Professional Documents

Culture Documents

Welding Procedure Specification (WPS) : in The Outer Tube

Uploaded by

Mohamed Alkhawaga0 ratings0% found this document useful (0 votes)

252 views1 pagewps

Original Title

WPS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentwps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

252 views1 pageWelding Procedure Specification (WPS) : in The Outer Tube

Uploaded by

Mohamed Alkhawagawps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

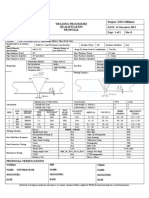

Welding Procedure Specification (WPS)

Location: CERN bat 276 Examiner or examining body: N/A

Manufacturers Welding Procedure:

Reference n: N/A Method of Preparation and Cleaning: ungreased

WPAR n: N/A

Welders Name: Claude Masure Parent Material Specification: 304 L

Welding Process: TIG Marerial Thickness (mm): 3.2 mm

Joint Type: 4 sections Outside Diameter (mm): 88.9 mm

Welding Preparation Details (Sketch): Guiding the inner tube

in the outer tube

Welding Position: in position

Joint Design Welding Sequences

1- Water cooled the brazed zone thanks to a fabric

2- Cleaning and tag welded

3- Run of 1/4 of the diameter

4- Air cooled on the run

5- Water cooled the fabric

6- Repeat the sequence 3-4-5, four times

Control of the temperature with the thermometer A

Welding details

Run Process Size of filler

metal

Current

(A)

Voltage

(V)

Type of current

Polarity

Wire feed speed

(m/min)

Travel speed

(cm/min)

1 TIG D= 1 mm 65/20 N/A impulsion 60/40% manual N/A

Filler Metal : 317 L Classification: DIN 8556

Trade Name: Bohler Thyssen

Any Special Baking or Drying: N/A

Gas/Flux: Shielding: Ar

Backing: Ar

Gas Flow Rate (l / min.): Shielding: 10 l

Backing: 10 l

Tungsten Electrode Type/Size: 1.6 /Tungsten

Preheat Temperature: N/A

Details of Back Gouging/Backing: N/A

Interpass Temperature: 1 pass

Post-Weld Heat Treatment and/or Ageing:

Time, Temperature, Method: 45 min, 400 degres C, manual

Heating and Cooling rates: Controled

Other information: The brazed zone makes use of:

Cu 45-Zn 20/25 Arg 22

Temperature : 700 degres C

Trade Name: Castolin

Test carried out in the presence of: Christine Darve

Manufacturer

Name, date and signature

Examiner or examining body

Name, date and signature

Claude Masure, 22-3-00 Ch. Darve, 22-03-00

SS; Do = 84.5 mm SS; D= 84.5/88.9

Brazed zone:

Cu; Di= /88.9mm

Brazed 720 C

Weld TIG

13.5

mm

A

You might also like

- Mcnichols GratingsCat09Document21 pagesMcnichols GratingsCat09jasonvigilNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationSAKDA MAPRADITKULNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocument1 pageNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- How To Calculate Hydrostatic Test Height in TanksDocument4 pagesHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Welding Procedure Specification (WPS) FormDocument2 pagesWelding Procedure Specification (WPS) FormEarl Harbert0% (2)

- WPS - 017Document12 pagesWPS - 017MAT-LIONNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Pretest Piping Punch List (Empty)Document1 pagePretest Piping Punch List (Empty)Jorge GarciaNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- TWI CSWIP Training Plan - Dynaquest Energy LimitedDocument2 pagesTWI CSWIP Training Plan - Dynaquest Energy LimitedAdeniyi100% (1)

- Welder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#Document1 pageWelder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#satnamNo ratings yet

- Transformer-WPS OfficeDocument19 pagesTransformer-WPS OfficeVinaya kumar BGNo ratings yet

