Professional Documents

Culture Documents

Design of Retractable Steel Dome Part-8

Uploaded by

NikhilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Retractable Steel Dome Part-8

Uploaded by

NikhilCopyright:

Available Formats

---- ---- --- ---

- -

- - -- -- --------

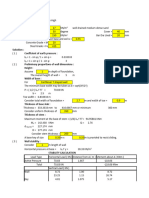

Hence. The SecNOIl is SAFE.

(d) 'Thi!cklless= 6.8 mm.

l e] Cress-Section Area = 7U;" I cm2

(f) Moment Of Inetna = 1 0&6 ~ ,42 c.m'4 (g) Modw.us OfSecti~n = 588.39 cm3

(' ) Radi U$ Of Gyration = 11. SS eM

('DECK

Check I'''o.r Slende7.neMi Ratio'

As the maximum lengdl= 6. l 8 m

f;ffecliive~ength = 0.61::.;6 .. 1.8 = ~.14 m. (Fe-fRigid j,oirrut~dFrnme) Radius OfGpation "" ~. t85 em

S~e:nde,me~s &&tI0 """,. J~ I r

"'" 4. i4rx lO~111.8:5xl0 = 34 .. 9,f

M wt is Less tmilan assumed Ifr ratio = 140

CheckFo, Thickness

"l'ilickness ,of section rr,oviited, gIleaterof two of foU(l'\vmg,

(a) FO.r Exposed. To WeaOIeo{ Si.tuation,. Mimmmn.Thic-lrness = ,4.00 :mm (b) POif Not Exposed 1'01 W,eather Sitwt~on" Mi~im.1Jlm. Th~ck~e·ss ea 3 . .2I'lm

As W,e Provide ,6.8 mm Thickness

Hen&e.._The Section is SAFE.

,Max/llmm Lo,a4 CflTl'yi"" ICapacity Accordiml,g .~ IS:806-l968 (page-6) For krdt = 34.9~~

Permissibfe CQ.m.pressive SDes:s = 164.:5 N/mm2 Compressive Lead Cmying Capacity "'" 164 .. S 1< 11.6,1 KI. 0;2: = 111'.'98KN

Ma.xintJJum Axial Tensile s.tn~ss For ys~ 32 (at) "'" 190 N/mm2 Hence, Tensile Load Carrying Capacity = 11'90 x~7J.!6 I xl (i

= B60,S'9KN

Thus, Tille Load C.wrying Capacity ofgjven Section is greater thyl. reqwred.

l!elz'Ce. The Section is SAFE:

.(86)

--- -- - -- - --- -- - - -- --

...._

Momt!ll,t Carrying Captlclty Accommg to, IS: 8M~ 1968,

Permissible Bending Smess in. Extreme Pibre in Tens~o.n & Cornpressien, P,or YsO.2 is Fb,= 105 NJmm?

RJesulmfllt.Betu:!ling Moment = 115.22+4.408 ~ ) 19.63 KN-m

Now.MH-mas Of Section (z) ReqU!Hed

~= I ~.'9.6'Jx url20s

= 583.56)( iOJ mm3

As~ Required. ,s'ecltion m.oduhLS .is~ess tEn proivided

H:ence~ 'lhe Secsion is SAFE.

ClJeck Fo', Shwu

A()co~ding tu IS:. 806-1.'96:8 (page-1) for~ Yst 32

The Permissibme Silear Stress (!F~) ~ 135 Nlmmil

T!1Ie: maximum shear stress is, to be: wlcwiitedb:y dividi~g~he sheaf Iowoob,y the lMlf ,els ,area.

EiJective cis Area for shear = 358@ .. 5 mOl? Mbiimwn :sh.em' canyi~s capacity = 135x3S80.5

"'" 483 . .37 .KNl

M~he shear cmywng a,achy ~s m.ore ·tmm required,

Hence, '1 'he Sec1ion is SAl- "1:;.

(87)

--- --- --- ---

-

- - ---- - - -- -- - - -

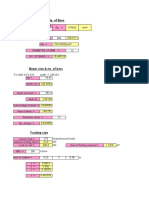

'.5 DESIGN OF WELDED JOINT

Here, we give, one ,crucIla,tiQn. of welded j()in~ af Tulbum. Sectiea formembe:r 4,10,12.] ,8 &; 10,. which has the compli1camd. jo.rint. Simi~arly ~ Otber Mem~e:rs are desigaedas shewn in figure.

