Professional Documents

Culture Documents

Puff Biscuits Chapter

Uploaded by

Daniel PaulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Puff Biscuits Chapter

Uploaded by

Daniel PaulCopyright:

Available Formats

26

Puff biscuits

D. Manley, Consultant, Duncan Manley Ltd, UK

Abstract: The eating quality of puff biscuits is determined very largely by the nature of the

fat used for laminating. Forming the laminar structure in the dough is a delicate operation

dependent on the fat composition and consistency.

Key words: lamination, fat consistency, cold doughs.

26.1 General description

The aky structure of puff biscuits offers an attractive alternative to those with more

uniform internal structure. Puff biscuits are all made from doughs in which there is

a non-homogeneous distribution of fat. When this dough is laminated the fat causes

discontinuities between the layers of dough and during subsequent baking these

layers separate to give a very aky structure. The laminar structure of puff biscuits

bears some similarities to cream crackers but the dough differs in that the fat is

concentrated between the laminations and little is used to form the basic dough.

The dough is not fermented and is invariably cold and underdeveloped. The methods

for distributing the fat in the dough determine the type of mixers and laminators

needed. The eating quality of puff biscuits is determined very largely by the nature

of the fat used for laminating. Unlike puff pastry for sausage rolls and vol-au-vents

which are best eaten hot, puff biscuits are eaten cold so the fat used must not have

a high melting waxy tail which does not melt in the mouth. This means that close

attention must be given to the melting point of the fat and the plasticity and tem-

perature at the time of use. Thus biscuit puff doughs are always handled cold to

ensure that the fat has a relatively high solids content during processing. It is gener-

ally recognised that puff doughs are among the most difcult biscuit doughs to

handle.

Puff biscuits may be used as unsweetened carriers for butter, cheese, jam, etc., or

as shells for sweet or savoury cream sandwiches (Figs 26.1 and 26.2). In essence they

are a type of cracker biscuit. Where used as sweet biscuits, it is usual to garnish the

surface prior to baking with sugar. During baking this sugar will melt and form a

glossy, lightly browned surface which on cooling is hard. Puff dough made into very

small biscuits may be sold as snacks of various avours, often in jumble packs. Fresh

cheese is often used as the avour material.

Puff biscuits 307

There are some more exotic biscuits which are on the borderline with our con-

fections usually produced by bread and cake bakers. Palmier is one such type made

from puff dough. The dough for palmier is folded after laminating and is then sliced

across the laminations to form pieces for baking. Thus, the expansion is sideways,

not upwards, to produce a aky structure during baking (see Fig. 26.3).

Fig. 26.1 Lemon Puff biscuit.

Fig. 26.2 Cornish wafer.

Three stages of dough

folding before slicing

and baking

Appearance of baked

biscuit

Fig. 26.3 Formation of palmier biscuits.

308 Manleys technology of biscuits, crackers and cookies

26.2 Puff dough preparation

The preparation of layers of dough separated by a lm of fat is the basis of puff

dough. It is necessary that there should be a great number of dough layers and that

each is very thin and more or less discrete. Thus, an extensible dough is required

and the fat must be spread as a thin lm between the layers. The fat must be in a

condition where it has a low liquid fraction and therefore does not become incor-

porated in the dough and is plastic enough to be rolled out into thin lms between

the dough layers.

Much attention must be given to forming a strong but extensible dough and to

ensuring that fat is in the correct condition. Since the fat must have relatively high

solids at processing temperatures but with little solids melting above blood heat, it

is necessary to select an appropriate fat with steep dilatation and to use it well

plasticised at cool or cold dough temperatures.

