Professional Documents

Culture Documents

Standard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved by

Uploaded by

sbmmlaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved by

Uploaded by

sbmmlaCopyright:

Available Formats

STANDARD OPERATING

PROCEDURE

( COILS / TUBES )

Prepared By: Checked By Approved By:

Sandeep S. Bhandari M. K. Jadhav A. S. Kulkarni

SOP / BnHQAC / 01, Rev. 0 Page 1 of 4

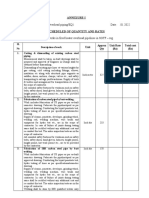

SOP:- STANDARD OPERATING PROCEDURE

COILS [ECO. / SH / INBED], LOOSE, SUPPORT TUBES

For Tolerance, refer control sheet no.

Getting Drawing:-

Ensure that approved drawing is received and if any backside is there then it shall be pasted on

backside of drawing. The drawing shall be provided by planner to shop QC / Shop.

Review of ITP (Inspection & Test Plan):-

Shop QC shall review the latest revision of ITP to ensure which stages are to be offered to TPI / IBR /

IA & if any special requirement mentioned.

Tools Requirement:-

Scale, Thin rope, Chalk, Measuring Tape, Ultrasonic thickness meter, Permanent Marker, Vernier

caliper

Layout Marking & Inspection:-

Ensure that platform used for layout marking is in water level condition. Production to carry out layout

& shall get it check from Shop QC. Flatness of Plate shall be within 1mm / meter.

Shop QC shall ensure all parameters of layout marking such as Orientation, All dimensions [Length,

Width, Tan. Point to Tan. Point distance, diagonal, Bend Radius, Bend Degree, Pitch, No. of bends,

Support distance, Sleeve distance, End markings] & Identification Blr No. & Component

Sample / First Production Bend (Max. bend degree):-

After Clearance of previous stage by Shop QC, Production shall prepare the sample production bend

with 1800 or max. degree (as applicable) and shall offered to Shop QC for inspection.

Shop QC shall ensure that proper material as mentioned in drawing is used [Size, Specification] & is

cleared by inspecting authority as applicable.

Shop QC shall inspect the sample bend for Dimensions of Bends on layout [Bend Radius, bend

Degree, Pitch], Ovality, Thinning, Flow area, Kink, Flatness as per template, wrinkles & any surface

defects, die marks.

Shop QC shall fill sample bend inspection report & shall offer to inspecting authority, as applicable

After clearance by Shop QC, Production shall start the production of coil & shall offer for inspection

to Shop QC.

Bending of Tubes:-

Production shall start the bending of tubes with the same parameters of machine as used for sample

bend & production shall check first 10 bends for dimensionlly & visually.

Shop QC shall ensure the ovality, thinning, ball pass for on continuing production runs at least one

bend of every hundred bends along with Visual insepction of surface & shall maintain the records for

the same on each bending station.

SOP / BnHQAC / 01, Rev. 0 Page 2 of 4

If Ovality & thinning founds unacceptable then bending shall be stop & setting of the machine to be

changed & sample bend shall be prepared again & 100% inspection shall be carried out for deviated

lot of bends.

If pinching is resulting from die forming which is not acceptable then blend grind uniformly to

surrounding metal & thickness check to ensure that minimum wall thickness is maintained as per

drawing or torus formula.

Inspection of coils after bending & Setup of butt joints:-

Shop QC shall ensure that proper material is used as per drawing & color coding is done, if required.

Shop QC shall ensure the matching of coils on layout & it shall be within acceptable limit as

mentioned.

Shop QC shall ensure the Identification marking of coils [ BLR No., Coil No., Item description]

Shop QC shall ensure that joint & 1" area adjacent to butt joint is cleaned on both sides.

Shop QC shall ensure the Orientation, Setup dimensions [Groove angle, Root Gap, Root Face] as per

drawing on layout.

Shop QC shall ensure the alignment of coils & shall be within acceptable limit

Shop QC shall ensure the orientation, dimensional parameters for Structural attachments on layout as

per drawing.

Shop QC shall ensure that edge preparation at ends is carried out as per drg. & dimensions are

matching on layout.

