Professional Documents

Culture Documents

Antibacterial Liquid Hand Soap

Uploaded by

jheyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Antibacterial Liquid Hand Soap

Uploaded by

jheyCopyright:

Available Formats

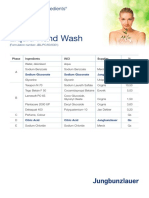

ANTIBACTERIAL LIQUID HAND SOAP

Antibacterial hand cleanser

Featuring: ACULYN™ 88 Rheology Modifier

KATHON™ CG Preservative

Ingredients:

Trade Name % Wt. INCI Name Supplier

Phase

A Water 54.61 Water

A ACUYLN™ 3.48 Acrylates/Steareth-20 Dow Chemicals

88(28.8%) Methacrylate Crosspolymer

A Stepanol AMV 25.00 Ammonium Lauryl Sulfate Stepan

(30%)

A Triethanolamine 1.51 Triethanolamine Acros Organics

(99%)

B Mackanate EL 8.00 Disodium Laureth Sulfosuccinate McIntyre

(40%)

B Amphosol CA 4.00 Cocamidopropyl Betaine Stepan

B Disodium EDTA 0.10 Disodium EDTA Fisher

B Glycerin 2.00 Glycerin Fisher

C Propylene Glycol 2.00 Propylene Glycol Fisher

C Triclosan 0.50 Triclosan Protameen

C Tween 20 0.50 Polysorbate 20 Uniqema

C Mandarin Lily 0.20 Fragrance Custom Essence

C KATHON™ CG 0.10 Methylchloroisothiazolinone, Dow Chemicals

Methylisothiazolinone

100.00

Processing Instructions:

1. Combine Phase A ingredients in order with mixing.

2. Charge Phase B ingredients to Phase A in order with mixing.

3. Pre-mix propylene glycol and Triclosan. Add to batch with mixing.

4. Pre-mix Tween 20 and Fragrance. Add to batch with mixing.

5. Add KATHON™ CG with mixing.

Product Characteristics:

Parameter Range Method

Appearance Clear Visual

pH (as is) 6.6 pH Meter

Viscosity 1690 cps Brookfield Viscometer RV #3 @ 20 rpm

Stability 3 Months / 45°C Visual

5 Freeze Thaw Cycles

(15°F/70°F, 24 h Per Cycle)

Aculyn and Kathon are trademarks of The Dow Chemical Company (“Dow”) or an affiliated company of Dow.

Date of Revision: NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use

06/2006 conditions and applicable laws may differ from one location to another and may change with time,

Customer is responsible for determining whether products and the information in this document

are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal

practices are in compliance with applicable laws and other governmental enactments. The product

shown in this literature may not be available for sale and/or available in all geographies where

Dow is represented. The claims made may not have been approved for use in all countries. Dow

assumes no obligation or liability for the information in this document. References to “Dow” or the

“Company” mean The Dow Chemical Company and its consolidated subsidiaries unless otherwise

expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

For questions or comments, please contact your local Dow Technical Sales office.

JABON LIQUIDO PARA LAVAR PLATOS

Ingredients % Wt

Caustic soda (50% sodium hydroxide) 3.3

Dodecylbenzene sulfonic acid (DDBSA) 13.00

Trycol 6953 POE (12) Nonylphenol 2.0

Sodium ethoxylated alcohol sulfate (60% 7.5

active)

EMID 6514 Cocoamide DEA 2.0

Sodium xylene sulfonate (SXS) 3.0

Citric Acid (50%) to pH 6.5 - 7.5 q.s.

Fragrance, dye, opacifier, and preservatives desired

Water balance

[See more dishwashing formulations: manual, automatic, ecological, economy,

good quality, high quality, gel, industrial, liquid, powder, wtih chlorine bleach]

Blending Procedure:

To the blending tank, add the water, caustic soda and DDBSA. At this point, the pH

should be greater than 5.0 to prevent tank corrosion. If not, immediately add more

caustic soda. Add the remainder of the ingredients in the order listed. The amount

of EMID and SXS can be adjusted to obtain the desired viscosity. Increase EMID

6514 to increase viscosity. Increase SXS to decrease viscosity.

Adjust the batch to final pH before the dye (as an aqueous solution) is added.

Note: Be careful with caustic coda or sodium hydroxide , it is corrosive.