MEMBER 4,1(J~, 12~ 18~& JD.,

Mewer " &: J(J

Ande Betwee.n. Memibe.r 4! "20 . 9 "'" 62.79

a = (dI2), cosec (II

= 34212 0000': 62 .. 19 = ~,'92.,2i6 mm

b = (d/3) [3..(dID),;I2-{dJDi')

= 34213 x [3-(342/1 ($IS) 2:12-(3421165) 2] "'" 5:9.38 mm

The Length ,of' GIWVe of mtersection L =a + b + 3(a2+ Ib'2) III

"'" 192.26 to 59'38 +3092.2.0-1 + 59'.382) ~a. = 85.530 mm

Let. t be the tlliuoat thickness oi fiUe~ weld, The allowable stress in sheer In weld from. IS: tU6~1'969'

f,= UONlmm2

t= {9't4:8,1~ 1(f)J(1 Wx855.30) = O.9"1mm.

The size of weld required S = «(1'.'97/0. 7) ~ 10 = ~.1.8i9mm

Provide m4 mm FiUet W'eldfor the joint

(88)

- - -- - -- - - - --- - - -- -

1

-

- -- ---- -- -- - - ----

~Vemer4& 18

Angl.e Between .MemJOO.iI: 4, & 18 10!= 63.13

a= (df2)rosec 0

= 244/2' cosec 63. B = 1.36.77 m_m

b = (dl3) [3~dID)2,t2~d!Di]

= 2.44/3 x [3-(244fW.,65) 2/2-(24411 65)2] = 353.96mm

The Lenph ofCW1o\e: of m,t,ersect!om 1.= a + b + 3(82 + b1) 1.1l

= 136 .. 71+ .353.96 + 3(U6.1T + 353.9(2) 112 =S70.20mm.

Let t.be the throat thickness of fiUe~ weld. The allowable stress in shear in weld from IS: ~u 6-19,~9

t= IION/mml;

t = ~61.51)( ~03:)I(11O>l810 . .20) =O.64mm

The size ufweld requirl(:d S = (0_64/0,.7), x W =9.14mm

Provide 10 mm Fmet Weld for the joint

Member 4 &: 12

Aoglle6et'\weD MemMii 41 & 12 9'""'17.9'4

a. ~ (dI2) cosec Q

~ '21512: cesee 77.'94 == 14fO.6~.mm

b = ~dl3)1 [3-(dlDl!2-(dID)ol]

,= 215/3)(.[3-,(21.5/165) 2J2-{215J16S) 2l 0;;;-26 .. 1.'9 mm

(89)

--

--- - --- --- .... ---

, -..---

---- -

The Length of Curve of intersection L = a + b + 3Ga? -+ ,02) In

= W40.6~ - 2~6.19 +3040.611 + 26J92)Y2 = 595,,8:9 mm

Let L be the throat thickness of'Iillet weld. Theallowable stress in shear in weld from IS: R 16-1969

. - .. . 2 fs = 110 N/mm-

t = (54.31 x lQrl)/(l WXS95.89) =O.S3mm

The size of weld. required S = (0.83/0,7)' x 10 = 11.84mm

Provide 12 mm Fillet Wedd for the joint.

Membe:r 4& 10

Angle Between Member 4 &:; 10 0'=9'8.02

a = (dl2) cosec ,9

= 270/2 cosec 98.02 = 136 .. ,33 mm

b = (d/3) (3-(dJDi;f2-(d!Di~]

= 210'/3 x [3-(210/165) 212-(270116:5) 2] =42.79 mm

The Length of Curve of intersection.

L=a+ b+3(a2+ b2)Yl

= 136..33+ 42.79' +3(l36..3,i~ + 42.7~) 1!2 =607,.78mm

Let t be (he Iihir~~ tbjckness of nOeL we]d.The allowable suess in shear in. weld from 18: 8. 16~19\69

fs= IWNJmm2

t = (91.48.1xlo1)/(110x601.78) = 1.37 mm

(9U)

The s~ze of weld required 8 = 0.3110..7) x lO = 19.57'mm

Provide 20' mID fme~WeM for tbejoinrt"

y

Lx

9~' UESIGN OF PIN_CONNECI10N STEP-I. pun Tmns:mitted By' Each Eye Bar.