Extensible doughs for bread or other types of biscuits involve a signicant amount

of development by mixing, with or without the help of yeast, and dough tempera-

tures are usually 30C or above. To produce extensible doughs for puffs, which are

at 18C or less, necessitates the use of strong ours, more water and maybe some

sodium metabisulphite (SMS). No fat, or very little, is used in the dough to ensure

minimum shortening effects so the dough recipe is simply our, water and salt (and

perhaps SMS), there may also be a little milk powder to soften the biscuit texture

and enhance surface colouring during baking. As a consequence, the dough tends

to be rather sticky and this feature limits the level of water that can be used while

making sheeting and gauging possible. In order to achieve a cohesive gluten struc-

ture in such a dough it is necessary to allow relation times for the dough between

each gauging and laminating stage.

The fat may be introduced either as lumps in the partially mixed dough, or as a

layer between two dough sheets on the forming plant. Considering rstly the intro-

duction of the fat into the dough at the mixer, it will be appreciated that the principal

requirements are to distribute the lumps uniformly while pressing as little as pos-

sible of the fat into the dough. It is necessary to use a mixer with gentle cutting and

good blending action and probable that fat lumps of uniform size, say about 2.5 cm

cube, will be best. Too large lumps will give sheeting and laminating problems and

too small pieces will tend to merge into the dough reducing the effect of the fat and

causing shortening of the dough. The fat must be plastic and of similar consistency

to the dough of which it is a part. The lumps may be of pure fat, a mixture of fat

and our or fat emulsied with some water (similar to butter or margarine). Prepa-

ration of plasticised fat is of great importance and is described in Section 12.2.1.

Where the fat is spread between two sheets of dough the means of distributing

the fat (or fat mixture) is the principal problem. On standard biscuit plant the sheets

may be 8001200 mm wide and it is virtually impossible to extrude fat of the desired

consistency evenly over this width. The most satisfactory system involves spreading

akes of fat either by hand or by raking. The layer of fat must be as uniform as

possible to allow even control of plant and product later in the process.

There are special puff dough plants available where a layer of plasticised fat is

extruded between two sheets of dough but the width of this part of the plant is

usually narrow. If the lamination is with a lapping type of laminator where a 90

turn is made, it is possible to increase the plant width by lapping the narrow dough

sheet over a wider conveyor.

Puff biscuits 309

Having introduced the fat, whether discretely in a layer between two dough

sheets, or randomly through the dough as lumps, it is then necessary to gauge and

laminate in order to build up the structure. Considerations of dough stickiness and

fat solids determine that the dough is usually of higher consistency than either cream

cracker or semi-sweet biscuit dough so it is less malleable in terms of folding on a

continuous lapper type laminator. A cut sheet laminator where no folding stresses

are involved is thus preferable. The limitation is that on cut sheet laminators because

the centre of the dough is exposed in the cut edges, fat placed between two sheets

and thus exposed will form surface marking which will be unacceptable later in the

process. This means that mechanical laminating must suit the type of dough prepara-

tion involved.

The number of laminations, the number of turns (90 changes in direction) and

the speed of processing must all be considered carefully. If the laps are too few the

biscuit structure will be coarsely aky and may be irregular in development. If there

are too many laps (laminations) the rolling and stretching involved will exceed the

elasticity of the dough causing breakdown and loss of laminations. This will give a

poor structure also. The thickness, development of the puff structure in the biscuit,

increases with the number of laminations to a certain point and then it collapses

rapidly. The optimum number of layers must be found by experiment and if possible

a standard established so that variations in dough quality, which affect the biscuit

development and which will occur from time to time, may be compensated for by

laminator settings. As a general rule, about 42 layers (7 at the rst laminator fol-

lowed by 6 at a second laminator involving one or two turns) may be near the

optimum for puff biscuits. It will be necessary to dust the dough with our through

successive gauge rolls to prevent sticking and tearing of the delicate layers as they

are rolled.

It is a matter for debate whether the passage through the gauge rolls should be

done slowly or rapidly. There will be some spring and recovery of the dough follow-

ing deformation and, traditionally, puff pastry doughs are allowed to stand and relax

following each reduction. The use of SMS has reduced the need for relaxation, but

it is still possible to exceed the elastic limits of the gluten in the dough if processing

is too severe (either by pressure or speed). If possible the gauging reductions should

be made gradually through a multiplicity of rolls. Unfortunately, a plant with two

laminators is already long and complex so the introduction of extra gauging rolls is

usually impracticable. Although it is not commonly used by biscuit makers at present,

it is worth noting the special puff dough method offered by the Rheon company of

Japan. This is built primarily for the our confectionery trade rather than for biscuits

but it offers some interesting techniques.