Read more: http://www.pinoychem.com/2007/09/dishwashing-liquid-

4.html#ixzz1Lj2aALYm

You might also like

- Practical ElectricityDocument104 pagesPractical Electricityray davis100% (1)

- Complete Formulas PDFDocument46 pagesComplete Formulas PDFramu_uppada67% (6)

- 27 1811 01 Chill Lasting Effect Cooling GelDocument1 page27 1811 01 Chill Lasting Effect Cooling GelludmigonNo ratings yet

- Dish WashDocument2 pagesDish WashAnoop Thoombayil50% (2)

- Formulary HI&I Version 5.5Document98 pagesFormulary HI&I Version 5.5Amedeus Eros100% (17)

- Advanced Cleaning Product Formulations VDocument255 pagesAdvanced Cleaning Product Formulations VPeter munodaz100% (1)

- Making Hand Wash Liquid SoapDocument3 pagesMaking Hand Wash Liquid SoapDr Srinivasan Nenmeli -K80% (20)

- Laundry Formulation EbookDocument10 pagesLaundry Formulation EbookOprasi Wisono90% (10)

- Industrial Surfactants: An Industrial GuideFrom EverandIndustrial Surfactants: An Industrial GuideRating: 5 out of 5 stars5/5 (2)

- Air Freshener Gel Formulations - 084Document2 pagesAir Freshener Gel Formulations - 084naingwin1976100% (1)

- CM 1275052218 Formulation GuideDocument12 pagesCM 1275052218 Formulation GuideNemanja Nikolic50% (2)

- Instant Under-Eye Bag Relief With Dynalift ED 0038 ADocument2 pagesInstant Under-Eye Bag Relief With Dynalift ED 0038 Azaryab khanNo ratings yet

- Supreme Clear Sulfate Free Structured Conditioning ShampooDocument1 pageSupreme Clear Sulfate Free Structured Conditioning ShampooDaniel QuinteroNo ratings yet

- H-DC-0019 Natural Dishwashing LiquidDocument2 pagesH-DC-0019 Natural Dishwashing LiquidOsamaAliMoussaNo ratings yet

- Organic Toilet Cleaner Mini KitDocument3 pagesOrganic Toilet Cleaner Mini Kitpratsriv0% (1)

- Green Liquid Laundry Detergent 2x HE C800-157-1Document1 pageGreen Liquid Laundry Detergent 2x HE C800-157-1perrobastardo100% (1)

- Detergent Powder FormulationDocument3 pagesDetergent Powder Formulationsonu100% (1)

- Formulaciones Nourishing Chocolate Milk BodyDocument1 pageFormulaciones Nourishing Chocolate Milk Bodyandres david jimenez acostaNo ratings yet

- H-DC-0023 (AP) Economy Manual Dishwashing LiquidDocument1 pageH-DC-0023 (AP) Economy Manual Dishwashing LiquidShiraz Khan83% (6)

- 40 Plus Homemade Body Butter Recipes: Natural Treatment For Rejuvenating And Hydrating All Skin TypesFrom Everand40 Plus Homemade Body Butter Recipes: Natural Treatment For Rejuvenating And Hydrating All Skin TypesNo ratings yet

- Detergent FormulationDocument4 pagesDetergent FormulationJehonadab Nwankwo67% (3)

- Skin Cleansing Formulation GuideDocument57 pagesSkin Cleansing Formulation GuideFADZAI DUBENo ratings yet

- Acid Thickener Tech DataDocument3 pagesAcid Thickener Tech Dataanneleiaaa62% (21)

- Manufacturing Phenyl DisinfectantDocument6 pagesManufacturing Phenyl DisinfectantShivam Vinoth100% (4)

- Formulation For Detergents and CleanersDocument5 pagesFormulation For Detergents and Cleanersgert128378% (9)

- Chemical Formulation List 2007-2010Document4 pagesChemical Formulation List 2007-2010Onkar Kanda77% (13)

- Household Toilet Bowl Cleaner #1166Document2 pagesHousehold Toilet Bowl Cleaner #1166jerc1324100% (1)

- I I Formularies Hard Surface Cleaning Industrial Metal Cleaners 110-12-009 USDocument8 pagesI I Formularies Hard Surface Cleaning Industrial Metal Cleaners 110-12-009 USbexigaobrother100% (4)

- Skin Effect in Transmission Lines ExplainedDocument13 pagesSkin Effect in Transmission Lines Explainedthilini100% (1)

- Formulation GuidelinesDocument11 pagesFormulation GuidelinesArifin Subijanto91% (11)

- Mild And Foaming Dishwashing LiquidDocument8 pagesMild And Foaming Dishwashing LiquidMichael UrbinaNo ratings yet

- Natural Crystal Clear Deo Spray PPDocument2 pagesNatural Crystal Clear Deo Spray PPMayra PeñaNo ratings yet