Workjns Stress in i\xialJ Teosmon fy = 0.6 fy

= 0.6x260 N/mLm1

PULL (P) = (O.6x260x3950/1000)

~6116.2 KN

Cis Area .of200' mm Din Bore = 3950 mm2 Shear Force at X] ,01 X2'_ 1616.2 KN

Max.i:mWD Bending Moment at Xl or Xl _,.. MI6.2x(200n +3 +20)1 = 75192.6 KN;'mm

(91)

STEP-,2: Section Modulus, of Pin Required.

Z == 7S792.6x 103/0.,66 x 260 "" 441.68x~03mmJ

STEP .. ], Dia of Pin

Section Modulus ora cylmdnealPin = (x /32)x&3 mm3 Wber,e d = Diameter ofpin in mm.

(rc 132)xd3,.,. 44L68xl03

d= 165.08.mm

Provide] 10 mm diameter of pin,

STEP-4 Check

I _ Average Shear Stress in the Pin. t:ItV"" 616,_2x 103/(x 14) (l70~2

= 27.14 N/mm2<WOO Nlm:m2

2. Bearing stress in. Pin

Gr = 616.2xIO~1l70x40 =-0 '90.62 N/mm2<300 N/mm2 Hence, Satisfactory.

Provide 110 mm Diameter UndriUedPin for Pin Connection.

(92)

- -- -- - - -- ---

-- - - -- - -- -

"'.7 DESIGN OFMEMJI;ER FOR LAMELLA. DOME IN CIJOSEDPOSrrlON

fr,om the arna~ys~s fesrufs" it is; S'eeEI thai!! the ma~. fowes Me' I'Fedwminamt~ theremre members are designed fnr axiaJ ,eompresSJive fOl-ce and c~ecl:ecl for omer actions, The members, ,3ft! designed [I, same \Wyas Oil.ember for ReuaClaM.€ Dome{Secu!offil 9.4). The Seot\ion.ofMembe.r IS ShOYmID fipre bell)w~

DESIGN VALUES FOR I'IEM:BER

(1), Axja~ Fo,r,ees-(C) "'" -30.284 .KN

(2) Shear Foree 1m. Y ~Difec;tion ~ 1 .. 25 KN

Z~D.~n::ctlon =r.n KN

(3) "forsio,nal Moment = 0 .. 0994 KNi..,M lBendling In Y ~Direction "" ~ 1.086 KN~M Bending T_R. Z-Direct;i!on = 0"769' ICNi-M

(93)

'9'.8 DESIGN OF WELDED ,JO.JN:[

Here, the calculations cf welded joml! o:f Tubtdar SedJicms are designed in same way as ICidcullted in section 9 .. 5' . The Section of Member is, sho,WJl in figure: below,

-- -- - -- -- -- -- --- -

-- - -

1

DESIGN OF COLUi'm fOR JOI'l\rl NO.1" 2,.

X-.FORCE = 64 . .38 KN Y-FORCE ,= -'0.536 KN Z-FORCE = 1 ~. 71.teN

Use Ml,5 Grade: CO~CTete~ndFe 41 S steel

X';MOMENr= 3.595 KN~M Y-MOlvffiNT = 44.23 KN-M z..MOlvlliNT ~ -:~ 7575 KN-,M

Design. Force = (1..5')(2)(_65.45) {PJ= '19:6 .. 35 KN =.2UOKN

Assume Uni-axial Mome~~ M~ = 3.:),95 + 44,23 + ~ 7.,5i5 =6S.4KN~M

Fa.ctared.M0111lent.= (1.5)65..4 = 9'8.1 KN-M Assume600x600 mm,:2 Squre CO~Utmil..

Now,

Pu . = ___20Lhdl O~ ,.." 0.037

fcl;.b"D 1:5 :<600..><600

.. ~. 0:;0 _j.2.1 X ~OG = 0,.03

_ t~.b.D~ 15xl60Cix (600i

Ut.;~ng 25mm dia bars w.itb40 mm c~earrov~d "" 4<0 + ~2.5 = 52.5 mm

d = 52.5= 0.0'87.5

- -

D 600

From SPJ6 Chart of'Fig, 17-1 5 P = 0_01

filiI;;

Percentage of steel r = O.OIxI5

= 0 15 <: 0-8 (minimum)

Tate. 0.8 %

- -- -- -- --

-- --

- --

Area, of stee] ~ A:~:; .0.8)( 6{)O X 600 = 28 SO mm2 100

P.mViide 6 :110,,25 mm dia, BarfS = 294$.24 wn1,.,equaJly distributed.

