Professional Documents

Culture Documents

HF MG.26.02CRF Change Request Form

Uploaded by

Geovanny HernándezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HF MG.26.02CRF Change Request Form

Uploaded by

Geovanny HernándezCopyright:

Available Formats

CHANGE REQUEST FORM

Design Change or Manufacturing Instruction Change

Supplier Information

Information

Originator/Date Existing D/C or M/I Number

Supplier Issuing New D/C or M/I Number

Supplier Approval/Date 1 Design Change

Proposed MP Ship Date 2 Die/Mold Change

HFI Plant Affected 3 Inspection Method Change

X All Applicable

Part Information 4 Jig/Tool Change

Component Part Name 5 Machine Change

Component Part Number 6 Manufacturing Method Change

Quality Documents Revised (circle one or more) 7 Manufacturing Process Order Change

Control Plan FMEA Quality Standard 8 Material Change

Process Flow Chart Operation Standard 9 New Supplier

Current (show sketch or picture) Proposed Change (show sketch or picture)

Supplier to ensure this section is complete

Change is NOT to be shipped for mass production until the supplier has received an APPROVED PSW

X All Applicable

HFI PPAP Requirements

Design Records and IMDS Control Plan Appearance Approval Report

Engineering Change documents MSA Studies Sample Parts

Customer Engineering Approval Dimensional Results Master Sample

Design FMEA Material / Performance Test results Checking Aids

Process Flow Diagram Initial Process Studies Customer Specific Requirements

HFI use only

Process FMEA Qualified Laboratory Documentation Part Submission Warrant (PSW)

Additional or other requirements

HFI REA# (list all that apply)

Quality Approval of Requirements Date

HFI Distribution List

Facility Supplier QE Facility CSR/Product Planner If change affects more than 1 HFI location, also cc:

Facility Quality Manager Corporate Supplier Development Specialist

Facility Buyer Corporate Purchasing Manager

Facility Materials Manager Corporate Planning Manager

Facility Engineering Manager Corporate Quality Manager

1. When submitting this request the Supplier must include a quality confirmation plan and a schedule. Request MUST be a minimum of 30 days prior to change.

2. Any parts received by HFI that require PPAP approval but have not been approved, may be judged as non-conforming and may be charged back to the supplier. IPP process must

be followed after PPAP approval.

Document Number: HF MG.26.02 1/1 Effective Date: 6/15/11

CHANGE REQUEST FORM

Design Change or Manufacturing Instruction Change

Supplier Information

Information

Originator/Date Existing D/C or M/I Number

Supplier Issuing New D/C or M/I Number

Supplier Approval/Date 1 Design Change

Proposed MP Ship Date 2 Die/Mold Change

HFI Plant Affected 3 Inspection Method Change

X All Applicable

Part Information 4 Jig/Tool Change

Component Part Name 5 Machine Change

Component Part Number 6 Manufacturing Method Change

Quality Documents Revised (circle one or more) 7 Manufacturing Process Order Change

Control Plan FMEA Quality Standard 8 Material Change

Process Flow Chart Operation Standard 9 New Supplier

Current (show sketch or picture) Proposed Change (show sketch or picture)

Supplier to ensure this section is complete

Items in GREEN to be

filled out by Supplier

Change is NOT to be shipped for mass production until the supplier has received an APPROVED PSW

X All Applicable

HFI PPAP Requirements

Design Records and IMDS Control Plan Appearance Approval Report

Engineering Change documents MSA Studies Sample Parts

Customer Engineering Approval Dimensional Results Master Sample

Design FMEA Material / Performance Test results Checking Aids

Process Flow Diagram Initial Process Studies Customer Specific Requirements

HFI use only

Process FMEA Qualified Laboratory Documentation Part Submission Warrant (PSW)

Additional or other requirements

Items in BLUE to be filled

out by HFI Quality

HFI REA# (list all that apply)

Quality Approval of Requirements Date

HFI Distribution List

Facility Supplier QE Facility CSR/Product Planner If change affects more than 1 HFI location, also cc:

Facility Quality Manager Corporate Supplier Development Specialist

Facility Buyer Corporate Purchasing Manager

Facility Materials Manager Corporate Planning Manager

Facility Engineering Manager Corporate Quality Manager

1. When submitting this request the Supplier must include a quality confirmation plan and a schedule. Request MUST be a minimum of 30 days prior to change.

