Professional Documents

Culture Documents

Control Plan

Uploaded by

ilaya rajaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Plan

Uploaded by

ilaya rajaCopyright:

Available Formats

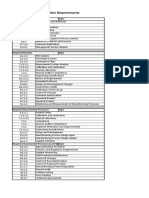

FM/7.

1/01/10

CONTROL PLAN

Control Plan No:- CP/MMPL/UFSLP1/ N127036

Control Plan Type : Key Contact Person / Phone Numbers : Key contact / phone no Original Date : 22.05.13 Rev No & Date : 02/08.09.21

Proto type Pre Launch Production TOOL NO: TL1015 G.Sathiyamoorthy / 9841578560

Core Team : Customer engineering approval / date (if req)

Part Description : SEAL Product Drawing Number : N127036

S.Govindarajan,G.Sathiyamoorthy,V.Ravi.

Customer Part Number: N127036 Issue No. :- Organization/ plant approval Customer Quality approval / date (if req)

Rev. No. :

Customer Name :Ucal Fuel System Ltd Other approval / date PAGE NO

Characteristics Methods Sample

Special

Process Control Method & Error Reaction Plan Corrective

Process Description Process Machine, Jig, Tool for Mfg. Char. Product / Process Evaluation / Measurement

Number. Product Process Responsibility Size Frequency Proofing Action

Class Specification / Tolerance Technique

Batch No And Compound Quarandined in hold area

Identification -

Reference(710/3) raise Flash Report

10 Blanking Visual 100% Remarks on DC

Receipt Of Compound Manual Every Batch

Supervisor

Weight Weight Mentioned in DC / ID

- Inform Supplier

Tag

- Nip Setting 2.3-4.5 Reading Scale

- Uniform Sizing 180 REF Vernier 100% Every Sheet Resheet

- Stroke Setting 18.5 - 19.8 mm Vernier

20 1.Sheeting Mill 2.Scissor / Blade cutting 3.Blank

Blanking

cutting Machine

Sheet Thickness - 3.5 - 6.5 mm DTG / Vernier

Sheet Breadth - 18.5 - 21.5 mm Vernier Daily once Daily Once First off Inspection Stop And Inform Supervisor

Blank Weight - 18.0 - 19.8 GM Weighing Balance

Operator /

Mat Thickness - 0.2 mm max Inspector DTG

_ Temperature 180 - 200°C DTI

ACMM Once in 4 Hrs Once in 4 Hrs

_ Time 105 Sec DT

_ Pressure 2000 - 4000 PSI PG Stop Production Inform to

Moulding

Supervisor

30 Product Profile - limit sample

Mould Visual Every Lift Every Lift Inprocess Inspection

Free from Visual Defects Flow,Shortfill,curing

_

rejection,Air bubbles,Tearing

OD 12.80 / 13.20 mm vis

Dia 3.60 / 3.80 mm vis / vernier

Ref Layout inspection report Inspector Stop Production and Rectify

First Off Inspection Inspector dimension 1 31.70 / 32.30 mm vis / vernier 5 Nos Random Once in a shift First off Inspection

FM/8.2/06-A in the Die

dimension 2 7.30 / 7.70 mm vis / vernier

dimension 3 8.80 / 9.20 mm vis / vernier

50 Manual Removal Of Flash Operator / Visual Stop Deflashing Inform To

Deflashing - Limit Sample 5 Nos Lot Inprocess Inspection

Inspector Supervisor

Normal Eyes (Rod inspection) - Limit Sample/ 48 Hours with Visual 100% Visual Inspection 100% Visual Quarantined in hold area

Inspection 100% Visual Inspection _

Rod condition Inspection and raise Flash Report

60

As per Quality Plan Dimension As per Quality Plan As per Quality Plan Quarantined in hold area

PreDelivery Inspection - As per Quality Plan Inspector PDIR

and raise Flash Report

Weighing Balance

70 Packing and Approval Counting Mchine Counting - As per AOI-Part - C Despatch Head Counting Mchine Each Lot Verification Recount / Repacking

Record(Calibration)

OPR-Operator , DTG - Dial Thickness Gauge , DTI - Digital Temperature Indicatior , DT - Digital Timer -( On display) , PG - Pressure Gauge , AOI - Agreement Of Inspection , VIS - Vision Inspection System( Profile) , PDIR - Per Delivery inspection report

Amendment Record

SI NO AMENDMENT DETAIL DETAIL OF CHANGE REASON FOR CHANGE CURRENT REV NO / DATE REVISED REV NO / DATE RESPONSIBILITY APPROVED BY ISSUED BY

