Professional Documents

Culture Documents

Lecture 12 Assembly Modeling

Uploaded by

toshugoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 12 Assembly Modeling

Uploaded by

toshugoCopyright:

Available Formats

1

MAE 455 Computer-Aided Design and Drafting

Assembly Modeling

MAE 455 Computer-Aided Design and Drafting 2

Assembly models

An assembly is modeled as a collection of

components (parts and sub-assemblies)

arranged in a specific way.

Assembly models are useful for:

E.g., Widget assembly has

components: A, B, C.

C B A

2

MAE 455 Computer-Aided Design and Drafting 3

Assembly Part Info.

In early Assembly Modelers, all the information for each component

was put in the file. This was very inefficient when the same part was

used multiple times. E.g., A and C are the same. Information for A and C was

included twice.

Now CAD systems keep references to the part or sub-assembly

information. I.e., an assembly only keeps track of which file has the

part information for each component.

C B A

Widget Assembly End_part Middle_part

MAE 455 Computer-Aided Design and Drafting 4

Assembly Positioning

Since the details of each component come from a separate part file, it

is also necessary to keep track of the location of each component.

The location of each component is given by:

the position of the origin of the parts coordinate system

the directions of the x, y, and z axes of the parts coordinate system.

B

A

Widget Assembly End_part Middle_part

x

y

x

y

x

y

C

x

y

x

y

x

y

3

MAE 455 Computer-Aided Design and Drafting 5

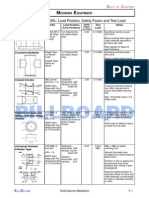

Assembly Constraints

Components can be positioned with respect to

each other using positioning commands.

However, modern CAD systems use constraints

(or mating conditions) to automatically position

components.

Assembly constraints allow components to be

automatically re-positioned when the size of a

part changes (e.g., if Middle_part becomes wider, component C

automatically moves right.)

SolidWorks assembly constraints are:

MAE 455 Computer-Aided Design and Drafting 6

Assembly Information

For each component, an assembly keeps track of:

4

MAE 455 Computer-Aided Design and Drafting 7

Bottom-Up vs. Top-Down Design

Bottom-up: component parts are designed and

edited apart from their usage in a higher

assembly.

1. Create part solid models.

2. Combine parts into sub-assemblies.

3. Combine sub-assemblies into assemblies.

Top-down: the hierarchy of assemblies and sub-

assemblies is designed first, then part solid

models are designed in place.

1. Create highest level assembly.

2. Add empty sub-assemblies and parts to assemblies.

3. Create solid models in empty part files.

MAE 455 Computer-Aided Design and Drafting 8

Bottom-Up vs. Top-Down Design

Bottom Up Top Down

1.

2.

3. 1.

2.

3.

5

MAE 455 Computer-Aided Design and Drafting 9

Also known as Design in Context.

Solid Models are created such that the part and

assembly coordinate systems line up in the assembly.

Neighboring part can be used as reference.

Design in Place

Not Designed in Place Designed in Place

x

y

x

y

x

y

x

y

x

y

x

y

x

y

x

y

x

y

x

y

x

y

You might also like

- Mechanical Assembly DesignDocument43 pagesMechanical Assembly DesignMUHAMMAD KHUSAIRI JOHARINo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Assembly ModellingDocument32 pagesAssembly ModellingKamarul NizamNo ratings yet

- NX_CAM_Setup_TemplatesDocument10 pagesNX_CAM_Setup_TemplatesCadcamnx BrasilNo ratings yet

- Assembly Modeling: AssembliesDocument5 pagesAssembly Modeling: AssembliesPerustar78No ratings yet

- A1 Methods - Take Home PointsDocument4 pagesA1 Methods - Take Home Pointsdanilamihay86No ratings yet

- Assembly-Modeling ClassDocument63 pagesAssembly-Modeling Classkumar km100% (4)

- Catia Is Also Known As Computer Aided Three Dimensional Interactive Application. CATIA Was Started in 1977 by French Aircraft ManufacturerDocument21 pagesCatia Is Also Known As Computer Aided Three Dimensional Interactive Application. CATIA Was Started in 1977 by French Aircraft ManufacturerBhavesh KumharNo ratings yet