2. Any parts received by HFI that require PPAP approval but have not been approved, may be judged as non-conforming and may be charged back to the supplier. IPP process must

be followed after PPAP approval.

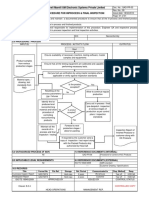

MIN 30 DAYS IN MIN 30 DAYS IN ADVANCE OF

ADVANCE OF CHANGE MATERIAL BUYER

-ensure CRF completed, CHANGE

3rd party vendor completes forward to Quality Quality dept of HFI supply location completes

green section of form; attaches green section of form; attaches implementation

implementation plan plan

SQE enters REA into

database (or confirms #

HFI SQE if already entered)

-reviews CRF -attach CRF

- determines PPAP submission - identify if customer

requirements and impact on customer PPAP approval required

Facility Quality HFI ENGINEERING

Manager signs - follow engineering change procedure

approval - ensure customer PPAP submission

included on checklist if required

SUPPLIER HFI SQE

SUBMITS PPAP REQUIREMENTS PRIOR - returns CRF to supplier contact

TO CHANGE FOR APPROVAL - sends CRF to HFI distribution list on

form based on type of change

Return of approved

PSW may be delayed

HFI SQE until customer approval

APPROVES PSW received

SUPPLIER IPP'S CHANGE TO HFI

Document Number: HF MG.26.02 1/1 Effective Date: 6/15/11

MIN 30 DAYS IN MIN 30 DAYS IN ADVANCE OF

ADVANCE OF CHANGE MATERIAL BUYER

-ensure CRF completed, CHANGE

3rd party vendor completes forward to Quality Quality dept of HFI supply location completes

green section of form; attaches green section of form; attaches implementation

implementation plan plan

SQE enters REA into

database (or confirms #

HFI SQE if already entered)

-reviews CRF -attach CRF

- determines PPAP submission - identify if customer

requirements and impact on customer PPAP approval required

Facility Quality HFI ENGINEERING

Manager signs - follow engineering change procedure

approval - ensure customer PPAP submission

included on checklist if required

SUPPLIER HFI SQE

SUBMITS PPAP REQUIREMENTS PRIOR - returns CRF to supplier contact

TO CHANGE FOR APPROVAL - sends CRF to HFI distribution list on

form based on type of change

Return of approved

PSW may be delayed

HFI SQE until customer approval

APPROVES PSW received

SUPPLIER IPP'S CHANGE TO HFI

Document Number: HF MG.26.02 1/1 Effective Date: 6/15/11

Instructions for Completing Change request Form (CRF)

Item Explanation

Number is to be issued by HFI when supplier submits CRF. REA # (Request for Engineering Approval) is assigned from the REA

1

REA # database.

2

Date Date that CRF was submitted to HFI

3

Supplier Supplier submitting CRF

4 Originator Contact person at supplier

5

Proposed MP Ship Date Indicate when the proposed change will take effect at mass production

6 HFI Plan Affected Which HFI Plant will the proposed change affect? (Alabama, Columbus, Monclova, Obregon)

7

Existing D/C or M/I Number Indicate current design change number or manufacturing instruction number

8

New D/C or M/I Number Indicate new design change number or manufacturing instruction number

9

Component Part Name Name of component

10

Component Part Number HFI part number

11

Quality Documents Revised Indicate which documents are being revised to facilitate the change

12

Type of Change Indicate the type of change being made

13

Current Describe the current process, dimensions or attributes of the product. Include picture or sketch.

14

Proposed Change Describe the change to the process, dimensions or attributes of the product. Include picture or sketch.

HFI will fill out this section and send back to the supplier indicating PPAP level expected from the supplier before new parts or

15

PPAP Requirements process is approved for mass production

16

Additional/Other Requirements HFI will fill out this section and indicate any additional or other requirements needed

17

Quality Approval of Requirements HFI Quality Dept for location receiving changed product signs approval of requirements

Document Number: HF MG.26.02 1/1 Effective Date: 6/15/11

You might also like

- 4M Change RequestDocument5 pages4M Change RequestNJMU LAB67% (3)

- Engineering Change / Process Change Request Form: MDT ApprovalDocument4 pagesEngineering Change / Process Change Request Form: MDT ApprovalRaja Durai100% (2)