Percentage P = 29'45 .. 24 x, 100 = O.8~8 600x600

p ~ 0.8:18,= 0',,0545

f~k 15

The assumed section is now checked.

Ma,,] = Muyl = 0.09 x IS x 660 x (600i x 10'" ;; 29'~.6, KN"-M

Pm = .oA$ fd: ~ + 0.75 '1' s;

Ac .,; 600 X ,600 - 2945'.24 :; 3:57054.1,6 mm2

Pm. = OAj X 15, x 357054.,7,6 + 0.7,5 X 4lS X 2945.24 X 10-3 = 2410.11 + '916.705

= 33,26.82 KN

Pil ,= ~l06 PIl?

O:I:I~]

CHECK:

~J~:I

CHECK FOR ,QOlUZONTAL THR',USl'{SBEAR) Horizontal F orce = ,64 .. 38 K:N'

Area of column= 600!x6001 mml

Actual Shear stress = 6438)( Hl~ = 0.18 < Permissible (0.1{) 600;;.:600

...... --

-- -

(97)

DESIGN OF_TIES

Minimum diameter= 25/4 "'" ,6.2;5, rum

Use 8 mm dwa.M.S. ties.

Spacing shouWd not exceed

(1) 600mm

(2)0 16 x25'""' 400mm

(3) 3DDmm

Provide 8mm. dis M . .S, ties @ 3,00 nun cle.

F.Q.~TING BE·LOW JOINT -1

(ISOLATED RECTANGULAR FOOTING)

MIS Grade concrete and HYSD reinforcement of Grade Fe 415

{aJ' SIZE OF FOOTING~·

Column load = 210 KN (including dead wt Of cclumn) Se~f;'wt Of footing =' 42 KN (20 % ,of cehann load)

TOltal ~ 251 KN

Safe Bearing Capacity ,of SoH. "'" 200 KN/m2

2 Area required for axial load only = _252 "" 1.26 m

200

Try 1 1.2x 1.2 m Size

A = 1.2xl.2 = 1.44 ni2

Z = U6x J .2x (1.2)2 = 0.288 :mJ p = 252 = 175 KN/m2

A 144

M =65.4 = 227. ~ KN/m? Z 0.288,

Pma~ = PIA +:M/Z'~ 175 +227.1 = 40.2.1> 200 Pmin = PIA -M/Z = 175 - 227.1 = -52.1 < 0

Try.2 t5xl.:5 m Size

A. = l5x 1.5 "'" 2.25m2,

Z = V6xL5x (l.5r", 0.5625 mJ PIA = 25212.25: = ~ 12 KN~m2

M/Z = 65.4/0.5625 ~ 11,6.27.KN/m2

p~x = P/A+ WZ = 112 + 116.27 = 228.27 KN/m2 > 200 Plffi.lill = PIA -lW'/Z . .." W 12 - 11.'6.27 , .. -4.21 KNfm~ <: 0

- -- --- -- -- --- -- ---

-....._

--- --

Try 3 2x:2 m.S~ze A,=2x2 =4 ml

Z'''''' ~16x2x (2)2 ~L33,m3 PIA;:;; 252/4 = 63 I{NIhn2

ft A.n· ~5'4-1'~ '3'3' 4:9'. 1-' ~!I;;;'11

~""'!IIL ;:::::: 'ii. . L .. ' = c.' . .. !f'!..!i."II.m

Pma)i = '/A+ .M!Z =63 +49.l1 = 112" Ii !KN/m] <:WO PmiD ~P/A ~WZ = 63-49.11 = 13.83 KNIm.2 >0 Adopt 2x 2 m S,~ze. :fiDotjng~

.(6)1 .NET lJPWARD PRESSU1lE:

Nell up'WMdipressmes fo-rfoo.tin.g des~gn.

P = 200{4 :t 6:5.4/1.33 ~ 50;:1:; 49.11 K,Nim.2

Pma_~= 99.11 KN/m2 P'1Itill = 0.83 KN/m2

Net upwaJid. pressures actmg on :footing ~re mo,YiI1l in fig. (e) MOMENTCALCULA.TlONS· ..

