Professional Documents

Culture Documents

LPT As Per Asme & Iso

Uploaded by

sbmmla0 ratings0% found this document useful (0 votes)

63 views2 pagesOriginal Title

LPT AS PER ASME & ISO

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views2 pagesLPT As Per Asme & Iso

Uploaded by

sbmmlaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

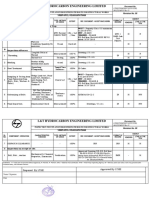

LİQUİD PENETRANT TESTİNG AS PER ASME CODES & ISO STANDARS

DIFFERENCES AND SIMILARITIES

DESTRIPTION ASME ISO

Written procedure Required Required

Personnel qualification As per written practice As per ISO 9712 or

equivalent

Equipment Conforms with SE 165 Conforms with ISO

3452-4

Temperature limits As a standard The testing material,

technique, the the test surface and the

temperature of the ambient temperature

penetrant and the shall be within the

surface of the part to be range from 10 °C to 50

processed shall not be °C, except for the drying

below 40°F (5°C) nor process.

above 125°F (52°C)

throughout the

examination period

Application of The penetrant may be Penetrant can be

penetrant applied by any suitable applied to the part to be

means, such as dipping, tested by spraying,

brushing, or spraying. brushing, flooding,

dipping or immersion

Dwell time The maximum dwell The penetration time

time shall not exceed 2 shall be between 5 min

hr or as qualified by and 60 min and shall

demonstration for not be less than the

specific applications. manufacturer’s

recommended time for

the required sensitivity.

Excess removal water Excess water-washable The excess penetrant

washable penetrants shall be shall be removed by

removed with a water washing (rinsing),

spray. The water immersion or wiping

pressure shall not using water. Pressure

exceed 50 psi (350kPa), not specified.

and the water

temperature shall not

exceed 110°F (43°C).Or

wiping with cloth

Lipophilic emulsifier The excess surface penetrant it shall be rendered water

shall be emulsified by rinsable by application of an

immersing or flooding the part emulsifier. This can only be

with the emulsifier. done by immersion

Hydrophilic emulsifier Pre-rinse before application of Pre-rinse before application of

emulsifier is recommended emulsifier is recommended

Light intensity during excess UV-A lights shall achieve a For fluorescent technique

removal (Fluorescent) minimum of 1000 μW/cm2 on minimum 100µw/cm2 on test

the surface of the part being surface and visible light not

examined throughout the more than 100 lux in dark

examination. room.

Light intensity during excess Not specified For colour contrast penetrants

removal (Visible) the white light illuminance on

the test surface shall be more

than 350 lx

Developing time Final interpretation shall be The development time should

made not less than 10 min nor be between 10 min and 30 min

more than 60 min

Dark adaptation Examiners shall be in a Sufficient time shall be

darkened area for at least 5 allowed for the operator’s

min prior to performing eyes to become darkadapted

examinations to enable their in the inspection area, at least

eyes to adapt to dark viewing 1 min.

Light intensity during UV-A lights shall achieve a The UV-A irradiance at the

inspection (Fluorescent) minimum of 1000 μW/cm2 on surface inspected shall be 10

the surface of the part being W/m2 (1000μW/cm2 ) or

examined throughout the greater with a low level of

examination. It shall be visible light (maximum total of

performed in a darkened area ambient and from UV-A source

with a maximum ambient 20

white light level of 2 fc (21.5

lx)

Light intensity during The minimum light intensity For inspection, the illuminance

inspection (Visible) shall be 100 fc (1 076 lx) at the test surface shall be 500

lx or grea

Post cleaning When required by procedure When required by next

operation

Acceptance criteria Any referencing code can be As per ISO 23277

used

Process control As per SE 165 As per annexure B of ISO 3452-

1

Halogen and sulfur content Less than 0.1% by weight Less than 200 ppm (ISO 3452-

2)

Sensitivity level Not specified To be determined by using

Type 1 reference block (ISO

3452-3)

You might also like

- DPI (Dye Penetrant Inspection) : Main PurposedDocument9 pagesDPI (Dye Penetrant Inspection) : Main PurposedAgung Prastyo WibowoNo ratings yet

- Magnetic Particle Examination of WeldsDocument4 pagesMagnetic Particle Examination of WeldsshruthiNo ratings yet