- VAMOS CAA V5 Based: Progressive DiesDocument4 pagesVAMOS CAA V5 Based: Progressive DiesRodolfo GarciaNo ratings yet

- Using & Customizing The Autodesk Inventor® Frame Generator 401 - MA31-2Document14 pagesUsing & Customizing The Autodesk Inventor® Frame Generator 401 - MA31-2Graham MooreNo ratings yet

- Creating Flat Harnesses: Module OverviewDocument1 pageCreating Flat Harnesses: Module OverviewPraveen SreedharanNo ratings yet

- Introduction To Modeling PDFDocument16 pagesIntroduction To Modeling PDFanup chauhanNo ratings yet

- Frame Generator PDFDocument13 pagesFrame Generator PDFWilly PeralesNo ratings yet

- Assembling Parts: in This ChapterDocument44 pagesAssembling Parts: in This ChapterSyed KuNo ratings yet

- 3D Modeling & Design ME-3131: Dr. Michael J Rider Biggs 135 Spring 2018Document24 pages3D Modeling & Design ME-3131: Dr. Michael J Rider Biggs 135 Spring 2018Nguyễn Hiền NhânNo ratings yet

- K. D.K. College of Engineering, Nagpur Department of Mechanical EngineeringDocument9 pagesK. D.K. College of Engineering, Nagpur Department of Mechanical EngineeringVedprakashNo ratings yet

- Top-Down Design With Autodesk® Inventor™ Using Skeletal ModelingDocument14 pagesTop-Down Design With Autodesk® Inventor™ Using Skeletal ModelingNOCHE3No ratings yet

- Unit Iv Me16501 PDFDocument146 pagesUnit Iv Me16501 PDFSelva BabuNo ratings yet

- Solidworks Best Practices: by Matt Lombard For Brugs April 6, 2006Document30 pagesSolidworks Best Practices: by Matt Lombard For Brugs April 6, 2006rodriguez.gaytan100% (1)

- TRN 4508 400 01 - Overheads - EN PDFDocument120 pagesTRN 4508 400 01 - Overheads - EN PDFflorentinaNo ratings yet

- Allegro Package Designer FlowsDocument20 pagesAllegro Package Designer FlowsAnonymous eNddb31Y100% (1)

- Catia V5: Training ModulesDocument13 pagesCatia V5: Training ModulesAman MaanNo ratings yet

- Top-Down Design OverviewDocument29 pagesTop-Down Design OverviewDhoom MachaleNo ratings yet

- Introduction To Computer Aided Design: Whoami?Document18 pagesIntroduction To Computer Aided Design: Whoami?Tiga002No ratings yet

- Preparing and Linking A Revit Architecture Model For Your MEP ProjectDocument22 pagesPreparing and Linking A Revit Architecture Model For Your MEP ProjectJeneish JustusNo ratings yet

- Pptoncatia 150906151126 Lva1 App6891Document20 pagesPptoncatia 150906151126 Lva1 App6891AmexTesfayeKoraNo ratings yet

- CATIA v5 Training: Assembly DesignDocument7 pagesCATIA v5 Training: Assembly DesignTiga002No ratings yet

- Computer Aided Design ME-451Document33 pagesComputer Aided Design ME-451Sheelendra kumarNo ratings yet

- CAD Data ExchangeDocument10 pagesCAD Data ExchangeRaghuNo ratings yet

- Assembly Drawing GuideDocument15 pagesAssembly Drawing GuideManas KapseNo ratings yet

- Group Technology and Cellular Manufacturing-IDocument20 pagesGroup Technology and Cellular Manufacturing-IelkhawadNo ratings yet

- 2 Data Base Structures and ModelsDocument22 pages2 Data Base Structures and Modelsbt21109002 AlishaNo ratings yet

- ABAQUS CAE Tutorial: 2D Plane Stress Cantilever BeamDocument26 pagesABAQUS CAE Tutorial: 2D Plane Stress Cantilever BeamlucNo ratings yet

- OrCAD Layout Plus TutorialDocument14 pagesOrCAD Layout Plus TutorialuqinkNo ratings yet

- ABAQUS CAE Tutorial: 2D Plane Stress Beam AnalysisDocument26 pagesABAQUS CAE Tutorial: 2D Plane Stress Beam Analysisibrahim alshaikhNo ratings yet