M)o; = (~x 64.15 x 10.1 x H3 x 0.1) + (% x 99.11 x, 0.7 x 213 x 0.1) ~. 21.491 KNl .. m.

dlll ~ 300- 50 -6 = 244:mm

d:;, = 244- 12 ""'232 mm, Stee1ParaJleJ to, X & Y..mmcltion

MJbd2= 36.75 x lcft2t)QO x 244 x 244 :;0:' 0.309

~ = 1 .. 5x21.·49 ::;;; 32.24 KN-m

My = ~O.1)~ x 2 x (0.8.3+99.11) ""'. 24L:51CN-m,

'2 2

Muy ,:;;: l:5 x 24 .. 5 ~ .36, .. is lCN"~m (6') MOMEN'l'STEEL:

Dep~reqmred for tlIe~

d = 136,75 x IQ~ = 94.22 DUl!1I V'iJJ1 x 2000

Tty an, t'lV'em11 dep., O'f 300 mm. Larger d.epm is. required fOF silear lieqwRml.ellil.

V =: 0.456>: (76.75+99.17) x 2 ~ 8.0.22 KN

2

Vu ~ 15x80.22 =- 120.3.3 KN

~,= 120.33xlO~/(2000x244) "" 0.247 N/mml 100 As "" WOx~028 = 0.2106

bd. 2000x 244

Pereenmge steel p( ~ :50 (' ,I -\11 - 4.6/&kX MAJ)

_ . fy/fd._ J. .

= 50.[1 - \A - 4.61i5 x 0.309J 415/15

= 0.081 < 0.,205 (mimmum 85/fy) Adopt 0.205 % stee~

~I ;;;; (0..205/100.) x2000x244 ""lOOOA mm2

13, "'" Longer side of footing ~. I Shorter side 'of footing

2/(r3-rl) == I

Re~nfol7CeBlent is, equally distribut:ed.m 2 m width. = 1x1OOO.4 = IOOo..4mml

Spacing = 113J)9xlOOO/lOOO,.4 =113.04 mm Provide 12mm, dia, Bars @ 110 mm. c1c= 1028.09. mm2 (e) ON£WA.F SHEAR:

t~ = 0.327 N/mm? (J) l'W(bWAYSHEAR:

[3e = Short side of cnlumn = 1

LOong side of column

k, = (O.5+fJ¢,) == 1.5:> 1 k£= 1

i-c= 0,25 (tx)][.l, = 0.25 (l5J'12 = 0..967

Design Shear strenBJth = k~ tc= lxO.'967 "'" 0.967 Nlmm2

Tw~wa~ shear along line AB~ (0.844 + 2) (70.75 + 99.17) x 0.578

2 2

;;;;,69.8:3KN

(SAn)

(99)

Vu = 1.5 x 6'9.83 = :W4.c74c KN

t~, = 104.14 x 103 844.x :244

'= O,S086 Nlmml <: 0..967 NJmm2 I[SAFE)

(g) TRANSFER OF.LOAJ) FROM COLUMN TO' POOTlNG.~ Design tieariOjg pressure at the base 01 co:hunn. "" 0.45 .~ =01.45 xU

= 6.c7S 'NJmm,2~=--.....:(1)'

At the ~()P of footing

At = 0.6;.:0.6 = ,0.3,6 m2

AI "" Smaller of (1)2 x 2;.= 4- m2

(2) (0.6 + 4 x 0.,.244) 2; "" 3.152mr2

AI = 3'.152 ml A~. = 2.96:> 2.

A2

Adop.t~ 2"

Design bearing pressure"" 2xQi,.4i,5x15 .... 13.5 Nlmm2 ~~~~- ~~(.l)

Des:~gn bearilgpressU[~ from (I) ,and (2) ~ 16.13 Nlmm::.!

Acmw. bemng pressure = 1.~~c~ : !~, + 166~:!'~6~~~? 356 -c 6.15 N I mm2

There is no need of dowel. bars

I

~

0.83 ,'.i

64.7-, ~ -··9.17

(l00)

D

(II) WEIGHT:

'W =4 x 4i x 0.3 x .25 = 1:20 KN >42 KM

Note 'tha!~ 'die d!~ll1Iemsiio.Im '0'[ footin.g are l:M'ger~n th~s case alJe: to m~me!llt In some cases, it may be necess.y to assume m()l,e than 10> % self-weight o:f~Jle :[ootimg wiI:I~, ae ftn)tilfll is subjected iWmoment

I II 'I 'I

____ J l L _

~I ~ ~ ~

I

r::::::::::Q1

,-..,....