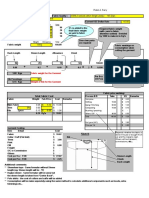

Dough is extruded in a tubular form and a lining tube of fat is co-extruded within

it. The double tube is attened, gauged then laminated before being gauged and

laminated again. The gauging is by means of what is known as a stretcher which

consists of an endless chain of rollers arranged behind one another. These rollers

pass over the dough sheet supported on a total of three or more conveyors. The

rollers are driven over the dough faster than it is carried on the conveyors so they

perform a gradual gauging action in a relatively short length. The effect is not only

to reduce the thickness more gradually than one conventional biscuit gauge roller,

but also to increase the dough sheet width somewhat. It is undoubtedly more

gradual in action than any other method, but the change in dough width may

represent some problems unless the nal sheet width can be guaranteed for the

310 Manleys technology of biscuits, crackers and cookies

purposes of cutting and weight control. Figure 26.4 shows the principle of the Rheon

system (see also Cleven and Fluckiger [1]).

The technique of co-extruding the fat in the form of a lining to a tube of dough

is a good idea as an alternative to two dough sheets and spreading of fat by any

other means. However, unless high melting point pastry margarines are used, close

attention should be given to the dough and ambient temperature because the con-

sistencies of the fat and dough must be well related.

Puff dough pieces are cut, garnished and panned onto the oven in a similar

method to other types of biscuits. The scrap dough must be returned to the head of

the laminator and introduced in some form of even sheet. The scrap dough will be

of signicantly different quality from the fresh dough by virtue of both the fat

content or the form of the fat within it.

26.3 Baking of puff biscuits

Baking presents no particular problems. Optimum development is obtained with an

oven temperature prole that is very hot at the front as for cracker ovens. If the

front bottom heat is too high relative to the top heat, the biscuits will tend to curl

into a saucer shape with the edges high. Increasing the top heat will encourage the

centres to rise more giving either at biscuits or a doming with the centres high.

Control of top and bottom heat at the front of the oven is easier if light, wire mesh

bands are used.

Final moisture contents are not very critical as far as checking is concerned so in

this respect puff biscuits are not like cream crackers. Moistures of around 2.5% are

quite satisfactory. The molten sugar glaze frequently found on puff biscuits results

from ne sugar melting during baking. Temperatures high enough to melt the sugar

on the biscuit surface are easily achieved provided that there is good development

Dough

Plasticised

fat

Extruded tubes of dough and fat

Dough

Dough sheet thickness reduction

Flattened tube of dough

containing fat

Fig. 26.4 Some stages in the Rheon method of puff dough manufacture.

Puff biscuits 311

of the aky structure. If development is poor the surface temperature is held down

and the sugar will not melt and begin to caramelise. In these cases, strong radiant

heat directed at the biscuit surface at the oven exit may prove useful in obtaining

the desired appearance. Alternatively, a mixture of dextrose monohydrate and sugar

used as the garnish will more readily melt and give a pleasing surface colour and

gloss. The disadvantage of using dextrose to give a surface colour and gloss is that

it is more hygroscopic than sucrose glass and this means that the biscuits rapidly

become sticky either when the pack is unwrapped or before packaging on days of

high humidity.

26.4 Puff biscuit production techniques

It would seem that little has been published about modern puff biscuit production

methods. This is probably because techniques are closely guarded as are recipes

for speciality products. However, more is disclosed about puff pastry techniques.

