Professional Documents

Culture Documents

Me2252 Manufacturing Technology II r8 April - May 2010

Uploaded by

nkchandruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me2252 Manufacturing Technology II r8 April - May 2010

Uploaded by

nkchandruCopyright:

Available Formats

tnlearner.

net

www.tnlearner.net Page 1

Reg. No. :

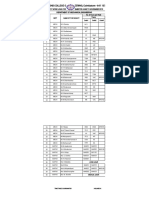

Question Paper Code: E3134

B.E./B.Tech. DEGREE EXAMINATION, APRIL/MAY 2010

Fourth Semester

Mechanical Engineering

ME2252 MANUFACTURING TECHNOLOGY II

(Regulation 2008)

Time: Three hours Maximum: 100 Marks

Answer ALL Questions

PART A (10 2 = 20 Marks)

1. How do you classify tool wear?

2. Define Tool Life.

3. Distinguish between Capstan lathe from Turret lathe.

4. State the different methods of taper turning.

5. How do you classify milling cutters?

6. Define Broaching.

7. State the applications of honing and lapping finishing methods.

8. Compare gear forming with gear generation method.

9. State the limitations of CNC machine tools.

10. What is a Canned cycle?

PART B (5 16 = 80 Marks)

11. (a) (i) Discuss the various types of chips produced during metal

machining. (6)

(ii) State the parameters that influence the life of tool and discuss. (10)

Or

(b) (i) What is meant by Orthogonal Cutting and Oblique Cutting? (6)

(ii) Explain Merchant force circle along with assumptions. (10)

tnlearner.net

www.tnlearner.net Page 2

12. (a) (i) Discuss the main parts of a turret lathe. (6)

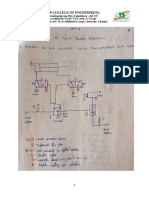

(ii) Explain the working of Swiss type auto lathe with a neat sketch.

(10)

Or

(b) (i) What is meant by tool layout of a turret lathe?

(6)

(ii)

Name the various lathe accessories. How does

differ from a three jaw chuck?

a four jaw

chuck

(10)

13. (a) (i) What are the operations performed on a milling machine? (6)

(ii) Explain different types of drilling machines with their specific

features. (10)

Or

(b) (i) Discuss the various types of broaches. (6)

(ii) Discuss the common work holding devices used on shapers, slotters

14.

(a)

(i)

and planers. (10)

Give the specification of grinding wheel. (6)

(ii)

What is meant by dressing and truing of grinding wheel? (10)

Or

(b) (i) List the advantages and limitations of gear shaping. (6)

(ii)

Explain the principle of gear hobbing with neat sketches.

(10)

15.

(a)

(i)

Under what conditions of production the numerically

machine tools are employed?

controlled

(6)

(ii) Explain the various elements of NC machine with closed loop

control system. (10)

Or

(b) (i) Explain the main difference between point to point and continuous

path type of numerically controlled machine tools. (6)

(ii) List any five motions and control statements of computer assisted

NC programming and explain. (10)

You might also like

- Weekly Workshop Series SathishDocument3 pagesWeekly Workshop Series SathishnkchandruNo ratings yet

- Workload 19-20Document2 pagesWorkload 19-20nkchandruNo ratings yet

- RMD Ac in Dept Eee Index PHPDocument1 pageRMD Ac in Dept Eee Index PHPnkchandruNo ratings yet

- 4790 32542 1 PBDocument6 pages4790 32542 1 PBJogi Oscar SinagaNo ratings yet

- SNS College Engineering Answer Key Covers Entrepreneurship DevelopmentDocument5 pagesSNS College Engineering Answer Key Covers Entrepreneurship DevelopmentnkchandruNo ratings yet

- TroubleshootingDocument2 pagesTroubleshootingnkchandruNo ratings yet

- VacationDocument1 pageVacationnkchandruNo ratings yet

- Two Days Workshop For Composite MaterialsDocument2 pagesTwo Days Workshop For Composite MaterialsnkchandruNo ratings yet

- Cotter Joint Design GuideDocument15 pagesCotter Joint Design GuidenkchandruNo ratings yet

- Npec 032Document6 pagesNpec 032nkchandruNo ratings yet

- DonDocument4 pagesDonnkchandruNo ratings yet

- U-4, Topic 7Document2 pagesU-4, Topic 7nkchandruNo ratings yet

- RTGS Transfer AcknowledgementDocument1 pageRTGS Transfer AcknowledgementnkchandruNo ratings yet

- Deformation and stresses in thin spherical shellsDocument8 pagesDeformation and stresses in thin spherical shellsnkchandruNo ratings yet

- Design and Fabrication of Modified Crop HarvesterDocument13 pagesDesign and Fabrication of Modified Crop HarvesternkchandruNo ratings yet

- Deformation and stresses in thin spherical shellsDocument8 pagesDeformation and stresses in thin spherical shellsnkchandruNo ratings yet

- CE6306 STRENGTH OF MATERIALS PART-B TOPICSDocument8 pagesCE6306 STRENGTH OF MATERIALS PART-B TOPICSnkchandruNo ratings yet

- Archive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessDocument9 pagesArchive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessnkchandruNo ratings yet

- APDocument10 pagesAPnkchandruNo ratings yet

- E6311 Set4Document2 pagesE6311 Set4nkchandruNo ratings yet

- NEDocument59 pagesNEnkchandruNo ratings yet

- Train No. Name From To Departure Arrival Duration Sun Mon TueDocument56 pagesTrain No. Name From To Departure Arrival Duration Sun Mon TuenkchandruNo ratings yet