- Manufacturing Process Audit ScorecardDocument1 pageManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- Engineering Change NoticeDocument4 pagesEngineering Change NoticeLooi Kok HuaNo ratings yet

- Hyundai Transys Lear S/Cover OTR Packing ChangeDocument2 pagesHyundai Transys Lear S/Cover OTR Packing ChangeManikandanNo ratings yet

- Engineering Change Notice for Supersonic TurnersDocument1 pageEngineering Change Notice for Supersonic TurnersVIBHORNo ratings yet

- Change Management Matrix for Vendor Updates in May 2022Document1 pageChange Management Matrix for Vendor Updates in May 2022nitin rathoreNo ratings yet

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- NC Closure 5 Why AnalysiDocument26 pagesNC Closure 5 Why AnalysiKaran MalhiNo ratings yet

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- Minutes of MRM: STANDARD: IATF 16949: 2016Document7 pagesMinutes of MRM: STANDARD: IATF 16949: 2016Raja Durai100% (1)

- Format 11 - Appearance Approval ReportDocument1 pageFormat 11 - Appearance Approval ReportvijayNo ratings yet

- APQP Flow Chart Sample 2 Rev ADocument9 pagesAPQP Flow Chart Sample 2 Rev ALuis AlejandroNo ratings yet

- Form04 - External Master List of DocumentsDocument1 pageForm04 - External Master List of DocumentsAna Hidayah SyuhadaNo ratings yet

- Work Instruction - Loading-TamilDocument28 pagesWork Instruction - Loading-Tamilshanmugam8678% (23)

- Injection Molding SOP for Mini-Jector #55.1 MachineDocument12 pagesInjection Molding SOP for Mini-Jector #55.1 MachineYusuf SethNo ratings yet

- Iso IATF 16949 Upgrade Planner and Delta ChecklistDocument14 pagesIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- Supplier Deviation Request FormDocument1 pageSupplier Deviation Request Form57641No ratings yet

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaNo ratings yet

- Inspection standards for foam packing partsDocument9 pagesInspection standards for foam packing partsBalvinder SinghNo ratings yet

- Internal Audit Checksheet ReviewDocument32 pagesInternal Audit Checksheet ReviewRambir KaushikNo ratings yet

- Manufacturing Process Audit Checklist: Reference DocumentsDocument4 pagesManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Corrective Preventive Action FormDocument2 pagesCorrective Preventive Action FormSyed Mujtaba Ali BukhariNo ratings yet

- Checking Aids Format for Supplier AuditsDocument3 pagesChecking Aids Format for Supplier Auditsdaniel_sasikumarNo ratings yet

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- MRM FormatDocument3 pagesMRM FormatPk NimiwalNo ratings yet

- Guidelines Receiving MaterialsDocument3 pagesGuidelines Receiving MaterialsAman KatiyarNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements MatrixEr Sharan JubreNo ratings yet

- Optimize Company Control PlanDocument6 pagesOptimize Company Control Planazadsingh1No ratings yet

- Product Non Conformance ReportDocument2 pagesProduct Non Conformance ReportAlaa100% (1)

- Sr. No. Requirements: Ppap Check ListDocument3 pagesSr. No. Requirements: Ppap Check Listkamlesh kuchekarNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- Sop-Special Characteristics IdentificationDocument3 pagesSop-Special Characteristics IdentificationSaravana kumar NagarajanNo ratings yet

- CAR ReportDocument2 pagesCAR ReportConfluenceNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Al PSW FormatDocument2 pagesAl PSW Formatabhayjha1988No ratings yet

- F-01 QA03 Daily Rejection Analysis Report (Pen Clip)Document1 pageF-01 QA03 Daily Rejection Analysis Report (Pen Clip)Rohtash fastner100% (1)

- Control of Nonconforming Output ProcedureDocument4 pagesControl of Nonconforming Output Procedureandi wahyudin50% (2)

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Plating FMEADocument1 pagePlating FMEAshiv jangale80% (5)

- Molding condition sheet settingsDocument1 pageMolding condition sheet settingsNur AmiraNo ratings yet

- 4M Change Procedure - PED 02Document2 pages4M Change Procedure - PED 02sathyabalaraman87% (23)

- Procedure For in Coming InspectionDocument12 pagesProcedure For in Coming InspectionRohit Attri100% (1)

- 4M Change Management For Supplier - TennecoDocument1 page4M Change Management For Supplier - TennecoOBSC PerfectionNo ratings yet

