Professional Documents

Culture Documents

Work Instruction For Spray Coating

Uploaded by

Krunal JaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction For Spray Coating

Uploaded by

Krunal JaniCopyright:

Available Formats

Samarth Airtech Pvt. Ltd.

Work Instruction for Spray Coating

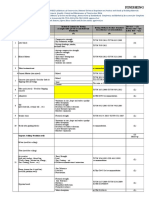

PFC: WI/SC/01 Revision No. 00 Date 01/12/11 Page no.: 1 of 3

Work Instruction for Spray Coating

Prepared by: Top Management Reviewed & Approved by: Top Management Issued by: MR Issued To Controlled Copy No.

Production & QC

1. Select your paint. Oil based enamels are most easily used with a compressed air sprayer, but acrylics and latex paints can be sprayed if they are modified with a suitable conditioner. This will thin the paint so that it will flow through the siphon tube and out the orifice. 2. Prepare the area where you will paint. For "fixed" projects, like the one illustrated here, you will need to protect adjacent surfaces, and make sure you have adequate ventilation. Protect nearby surfaces from "over spray" with masking or painter's tape and painter's paper or newspapers. 3. Prepare the surface to be painted. Grind, brush, or sand off rust and corrosion from metal, removing all oil, dust, or dirt, and make sure it is dry. Wash the surface: for oilbased paints, use mineral spirits; for latex or acrylic paints, use soap and water, rinsing thoroughly. 4. Prime the surface, if required. You can use the sprayer to apply the primer, following the steps below as if it were paint, or it may be applied with a brush or roller, then sanded smooth if needed. 5. Set your paint and thinner on a suitable surface so that spills will not damage anything. Place a drop cloth, sheet plastic, scrap lumber or other material on the ground, floor, or a table for mixing. 6. Turn on the air compressor. You will use some air for priming and testing your sprayer, so let it build up pressure while you get your paint ready. The compressor should have a regulator to allow you to set the pressure for the sprayer correctly, otherwise, fluctuations will occur as the pressure rises and falls while you are spraying.

Samarth Airtech Pvt. Ltd.

Work Instruction for Spray Coating

PFC: WI/SC/01 Revision No. 00 Date 01/12/11 Page no.: 2 of 3

7. Adjust the regulator on the compressor to between 12 and 25 PSI (pounds per square inch), depending on your sprayer. Attach the air hose coupling to the sprayer. Make sure it is tight, and you may wrap the threads with Teflon tape to insure an airtight seal. This does not apply if your sprayer and hose are equipped with quick connect couplings. 8. Pour a small amount of thinner into the paint cup, (the reservoir attached to the bottom of your spray gun). Use just enough to submerge the siphon tube in it. 9. Open the metering valve slightly. This is usually the lower of two screws above the handle (pistol grip) of the sprayer. 10. Mix enough paint to do your project. After opening your can of paint, mix it thoroughly, then pour enough of it to do the job into a separate, clean container. If the paint has been stored for any length of time, it is a good idea to strain it through a paint filter to remove any lumps of hardened paint which may have formed. These lumps can stop up the siphon tube or the metering valve, causing the flow of paint to stop. 11. Thin the paint you have poured with a suitable thinner, to allow it to flow freely through the siphon tube, metering valve (fluid) assembly, and out the nozzle. Different sprayers are calibrated and the orifices are differently sized, but usually the paint should be thinned about 15 to 20% for a good flow. Notice how thin the paint looks when you use an aerosol spray paint and it will give you an idea of what you are looking for. 12. Prime the sprayer. Aim the nozzle into a waste bucket, and squeeze the trigger. It usually takes a few seconds for the sprayer system to prime with liquid, so at first, only air will come out of the nozzle. After a moment, you should get a flow of paint thinner. If no thinner comes out of the nozzle, you may have to disassemble the sprayer to check for stoppages or loose seals in the siphon tube assembly. 13. Empty the spray cup of any remaining thinner. A funnel helps, here, so you can return it to the original container. Mineral spirits and turpentine (two common thinners) are flammable solvents, and should only be stored in their original containers. 14. Fill the paint cup about 2/3 full of paint, and lock it on to the sprayer. Whether the spray cup attaches to the bottom of the sprayer with a clamping assembly and hooks, or is threaded, be sure to attach it securely. You do not want the spray cup to drop off suddenly while in use. 15. Hold the sprayer about 5-10 inches from the surface. Begin moving the spray gun in a side to side, or up and down sweeping motion, parallel to the surface. If you have never used this type of paint applicator before, practice holding and swinging it for a moment, to get a feel for the balance and weight of it. 16. Squeeze the trigger to spray the paint. Keep the sprayer moving whenever the trigger is squeezed, to avoid drips and runs caused by over application. 17. Overlap each pass slightly, so the "feathered" edge at the edge of the spray pattern gets an equal coverage of paint. Watch for drips and runs, moving fast enough to keep the paint from getting too thick as you spray.