In addition to that about the Rheon equipment [1], a useful paper was given by

Thursby [2] to the British Society of Baking in 1976. This was about puff pastry

production which is signicantly different from biscuits being orientated to small-

scale production and mostly for savoury (meat) products. Details, however, are given

of the principles involved and the effects of different ingredients, particularly fats

and margarines. As has been stated earlier, there is a quality problem if biscuits,

which are eaten cold, have been made with high-melting-point fats typical of pastry

margarines. The reader is also referred to publications by puff pastry fat

manufacturers.

26.5 References

[1] cleven, f. and uckiger, W. (1977), A new method of continuous puff pastry and aky

pastry production, Getreide, Mehl und Brot, 31, 7374 (in German).

[2] thursby, r. f. (1976) The Modern Production of Puff Pastry, Proceedings of British

Society of Baking, March.

26.6 Useful reading

[3] manley, d. (2001) Biscuit, cracker and cookie recipes for the food industry. Woodhead

Publishing, Cambridge.

You might also like

- Autonomos College Mannual Final 16122022 PDFDocument114 pagesAutonomos College Mannual Final 16122022 PDFSourav SircarNo ratings yet

- Michael Genesereth, Introduction To Logic-Morgan (2017)Document161 pagesMichael Genesereth, Introduction To Logic-Morgan (2017)HnzDNo ratings yet

- Schaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaDocument807 pagesSchaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaJ Andres Gonzalez83% (23)

- Introduction To Material HandlingDocument244 pagesIntroduction To Material HandlingAreda100% (3)

- Stoichiometry and Process CalculationsDocument610 pagesStoichiometry and Process CalculationsDaniel PaulNo ratings yet

- Cold Storage HandbookDocument69 pagesCold Storage HandbookManish ParataneNo ratings yet

- A General Introduction To The BIBLEDocument501 pagesA General Introduction To The BIBLERuben Beniamin Ghidanac88% (42)

- Passion Prayer of Jesus The ChristDocument158 pagesPassion Prayer of Jesus The Christbeccabills_nig100% (3)

- Structure and Properties of GlutenDocument10 pagesStructure and Properties of GlutenDaniel PaulNo ratings yet

- Jam, Jelly, Squash, MarmaladeDocument16 pagesJam, Jelly, Squash, MarmaladeDaniel PaulNo ratings yet

- Ice MachineDocument1 pageIce MachineDaniel PaulNo ratings yet

- Fluids MechanicsDocument180 pagesFluids MechanicsAnonymous BW2VsFifi9No ratings yet

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrNo ratings yet

- Heat LecturesDocument89 pagesHeat LecturespalashagrawalNo ratings yet

- 10.1023 A 1009504209276Document16 pages10.1023 A 1009504209276Daniel PaulNo ratings yet

- TocDocument8 pagesTocDaniel PaulNo ratings yet

- Guidelines For Writing Thesis or DissertationDocument8 pagesGuidelines For Writing Thesis or DissertationCzerina CartelNo ratings yet

- Food Production Trends and Programmes Course OutlineDocument100 pagesFood Production Trends and Programmes Course OutlineRemya PillaiNo ratings yet

- Ca & MaDocument11 pagesCa & MaKafeel Khan PathanNo ratings yet

- 40 02 08Document6 pages40 02 08Daniel PaulNo ratings yet

- Fluid Machinery - Centrifugal PumpsDocument33 pagesFluid Machinery - Centrifugal PumpsDaniel Paul67% (3)

- Meeting Minutes For VCDocument1 pageMeeting Minutes For VCDaniel PaulNo ratings yet

- BoilersDocument38 pagesBoilersAshlin Augusty92% (24)

- Victor CVDocument1 pageVictor CVDaniel PaulNo ratings yet

- Boe Vip Vip 1Document8 pagesBoe Vip Vip 1gorakhdagadeNo ratings yet

- Cavitation in Centrifugal PumpsDocument2 pagesCavitation in Centrifugal PumpsArun KumarNo ratings yet

- Determination of Saponification Number.: PrincipleDocument3 pagesDetermination of Saponification Number.: PrincipleDaniel PaulNo ratings yet

- Speed Torque Power RelationshipDocument1 pageSpeed Torque Power RelationshipDaniel PaulNo ratings yet

