0% found this document useful (0 votes)

3K views1 pageQuality Control Plan

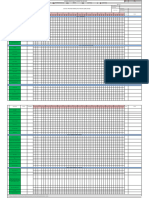

This quality control plan outlines 12 key steps for processing a part including: 1) receiving raw materials and checking dimensions, 2) turning on a lathe to mark the center point, 3) machining the diameter and length on a CNC lathe, 4) grinding for straightness and roundness, 5) turning and tapping holes, 6) milling to depth, 7) drilling additional holes, 8) numerically punching a logo, 9) hardening the surface, 10) grinding to remove marks, 11) chroming the surface, and 12) conducting a heat treatment. Process controls include measurements with tools like micrometers and dial gauges and maintaining specifications for dimensions, depths, hardness

Uploaded by

Joki PenangCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

3K views1 pageQuality Control Plan

This quality control plan outlines 12 key steps for processing a part including: 1) receiving raw materials and checking dimensions, 2) turning on a lathe to mark the center point, 3) machining the diameter and length on a CNC lathe, 4) grinding for straightness and roundness, 5) turning and tapping holes, 6) milling to depth, 7) drilling additional holes, 8) numerically punching a logo, 9) hardening the surface, 10) grinding to remove marks, 11) chroming the surface, and 12) conducting a heat treatment. Process controls include measurements with tools like micrometers and dial gauges and maintaining specifications for dimensions, depths, hardness

Uploaded by

Joki PenangCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Quality Control Plan Overview: An overview of the Quality Control Plan listing details such as product names, GMP numbers, and specifications.