- Recall Log Appendix-ADocument1 pageRecall Log Appendix-APharmacistNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Form IA-010NC (Audit Notification Letter) (3!28!2012)Document1 pageForm IA-010NC (Audit Notification Letter) (3!28!2012)granburyjohnstevensNo ratings yet

- Supplier Deviation Request FormDocument1 pageSupplier Deviation Request FormBESNo ratings yet

- Customer Specific Requirement Check ListDocument2 pagesCustomer Specific Requirement Check ListMuthu100% (2)

- Apqp - DR SHFTDocument60 pagesApqp - DR SHFTrajesh5000100% (2)

- Critical quality control sheetDocument22 pagesCritical quality control sheetazadsingh1No ratings yet

- Capacity VerificationDocument4 pagesCapacity VerificationLucinei SantosNo ratings yet

- CRF change request formDocument3 pagesCRF change request formswaran autoqaNo ratings yet

- Supplier Change Request (SCR) : Approved PSWDocument3 pagesSupplier Change Request (SCR) : Approved PSWswaran autoqaNo ratings yet

- Sop For Change ManagementDocument1 pageSop For Change ManagementGaurav Wadhwa0% (1)

- GDC QF 003 - Allegion PPAP Workbook: Instructions: Fill Out Requested Information in TheDocument31 pagesGDC QF 003 - Allegion PPAP Workbook: Instructions: Fill Out Requested Information in TheAbhijit shindeNo ratings yet

- Process Change Note DocumentationDocument1 pageProcess Change Note DocumentationSUBODHHNo ratings yet

- Change Control Management Matrix For Vendors (Vendor Name) Report FormatDocument6 pagesChange Control Management Matrix For Vendors (Vendor Name) Report FormatVaruNo ratings yet

- Cost Model For Data Management Center (DMC) Main MenuDocument63 pagesCost Model For Data Management Center (DMC) Main MenuGeovanny Hernández0% (1)

- Green: Input Data For Cells OnlyDocument2 pagesGreen: Input Data For Cells OnlyUtkarsh SinhaNo ratings yet

- Cost-of-Poor-Quality Lecture 2017 June.pDocument27 pagesCost-of-Poor-Quality Lecture 2017 June.pGeovanny HernándezNo ratings yet

- Turnover Cost Calculation: Essential DataDocument4 pagesTurnover Cost Calculation: Essential DataGeovanny HernándezNo ratings yet

- Implementation of Statistical Process Control (SPC) in The Sewing Section of Garment Industry For Quality ImprovementDocument13 pagesImplementation of Statistical Process Control (SPC) in The Sewing Section of Garment Industry For Quality ImprovementRafael A. Matos MéndezNo ratings yet

- Implementation of Statistical Process Control (SPC) in The Sewing Section of Garment Industry For Quality ImprovementDocument13 pagesImplementation of Statistical Process Control (SPC) in The Sewing Section of Garment Industry For Quality ImprovementRafael A. Matos MéndezNo ratings yet

- Astm D792Document6 pagesAstm D792Aabraham Samraj Ponmani100% (1)

- Philips-Sector LightingDocument96 pagesPhilips-Sector LightingGeovanny HernándezNo ratings yet

- Part Process M FG ChangeDocument2 pagesPart Process M FG ChangeGeovanny HernándezNo ratings yet

- Corp Sqadoc 004Document84 pagesCorp Sqadoc 004Geovanny HernándezNo ratings yet

- Ask For Banking Information SupplierDocument1 pageAsk For Banking Information SupplierGeovanny HernándezNo ratings yet

- HFM-C 007Document8 pagesHFM-C 007Geovanny HernándezNo ratings yet

- Green: Input Data For Cells OnlyDocument2 pagesGreen: Input Data For Cells OnlyUtkarsh SinhaNo ratings yet

- Part Submission ChecklistDocument8 pagesPart Submission ChecklistGeovanny HernándezNo ratings yet

- Control Plan: Prototype Pre-Launch ProductionDocument1 pageControl Plan: Prototype Pre-Launch ProductionGeovanny HernándezNo ratings yet

- PPAP Review ChecklistDocument3 pagesPPAP Review ChecklistGeovanny HernándezNo ratings yet

- Bulk Materials Checklist Project RequirementsDocument1 pageBulk Materials Checklist Project RequirementsGeovanny HernándezNo ratings yet