Samarth Airtech Pvt. Ltd.

Work Instruction for Spray Coating

PFC: WI/SC/01 Revision No. 00 Date 01/12/11 Page no.: 3 of 3

18. Refill the paint cup as needed, until the project is done. Do not allow the sprayer to set with paint in it. If you need a break, remove the cup, and spray some thinner through the sprayer before leaving it unused. 19. Clean the sprayer by pouring out the unused paint. If you have a significant amount of paint left, you can return it to the original can, but remember the amount you return to the can has already been thinned, so the next time you use it, you may need to adjust the amount of thinner used. While you have the spray cup removed, rinse it with thinner, along with the siphon tube, and wipe any excess paint off of and out of it. Next, fill the spray cup about 1/4 full paint thinner, slosh it around in the spray cup to rinse the inside, then spray it through the sprayer until it comes out clear. If there is too much paint left in the cup or the spray assembly, you may have to repeat this step 2 or more times. 20. Allow the paint to dry, then re coat if desired. For most paints, a good, even "wet" coat is sufficient, but a second coat may give a more durable finish. Sanding between coats is recommended for varnishes, polyurethane finishes, and other glossy paints, to improve the bond between the coats. 21. Remove all masking tape and paper as soon as the final coat is dry. Leaving the tape on the surface for an extended period will allow the adhesive to "set", making it difficult to remove.

You might also like

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- Wi (2) Powder CoatingDocument9 pagesWi (2) Powder CoatingMalathi ISONo ratings yet

- Work Instruction - Plate CuttingDocument11 pagesWork Instruction - Plate Cuttingbalakumar rajaram0% (1)

- Work Instruction Manual: Document ControlDocument4 pagesWork Instruction Manual: Document ControlAriel Ortiz100% (1)

- HF MG.26.02CRF Change Request FormDocument4 pagesHF MG.26.02CRF Change Request FormGeovanny Hernández0% (1)

- Work Instruction - Loading-TamilDocument28 pagesWork Instruction - Loading-Tamilshanmugam8678% (23)

- Painting RecordDocument1 pagePainting RecordHimawan SetyarsoNo ratings yet

- Inprocess Inspection ReportDocument8 pagesInprocess Inspection Reportpardeep kumarNo ratings yet

- Finishing Material-Product Testing-SVN - Rev1Document15 pagesFinishing Material-Product Testing-SVN - Rev1HNmaichoiNo ratings yet

- All Work InstructionsDocument7 pagesAll Work InstructionsAmine Chahi100% (1)

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- Policy and Procedure of Employee SatisfactionDocument8 pagesPolicy and Procedure of Employee SatisfactionAbdur Rashid KhanNo ratings yet

- Procedure Flow Chart For Production PlanningDocument1 pageProcedure Flow Chart For Production PlanningSachin Kumbhar100% (1)

- Process Flow Chart - Incoming TestingDocument1 pageProcess Flow Chart - Incoming Testingraza239No ratings yet

