersion in cold water is given by the following formula:

Mz--1 x Ml

3.3 The number of specimens for the test shall be selected according to IS 5454 : 1976. 4 METHODS 4.1 24-hoar Immersion Cold Water Test

loo

As in the Original Standard, this Page is Intentionally Left Blank

IS 3495 ( Part 3 ) : 1992

Indian Standard

METHODS OF TESTS OF BURNT CLAY BUILDING BRICKS

PART 3 DETERMINATION ( OF EFFLORESCENCE

Third Revision )

whole arrangement in a warm ( for example, 20 to 30C ) well ventilated room until all the water in the dish is absorbed by the specimens. and the surplus water evaporates. Cover the dish containing the brick with suitable glass cylinder so *hat excessive evaporation from the dish may not occur. When the water has been absorbed and bricks appear to be dry, place a similar quantity of water in the dish and allow it to evaporate as before. Examine the bricks for efflorescence after the second evaporation and report the results. 4.3 Report

1 SCOPE 1.1 This standard ( Part 3 ) covers the method of determination of efflorescence of burnt clay building bricks. 2 REFE_RENCE 2.1 The Indian Standard IS 5454 : 1976 Method for sampling of clay building bricks ( first revision ) is a necessary adjunct to this standard. 3 GENERAL 3.1 The dimensions nearest 1 mm. shall be measured to the

The liability to efflorescence shall be reported as nil, slight, moderate, heavy or serious in accordance with the following definitions:

3.2 All apparatus and testing equipment calibrated at frequent intervals.

shall be

d Nil - When there is no perceptible deposit

of efflorescence.

3.3 The number of specimens for the test shall be selected according to IS 5454 : 1976. 4 METHOD 4.1 Apparatus A shallow flat bottom dish containing sufficient distilled water to completely saturate the specimens. The dish shall be made of glass, porcelain or glazed stoneware and of size I80 mm x 1SO mm X 40 mm depth for square shaped and 200 mm dia X 40 mm depth for cylindrical shaped. 4.2 Procedure Place the end of the bricks in the dish, the depth of immersion in water being 25 mm. Place the

b) SIigltt -

When not more than 10 percent of the exposed area of the brick is covered with a thin deposit of salts. When there is a heavier deposit than under slight and covering up to 50 percent of the exposed area of the brick surface but unaccompanied by powdering or flaking of the surface. When there is a heavy deposit of salts covering 50 percent or more of the exposed area of the brick surface but unaccompanied by powdering or flaking of the surface.

cl Moderate -

d) Heavy -

Serious -

When there is a heavy deposit of salts accompanied bp powdering and/or flaking of the exposed surfaces.

As in the Original Standard, this Page is Intentionally Left Blank

IS 3495 ( Part 4 ) : 1992

IJjdian Standard

METHODS OF TESTS OF BURNT CLAY BUILDING BRICKS

PART 4 ( 1 SCOPE 1.1 This standard ( Part 4 ) covers the method of E;;it$nation of warpage of burnt clay building 2 REFERENCE 2.1 The Indian Standard IS 5453 : 1976 Method for sampling of clay building bricks ( first revision) is a necessary adjunct to this standard. 3 GENERAL 3.1 The dimension nearest 1 mm. shall be measured to the DETERMINATION OF WARPAGE

Third Revision )

The wedge shall be graduated in 05 mm divisions and numbered to show the thickness of the wedge between the base AB and the slope AC ( see Fig. 1 ).

b) A flat surface of steel or glass, not less

than 300 mm x 300 mm in area and plane to 002 mm.

4.2 Preconditioning

Remove any dirt adhering to the surface of brick.

4.3 Testing 4.3.1 For Concave Warpage Place the flat surface along the surface to be measured selecting the location that gives the greatest departure from straightness. Measure the greatest distance of the brick surface from the edge of straightness by a steel rule or wedge. 4.3.2 For Convex Warpage Place the brick on the flat surface with the convex surface in contact with the flat surface. Measdre the distance from Rat surface to the four corners of the brick, and take the maximum of four measurements. 4.4 Report The higher of the distance measured and 4.3.2 shall be reported as warpage. in 4.3.1

3.2 All apparatus and testing equipment calibrated at frequent intervals.

shall be

3.3 The number of specimens for the test shall be selected according to IS 5454 : 1976. 4 METHOD 4.1 Measuring Instrument

4 A steel rule graduated

from one end in 05 mm divisions. Alternatively, a steel measuring wedge 60 mm in length, 15 mm in width and 15 mm in thickness at one end and tapered, starting at a line 15 mm from one end to zero t-hickness at the other end.

FIG. 1

MEASURING WEDGE

..

Bureau of Indian Standards BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country. Copyright

-..