After Clearance from Shop QC, production shall start the welding of butt joints & structural

attachments.

Shop QC & production shall ensure that proper preheating of joint & its adjacent 1" area is carried out

before welding & interpass temperature is maintained, if applicable.

Welding of Butt joints & Structural attachments:-

Shop QC shall carry out visual inspection [Weld profile, appearance, Weld reinforcement] of all butt

joints & shall check that all coils are identified with welder No.

Shop QC shall ensure flow area by ball test.

For Stud welding & other requirements, Refer SOP no.

After clearance of Visual insepction & Ball test, Production shall offer the coils for applicable NDT to

NDE cell.

Post Forming / Bending Heat Treatment:-

If R/D ratio < 1.25, then Stress relieving shall be caried out for cold bends as per heat treatment cycle

given by welding cell.

Final Inspection:-

Shop QC shall ensure that required NDT is completed & is cleared.

SOP / BnHQAC / 01, Rev. 0 Page 3 of 4

Shop QC shall ensure the inspection of coils [Overall dimensions, Edge preparation, End

Identification, Coil No., Item description]

Shop QC shall ensure that scope of drawing & BOM is complete

Shop QC shall ensure the edge preparation of the coils by stacking of all the coils in bunch lying with

support on all sides so as to verify that none of the coil is short or excess in length.

After completion of inspection, coils shall be offered for painting.

Painting Inspection:-

Shop QC shall ensure the proper cleaning of coils before painting form O/s.

Shop QC shall ensure the edge preparation of the coils by stacking of all the coils in bunch lying with

support on all sides so as to verify that none of the coil is short or excess in length.

Shop QC shall ensure that proper shade of paint, approved brand of paint, Batch no. of paint

Shop QC shall ensure visually that no Rundowns, Peel - offs, cracks are present & complete coverage

of coils.

Shop QC shall check the DFT of paint.

Shop QC shall ensure the cleaning of coils from inside before capping & ball test to be carried out.

Shop QC shall ensure that all tubes ends are properly capped.

Shop QC shall ensure that color coding is carried out as per the material & idnetified chart, if

applicable.

Shop QC shall ensure the stenciling [BLR No., Drg. No., Mark No.,Part No., Coil No.]

Hard Stamp of IBR

SOP / BnHQAC / 01, Rev. 0 Page 4 of 4

You might also like

- Standard Operating Procedure (Headers) : Prepared By: Checked by Approved byDocument5 pagesStandard Operating Procedure (Headers) : Prepared By: Checked by Approved bysbmmlaNo ratings yet

- Membrane Panel SOPDocument5 pagesMembrane Panel SOPsbmmlaNo ratings yet

- PTL Rev1HartlepoolDocument4 pagesPTL Rev1Hartlepoolharry_1981No ratings yet

- Guidelines For Fabrication of Steel GirderDocument17 pagesGuidelines For Fabrication of Steel Girderradhakrishnang100% (3)

- Guidelines For Fabrication of Steel Girder Procedure in WordDocument17 pagesGuidelines For Fabrication of Steel Girder Procedure in WordManas Rawat100% (1)

- Pulley Manufacturing ProceduresDocument4 pagesPulley Manufacturing ProceduresVijayakumar SamyNo ratings yet

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDocument5 pagesWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNo ratings yet

- Tank Construction Quality ProceduresDocument36 pagesTank Construction Quality ProceduresJagdish Busa100% (2)

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Document57 pagesBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNo ratings yet

- Typ. Construction MethodologyDocument29 pagesTyp. Construction MethodologyvijayshelkeNo ratings yet

- Tank ErectionDocument13 pagesTank Erectionsajay2010No ratings yet

- Job Methodology For Fabrication & Erection of TankDocument22 pagesJob Methodology For Fabrication & Erection of TankBIPIN BALANNo ratings yet

- Hydromechanical - Technical SpecificationsDocument16 pagesHydromechanical - Technical SpecificationsdishkuNo ratings yet

- Fabrication, Inspection, Testing and Supply of Stainless Steel DrumsDocument17 pagesFabrication, Inspection, Testing and Supply of Stainless Steel DrumsAmitNo ratings yet

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- API 650 TanksDocument5 pagesAPI 650 TanksCemal NergizNo ratings yet