- SNIS UT 578 - Steel PlatesDocument14 pagesSNIS UT 578 - Steel PlatesShailesh DeshmukhNo ratings yet

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNo ratings yet

- 4260Document10 pages4260Lipika GayenNo ratings yet

- Dye Penetrant Inspection ProcedureDocument13 pagesDye Penetrant Inspection ProcedureHafidzManaf100% (1)

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Interview QuestionsDocument13 pagesInterview QuestionsWalter RuedaNo ratings yet

- NDT Application FormDocument4 pagesNDT Application FormAhmed Shaban KotbNo ratings yet

- ASNT Level-II Visual & Optical Testing ProcedureDocument5 pagesASNT Level-II Visual & Optical Testing ProcedureFadil WimalaNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- VT & PT - NotesDocument10 pagesVT & PT - Notessanjeev sahota100% (1)

- Written PracticeDocument27 pagesWritten PracticeSefa KasapogluNo ratings yet

- Demo SUMDocument27 pagesDemo SUMRudolph RednoseNo ratings yet

- UT Shear Wave Skip Distances and Search For Indications LabDocument4 pagesUT Shear Wave Skip Distances and Search For Indications Lab1248a9a9a1q3we71No ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- JNK SOP for Weld Visual InspectionDocument17 pagesJNK SOP for Weld Visual InspectionAvishek GuptaNo ratings yet

- E428Document6 pagesE428valentinNo ratings yet

- 2013 Asme VIII Acceptance CriteriaDocument8 pages2013 Asme VIII Acceptance CriteriaSiggy LaiNo ratings yet

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- Penetrant Testing (PT)Document11 pagesPenetrant Testing (PT)Maria Cristina DijmarescuNo ratings yet

- Engineering Specifications - Inspection: Rev. FDocument17 pagesEngineering Specifications - Inspection: Rev. Fstephen lewellen100% (1)

- NDT Level 2Document4 pagesNDT Level 2sateeshNo ratings yet

- Normal Probe Range Calibration (Work Instruction) : TH THDocument7 pagesNormal Probe Range Calibration (Work Instruction) : TH THBhadresh PatelNo ratings yet

- Dye Penetrant TestingDocument20 pagesDye Penetrant TestingRamesh RNo ratings yet

- Liquid Penetrant Examination Procedure For Asme CodeDocument15 pagesLiquid Penetrant Examination Procedure For Asme Codeshabbir626No ratings yet

- SAWAED'S LIQUID PENETRANT TEST PROCEDUREDocument7 pagesSAWAED'S LIQUID PENETRANT TEST PROCEDUREAlam MD SazidNo ratings yet

- RT Procedure for Egyptian Gas Pipeline ProjectDocument14 pagesRT Procedure for Egyptian Gas Pipeline ProjectaravindanNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Radio Graphic ExaminationDocument33 pagesRadio Graphic ExaminationSakthi PanneerSelvam Tanjai100% (6)

- 4102 NDT Notes PDFDocument14 pages4102 NDT Notes PDFAjay Kumar Reddy KNo ratings yet

- WELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Document65 pagesWELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Ethem Güngör100% (1)

- L&T Hydrocarbon Engineering LimitedDocument2 pagesL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQveNo ratings yet

- Form PAUTDocument2 pagesForm PAUTLuong Ho Vu100% (1)

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Procedure for Radiographic Testing of Welded Steel JointsDocument30 pagesProcedure for Radiographic Testing of Welded Steel JointsG_ARVALIS8470No ratings yet

- PREQUALIFIED WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesPREQUALIFIED WELDING PROCEDURE SPECIFICATION (WPSNuril VS theWorldNo ratings yet

- Ultrasonic TestingDocument4 pagesUltrasonic TestingSyahmie AzreeNo ratings yet

- High Temperature Ultrasonic ScanningDocument7 pagesHigh Temperature Ultrasonic ScanningscribdmustaphaNo ratings yet

- Dye Penetrant ProcedureDocument8 pagesDye Penetrant ProcedureTouil HoussemNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- NDT Steel CastingsDocument17 pagesNDT Steel CastingsWoodrow FoxNo ratings yet

- Visual Examination Procedure: 1. PurposeDocument4 pagesVisual Examination Procedure: 1. PurposeElvin MenlibaiNo ratings yet

- NDT For WeldersDocument66 pagesNDT For WelderssameeraNo ratings yet

- AWS D1.1 Weld Technique SketchDocument6 pagesAWS D1.1 Weld Technique SketchnathgsurendraNo ratings yet

