Professional Documents

Culture Documents

WPS

Uploaded by

NidhinkorothCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS

Uploaded by

NidhinkorothCopyright:

Available Formats

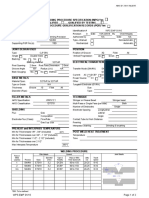

WPS No: ALU-WPS-017 Rev.

0

Welding Process: FCAW (136)

Code: BS EN ISO 15614-1:2004

Thickness Range:

Specification type & Grade : Position(s) Groove

Pipe Plate : :

:

SFA Specification A 5.20

Interpass Temperature

F No. 6

A No. 1 Shielding Gas: Argon+CO2 8% / 20%

Size of Electrode/Wire 1.2 mm Trailing/Backing: None Flow Rate: 25 - 30 Ipm

Filler Addition N/A

Consumable Insert Not allowed String or Weave Bead : String & Weave

Filler metal Product form N/A Orifice or Gas cup size : N/A

Flux N/A Maximum weave width : 3 times Electrode Dia

Method of Cleaning : Griding / Power Brushing

POST WELD HEAT TREATMENT Method of Back Gouging : N/A

Soaking Temp. Range : : Multiple Pass

Time Range : : Single

Rate of Heating : Travel Speed : 200 - 600 mm / min.

Rate of Cooling

:

Contact tube to work distance: 19mm (FCAW)

Oscillation : None

Use of thermal process :

Dia Amp. Range

FCAW 1.2MM 150-170 20-26

FCAW 1.2MM 185-235 22-28

FCAW 1.2MM 185-235 22-28

FCAW 1.2MM 185-235 22-28

Name

Sign.

Date

Joint Design: Single "V"

Backing : With or without

Retainer: None

Preparation: Flame Cut / Machinging / Grinding

WELDING PROCEDURE SPECIFICATION

PQR : ALU-PQR-017 Rev.0

Date: 24.11.2012

Type: Semi-Automatic

JOINTS

BASE METALS

Material Designation: S355G8 N 355EMZ API2H50N A5371MT LREH36 POSITIONS

Dia/Thickness: 40 mm Plate All

Thickness Range 20 mm - 80 mm

Other: Pipe Dia > 150mm in PA or PC & > 500mm all positions

Progression: Uphill Postion (s) Fillet : All

AWS Classification E71-T1

250 Deg C

Preheat Maintenance

FILLER METALS PREHEAT

Preheat Temperature

30C I(For t <1", otherwise 100C

for t >1")

N/A

Continuous or special heating where

applicable should be recorded.

GAS

TECHNIQUE

N/A

Multiple or Single Pass per Side

N/A

Single or Multiple Electrodes

N/A

None

ELECTRICAL CHARACTERISITICS (QW-409)

Weld Layer Process

Filler Metal Current

Volt Range

Travel Speed

Range (mm/mt)

Max. Heat Input

Kj/mm

Class

Type/

Polarity

Root E71-T1 DCEP

Hot E71-T1 DCEP 200-610

210-230

Cap E71-T1 DCEP 200-610

Fill E71-T1 DCEP 200-610

ALUCOR LTD THIRD PARTY CLIENT

+10

-5 60

2.5mm to 3.5mmmm

1 to 2 mm

You might also like

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Cswip 3.0 ReportingDocument32 pagesCswip 3.0 ReportingAvijit DebnathNo ratings yet

- Magnetic Particle Examination of WeldsDocument4 pagesMagnetic Particle Examination of WeldsshruthiNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Al-Suwaidi Industrial Welding ReportDocument85 pagesAl-Suwaidi Industrial Welding ReportwalitedisonNo ratings yet

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDocument1 pageASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & IsosbmmlaNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Weld Checklist PQRDocument2 pagesWeld Checklist PQRScott Trainor100% (1)

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Contact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Document4 pagesContact Us: Guides in PDF: (Member Access) Welding Procedure Specification (WPS)Maulik PatelNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- Welder Qualification Test RequestDocument1 pageWelder Qualification Test RequestgoguluNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Ultrasonic Testing ReportDocument3 pagesUltrasonic Testing ReportsingaduraipandianNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Welding IiwDocument6 pagesWelding IiwletsmakeithappenNo ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- Macro 418-23-1Document1 pageMacro 418-23-1Gigin S GumilarNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument11 pagesWelding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh raja100% (1)

- ET NDT Sample Test Report FormatDocument1 pageET NDT Sample Test Report Formatanas dwiNo ratings yet

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauNo ratings yet

- 24 Practical Visual InspectionDocument5 pages24 Practical Visual InspectionMai Anh TaiNo ratings yet

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- TWI CSWIP 3.1 Wis 5 Welding Inspection Heat Treatment: World Centre For Materials Joining TechnologyDocument9 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Heat Treatment: World Centre For Materials Joining TechnologyOnur AltuntaşNo ratings yet