- --

.Des;ign Of Cub le .Factored Tension In Cable = 1.5 x 45.97' = 6K95KN = 701eN

From IS:2266-19'70) T ABLE~ 1 (p'age-S) Use 6x19' (12/6/1) Which has. Nominal Diameter D = l.3mm

,:lWass of Fiber core = 58.5 Kg/IOO m Mass of Steel Co,re: == ,64.3 Kg/WO m

Minimum Breaking LOad Corresponding to Tensile Designatio1n of the wires.

For 160~ Fiber Cure = 83.10 lK.N Steel Core = 89 .. 70 KN

HINGE

Ma =8.74 x 10.706 + 273.37 x 2.004 -143.51 + 10.706 x Tcos9 +2.004 x TsinElI =0

T cable = 4:5.97 KN

DESIGN OF C~E

We' MiVe to p:rov~de Cable At Joint 00.,9 through. the pole.

At Joint no. 9" Maximum tension is de;ve~oped ail 54JJ625 e romD1tioncondition.

X-Foroe "'" 8.74 KN Y-Force' = 0

Z-Force = 273.37 KN

Tension In Cable:

Taking Moment about Hinge Point B. Angle of cable with horizonWll. (X) axis 6r "'" tan" 0.764/2.521 = 16"::!2°

X-Moment = 0

Y-Moment ... -14351 KN-m ~Moment=O

FIXED

Design .of Motor:

Ra'tio Of Driving Tensions: T2 = e"a T]

Where •. e = An;gle of lap in mdiaml = 100.82 x n1UIO

IJ = Cc-efficient ef'Prietion For Rope on the PuUey

= 0.3

e = Base of the napienaD.l0,g = 2.718 T;;:= Tension (determined)

T I""" Tension = 700 KN

(Wi)

002)

12;;;::: {2..7l8)O>.3,dOO,;82xKlllW -'0

T 2 ~ 7{)xl.69:5 T2= UK6S;KN

If We Take Vielocity v =" 8, m/min. ~ 0.133 m/sec." POWER P ""'(Tz - T.]) V

= (120 -70 ) 0.133, =,6.,65 KW Of 6650 W As I W =0.00134 hp

Tberefbre 9 bpmotor 'required ..

Desigll 01 Pulley:

If Pulley run, :ZOO rpm. Velocity V = 1Cxdxn/60

= 0,133 mlsec n = 200 rpm.

0, B3 =]txdx200160 d=OJH27m

Used 15 mm diameter Pulley,.

Desi,gn of'Pole:

Use M20 Grade Concrete and HYSD Reinforcement ofFe415 Length =17 m,

:lclT = 0.8.:< 17=13.'6 m Axma~. Force ""'120 KN

Horizontal Thrust == ,67 KN (Due to. Cable) Willd Load:

Wind Pressure ..01.5 KN~m2 Tfwe take 750xSOOmm Pole

Then Horizontal Shear = 11xO. 75x 15 = 19 .. 13 KN Total Horizontal Thrust = 86 .. ,13 KN

As tit is Long: Column ~

Reduction oo-.efficient eli = 1 . ..25 -1mfI48 b

== l25 -13.6x103/48x500 =0.68,

Sate Load on Column = Ct(0'.45: fd;.Ae + O.75.ty.AsQ.)

= 0.'68 (OAS:x20xO.992xAg +O.75x415xO.008Ag) . <=" 8.8,g As

"" 135018.,64 mm2

Provide 750x500 mm RocUIn;guJar Co~umn,

~ "" 0.008><3,75000 :2 =]OOOm_m

Provide 6 nu. 'of2Smm dia, Barn ~ 6x490.,S,c7

= 294S.24mm2

Use 8 mm dia, Lateral ties, Spaciillg shall be lesser oli (1) 5'00 rom.

(2) 16x2:5 =400 mm

3) '100 mm

se 8mm dill. Lateral Ties @ .300 mil ,e/c.