- Methodology for Rebars InstallationDocument4 pagesMethodology for Rebars InstallationVector DesignsNo ratings yet

- Piping Work Method For Fuel Oil Pipe Fabrication Installation and TestingDocument7 pagesPiping Work Method For Fuel Oil Pipe Fabrication Installation and Testingsamsul maarif100% (1)

- Job Procedure For Eriction of TankDocument13 pagesJob Procedure For Eriction of TankAnonymous i3lI9M100% (2)

- 5.2.3 Piling WorksDocument12 pages5.2.3 Piling WorksPaul KwongNo ratings yet

- Government Guidelines on Fabrication of Steel GirdersDocument55 pagesGovernment Guidelines on Fabrication of Steel GirdersradhakrishnangNo ratings yet

- Duties of Welding InspectorDocument1 pageDuties of Welding InspectorJennifer French100% (1)

- Storage Tank (API 650) - Home Welding & InspectionDocument34 pagesStorage Tank (API 650) - Home Welding & InspectionHussain AliNo ratings yet

- MOS for Clean Agent Fire Suppression SystemDocument5 pagesMOS for Clean Agent Fire Suppression SystemrobertNo ratings yet

- Annexure IDocument3 pagesAnnexure IRadhakrishnan SreerekhaNo ratings yet

- Method Statement For SS & CS - Uaq Independent Water Project - 150 MigdDocument14 pagesMethod Statement For SS & CS - Uaq Independent Water Project - 150 MigdMdubdtNo ratings yet

- PipingDocument8 pagesPipingAhmed ElalfyNo ratings yet

- New Storage Tank Construction Method StatementDocument10 pagesNew Storage Tank Construction Method StatementEmmanuel kusimoNo ratings yet

- Fabrication and Erection ProcedureDocument13 pagesFabrication and Erection ProcedureshivanshsovNo ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- Tender For Fabrication of Tanks For Tank Farm Phase 03Document6 pagesTender For Fabrication of Tanks For Tank Farm Phase 03khansaleemNo ratings yet

- A. Manufacturing ProcessDocument7 pagesA. Manufacturing ProcessPHILIPANTHONY MASILANGNo ratings yet

- Method Statement-Welding of Piping DabbaiyaDocument11 pagesMethod Statement-Welding of Piping Dabbaiyasivaparthiban67% (3)

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- Work Instruction For Die Life: Doc No-Pdf/Wi/Dl-15 Orgin Date-22-09-17 Rev No-00 Rev Date-00Document9 pagesWork Instruction For Die Life: Doc No-Pdf/Wi/Dl-15 Orgin Date-22-09-17 Rev No-00 Rev Date-00amalesh84No ratings yet

- British Standard 5289: 1976: Visual InspectionDocument10 pagesBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNo ratings yet

- Welding InspectionDocument132 pagesWelding InspectionEnrique TaviraNo ratings yet

- FIELD INSPECTION PROCEDURESDocument29 pagesFIELD INSPECTION PROCEDURESsbmmla91% (22)

- SOP For Handling Punches and DiesDocument8 pagesSOP For Handling Punches and DiesaydiNo ratings yet

- Maharashtra Industrial Development CorporationDocument4 pagesMaharashtra Industrial Development CorporationNilesh LokhandeNo ratings yet

- Introduction To Piping FabricationDocument5 pagesIntroduction To Piping FabricationSyed IbrahimNo ratings yet

- Fuel Gas Tree Project LPG Plant, Kurdistan, IraqDocument5 pagesFuel Gas Tree Project LPG Plant, Kurdistan, Iraqgodenny100% (1)

- Procedure D'inspectionDocument9 pagesProcedure D'inspectionsalahjallali100% (2)

- STANDART PROCEDURE Welding Dan TestingDocument6 pagesSTANDART PROCEDURE Welding Dan TestingvayakunNo ratings yet

- CSWIP 3.1 Welding Inspection NotesDocument102 pagesCSWIP 3.1 Welding Inspection NotesMohamad Junid Bin Omar91% (32)

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Rev.1Document5 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Rev.1iplaruffNo ratings yet