- Galvanize Inspection ReportDocument1 pageGalvanize Inspection ReportMuhammad FajarNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- DNV OS C 401 (2001) Rules Fabrication and Testing of Offshore Structures PDFDocument44 pagesDNV OS C 401 (2001) Rules Fabrication and Testing of Offshore Structures PDFrami ghorbelNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDocument1 pageQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Tndt-frm-ndt-007 Magnetic Particle Inspection ReportDocument2 pagesTndt-frm-ndt-007 Magnetic Particle Inspection ReportKhalid Hidayatullah100% (1)

- Specification (WPS) Welding ProcedureDocument1 pageSpecification (WPS) Welding ProcedureBranko FerenčakNo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- WPQR3Document3 pagesWPQR3Dimitris NikouNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Pipeline ProcedureDocument26 pagesPipeline ProcedurekeronsNo ratings yet

- Norcan ImplementingPAS 55v11Document45 pagesNorcan ImplementingPAS 55v11Nelu BadalanNo ratings yet

- Iamp As 55 Brochure LRDocument2 pagesIamp As 55 Brochure LRMohamed AlkhawagaNo ratings yet

- ssm1 2100018isopc251n48 PDFDocument23 pagesssm1 2100018isopc251n48 PDFandprod728No ratings yet

- Safety Relief Valve - Selection, Operation & TroubleShootingDocument2 pagesSafety Relief Valve - Selection, Operation & TroubleShootingMohamed AlkhawagaNo ratings yet

- ssm1 2100018isopc251n48 PDFDocument23 pagesssm1 2100018isopc251n48 PDFandprod728No ratings yet

- Shannon Safety Considerations For Flow and Level Instrumentation On Oil Storage TanksDocument9 pagesShannon Safety Considerations For Flow and Level Instrumentation On Oil Storage TanksMohamed AlkhawagaNo ratings yet

- 07 Storage Tank ReqsDocument28 pages07 Storage Tank ReqsMohamed AlkhawagaNo ratings yet

- Visual Inspection of Welds PDFDocument13 pagesVisual Inspection of Welds PDFr0m14r100% (1)

- 8000Document6 pages8000Mohamed AlkhawagaNo ratings yet

- Sap 2000Document1 pageSap 2000Mohamed AlkhawagaNo ratings yet

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- Adraft Acad Acadlt2013essentialsDocument2 pagesAdraft Acad Acadlt2013essentialsMohamed AlkhawagaNo ratings yet

- ANSI Flange Bolt & Stud ChartDocument2 pagesANSI Flange Bolt & Stud Chartkh88hmiNo ratings yet

- Tech 2: SolutionsDocument4 pagesTech 2: SolutionsNandakishor YaragattiNo ratings yet

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 pagesCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- V 4 Preprint 13Document29 pagesV 4 Preprint 13Mohamed AlkhawagaNo ratings yet

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 pagesCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- Shannon Safety Considerations For Flow and Level Instrumentation On Oil Storage TanksDocument9 pagesShannon Safety Considerations For Flow and Level Instrumentation On Oil Storage TanksMohamed AlkhawagaNo ratings yet

- The Corrosion ProtectionDocument28 pagesThe Corrosion Protectionjewettwater100% (1)

- The Fundamentals of Heat ExchangersDocument4 pagesThe Fundamentals of Heat ExchangersJojie-Ann AlabarcaNo ratings yet

- Viw Lesson PlanDocument5 pagesViw Lesson PlanMohamed AlkhawagaNo ratings yet

- 8886Document8 pages8886Mohamed AlkhawagaNo ratings yet

- P&IDsDocument4 pagesP&IDsRamadhan PrasetyaNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- 2013 ACM P&ID Engineering Drawings Interpretation Course 2Document4 pages2013 ACM P&ID Engineering Drawings Interpretation Course 2Mohamed AlkhawagaNo ratings yet

- 2013 ACM P&ID Engineering Drawings Interpretation Course 2Document4 pages2013 ACM P&ID Engineering Drawings Interpretation Course 2Mohamed AlkhawagaNo ratings yet

- Engineering Standrad For Piping and Instumention DrawingDocument111 pagesEngineering Standrad For Piping and Instumention DrawingNeo100% (4)