- Liquid Penetrant Testing Procedure (StructuralDocument8 pagesLiquid Penetrant Testing Procedure (StructuralGoutam Kumar Deb100% (1)

- Cswip 3.0 ReportingDocument32 pagesCswip 3.0 ReportingAvijit DebnathNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Ultrasonic Test Report: Testing TechniqueDocument2 pagesUltrasonic Test Report: Testing TechniqueMd RizwanNo ratings yet

- Feritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelDocument8 pagesFeritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelBiju_PottayilNo ratings yet

- Interzone 505: Glass Flake EpoxyDocument4 pagesInterzone 505: Glass Flake EpoxyAidil Luthfansyah PutraNo ratings yet

- Liquid Penetrant Testing ProcedureDocument10 pagesLiquid Penetrant Testing ProcedureirfanNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1120 - Eng - A4 - 20201117Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1120 - Eng - A4 - 20201117Ramesh RathinamNo ratings yet

- Site Inspection ChecklistDocument3 pagesSite Inspection ChecklistsbmmlaNo ratings yet

- Types of Pressure TermsDocument10 pagesTypes of Pressure TermssbmmlaNo ratings yet

- RT Hand Written BookDocument22 pagesRT Hand Written BooksbmmlaNo ratings yet

- Basic InstrumentDocument85 pagesBasic InstrumenthaseebmonNo ratings yet

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaNo ratings yet

- Welding DefectsDocument8 pagesWelding DefectssbmmlaNo ratings yet

- Film Defects - AMERONDocument94 pagesFilm Defects - AMERONER RaviNo ratings yet

- BASIC SNT-TC-1A GUIDELINES FOR NDT PERSONNEL CERTIFICATIONDocument20 pagesBASIC SNT-TC-1A GUIDELINES FOR NDT PERSONNEL CERTIFICATIONsbmmlaNo ratings yet

- Basic Valve and Testing Method - 1Document37 pagesBasic Valve and Testing Method - 1Fouad OudinaNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATIONDocument2 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATIONsbmmlaNo ratings yet

- PT 3 Types of Cleaning, Equipment's and MaterialsDocument13 pagesPT 3 Types of Cleaning, Equipment's and MaterialssbmmlaNo ratings yet

- Pamphlet On Safety Precautions For Steel Erection WorkDocument4 pagesPamphlet On Safety Precautions For Steel Erection WorksbmmlaNo ratings yet

- DNV Os-E403Document38 pagesDNV Os-E403ReadersmoNo ratings yet

- BGas MaterialDocument65 pagesBGas Materialslxanto100% (4)

- Quality Control ManualDocument77 pagesQuality Control ManualsbmmlaNo ratings yet

- API 510-Kuwait Petroleum TrainingDocument160 pagesAPI 510-Kuwait Petroleum Trainingsbmmla100% (1)

- Tube to Tube Welding ProcedureDocument1 pageTube to Tube Welding ProceduresbmmlaNo ratings yet

- Static Equipment AwarenessDocument137 pagesStatic Equipment AwarenessZeshan100% (1)

- Standard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved byDocument4 pagesStandard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved bysbmmla100% (1)

- Sop Piping Tubes Standard Repair ProcedureDocument3 pagesSop Piping Tubes Standard Repair ProceduresbmmlaNo ratings yet

- Piping Dimension Chart UsefulDocument1 pagePiping Dimension Chart UsefulrizkiNo ratings yet

- Nozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1Document1 pageNozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- Technical Data and Safety Guidelines for Finned Tube Bending MachineDocument3 pagesTechnical Data and Safety Guidelines for Finned Tube Bending MachinesbmmlaNo ratings yet

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Document1 pageSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- Membrane Panel SOPDocument5 pagesMembrane Panel SOPsbmmlaNo ratings yet

- Swaged End - NormalisingDocument1 pageSwaged End - NormalisingsbmmlaNo ratings yet

- SOP NM ReportingDocument2 pagesSOP NM ReportingsbmmlaNo ratings yet

- Pre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DateDocument1 pagePre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DatesbmmlaNo ratings yet

- Downcomer Nozzle To Drum Welding Procedure: 1.0 ScopeDocument1 pageDowncomer Nozzle To Drum Welding Procedure: 1.0 ScopesbmmlaNo ratings yet