- Technical-specs-Heat ExchangersDocument96 pagesTechnical-specs-Heat ExchangerssudokuNo ratings yet

- Inspection Test Procedure TemplateDocument8 pagesInspection Test Procedure TemplateMahesh SuthaNo ratings yet

- Works Instruction For Piping Welding InspectionDocument5 pagesWorks Instruction For Piping Welding InspectionAbg SepulNo ratings yet

- Tank Field Inspection and Test ProcedureDocument29 pagesTank Field Inspection and Test ProcedureFadlul Akbar Herfianto100% (2)

- QC Piping Inspector Duties & ResponsibilitiesDocument11 pagesQC Piping Inspector Duties & Responsibilitiesmohammad atif aliNo ratings yet

- Quality control and fabrication of composite bridge girdersDocument7 pagesQuality control and fabrication of composite bridge girdersradhakrishnangNo ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Types of Pressure TermsDocument10 pagesTypes of Pressure TermssbmmlaNo ratings yet

- Basic InstrumentDocument85 pagesBasic InstrumenthaseebmonNo ratings yet

- RT Hand Written BookDocument22 pagesRT Hand Written BooksbmmlaNo ratings yet

- Pamphlet On Safety Precautions For Steel Erection WorkDocument4 pagesPamphlet On Safety Precautions For Steel Erection WorksbmmlaNo ratings yet

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaNo ratings yet

- Film Defects - AMERONDocument94 pagesFilm Defects - AMERONER RaviNo ratings yet

- Site Inspection ChecklistDocument3 pagesSite Inspection ChecklistsbmmlaNo ratings yet

- Basic Valve and Testing Method - 1Document37 pagesBasic Valve and Testing Method - 1Fouad OudinaNo ratings yet

- BGas MaterialDocument65 pagesBGas Materialslxanto100% (4)

- Welding DefectsDocument8 pagesWelding DefectssbmmlaNo ratings yet

- PT 3 Types of Cleaning, Equipment's and MaterialsDocument13 pagesPT 3 Types of Cleaning, Equipment's and MaterialssbmmlaNo ratings yet

- Swaged End - NormalisingDocument1 pageSwaged End - NormalisingsbmmlaNo ratings yet

- Static Equipment AwarenessDocument137 pagesStatic Equipment AwarenessZeshan100% (1)

- FORM QW-482 WELDING PROCEDURE SPECIFICATIONDocument2 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATIONsbmmlaNo ratings yet

- BASIC SNT-TC-1A GUIDELINES FOR NDT PERSONNEL CERTIFICATIONDocument20 pagesBASIC SNT-TC-1A GUIDELINES FOR NDT PERSONNEL CERTIFICATIONsbmmlaNo ratings yet

- DNV Os-E403Document38 pagesDNV Os-E403ReadersmoNo ratings yet

- Quality Control ManualDocument77 pagesQuality Control ManualsbmmlaNo ratings yet

- Technical Data and Safety Guidelines for Finned Tube Bending MachineDocument3 pagesTechnical Data and Safety Guidelines for Finned Tube Bending MachinesbmmlaNo ratings yet

- Sop Piping Tubes Standard Repair ProcedureDocument3 pagesSop Piping Tubes Standard Repair ProceduresbmmlaNo ratings yet

- API 510-Kuwait Petroleum TrainingDocument160 pagesAPI 510-Kuwait Petroleum Trainingsbmmla100% (1)

- Pre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DateDocument1 pagePre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DatesbmmlaNo ratings yet

- Tube to Tube Welding ProcedureDocument1 pageTube to Tube Welding ProceduresbmmlaNo ratings yet

- SOP NM ReportingDocument2 pagesSOP NM ReportingsbmmlaNo ratings yet

- Piping Dimension Chart UsefulDocument1 pagePiping Dimension Chart UsefulrizkiNo ratings yet

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Document1 pageSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- Downcomer Nozzle To Drum Welding Procedure: 1.0 ScopeDocument1 pageDowncomer Nozzle To Drum Welding Procedure: 1.0 ScopesbmmlaNo ratings yet

- Nozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1Document1 pageNozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- ULTRASONIDODocument248 pagesULTRASONIDOJorge Vera Alvarado0% (1)