- SNS College Internal Assessment Exam ThermodynamicsDocument2 pagesSNS College Internal Assessment Exam ThermodynamicsnkchandruNo ratings yet

- Intercooling in Gasturbine Power Plant PDFDocument12 pagesIntercooling in Gasturbine Power Plant PDFnkchandruNo ratings yet

- 1.mark The Higher and Lower TemperatursDocument2 pages1.mark The Higher and Lower TemperatursnkchandruNo ratings yet

- Studies of Welded Joints: Archives of Foundry EngineeringDocument6 pagesStudies of Welded Joints: Archives of Foundry EngineeringnkchandruNo ratings yet

- Archive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessDocument9 pagesArchive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessnkchandruNo ratings yet

- Provisional Certificate Letter: Date and SealDocument1 pageProvisional Certificate Letter: Date and SealnkchandruNo ratings yet

- CHAPTER 8 THERMODYNAMICS MCQs YEAR 2012-2009Document68 pagesCHAPTER 8 THERMODYNAMICS MCQs YEAR 2012-2009Kumar SahebNo ratings yet

- ACFrOgAz1tI7u2Z7arXhthcDfA - StuFW8ULNj4idegLIoompNo79Rl Fy2aiiH94DLXw3e1CM49Zfsvpq9tCctKkpuz2obwc oIXRDWvLEACOcGA - ONHYiNgYK OmV4Document1 pageACFrOgAz1tI7u2Z7arXhthcDfA - StuFW8ULNj4idegLIoompNo79Rl Fy2aiiH94DLXw3e1CM49Zfsvpq9tCctKkpuz2obwc oIXRDWvLEACOcGA - ONHYiNgYK OmV4nkchandruNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gaslands - FAQDocument11 pagesGaslands - FAQfuzzy sadistNo ratings yet

- BW PTO Gear Systems for Ship PropulsionDocument2 pagesBW PTO Gear Systems for Ship PropulsionAndre MarthenNo ratings yet

- Manual BU Mechanik - en V23 - 2010 10 18 SmallDocument60 pagesManual BU Mechanik - en V23 - 2010 10 18 SmallArtemy Khotenov100% (2)

- Mechanically Operated Road Sweeper Design ReportDocument80 pagesMechanically Operated Road Sweeper Design ReportSANDIP PANDYANo ratings yet

- AT6501 (R-13) Notes PDFDocument131 pagesAT6501 (R-13) Notes PDFAashiq NawinNo ratings yet

- Practical Design of Small AirplaneDocument4 pagesPractical Design of Small AirplaneSenja RiraNo ratings yet

- Omron Servo MotorDocument123 pagesOmron Servo MotorAbdul MajeethNo ratings yet

- Automotive Servicing Workshop 3Document31 pagesAutomotive Servicing Workshop 3Alvin RazoNo ratings yet

- Reverse Gear MechanismDocument4 pagesReverse Gear MechanismJose Luis Llerena FloresNo ratings yet

- KR6-KR15 - Manipulator MaintenanceDocument25 pagesKR6-KR15 - Manipulator MaintenancePablo LuceroNo ratings yet

- Design and Analysis of A Two Stage Reduc PDFDocument74 pagesDesign and Analysis of A Two Stage Reduc PDFVijay KrishnasamyNo ratings yet

- Komatsu D375Document24 pagesKomatsu D375Bambang Cliquers50% (2)

- HH-Rotary Table ZP175 - ZP205 PDFDocument3 pagesHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCarlos Gabriel Estergaard100% (1)

- Product Knowledge DX140LCA-AFDocument11 pagesProduct Knowledge DX140LCA-AFArnara VerdiawanNo ratings yet

- Brevini Power Transmission Products 2008 UKDocument14 pagesBrevini Power Transmission Products 2008 UKSabith MohammedNo ratings yet

- 1 SM401Document55 pages1 SM401Yennhi NguyenNo ratings yet

- Design Procedure For Gear BoxDocument2 pagesDesign Procedure For Gear BoxTuji100% (1)

- Four-Unit Express Railcar Trains For Short-Distance ServiceDocument23 pagesFour-Unit Express Railcar Trains For Short-Distance ServicePablo MarajNo ratings yet

- Siemense Point Machine Used Over Indian RailwaysDocument8 pagesSiemense Point Machine Used Over Indian RailwaysVikas Srivastav100% (9)

- Diesel Tiller ManualDocument77 pagesDiesel Tiller ManualRickson Viahul Rayan C100% (3)

- Price ListDocument125 pagesPrice ListToth ZsoltNo ratings yet

- Rope CouplingDocument4 pagesRope CouplingKamal KapaNo ratings yet

- Manual Actuators For Use With Large Size Butterfly ValvesDocument5 pagesManual Actuators For Use With Large Size Butterfly Valvesmarsha.fsdNo ratings yet

- Chancador Primario Mk-Ii PDFDocument71 pagesChancador Primario Mk-Ii PDFIván Herrera ToroNo ratings yet

- DX9010SSPC JP PDFDocument221 pagesDX9010SSPC JP PDFВалентин МитовNo ratings yet

- Saab 96 Owners ManualDocument68 pagesSaab 96 Owners Manualmalte winbaldNo ratings yet

- Manufacturing of Gears and Its ProcessDocument21 pagesManufacturing of Gears and Its ProcessAnonymous uaKq5PQWcNo ratings yet

- Workshop Manual (2006MY) : Service Procedures: SECTION 2 - ChassisDocument69 pagesWorkshop Manual (2006MY) : Service Procedures: SECTION 2 - ChassisAfsar's SonNo ratings yet

- Electric Linear Actuators and Controls Full enDocument51 pagesElectric Linear Actuators and Controls Full ensaleemut3No ratings yet