Check/or RO'riwnm1' f'hrwl:

H =86,.] 3 KN'

A = 750xS:OO .mm,

-w= 86.1.3:< 1'1)311:50;.;:500 = 0 . .2296 N/mm2

(T0 Smal~)

DE· .1&," OF FOUNDA1,][ON &: COLUMN IN CLOSED lfiOSITION ,:

Foundari on and Column in. elesed posit!iomare des~gnedwn same way as desi~ for Retractable Dome(AiOOv,e Section). The Datal, ef Foundation and Cohwmnis as shown in ,5: ummarv below.

SUMMARY

JOL\! NO. S:tZE MAIN BAJR llE, BAJA:

3 &5 '1000 x :.;col mm2 S InUl'. 2Smm dia. a mm dial asoo mma:o

I

,

FOOTING

2: x 2 m,12: mm ,dia. ,At 1m mm de

,!....

fa loped Isolated

10 mm ,d[~a. At 1]0 mm O/e in x diredi~fl

,SUMMARY

FOOTING

IsIZE

JOlNT NO" ITYPE Of FOOTINGi

POtE:

, nO.25.flinJn aia.

I tension 70: KN .

• OTOR:

(104)

You might also like

- Ielts ResultDocument1 pageIelts ResultNikhil0% (1)

- Qatar Appointment LetterDocument2 pagesQatar Appointment LetterNikhilNo ratings yet

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- Inverted Beam DesignDocument11 pagesInverted Beam DesignNikhilNo ratings yet

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- United Projects Appointment LetterDocument1 pageUnited Projects Appointment LetterNikhilNo ratings yet

- Retaining WallDocument74 pagesRetaining WallNikhilNo ratings yet

- Continuous One Way Sunk Slab Design ProgrammeDocument24 pagesContinuous One Way Sunk Slab Design ProgrammeNikhilNo ratings yet

- Column, Beam & Footing SizeDocument2 pagesColumn, Beam & Footing SizeNikhilNo ratings yet

- Continuous Beam DesignDocument18 pagesContinuous Beam DesignNikhilNo ratings yet

- Simply Supported Sunk Slab-DesignDocument15 pagesSimply Supported Sunk Slab-DesignNikhilNo ratings yet

- Ductile Design of Column For Multistorey Building.Document4 pagesDuctile Design of Column For Multistorey Building.NikhilNo ratings yet

- Design of Concrete Gravity DamDocument10 pagesDesign of Concrete Gravity DamNikhil100% (1)

- Continuous Beam DesignDocument18 pagesContinuous Beam DesignNikhilNo ratings yet

- Ductile Detailing Criteria.Document5 pagesDuctile Detailing Criteria.NikhilNo ratings yet

- PassportDocument2 pagesPassportNikhilNo ratings yet

- Load of Cantilever Slab To Beam & Staircase To Beam.Document16 pagesLoad of Cantilever Slab To Beam & Staircase To Beam.NikhilNo ratings yet

- Cantilever Slab Beam Design For TorsionDocument17 pagesCantilever Slab Beam Design For TorsionNikhil100% (1)

- Load From Two-Way Slab To BeamDocument5 pagesLoad From Two-Way Slab To BeamNikhilNo ratings yet

- Interaction CurveDocument126 pagesInteraction CurveNikhilNo ratings yet

- Beam, Slab, Column, Footing Steel CriteriaDocument19 pagesBeam, Slab, Column, Footing Steel CriteriaNikhilNo ratings yet

- Moment in Column.Document9 pagesMoment in Column.NikhilNo ratings yet

- Column DesignDocument25 pagesColumn DesignNikhil100% (1)

- Continuous One Way Slab Design-ProgrammeDocument24 pagesContinuous One Way Slab Design-ProgrammeNikhil100% (1)

- Simply Supported Ell Beam DesignDocument3 pagesSimply Supported Ell Beam DesignNikhilNo ratings yet

- Theoretical Point of Cut-Off of Beam.Document1 pageTheoretical Point of Cut-Off of Beam.NikhilNo ratings yet

- Simply Supported Ell Beam DesignDocument3 pagesSimply Supported Ell Beam DesignNikhilNo ratings yet

- Simply Supported Ell Beam DesignDocument3 pagesSimply Supported Ell Beam DesignNikhilNo ratings yet

- Open Well Stair CaseDocument5 pagesOpen Well Stair CaseNikhilNo ratings yet

- Space Frame AnalysisDocument1,506 pagesSpace Frame AnalysisNikhilNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)