QUALITY MANAGEMENT PROCESS DOC. No.

: HTPC –SOP- 13

REV. No. : 01

TITLE: PROCEDURE FOR INSPECTION & TESTING DATE : 24.07.2023

Revision History

Change

Made By Approved Affected Revision

Date Changes Made

(QMS By (HOD) Section No.

HEAD)

01.06.2022 Original Release. All 00

24.07.2023 Activity and record of MR Quality 5.2 01

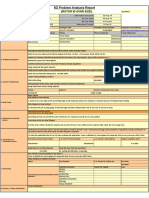

Incoming Inspection Report

Document Ownership and Timelines

PROCEDURE FOR Inspection

Title Date of Origin 01.06.2022

& Testing

Document Prepared By MR Shashi Shekhar

Document Issued and CEO Saurabh Gopalka

Review By

Document Approved By Quality Vikram Singh

Document Classification " Internal document"

Page 1 of 4

� QUALITY MANAGEMENT PROCESS DOC. No. : HTPC –SOP- 13

REV. No. : 01

TITLE: PROCEDURE FOR INSPECTION & TESTING DATE : 24.07.2023

1. PROCESS SCOPE:-

This Process is applicable to define the method used for monitoring and measurement of product’s

characteristics at various stages to verify that products meet specified requirements.

2. PROCESS OWNER: - HOD- QUALITY

3. DEFINITIONS/ABBREVIATION:- QA- QUALITY ASSURANCE

PDI- PRE DELIVERY INSPECTION

TPI- THIRD PARTY INSPECTION

RT- RADIOGRAPHY TEST

ECR- ENGINEERING CHANGE REQUEST

DMS- DEVIATED MATERIAL SLIP

4. PROCESS DESCRIPTION:-

Sr.

Activity Responsibility Ref. Doc.

No.

5.1 LAB SCOPE

Define & establish Laboratory Scope based on following:

Record and continuity to be taken care for the measuring

instruments and equipment. LIST OF MEASURING

To maintain adequate facility for visual inspection like light EQUIPMENT

Quality

etc.

Test certificates/ report given by the vendor kept F-QA-01

systematically in files

Method of Tests : linear measurement outside and inside,

internal measurement for hollow items.

Hydro-test for pressure containing items, and pneumatic test

for pressure containing item.

IN-COMING INSPECTION

5.2 Incoming inspection

The information regarding receipt of material shall be

report-

received from Stores through MRR.

Material shall be verified/inspected as per controlled In ERP

drawing/ specification.

The material found reject/non confirmative is kept

identified with ‘Red’ tag (red paint mark), inform to Quality

Supplier by mail.

The material found ok/ confirmative hand over to store

through ERP.

Make deviated material slip. DMS - F-QA-11

IN-PROCESS INSPECTION

Page 2 of 4

� QUALITY MANAGEMENT PROCESS DOC. No. : HTPC –SOP- 13

REV. No. : 01

TITLE: PROCEDURE FOR INSPECTION & TESTING DATE : 24.07.2023

5.3 In-Process Inspection

Assembly process and fabrication items to be verified Report – F-QA-03

/inspected as per controlled drawing/ specification.

Surface preparation after shot blasting, DFT and adhesion

test for primer coating and final coating to be verified Hydro test report

inspected as per specification. F-QA-04

Hydro test of lpg pipe lines, hose pipes, centre column Pneumatic test report

QA Team/

assy. lpg filling gun and spools. Production F-QA-05

Pneumatic test of pneumatic assy. Lab test offer F-QA-06

Welding parts offer to lab test

RT test offer F-QA-07

Welding parts offer to RT

Raise ECR ECR- F-QA-10

Rework Inspection Rework Inspection

logbook F-QA-12

FINAL INSPECTION

5.4 A PDI report shall be prepared and share to the dispatch

department for dispatch. PDI- F-QA-08

Quality

Offer to TPI

TPI- F-QA-09

Welding sample send to lab for testing.

FUNCTIONAL INSPECTION

5.6 Fitment of assembled items has been verified and

checked as per assembly drawing. Quality ----

5. KEY PERFORMANCE INDICATORS:-

In-process, rework after any remarks by Quality.

In-process painting, reprocess of painting (surface preparation, primer coat, final coat) after any remarks by

Quality.

6. REFERENCE DOCUMENTS & RECORDS:-

Sr. Description Format/ Doc. No. Responsibility

No.

01 LIST OF MEASURING (if any) Quality

F-QA-01

EQUIPMENT

02 INCOMING INSPECTION In ERP Quality

Page 3 of 4

� QUALITY MANAGEMENT PROCESS DOC. No. : HTPC –SOP- 13

REV. No. : 01

TITLE: PROCEDURE FOR INSPECTION & TESTING DATE : 24.07.2023

03 IN-PROCESS INSPECTION F-QA-03 Quality

04 HYDRO TEST REPORT F-QA-04 Quality

05 PNEUMATIC TEST REPORT F-QA-05 Quality

06 OFFER TO LAB TEST F-QA-06 Quality

07 OFFER TO RT F-QA-07 Quality

08 PRE DELIVERY INSPECTION F-QA-08 Quality

09 OFFER TO TPI F-QA-09 Quality

10 RAISE ECR F-QA-10 Quality

11 MAKE DMS F-QA-11 Quality

12 Repair log book F-QA-12 Quality

---------

Page 4 of 4