- Detergent Cake FormulationDocument8 pagesDetergent Cake FormulationRishabh Garg82% (22)

- Instant Under-Eye Bag Relief With Dynalift ED 0038 ADocument2 pagesInstant Under-Eye Bag Relief With Dynalift ED 0038 Azaryab khanNo ratings yet

- H-DC-0025 (In) Clear Manual Dish GelDocument1 pageH-DC-0025 (In) Clear Manual Dish Gelladyjane99100% (1)

- Liquid Detergents Excerpted From Chemical WeeklyDocument4 pagesLiquid Detergents Excerpted From Chemical WeeklyTanmoy Rahman100% (1)

- Formulation Guide HouseholdDocument19 pagesFormulation Guide HouseholdKhan SajjadNo ratings yet

- KIDDE PQS 2020 - PRE - E - IND - IG - PresentationDocument281 pagesKIDDE PQS 2020 - PRE - E - IND - IG - PresentationfranciscoNo ratings yet

- Pinoychem Chemical Formulation ListDocument4 pagesPinoychem Chemical Formulation ListRodrigo MuñozNo ratings yet

- Antibacterial Liquid Soap F-487 188Document1 pageAntibacterial Liquid Soap F-487 188mndmatt86% (7)

- Development Formulation: Hair Colour Cream With Crodafos HCE C5192Document2 pagesDevelopment Formulation: Hair Colour Cream With Crodafos HCE C5192Antonio Perez Molina100% (1)

- Air Freshener Gel Formulations No 084Document1 pageAir Freshener Gel Formulations No 084Chintan Navin Vora100% (1)

- Finished Wood Cleaner (Formulation #US FC 34)Document1 pageFinished Wood Cleaner (Formulation #US FC 34)nano100% (2)

- Formulating Liquid Laundry Detergents: Technical ArticleDocument4 pagesFormulating Liquid Laundry Detergents: Technical ArticleramzibtrNo ratings yet

- Detergent Formulation IngredientsDocument2 pagesDetergent Formulation IngredientsMuhammad Aasim Hassan100% (2)

- ISP Formulation GuideDocument48 pagesISP Formulation Guidesotitobahal92% (24)

- MIT CORREL HYDRAULICS GEOTECH 2nd TERM SY 2014 2015 Retake KEY PDFDocument10 pagesMIT CORREL HYDRAULICS GEOTECH 2nd TERM SY 2014 2015 Retake KEY PDFNadine PascualNo ratings yet

- Formulating Manual Dish Wash DetergentsDocument4 pagesFormulating Manual Dish Wash Detergentsluchoosorio76% (25)

- Chemical Formulation: An Overview of Surfactant Based Chemical Preparations Used in Everyday LifeFrom EverandChemical Formulation: An Overview of Surfactant Based Chemical Preparations Used in Everyday LifeRating: 4 out of 5 stars4/5 (5)

- Raw Materials Guide for Formulating Detergents and CleanersDocument138 pagesRaw Materials Guide for Formulating Detergents and CleanersOsamaAliMoussa78% (27)

- Soap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantFrom EverandSoap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantRating: 5 out of 5 stars5/5 (2)

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Liquid DetergentDocument6 pagesLiquid DetergentAshu GargNo ratings yet

- Industrial Hard Surface CleanerDocument8 pagesIndustrial Hard Surface CleanerLuis UlakiaNo ratings yet

- Role of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewDocument8 pagesRole of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewYASHICA VAITTIANATHANNo ratings yet

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- Soap-Making Manual A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap Plant.From EverandSoap-Making Manual A Practical Handbook on the Raw Materials, Their Manipulation, Analysis and Control in the Modern Soap Plant.Rating: 4 out of 5 stars4/5 (2)

- Microemulsions Theory and PracticeFrom EverandMicroemulsions Theory and PracticeLeon PrinceRating: 5 out of 5 stars5/5 (1)

- Soap Manufacturing TechnologyFrom EverandSoap Manufacturing TechnologyLuis SpitzRating: 4 out of 5 stars4/5 (6)

- Compact Conductor CalculationDocument3 pagesCompact Conductor CalculationGautama Chandra PradiptaNo ratings yet

- Five Fabric Softener Formulations ComparisonDocument3 pagesFive Fabric Softener Formulations ComparisonGurinder SinghNo ratings yet

- 27 2006 01 Smoothing Potion Leave in Conditioner 02272Document2 pages27 2006 01 Smoothing Potion Leave in Conditioner 02272suniel8080No ratings yet