- Testing and Commissioning Certificate On Lift Installation: Details of ProjectDocument32 pagesTesting and Commissioning Certificate On Lift Installation: Details of ProjectLo Chun KitNo ratings yet

- Qa Inspection and Test PlanDocument1 pageQa Inspection and Test Planit4scribdNo ratings yet

- Use This As Reference For Painting Process It May Be Similar To YoursDocument7 pagesUse This As Reference For Painting Process It May Be Similar To Yoursabdelnasser hasanNo ratings yet

- Dispatch of Goods and Receipt of Materials Audit ChecklistDocument3 pagesDispatch of Goods and Receipt of Materials Audit Checklistandruta197850% (2)

- AE-QA-02 - First Piece Inspection ReportDocument1 pageAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanNo ratings yet

- F QA 03 In-Process Inspection ReportDocument2 pagesF QA 03 In-Process Inspection ReportVikas Kashyap100% (1)

- Inspection Format Sheet MetalDocument3 pagesInspection Format Sheet Metalrockonarun100% (1)

- Display of Information Related To Air, Water and Hazardous Waste GenerationDocument2 pagesDisplay of Information Related To Air, Water and Hazardous Waste GenerationRaajha Munibathiran67% (3)

- Record of Staff Toolbox Meeting TemplateDocument2 pagesRecord of Staff Toolbox Meeting TemplatemetaNo ratings yet

- Ladders Inspection Register: Location: TSM ARABIADocument4 pagesLadders Inspection Register: Location: TSM ARABIAmuhammad imtiazNo ratings yet

- Control Plan PQCT TableII PDFDocument1 pageControl Plan PQCT TableII PDFRehman LatifNo ratings yet

- Sample Drawing Master ListDocument10 pagesSample Drawing Master ListNik Mohd BazliNo ratings yet

- Inprocess Inspection Report: Setup ApprovalDocument1 pageInprocess Inspection Report: Setup ApprovalKarthi Thiyagarajan100% (1)

- Environmental ObjectivesDocument4 pagesEnvironmental ObjectivesTalha LatifNo ratings yet

- Rework Record For Heat Treated Parts: Original Production DetailsDocument1 pageRework Record For Heat Treated Parts: Original Production DetailsBalram Ji100% (2)

- Work Instruction SampleDocument3 pagesWork Instruction SampleSundarapandiyan Sundaramoorthy89% (9)

- Work Instruction For Surface Finishing Lab (Paint Shop)Document7 pagesWork Instruction For Surface Finishing Lab (Paint Shop)DINESHCHOUDHARY88No ratings yet

- Poshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelDocument2 pagesPoshs Metal Industries PVT - LTD: SR - No. Inspection Area Remark Required Lux Level (Min) Actual Lux LevelSafety Dept100% (1)

- Checklist For Generator SetDocument1 pageChecklist For Generator SetKrsna ManahanNo ratings yet

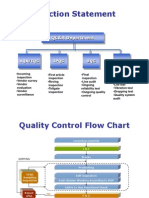

- Quality Control Flow ChartDocument3 pagesQuality Control Flow Chartlyouf0% (1)

- Real-Time Stability Study Report of OPI 2000 Product: Purpose Materials: Cut-Off: OPI2000Document6 pagesReal-Time Stability Study Report of OPI 2000 Product: Purpose Materials: Cut-Off: OPI2000jefferson rivera naresNo ratings yet

- Height Gauge (QA-SOP-02)Document1 pageHeight Gauge (QA-SOP-02)Rishi Gautam100% (1)

- Tcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaDocument20 pagesTcsi Quality Plan: One Ayala Avenue Project Makati City, Metro ManilaEugene Santiago PadillaNo ratings yet

- Supplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberDocument1 pageSupplier Deviation Request Form N°:: Part Description Part No: Revision PO Number57641No ratings yet

- NCR Reported by NCR Issued To: Non-Conformance ReportDocument2 pagesNCR Reported by NCR Issued To: Non-Conformance ReportRahul Sundar100% (1)