No part of these publications may be reproduced in any form BIS has the copyright of all its publications. without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be addressed to the Director (Publication), BIS. Review of Indian Standards Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of BIS Handbook and Standards Monthly Additions. This Indian Standard has been developed from Dot: No. CED 30 ( 50 I7 1 Amendments Amend No. Date of Issue Issued Since Publication Text Affected

BUREAU Headquarters:

OF INDIAN

STANDARDS Telegrams: Manaksanstha (Common to all offices) Telephone 323 76 17,323 38 41 { 337 84 86 99,337 85 9120 61 26,337 { 60 38 20 43 25

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telephones: 323 01 31,323 33 75,323 94 02 Regional Offices: Central Eastern Northern Southern Western Branches

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

: l/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCUTTA

700054 160022 600113

: SC0 335-336, Sector 34-A, CHANDIGARH

: C.I.T. Campus, IV Cross Road, CHENNAI

{ 235 02 15 16,235 19,235 04 23 42 15

: Manakalaya,

E9 MIDC, Marol, Andheri (East) MUMBAI 400093

832 92 95,832 78 58 832 78 91,832 78 92

: AHMADABAD.

BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR. PATNA. PUNE. THIRUVANANTHAPURAM.

Printed by Reprography Unit, BIS, New Delhi

You might also like

- Is 3495 1-4 1992 PDFDocument13 pagesIs 3495 1-4 1992 PDFmanuvthampyNo ratings yet

- Is 3495 1-4 1992 PDFDocument13 pagesIs 3495 1-4 1992 PDFDhruva ChodankarNo ratings yet

- Railway Handbook of Material Testing 1Document20 pagesRailway Handbook of Material Testing 1vpmohammedNo ratings yet

- CT Lab ManualDocument29 pagesCT Lab Manualamanvermaav089No ratings yet

- BS 1881 Part 122 83Document8 pagesBS 1881 Part 122 83Jennifer StokesNo ratings yet

- 20201120-Adhesion Strength Testing For Waterproofing Overlaid by AsphaltDocument18 pages20201120-Adhesion Strength Testing For Waterproofing Overlaid by Asphalttony13touchNo ratings yet

- AS 1012.6-1999 For The Determination of Bleeding of ConcreteDocument9 pagesAS 1012.6-1999 For The Determination of Bleeding of Concreteheyh jdjNo ratings yet

- Reconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- To Determine Compressive Strength of CementDocument5 pagesTo Determine Compressive Strength of CementAnish OhriNo ratings yet

- QC Tests For Road Works by Bhavanna Rao DVDocument24 pagesQC Tests For Road Works by Bhavanna Rao DVmilind_0786No ratings yet

- خرسانة عملي الفصل الاول والثانيDocument58 pagesخرسانة عملي الفصل الاول والثانيAhmed AlyasNo ratings yet

- Yogesh Rana (A62)Document50 pagesYogesh Rana (A62)Yogeshwar singhNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationUTTAL RAYNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- C 1027 - 99 - Qzewmjctotk - PDFDocument6 pagesC 1027 - 99 - Qzewmjctotk - PDFangeljosechuquiureNo ratings yet

- Aggregate 10% Fines Value BS 812-111 - BS en 1097 - 2Document4 pagesAggregate 10% Fines Value BS 812-111 - BS en 1097 - 2rajeshji_000100% (1)

- D 968 - 93 - Rdk2oc05mwDocument4 pagesD 968 - 93 - Rdk2oc05mwuocmogiandi_aNo ratings yet

- Proctor Standard Soil CompactionDocument11 pagesProctor Standard Soil Compactionikhwan100% (2)

- QAP Volume - 2Document75 pagesQAP Volume - 2HenRique Xavi Inesta100% (1)

- Quality Control Tests PDFDocument45 pagesQuality Control Tests PDFSuhaidi AliasNo ratings yet

- Burnt Clay Building Bricks - Methods of Tests: Indian StandardDocument8 pagesBurnt Clay Building Bricks - Methods of Tests: Indian Standardraviteja036100% (2)

- Burnt Clay Building Bricks - Methods of Tests: Indian StandardDocument8 pagesBurnt Clay Building Bricks - Methods of Tests: Indian Standardmohd waseemNo ratings yet

- MS-A.4 Determination of The Durability of Hardened MortarDocument5 pagesMS-A.4 Determination of The Durability of Hardened MortarTarek ChikerNo ratings yet

- f1f2 Bis 13429Document10 pagesf1f2 Bis 13429Aaquib akkiNo ratings yet

- As 1012.5-1999 PDFDocument9 pagesAs 1012.5-1999 PDFPham Duc QuangNo ratings yet

- Concrete &highway Lab New ManualDocument40 pagesConcrete &highway Lab New Manualshruthicivil100% (4)