- Cavitation in Centrifugal PumpsDocument2 pagesCavitation in Centrifugal PumpsArun KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- OU2 Unit TestsDocument42 pagesOU2 Unit Testsp.traid100% (3)

- Mini Case 8Document4 pagesMini Case 8remix001No ratings yet

- Pfaff 92 Sewing Machine Instruction ManualDocument53 pagesPfaff 92 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- C993 03 PDFDocument7 pagesC993 03 PDFdanzan1No ratings yet

- Makalah 7Document10 pagesMakalah 7agusismeNo ratings yet

- Housekeeping NC II CBLM (TESDA)Document44 pagesHousekeeping NC II CBLM (TESDA)Micaella Joanna67% (3)

- Shoe Rack PDFDocument15 pagesShoe Rack PDFTom Stuart Mitchell50% (2)

- Final Project On Aadhar by GaganDocument91 pagesFinal Project On Aadhar by GaganEr Bikramjit Singh100% (2)

- Inkee22 DictationDocument55 pagesInkee22 Dictation가각No ratings yet

- Australia Apparel MarketDocument5 pagesAustralia Apparel Marketsoumen biswasNo ratings yet

- Mangerial EconomicsDocument55 pagesMangerial EconomicsSandeep GhatuaryNo ratings yet

- Alden Catalog 12052016Document18 pagesAlden Catalog 12052016Peter DavidsonNo ratings yet

- Apparel CategoriesDocument32 pagesApparel CategoriesKumar Mayank100% (4)

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 pagesBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNo ratings yet

- Draping of FabricDocument25 pagesDraping of FabricAswathy Unnikrishnan100% (6)

- Six Sigma Infographics by SlidesgoDocument12 pagesSix Sigma Infographics by SlidesgoShouvik DuttaNo ratings yet

- Amazon's Global Expansion of Amazon Go StoresDocument76 pagesAmazon's Global Expansion of Amazon Go StoresAbinaya Santhakumar100% (1)

- Imagine That Your House Is The Same As The Next PicturesDocument7 pagesImagine That Your House Is The Same As The Next PicturesJose Manuel GutierrezNo ratings yet

- Buying and SellingDocument36 pagesBuying and SellingJocelyn D. Descartin LptNo ratings yet

- Presentation ON Export Strategy Presented By-Monika & Renu ROLL NO. - 03, 04 M.B.A (5.5)Document13 pagesPresentation ON Export Strategy Presented By-Monika & Renu ROLL NO. - 03, 04 M.B.A (5.5)Subodh SaharanNo ratings yet

- Recipe - Carat SalamancaDocument2 pagesRecipe - Carat Salamancasymy11No ratings yet

- Marketing Mix Strategy - PresentationDocument25 pagesMarketing Mix Strategy - PresentationAngga SwasditaNo ratings yet

- Futbolka Zhenskaya R XS-XXLDocument19 pagesFutbolka Zhenskaya R XS-XXLVilellita Vilella100% (1)

- Pattern Collection: Women: Knit, Relax, Smile, Repeat!Document5 pagesPattern Collection: Women: Knit, Relax, Smile, Repeat!Natalija Bokan100% (1)

- Protection Solutions: Above-the-NeckDocument42 pagesProtection Solutions: Above-the-NeckMatt DeganNo ratings yet

- Glossary of Leather Terms - ALCADocument33 pagesGlossary of Leather Terms - ALCAAnik AlamNo ratings yet

- Cost Working SheetDocument11 pagesCost Working SheetndieniNo ratings yet

- ISO-105-N02-1995: Colorfastness To Bleaching: PeroxideDocument12 pagesISO-105-N02-1995: Colorfastness To Bleaching: PeroxideNazmul Haque ShaikatNo ratings yet

- Textile Times Volume 12Document40 pagesTextile Times Volume 12mohammed_ismail69No ratings yet

- Mts 01 ADocument45 pagesMts 01 ApaquitatorresNo ratings yet