- Precast Company Set UpDocument31 pagesPrecast Company Set Uphieu49xfNo ratings yet

- 5 DD 9 F 1315 D 0 FBDocument81 pages5 DD 9 F 1315 D 0 FBjagadeesh Kumaran B (Jagan Jagadeesh)No ratings yet

- CAD LAB Intro To Creo 2 PDFDocument25 pagesCAD LAB Intro To Creo 2 PDFkawanjainNo ratings yet

- Unit V Cellular Manufacturing and Flexible Manufacturing System (FMS)Document32 pagesUnit V Cellular Manufacturing and Flexible Manufacturing System (FMS)manuNo ratings yet

- Solid Modeling PresentationDocument27 pagesSolid Modeling PresentationNilesh RanaNo ratings yet

- 0105 - Best Practices For Large NX Models and Drawings Training Slides-020513Document39 pages0105 - Best Practices For Large NX Models and Drawings Training Slides-020513AmolPagdal0% (1)

- Computer Aided Jig and Fixture DesignDocument18 pagesComputer Aided Jig and Fixture DesignRajesh RJNo ratings yet

- Concept: Step 1: Assembly and Cabling SetupDocument2 pagesConcept: Step 1: Assembly and Cabling SetupPraveen SreedharanNo ratings yet

- TD05 39JP en PDFDocument22 pagesTD05 39JP en PDFgia1985No ratings yet

- Apdl ModelingDocument47 pagesApdl ModelingagahNo ratings yet

- Advanced Assembly Modeling TechniquesDocument49 pagesAdvanced Assembly Modeling TechniquesRami NehmeNo ratings yet

- Solidworks Topdown PDFDocument10 pagesSolidworks Topdown PDFjoalsaayNo ratings yet

- Group Technology and Cellular Manufacturing-IDocument20 pagesGroup Technology and Cellular Manufacturing-IAnonymous NGBgXVq1xNo ratings yet

- (ETABS) COMPOSITE GENERAL Manual PDFDocument112 pages(ETABS) COMPOSITE GENERAL Manual PDFVũ Cao AnhNo ratings yet

- Assembly Modelling PDFDocument21 pagesAssembly Modelling PDFGjccNo ratings yet

- Unit 6 - UML Component Diagram: Software Development Life Cycle (SDLC)Document23 pagesUnit 6 - UML Component Diagram: Software Development Life Cycle (SDLC)JOSEPH NSUNZANo ratings yet

- Design IssuesDocument12 pagesDesign IssuesAnonymous uspYoqENo ratings yet

- CSG Brep Solid ModelingDocument64 pagesCSG Brep Solid ModelingHariNo ratings yet

- ME 252 Geometric Modeling Chapter Objectives and TolerancesDocument147 pagesME 252 Geometric Modeling Chapter Objectives and TolerancesAzooNo ratings yet

- Creating A Custom Component in NI Multisim - National InstrumentsDocument9 pagesCreating A Custom Component in NI Multisim - National Instrumentsbalu2258No ratings yet

- MF40601 Lecture 6Document13 pagesMF40601 Lecture 6Amitpal SINGHNo ratings yet

- Document Harness Design DrawingsDocument1 pageDocument Harness Design DrawingsPraveen SreedharanNo ratings yet

- Inventor Whats New 2022Document39 pagesInventor Whats New 2022sumaryantoyantoNo ratings yet

- Assembly DrawingsDocument12 pagesAssembly DrawingsThangadurai Senthil Ram PrabhuNo ratings yet

- PROG0101 Fundamentals of Programming Chapter 6 BranchingDocument16 pagesPROG0101 Fundamentals of Programming Chapter 6 BranchingtoshugoNo ratings yet

- CIVE2010 Water Engineering EssentialsDocument7 pagesCIVE2010 Water Engineering EssentialstoshugoNo ratings yet

- Stress ShipDocument14 pagesStress Shiptoshugo100% (1)

- MOORING EQUIPMENT SAFETY FACTORSDocument2 pagesMOORING EQUIPMENT SAFETY FACTORSCaptIsqan100% (1)

