100% found this document useful (1 vote)

3K views12 pagesProcedure For in Coming Inspection

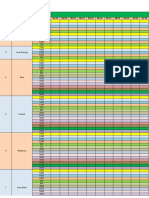

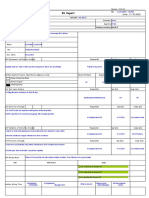

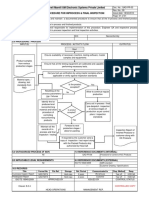

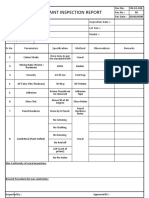

This procedure describes the incoming inspection process for all products received from suppliers. The quality inspector verifies documents and tests the material using measuring instruments and standards according to the control plan. Non-conforming materials are rejected, reworked if possible, or returned to the supplier. Conforming materials are added to storage. Records of the inspection results are maintained.

Uploaded by

Rohit AttriCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

Topics covered

- Rework Process,

- Inspection Protocols,

- Supplier Debits,

- Incoming Material,

- Material Tracking,

- Document Verification,

- Inspection Workflow,

- Process KPIs,

- Material Compliance,

- Material Verification

100% found this document useful (1 vote)

3K views12 pagesProcedure For in Coming Inspection

This procedure describes the incoming inspection process for all products received from suppliers. The quality inspector verifies documents and tests the material using measuring instruments and standards according to the control plan. Non-conforming materials are rejected, reworked if possible, or returned to the supplier. Conforming materials are added to storage. Records of the inspection results are maintained.

Uploaded by

Rohit AttriCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

Topics covered

- Rework Process,

- Inspection Protocols,

- Supplier Debits,

- Incoming Material,

- Material Tracking,

- Document Verification,

- Inspection Workflow,

- Process KPIs,

- Material Compliance,

- Material Verification