- QP 83001 Rev 09 Non-Conforming Material Control ProcedureDocument6 pagesQP 83001 Rev 09 Non-Conforming Material Control ProcedureImam MansyurNo ratings yet

- Format Punchlist PDFDocument27 pagesFormat Punchlist PDFDuan Tokcer100% (2)

- QAP MHFrameCoversDocument4 pagesQAP MHFrameCoversAnonymous ciKyr0tNo ratings yet

- Work Instruction - Loading-TamilDocument28 pagesWork Instruction - Loading-Tamilshanmugam86100% (2)

- DMN-8D Report: Target Date: Actual DateDocument1 pageDMN-8D Report: Target Date: Actual DateFudu KhichNo ratings yet

- Corrective Action Report: Department: Marketing & Sale Auditor: Ramki Auditee: JohnDocument1 pageCorrective Action Report: Department: Marketing & Sale Auditor: Ramki Auditee: Johnwinston11No ratings yet

- Industrial House Keeping and 5S Technique HINDIDocument79 pagesIndustrial House Keeping and 5S Technique HINDIAnkur DhirNo ratings yet

- Davies 5 700 Liquid Tile Primer PDFDocument1 pageDavies 5 700 Liquid Tile Primer PDFKissa DolautaNo ratings yet

- QC - Form-002 Form Master List of (Document or Record)Document1 pageQC - Form-002 Form Master List of (Document or Record)Fendi50% (2)

- Al PSW FormatDocument2 pagesAl PSW Formatabhayjha1988No ratings yet

- Non Conformance ReportDocument2 pagesNon Conformance ReportJJMSPM94% (16)

- Guideline On Use of Ready Mix ConcreteDocument2 pagesGuideline On Use of Ready Mix Concretebill_lee_242No ratings yet

- Non Conformance Control ProcedureDocument12 pagesNon Conformance Control ProcedurePanneer Bala100% (9)

- QMP-02 - Control of RecordDocument5 pagesQMP-02 - Control of Recordom cncNo ratings yet

- Dock Audit Report-16Document2 pagesDock Audit Report-16Vikas Kashyap100% (1)

- Roller Shutter Inspection ChecklistDocument6 pagesRoller Shutter Inspection ChecklistMin Thein HtutNo ratings yet

- Top 10 Airbrush Troubleshooting TipsDocument3 pagesTop 10 Airbrush Troubleshooting Tipscamilledungs18No ratings yet

- Earlex Hv1900 ManualDocument12 pagesEarlex Hv1900 ManualPaul CollinsNo ratings yet

- Refillable Cartridge Instructions For Epson PXXXX x9xx Universal CartridgesDocument6 pagesRefillable Cartridge Instructions For Epson PXXXX x9xx Universal CartridgesIon IonutNo ratings yet

- Application-0 1603076965Document9 pagesApplication-0 1603076965Ahmed AllamNo ratings yet

- AEROPRO R500 InstructionDocument7 pagesAEROPRO R500 InstructionAlejandro EnriquezNo ratings yet

- ISO 9001 - Awareness TrainingDocument27 pagesISO 9001 - Awareness TrainingKrunal Jani67% (3)

- Shree Shakti Engineering (G) Pvt. Ltd.Document16 pagesShree Shakti Engineering (G) Pvt. Ltd.Krunal JaniNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Idp Application FormDocument2 pagesIdp Application FormKrunal JaniNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- (Private and Confidential - For Office Use Only) : Educational Background With Aggregate ScoreDocument7 pages(Private and Confidential - For Office Use Only) : Educational Background With Aggregate ScoreKrunal JaniNo ratings yet

- Concure WB309: Water Based Concrete Curing CompoundDocument2 pagesConcure WB309: Water Based Concrete Curing CompoundMaki Salim HussainNo ratings yet

- 39nx 2pdDocument808 pages39nx 2pdWalter J Naspirán Castañeda100% (1)

- Liquid Penetrant Testing: Standard Practice ForDocument12 pagesLiquid Penetrant Testing: Standard Practice ForRuiNo ratings yet