- Unit 1 INTRODUCTION 1.1.introduction 1.2.objectives PDFDocument341 pagesUnit 1 INTRODUCTION 1.1.introduction 1.2.objectives PDFtoshugo100% (1)

- MOORING EQUIPMENT SAFETY FACTORSDocument2 pagesMOORING EQUIPMENT SAFETY FACTORSCaptIsqan100% (1)

- Answers1 PDFDocument4 pagesAnswers1 PDFtoshugoNo ratings yet

- Dry Dock PlanDocument1 pageDry Dock PlantoshugoNo ratings yet

- ME303 7 Head Loss 2 BranchedDocument39 pagesME303 7 Head Loss 2 BranchedtoshugoNo ratings yet

- 4011 Midterm Exam 2010Document2 pages4011 Midterm Exam 2010toshugoNo ratings yet

- Brodogradnja Plastikom PDFDocument64 pagesBrodogradnja Plastikom PDFtoshugoNo ratings yet

- Dock Pump - KSBDocument2 pagesDock Pump - KSBtoshugoNo ratings yet

- Nautical Terms For The Model Ship BuilderDocument85 pagesNautical Terms For The Model Ship BuilderemmdmkNo ratings yet

- Introduction to Ship Design and Naval Architecture BasicsDocument79 pagesIntroduction to Ship Design and Naval Architecture BasicsRENGANATHAN PNo ratings yet

- Product Data Management: Purpose of PDM SoftwareDocument7 pagesProduct Data Management: Purpose of PDM SoftwaretoshugoNo ratings yet

- Ejercicios Solidworks PDFDocument50 pagesEjercicios Solidworks PDFRic Frs80% (5)

- CAD Data Formats: Exchanging Data Between SystemsDocument4 pagesCAD Data Formats: Exchanging Data Between SystemstoshugoNo ratings yet

- Ejercicios Solidworks PDFDocument50 pagesEjercicios Solidworks PDFRic Frs80% (5)

- Using Vendor E-Catalogs: Identifying Needed Components & Obtaining Component Model FilesDocument2 pagesUsing Vendor E-Catalogs: Identifying Needed Components & Obtaining Component Model FilestoshugoNo ratings yet

- MAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 3: Advanced SketchingDocument1 pageMAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 3: Advanced SketchingtoshugoNo ratings yet

- SW Whats New-Ds 2013Document2 pagesSW Whats New-Ds 2013toshugoNo ratings yet

- MAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 4: Parametric Expressions and Creating DrawingsDocument1 pageMAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 4: Parametric Expressions and Creating DrawingstoshugoNo ratings yet

- Lecture 3 Geometric ModelingDocument14 pagesLecture 3 Geometric ModelingtoshugoNo ratings yet

- MAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 4: Parametric Expressions and Creating DrawingsDocument1 pageMAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 4: Parametric Expressions and Creating DrawingstoshugoNo ratings yet

- Lecture 2 SolidWorks IntroDocument7 pagesLecture 2 SolidWorks IntrotoshugoNo ratings yet

- Gerke Chapter 9Document2 pagesGerke Chapter 9toshugoNo ratings yet

- MAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 5: Assembly ModelingDocument1 pageMAE 455 Computer-Aided Design and Drafting Lab Instructions TUTORIAL 5: Assembly ModelingtoshugoNo ratings yet

- Lecture 11 Solid RepresentationsDocument6 pagesLecture 11 Solid RepresentationstoshugoNo ratings yet

- Mae 455 Computer-Aided Design and Drafting Lab Instructions Tutorial 1: Introduction To SolidworksDocument1 pageMae 455 Computer-Aided Design and Drafting Lab Instructions Tutorial 1: Introduction To SolidworkstoshugoNo ratings yet

- Getting More Knowledge (Theory) With Oracle RAC PDFDocument8 pagesGetting More Knowledge (Theory) With Oracle RAC PDFPraveen BachuNo ratings yet

- Human Gait Indicators of Carrying A Concealed Firearm: A Skeletal Tracking and Data Mining ApproachDocument17 pagesHuman Gait Indicators of Carrying A Concealed Firearm: A Skeletal Tracking and Data Mining ApproachStoie GabrielNo ratings yet

- Knowledge About GENEX Space V100R001C00SPC100T: Security LevelDocument23 pagesKnowledge About GENEX Space V100R001C00SPC100T: Security LevelChidhuro Owen100% (1)