- 27 1897 01 After Shave Wipe Formulation 00510Document2 pages27 1897 01 After Shave Wipe Formulation 00510Rene HernandezNo ratings yet

- Rejuvenating Peel-Off MaskDocument2 pagesRejuvenating Peel-Off Maskjavanuts idNo ratings yet

- Formula Card - GA - Liquid - Hand - WashDocument2 pagesFormula Card - GA - Liquid - Hand - WashGurinder SinghNo ratings yet

- MWPA300 Mechanical Engineering GuidelinesDocument43 pagesMWPA300 Mechanical Engineering GuidelinesJayden SimNo ratings yet

- DPC DR Moin by Suhan KhalidDocument9 pagesDPC DR Moin by Suhan KhalidRasheed doustamNo ratings yet

- Earth Science: Quarter 2 - Module 11Document24 pagesEarth Science: Quarter 2 - Module 11dayna palaubsanonNo ratings yet

- Coagulation of Natural Rubber Latex with Hydrochloric AcidDocument6 pagesCoagulation of Natural Rubber Latex with Hydrochloric Acidchaminda nayanajithNo ratings yet

- Buthelezi, Olaniran, Pillay. 2009. Turbidity and Microbial Load Removal From River Water Using Bioflocculants From Indigenous Bacteria IDocument7 pagesButhelezi, Olaniran, Pillay. 2009. Turbidity and Microbial Load Removal From River Water Using Bioflocculants From Indigenous Bacteria IAzb 711No ratings yet

- Ion DipoleDocument18 pagesIon DipoleblessyramasamillanoNo ratings yet

- Curriculum Vitae: Dr. Syed Sibte Asghar AbidiDocument5 pagesCurriculum Vitae: Dr. Syed Sibte Asghar AbidiDesh BhaktNo ratings yet

- Bore-log analysis and interpretationDocument6 pagesBore-log analysis and interpretationKaaviyan ThirunyanamNo ratings yet

- Claus Plants Prove FlexibleDocument3 pagesClaus Plants Prove Flexiblebakhtiari_afNo ratings yet

- Newtons Laws With Good PicturesDocument30 pagesNewtons Laws With Good PicturesMohammed RiyazuddinNo ratings yet

- Jan 23 WCH12 SolvedDocument28 pagesJan 23 WCH12 Solvedthe dsNo ratings yet

- 23 - High Temperature Materials - Torralba PDFDocument70 pages23 - High Temperature Materials - Torralba PDFAnish MahajanNo ratings yet

- The Astronet Infraestructure RoadmapDocument178 pagesThe Astronet Infraestructure RoadmapALNo ratings yet

- 11.VIA Group ElementsDocument3 pages11.VIA Group ElementsANIL KumarNo ratings yet

- En 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresDocument26 pagesEn 13237-2003 Terms and Definitions For Equipment and Protective Systems Intended For Use in Potentially Explosive AtmospheresGargiulo AnitaNo ratings yet

- 25) 8 ನೇ ತರಗತಿ ವಿಜ್ಞಾನ ಆಂಗ್ಲ ಮಾ.ಮಾ.ಪ್ರ.ಪ-1Document9 pages25) 8 ನೇ ತರಗತಿ ವಿಜ್ಞಾನ ಆಂಗ್ಲ ಮಾ.ಮಾ.ಪ್ರ.ಪ-1Abhisheck JatNo ratings yet

- Cuison Chapter 2Document41 pagesCuison Chapter 2Reinzo GallegoNo ratings yet

- Discover The Difference Between Glycolysis and Krebs CycleDocument5 pagesDiscover The Difference Between Glycolysis and Krebs Cyclepond_1993No ratings yet

- Storage of Bulk Solids Lec On 23-08-2021Document17 pagesStorage of Bulk Solids Lec On 23-08-2021Subhajit BagNo ratings yet

- The Otto Schmidt's Inter-Stellar Dust TheoremDocument1 pageThe Otto Schmidt's Inter-Stellar Dust TheoremKC CampilanNo ratings yet

- Thin Walled Pressure VesselsDocument20 pagesThin Walled Pressure VesselsGideon ValdellonNo ratings yet

- Soil Erosion in the PhilippinesDocument51 pagesSoil Erosion in the PhilippinesSHARON MANUELNo ratings yet

- Work Power Energy JEE TestDocument6 pagesWork Power Energy JEE TestAman RolandNo ratings yet

- 11962-Encapsulated Citric AcidDocument10 pages11962-Encapsulated Citric AcidantiquekNo ratings yet