- Standard Operating Procedure (Headers) : Prepared By: Checked by Approved byDocument5 pagesStandard Operating Procedure (Headers) : Prepared By: Checked by Approved bysbmmlaNo ratings yet

- Edd 503 RenosaDocument39 pagesEdd 503 RenosaMar-Elen Fe Guevara Reñosa100% (1)

- Road MarkingDocument6 pagesRoad MarkingPanchadcharam PushparubanNo ratings yet

- Math g3 m2 Full ModuleDocument303 pagesMath g3 m2 Full ModuleRivka ShareNo ratings yet

- Unix System Calls-1Document3 pagesUnix System Calls-1Sourav UpadhyayNo ratings yet

- Section 15010-Basic Mechanical Requirements Part 1 - General 1.1 Related DocumentsDocument5 pagesSection 15010-Basic Mechanical Requirements Part 1 - General 1.1 Related DocumentsObaidAliKhanNo ratings yet

- NORSOK Z-018 Documentation 2019Document36 pagesNORSOK Z-018 Documentation 2019tiziano01gmail.com OsnaghiNo ratings yet

- J Ijpvp 2013 04 017Document7 pagesJ Ijpvp 2013 04 017BheemannaChandurNo ratings yet

- PRESTIGE INSTITUTE COSTING METHODSDocument13 pagesPRESTIGE INSTITUTE COSTING METHODSziaa senNo ratings yet

- Man-V28 33D PDFDocument16 pagesMan-V28 33D PDFdavid artantoNo ratings yet

- Final Project Synopsis 1 (2) .Docx S.docx 1Document95 pagesFinal Project Synopsis 1 (2) .Docx S.docx 1Shyam Yadav100% (1)

- Vapodest 30: Instruction ManualDocument31 pagesVapodest 30: Instruction ManualleoNo ratings yet

- #Include #Include #Include Void Main (Document47 pages#Include #Include #Include Void Main (ChfNo ratings yet

- Surface Vehicle Standard: Rev. SEP81Document42 pagesSurface Vehicle Standard: Rev. SEP81anupthattaNo ratings yet

- Measure Conversion Chart UkDocument5 pagesMeasure Conversion Chart UkAbram Nathaniel AbayanNo ratings yet

- Comparing American and British Piping StandardsDocument2 pagesComparing American and British Piping Standardsfahimshah1301No ratings yet

- Philips Professional and Business Solutions: 26HF7875 26HF5445 32HF7875 32HF5445 42HF7845 User ManualDocument46 pagesPhilips Professional and Business Solutions: 26HF7875 26HF5445 32HF7875 32HF5445 42HF7845 User ManualTZM BucNo ratings yet

- Delta Valves Tech TipsDocument20 pagesDelta Valves Tech TipsmujeebtalibNo ratings yet

- Network Fundamentals Lesson PlanDocument8 pagesNetwork Fundamentals Lesson PlanDarshan PandaNo ratings yet

- 1Document245 pages1lutti68No ratings yet

- List of TCP and UDP Port NumbersDocument52 pagesList of TCP and UDP Port Numberssachin_khandelwal_10No ratings yet

- Uh-1 - 10 C20Document134 pagesUh-1 - 10 C20Clifford McKeithan100% (1)

- WAN Network Design OptimizationDocument40 pagesWAN Network Design Optimizationmcclaink06No ratings yet

- En 16252-2012Document42 pagesEn 16252-2012Fabio Manente100% (1)

- D5072-087 DTS0434Document2 pagesD5072-087 DTS0434mojinjoNo ratings yet

- Object Push Profile: AbstractDocument28 pagesObject Push Profile: AbstractsyahabdulrizalNo ratings yet

- Rule Xviii - Glass & Glazing (Book Format)Document2 pagesRule Xviii - Glass & Glazing (Book Format)Ardino Anilao100% (1)

- Wire and Cable Engineering Guide: Handling and Installation Excerpt From Prysmian'SDocument23 pagesWire and Cable Engineering Guide: Handling and Installation Excerpt From Prysmian'Sfairguy80No ratings yet

- MSS - More Than MESDocument6 pagesMSS - More Than MESrkponrajNo ratings yet

- CANBUSDocument18 pagesCANBUSSamuel SimbolonNo ratings yet

- DebugDocument15 pagesDebug14I Putu crisna WinjayaNo ratings yet