- SQL ExamplesDocument12 pagesSQL Examplessaleem_zeejaNo ratings yet

- Life cycle cost analysis and prognosis model for aviation enginesDocument6 pagesLife cycle cost analysis and prognosis model for aviation enginesmorage_key_ringNo ratings yet

- Distributed and Cloud ComputingDocument42 pagesDistributed and Cloud ComputingPallavi ANNo ratings yet

- Data Warehouse Testing - Practical ApproachDocument8 pagesData Warehouse Testing - Practical ApproachRahul SharmaNo ratings yet

- Social CommerceDocument3 pagesSocial CommerceSuhani VarshneyNo ratings yet

- Patching GuideDocument2 pagesPatching GuideLuis SalgadoNo ratings yet

- As 4480.1-1998 Textiles For Health Care Facilities and Institutions - Medical Sheepskins Product SpecificatioDocument7 pagesAs 4480.1-1998 Textiles For Health Care Facilities and Institutions - Medical Sheepskins Product SpecificatioSAI Global - APACNo ratings yet

- Fortigate SwitchDocument3 pagesFortigate SwitchneelNo ratings yet

- Manual de Instalación APD5 EpsonDocument8 pagesManual de Instalación APD5 EpsonLily DropletNo ratings yet

- QA - Sample Resume - CVDocument2 pagesQA - Sample Resume - CVsample.resumes.cv89% (19)

- Isom ReviewerDocument35 pagesIsom ReviewerKristian UyNo ratings yet

- Emtech Module5 Week5 LessonDocument5 pagesEmtech Module5 Week5 LessonMa. Crisanta A. AntonioNo ratings yet

- Commodore Component Catalog 1981Document194 pagesCommodore Component Catalog 1981Dave0% (1)

- Day 3 - PeopleCodeDocument27 pagesDay 3 - PeopleCodeprabindasNo ratings yet

- Test Suite Generation With Memetic Algorithms: Gordon Fraser Andrea Arcuri Phil McminnDocument8 pagesTest Suite Generation With Memetic Algorithms: Gordon Fraser Andrea Arcuri Phil McminnJatin GeraNo ratings yet

- 1.what Is BDC and Explain The Real Time Scenarios Where We Need To Write The BDC Programs ?Document15 pages1.what Is BDC and Explain The Real Time Scenarios Where We Need To Write The BDC Programs ?api-19817778100% (1)

- Arduino-Adafruit GpsDocument5 pagesArduino-Adafruit Gpsapi-248437787No ratings yet

- Complex SQL Queries ExamplesDocument6 pagesComplex SQL Queries ExamplesqwertyvibesNo ratings yet

- testo-174H-Data-sheet Mini Humidity Data LoggerDocument2 pagestesto-174H-Data-sheet Mini Humidity Data LoggerDr. M NASEEM KHANNo ratings yet

- Course Outline CSC 201 Computer Architecture AUG - DEC 2015Document3 pagesCourse Outline CSC 201 Computer Architecture AUG - DEC 2015church123No ratings yet

- AI in Defence Report Outlines Strategy and Ethics RoadmapDocument32 pagesAI in Defence Report Outlines Strategy and Ethics RoadmapAmogh VarshneyNo ratings yet

- Wireless Price ListDocument21 pagesWireless Price ListnboninaNo ratings yet

- Hetvi Palankar - CVDocument5 pagesHetvi Palankar - CVmiss_jyoti_kapoorNo ratings yet

- Domino Server Tasks and Console CommandsDocument26 pagesDomino Server Tasks and Console Commandsvc_nishank8890No ratings yet

- 2008 Argus DC Catalog - ReducedDocument100 pages2008 Argus DC Catalog - ReducedL IvanNo ratings yet

- Autodesk - Authorised Training Centres - India - KarnatakaDocument3 pagesAutodesk - Authorised Training Centres - India - Karnatakaचन्दनप्रसादNo ratings yet

- WhitePaper AVEVA TheBenefitsofMovingtoCloudUnifiedEngineering 22-02Document7 pagesWhitePaper AVEVA TheBenefitsofMovingtoCloudUnifiedEngineering 22-02mohsen12345678No ratings yet