- AIAG Component PPAP Forms: Important NoteDocument21 pagesAIAG Component PPAP Forms: Important NoteMarko OrdazNo ratings yet

- 8DDocument3 pages8DOuardi MohamedNo ratings yet

- Fall Protection GuidelineDocument93 pagesFall Protection Guidelinektz10No ratings yet

- Article Analysis Review - Research Methods - AmatondingDocument2 pagesArticle Analysis Review - Research Methods - AmatondingAMR-BIN OMAR AMATONDINGNo ratings yet

- Astm F1976 - 99Document5 pagesAstm F1976 - 99Miley LeNo ratings yet

- Numerical Method For Engineers-Chapter 21Document17 pagesNumerical Method For Engineers-Chapter 21Mrbudakbaek100% (5)

- A Theory of KnowledgeDocument16 pagesA Theory of KnowledgekemmerichNo ratings yet

- Role of Advertising in FMCG SectorDocument81 pagesRole of Advertising in FMCG SectorSami ZamaNo ratings yet

- Ayuda Swordfish CompilerDocument227 pagesAyuda Swordfish Compilerafgr1990No ratings yet

- Integration of A Radiation Sensor With A Mobile Robot Under ROSDocument17 pagesIntegration of A Radiation Sensor With A Mobile Robot Under ROSEdmund LeongNo ratings yet

- Csi Col ManualDocument119 pagesCsi Col ManualSunita ChaurasiaNo ratings yet

- Rizal Life, Works & Writings: ScoreDocument2 pagesRizal Life, Works & Writings: ScoresharjaNo ratings yet

- Context Analysis and Source EvaluationDocument97 pagesContext Analysis and Source EvaluationAnali BarbonNo ratings yet

- Aristotle's View of Substance as FormDocument4 pagesAristotle's View of Substance as FormYaniv AlgrablyNo ratings yet

- Daly-Movement Analysis RDocument14 pagesDaly-Movement Analysis RGeorge BaciuNo ratings yet

- Critical Appraisal For Speech and Language Therapists: Single Subject DesignsDocument5 pagesCritical Appraisal For Speech and Language Therapists: Single Subject DesignsSpeech & Language Therapy in Practice100% (1)

- Right brain left brain harmony Dieter RamsDocument31 pagesRight brain left brain harmony Dieter RamsAhmad Hafiz QifliNo ratings yet

- Belajar AFL Yuuk..Document46 pagesBelajar AFL Yuuk..Nyamo Suendro100% (1)

- Tekla OperatorsDocument26 pagesTekla OperatorsGaurav MevadaNo ratings yet

- The Power Reiki SymbolDocument3 pagesThe Power Reiki SymbolSeema QureshiNo ratings yet

- Ways to Earn Money LessonDocument3 pagesWays to Earn Money LessonSyarifahSyarinaSheikhKamaruzamanNo ratings yet

- Aristotle's Physics (Barnes)Document187 pagesAristotle's Physics (Barnes)Carlos CortésNo ratings yet

- SS RA - 010 Lean Concrete Pouring 1Document8 pagesSS RA - 010 Lean Concrete Pouring 1Sn AhsanNo ratings yet

- Chapter 16 (Philoid-In)Document19 pagesChapter 16 (Philoid-In)Ram KrishnaNo ratings yet

- Creating and Maintaining An Effective Filling Record System - 9-10 November, 2017Document1 pageCreating and Maintaining An Effective Filling Record System - 9-10 November, 2017Muhamad Fadli HarunNo ratings yet

- A Study On Employee Retention StrategiesDocument2 pagesA Study On Employee Retention StrategiesRajeshApexNo ratings yet

- The Making of A Modern Filipino HouseDocument16 pagesThe Making of A Modern Filipino HouseIvy Joy CamposNo ratings yet

- JohannaMarshaS CV2019Document1 pageJohannaMarshaS CV2019Anonymous A6EjGeNo ratings yet

- Fom5 Tif05Document30 pagesFom5 Tif05GeorgeAru100% (1)

- Feap Element LibraryDocument6 pagesFeap Element LibrarySnaga VjereNo ratings yet

- ETECH 223syllabusDocument4 pagesETECH 223syllabusferdie marcosNo ratings yet

- Experiment 6 Forces in A Roof TrussDocument5 pagesExperiment 6 Forces in A Roof Trusshafiey89No ratings yet