- Methods of Physical Tests For Hydraulic Cement: Indian StandardDocument6 pagesMethods of Physical Tests For Hydraulic Cement: Indian StandardchandraprakashhhNo ratings yet

- Civil Engineering Materials Lab Manual (Summer 2019)Document23 pagesCivil Engineering Materials Lab Manual (Summer 2019)Malik Shahrukh PashaNo ratings yet

- Soil Test ReportDocument38 pagesSoil Test ReportRohan RajNo ratings yet

- Procedure MDD OMDocument2 pagesProcedure MDD OMSreekala PrabhasankarNo ratings yet

- Experiment - 1 California Bearing Ratio Test: Date - 14/01/2016 Cycle - 4 and Subgroup - 1Document9 pagesExperiment - 1 California Bearing Ratio Test: Date - 14/01/2016 Cycle - 4 and Subgroup - 1Arpit GunawatNo ratings yet

- Lab 1 Chapter 3: Methodology Slump Test 2.1 Flow Chart: StartDocument18 pagesLab 1 Chapter 3: Methodology Slump Test 2.1 Flow Chart: StartHaiqal RafiqNo ratings yet

- 1716.2.3. Test Specimen and Sample Strength: Three Test Specimens Shall Be Made From EachDocument6 pages1716.2.3. Test Specimen and Sample Strength: Three Test Specimens Shall Be Made From EachSrikrishan singhNo ratings yet

- Sand Equivalent TestDocument6 pagesSand Equivalent TestFlavioMuhaleNo ratings yet

- Soundness of CementDocument3 pagesSoundness of CementKrishnaChaitanya100% (1)

- ASTM C 232 - Bleeding of Concrete PDFDocument5 pagesASTM C 232 - Bleeding of Concrete PDFXaviorOusephNo ratings yet

- 672CDocument3 pages672CJGD123No ratings yet

- IS 4031 - Part10Document5 pagesIS 4031 - Part10SourabhAdikeNo ratings yet

- D 2823 - 90 R97 Rdi4mjmDocument4 pagesD 2823 - 90 R97 Rdi4mjmdaovandongpktNo ratings yet

- Is2720 Part09Document6 pagesIs2720 Part09anvesh_kumar_16No ratings yet

- Saso 87 Methods of Test For Concrete (Cement) Building Bricks and BlocksDocument7 pagesSaso 87 Methods of Test For Concrete (Cement) Building Bricks and BlocksMohamed AbdinNo ratings yet

- Technical Specifications For Structural Works - All ProjectsDocument78 pagesTechnical Specifications For Structural Works - All ProjectsDushan Lalithya GamaethigeNo ratings yet

- Laboratory WorksDocument32 pagesLaboratory WorksCliff Jude ZehnderNo ratings yet

- Resumen de Todas Las Normas ISODocument33 pagesResumen de Todas Las Normas ISObarbadoblancoNo ratings yet

- Geotechnical Investigation SpecificationDocument7 pagesGeotechnical Investigation SpecificationT Bayu PratamaNo ratings yet

- Compressive Strength of Cement: 1. ObjectiveDocument7 pagesCompressive Strength of Cement: 1. ObjectiveAhmad FarooqNo ratings yet

- Cement Test eDocument10 pagesCement Test esajjad.ghazai2001No ratings yet

- Argillaceous Swellingxocks - Methods For Laboratory TestingDocument16 pagesArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20No ratings yet

- Burnt Clay Building Bricks - Methods of Tests: Indian StandardDocument8 pagesBurnt Clay Building Bricks - Methods of Tests: Indian Standardmohd waseemNo ratings yet

- Astm C 185Document3 pagesAstm C 185cristian_agpNo ratings yet

- Observation Book-Experiment Nos.1 To 5Document40 pagesObservation Book-Experiment Nos.1 To 5Machana vinay krishnaNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

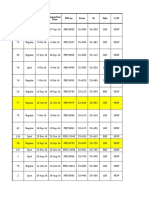

- SR No. RFI No. From To Side C/W Regular / Spot Submissio N Date Inspection DateDocument18 pagesSR No. RFI No. From To Side C/W Regular / Spot Submissio N Date Inspection DateVb SeriesNo ratings yet

- Bitumenrate PDFDocument2 pagesBitumenrate PDFVb SeriesNo ratings yet

- Irc 78 2000Document54 pagesIrc 78 2000Shiva Kumar M100% (2)

- Lafarge Aggregates & Concrete India PVT - LTD: S P SinglaDocument1 pageLafarge Aggregates & Concrete India PVT - LTD: S P SinglaVb SeriesNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Test Prcedure For ConcreteDocument57 pagesTest Prcedure For Concreteneroshan1978100% (2)

- Bar Bending SheduleDocument8 pagesBar Bending SheduleVb SeriesNo ratings yet