- AWS List of Welding CodesDocument16 pagesAWS List of Welding CodesLee Chong EeNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Determine necessary preheat temperature for steel weldingDocument11 pagesDetermine necessary preheat temperature for steel weldingromanosky11No ratings yet

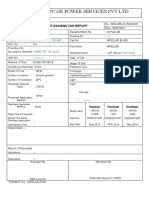

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- WPS SiloDocument1 pageWPS SiloNidhinkorothNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (1)

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Bonding Chemistry, Technology & Environment: Sustainable Coating SolutionsDocument9 pagesBonding Chemistry, Technology & Environment: Sustainable Coating SolutionsNidhinkorothNo ratings yet

- 5.0 - Occupational Health Screening and Medical Surveillance v3.1 EnglishDocument60 pages5.0 - Occupational Health Screening and Medical Surveillance v3.1 Englishengr587No ratings yet

- Access DoorDocument1 pageAccess DoorNidhinkorothNo ratings yet

- Woodworking Safety Unit CorrectDocument19 pagesWoodworking Safety Unit CorrectNidhinkorothNo ratings yet

- Brochures - Waterproofing SikaFuko - Injection Hose Systems - GCCDocument5 pagesBrochures - Waterproofing SikaFuko - Injection Hose Systems - GCCCharbel GhanemNo ratings yet

- 9 Dimensions of QualityDocument12 pages9 Dimensions of QualitySachin Methree60% (10)

- Kg2 Reading Challenge Record SheetDocument2 pagesKg2 Reading Challenge Record SheetNidhinkorothNo ratings yet

- KIM-Dubai Municipality - Certificate of Product Conformity - CL18020646-Exp-07-20Document3 pagesKIM-Dubai Municipality - Certificate of Product Conformity - CL18020646-Exp-07-20NidhinkorothNo ratings yet

- UAE FIre & Life SafetyDocument1 pageUAE FIre & Life SafetyNidhinkorothNo ratings yet

- Customer Satisfaction Survey: Please Indicate Your Level of Satisfaction in The Following CategoriesDocument1 pageCustomer Satisfaction Survey: Please Indicate Your Level of Satisfaction in The Following CategoriesNidhinkorothNo ratings yet

- Management of Information SystemDocument51 pagesManagement of Information SystemSwati singh100% (3)

- 2016 - WI Welding InspectorDocument3 pages2016 - WI Welding InspectorNidhinkorothNo ratings yet

- Audit Plan - Silicon ParkDocument1 pageAudit Plan - Silicon ParkNidhinkorothNo ratings yet

- Safat Book English Spread PDFDocument49 pagesSafat Book English Spread PDFMadan Kumar100% (2)

- UAE Fire & Life Safety Code of Practice 2017Document2 pagesUAE Fire & Life Safety Code of Practice 2017NidhinkorothNo ratings yet

- Send and track NCR emails in Arcadia AcademyDocument11 pagesSend and track NCR emails in Arcadia AcademyNidhinkorothNo ratings yet

- JD - VivekDocument2 pagesJD - VivekNidhinkorothNo ratings yet

- Training WWWEQDocument1 pageTraining WWWEQNidhinkorothNo ratings yet

- Again FakeDocument1 pageAgain FakeNidhinkorothNo ratings yet

- GYPROCK 202 Masonry Walls 201105Document2 pagesGYPROCK 202 Masonry Walls 201105NidhinkorothNo ratings yet

- Carillion's Annual Sustainability Report SummaryDocument2 pagesCarillion's Annual Sustainability Report SummaryedienewsNo ratings yet

- Studio4 LEED v4 Green Associate 101 Questions & 101 Answers First Edition PDFDocument214 pagesStudio4 LEED v4 Green Associate 101 Questions & 101 Answers First Edition PDFMohammad J Haddad88% (8)

- TrainingDocument1 pageTrainingNidhinkorothNo ratings yet

- Mission & VisionDocument1 pageMission & VisionNidhinkorothNo ratings yet

- Training WQWQWDocument1 pageTraining WQWQWNidhinkorothNo ratings yet

- New Microsoft Office Word DkjkjocumentDocument1 pageNew Microsoft Office Word DkjkjocumentNidhinkorothNo ratings yet

- Training AASASAWDocument1 pageTraining AASASAWNidhinkorothNo ratings yet

- New Microsoft Woadadrd DocumentDocument1 pageNew Microsoft Woadadrd DocumentNidhinkorothNo ratings yet

- New Microsoft Word Document (2) QWDocument1 pageNew Microsoft Word Document (2) QWNidhinkorothNo ratings yet

- New Microsoft Word DocuasmentDocument1 pageNew Microsoft Word DocuasmentNidhinkorothNo ratings yet