- PT17Document30 pagesPT17Pradeep Kumar BowmarajuNo ratings yet

- #Duvha ST Blade Root FailureDocument7 pages#Duvha ST Blade Root FailureCyrix.OneNo ratings yet

- List of Contents For Gs-15Document13 pagesList of Contents For Gs-15Kalai SelvanNo ratings yet

- Overhead Crane Inspection ProceduresDocument5 pagesOverhead Crane Inspection ProceduresRonniNo ratings yet

- API 577 Welding Certification TrainingDocument7 pagesAPI 577 Welding Certification TrainingInstech Premier Sdn BhdNo ratings yet

- Internship Report - Fauji Fertilizer Company (FFC)Document49 pagesInternship Report - Fauji Fertilizer Company (FFC)Muhammad Aqeel Ashraf75% (8)

- My CVDocument5 pagesMy CVNikhatRizaviNo ratings yet

- ASNT L3 - Renew ApplicationDocument12 pagesASNT L3 - Renew ApplicationaymenmoatazNo ratings yet

- Apt Inspection TechnologiesDocument6 pagesApt Inspection TechnologiesArunNo ratings yet

- Specification For NDE For Piping B016-6-44-0016 - Rev. 3Document21 pagesSpecification For NDE For Piping B016-6-44-0016 - Rev. 3Ayush Choudhary50% (2)

- Welding Repair Procedure for Diesel Fuel TankDocument4 pagesWelding Repair Procedure for Diesel Fuel Tankgstketut100% (2)

- API 570 in Service Inspection Piping System 1643295114Document32 pagesAPI 570 in Service Inspection Piping System 1643295114DeepakNo ratings yet

- A Comprehensive Approach To Reformer Tube InspectionDocument13 pagesA Comprehensive Approach To Reformer Tube InspectionHéctor S. RodríguezNo ratings yet

- Presentation Teledyne ICM NDT 2019 - DD - DIGITAL RADIOGRAPHY 1 SVDocument21 pagesPresentation Teledyne ICM NDT 2019 - DD - DIGITAL RADIOGRAPHY 1 SVdantegimenezNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- ISO 17025 NDT Lab Accreditation CertificateDocument3 pagesISO 17025 NDT Lab Accreditation Certificatekiki270977No ratings yet

- NDT Level-III Refresher Course - Announcment Jan 2016Document3 pagesNDT Level-III Refresher Course - Announcment Jan 2016idealparrotNo ratings yet

- NDT A Seminar ReportDocument24 pagesNDT A Seminar ReportSandesh S BhasriNo ratings yet

- Casting Advisory Circular Provides Guidance on ComplianceDocument14 pagesCasting Advisory Circular Provides Guidance on ComplianceKivanc SengozNo ratings yet

- Casting Inspection PDFDocument8 pagesCasting Inspection PDFamol koteNo ratings yet

- Số hiệu tiêu chuẩn Ngày công bốDocument19 pagesSố hiệu tiêu chuẩn Ngày công bốThành Nguyễn Quốc100% (1)

- Experimental Stress Analysis Two Marks With AnswersDocument24 pagesExperimental Stress Analysis Two Marks With Answersmatrixrajiv34100% (2)

- Fabrication and Testing Requirements Class: FTR 1 of 2 - 2016-01-12 MC H. Pelders S M. Ummelen ME R.J. Lammers/hpeDocument2 pagesFabrication and Testing Requirements Class: FTR 1 of 2 - 2016-01-12 MC H. Pelders S M. Ummelen ME R.J. Lammers/hpemokie305No ratings yet

- E 494 - 10 PDFDocument14 pagesE 494 - 10 PDFruben carcamo0% (1)

- ICNDT Guidelines 2016Document36 pagesICNDT Guidelines 2016Ndt ElearningNo ratings yet

- Part 145 Sample ExpositionDocument114 pagesPart 145 Sample ExpositionABDELRHMAN ALINo ratings yet

- FR 210-11 01 List of NDE Operator (New)Document1 pageFR 210-11 01 List of NDE Operator (New)aszlizaNo ratings yet

- Proposal For Bush ClearingDocument8 pagesProposal For Bush ClearingGagalo IL100% (1)