- Macropoxy C400V3Document2 pagesMacropoxy C400V3nellyNo ratings yet

- Installation Guidelines - Steam Conditioning ValvesDocument36 pagesInstallation Guidelines - Steam Conditioning ValvesMikeNo ratings yet

- Silicon Micro Venturi Nozzles For Cost-EfficientDocument10 pagesSilicon Micro Venturi Nozzles For Cost-EfficientAnnappa N ANo ratings yet

- Chartek 8 Application GuidelineDocument2 pagesChartek 8 Application GuidelineAhmed IbrahimNo ratings yet

- Dehydration of MilkDocument23 pagesDehydration of MilkMohammad Ashraf Paul50% (2)

- Product Line GuideDocument2 pagesProduct Line Guidenicolas yoris marcoglieseNo ratings yet

- Film Forming Spray A Comprehensive ReviewDocument9 pagesFilm Forming Spray A Comprehensive ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Flow-Induced Fatigue Failure in Tubular Heat ExchangersDocument7 pagesFlow-Induced Fatigue Failure in Tubular Heat ExchangersVelpandian ManiNo ratings yet

- Spray Nozzle CharacteristicsDocument5 pagesSpray Nozzle CharacteristicssyifaNo ratings yet

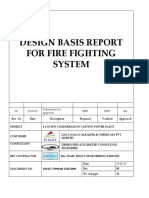

- DBR Fire Fighting System 12.08.2019Document16 pagesDBR Fire Fighting System 12.08.2019raaj bharathNo ratings yet

- BT 0832 Rethane FWP SB 672 - InglêsDocument2 pagesBT 0832 Rethane FWP SB 672 - InglêsProtection Representacoes Valter HugoNo ratings yet

- Plant Protection EquipmentDocument14 pagesPlant Protection EquipmentLUVAI KIOKO100% (1)

- Sampling For Pesticide Residue AnalysisDocument23 pagesSampling For Pesticide Residue AnalysisAle OosaNo ratings yet

- TDS OF H-806 Agriculture Super SpreaderDocument4 pagesTDS OF H-806 Agriculture Super SpreaderAda FuNo ratings yet

- Jotun Jotamastic Plus - Aluminium Application GuideDocument9 pagesJotun Jotamastic Plus - Aluminium Application Guidehendro.saranghaeNo ratings yet

- AP-42 Vol 2Document44 pagesAP-42 Vol 2Melanie AlejandraNo ratings yet

- School of Maritime Studies Vels University Thalambur: Fire Nozzle AimDocument2 pagesSchool of Maritime Studies Vels University Thalambur: Fire Nozzle AimAayush AgrawalNo ratings yet

- Spray Technology For Farm Mechanization CourseDocument6 pagesSpray Technology For Farm Mechanization CourseEmilna SuzanneNo ratings yet

- Fastfill Catalogue 2016 - 11.10.16 Technical CatalogDocument24 pagesFastfill Catalogue 2016 - 11.10.16 Technical CatalogRohmanNo ratings yet

- Cat.51 MetricDocument164 pagesCat.51 MetricAndy PaladeNo ratings yet

- Poxy Glasurit 285-730Document3 pagesPoxy Glasurit 285-730Jumadi AlkutsNo ratings yet

- Nozzle Catalog PDFDocument62 pagesNozzle Catalog PDFnetwork49No ratings yet

- Valmet Spray PipeDocument1 pageValmet Spray PipenotengofffNo ratings yet

- Heimbach - Keeping Formingfabrics CleanDocument4 pagesHeimbach - Keeping Formingfabrics CleanTunç TürkNo ratings yet

- Lecture II-Agricultural Operations and MachineryDocument131 pagesLecture II-Agricultural Operations and MachineryChileshe SimonNo ratings yet

- Aircraft Washing DesignDocument6 pagesAircraft Washing DesignSyazwan KhairulNo ratings yet

- Forberg MixerDocument8 pagesForberg MixerAli AmjadNo ratings yet