1 New Release _ _ 0/22.05.13 _ M.Murugammal G.Sathiyamoorthi S.Govindarajan

2 PFD Revised In line with ERP PFD Format Changed 0/22.05.13 1/15.04.15 M.Murugammal G.Sathiyamoorthi S.Govindarajan

3 CP Revised CSR Implemented layout inspection added 1/15.04.15 02/08.09.21 N Joseph G.Sathiyamoorthi S.Govindarajan

Prepared by:M.Murugammal Approved by: G.Sathiyamoorthi

You might also like

- Machining PFMEADocument8 pagesMachining PFMEASuraj RawatNo ratings yet

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj RawatNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Control Plan For Zinc Flake CoatingDocument3 pagesControl Plan For Zinc Flake Coatingx y100% (1)

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- ATTRIBUTE MSADocument2 pagesATTRIBUTE MSADINESHCHOUDHARY880% (1)

- 06.supplier QMS Development Audit ChecklistDocument5 pages06.supplier QMS Development Audit ChecklistvishvendanNo ratings yet

- Process Flow Chart (Pre-Launch / Production)Document1 pageProcess Flow Chart (Pre-Launch / Production)kumar0% (1)

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditSachin Kumbhar100% (1)

- Pfmea - Aiag-VdaDocument108 pagesPfmea - Aiag-VdaGLAUCIO DOS SANTOS SILVANo ratings yet

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- Fr-scm-085 Packaging StandardDocument3 pagesFr-scm-085 Packaging StandardKaramjit SinghNo ratings yet

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoDocument10 pagesFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapNo ratings yet

- Guideline 4M Change MatrixDocument3 pagesGuideline 4M Change MatrixAman JasujaNo ratings yet

- Template Format Gauge R & RDocument5 pagesTemplate Format Gauge R & RQC-Metinca Prima Industrial WorksNo ratings yet

- Siegel Robert Automotive Layered Process Audit ChecklistDocument12 pagesSiegel Robert Automotive Layered Process Audit Checklistmahesh KhatalNo ratings yet

- Melt Flow Work InstructionDocument1 pageMelt Flow Work Instructionsuresh kumarNo ratings yet

- D10414410a Fmea MachiningDocument13 pagesD10414410a Fmea MachiningSuraj RawatNo ratings yet

- Fmea CastingDocument8 pagesFmea CastingSuraj RawatNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlieNo ratings yet

- Process SheetDocument8 pagesProcess SheetSuraj RawatNo ratings yet

- CAPA Burr (TSSR)Document3 pagesCAPA Burr (TSSR)Mohit Singh100% (1)

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- Ppap For Neel MetalDocument40 pagesPpap For Neel MetalshuklahouseNo ratings yet

- GP-9 Process Control Plan Audit Summary SheetDocument5 pagesGP-9 Process Control Plan Audit Summary SheetAsifNo ratings yet

- Apqp Time Plan: Risk AnalysisDocument4 pagesApqp Time Plan: Risk AnalysisRakesh PandeyNo ratings yet

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- Problem Analysis and Corrective Action ReportDocument13 pagesProblem Analysis and Corrective Action ReportNITISH KUMARR100% (1)

- D10414410a Fmea CastingDocument7 pagesD10414410a Fmea CastingSuraj RawatNo ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- Deviation Request FormatDocument4 pagesDeviation Request FormatKumaravelNo ratings yet

- Turtle DiagramDocument22 pagesTurtle DiagramVikas0% (1)

- Supplier Audit - Report BlankDocument4 pagesSupplier Audit - Report Blankshobha shelarNo ratings yet

- 4M Change Monitoring Sheet: If There Is Any Change During The Shift Mark It With RedDocument1 page4M Change Monitoring Sheet: If There Is Any Change During The Shift Mark It With RedDINESHCHOUDHARY88No ratings yet

- Company Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportDocument1 pageCompany Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportSachin RamdurgNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- Control PlanDocument4 pagesControl PlanRakesh PandeyNo ratings yet

- 4M Change Monitoring SheetDocument1 page4M Change Monitoring SheetDinesh KumarNo ratings yet

- IATF 16949 DocumenDocument1 pageIATF 16949 Documenpunitg_2No ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- AIAG & VDA PFMEA FormatDocument1 pageAIAG & VDA PFMEA Formatmahesh KhatalNo ratings yet

- Tharaj Castings PVT - ltd.-1st & 2nd Phase PresentationDocument58 pagesTharaj Castings PVT - ltd.-1st & 2nd Phase PresentationAnkur DhirNo ratings yet

- In Process InspectionDocument4 pagesIn Process InspectionSuraj RawatNo ratings yet

- QP - NPD - 07 Procedure For Change ManagementDocument3 pagesQP - NPD - 07 Procedure For Change ManagementMASU BRAKE PADS QANo ratings yet

- VDA AIAG FMEADocument59 pagesVDA AIAG FMEA576410% (1)

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Document4 pagesMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaNo ratings yet

- Profile Cutting SOPDocument1 pageProfile Cutting SOPanbuNo ratings yet

- APQP TemplateDocument7 pagesAPQP TemplateBob ZepfelNo ratings yet

- 17.work Instruction For CNC-CLGDocument1 page17.work Instruction For CNC-CLGSAKTHIVEL ANo ratings yet

- Worksheet in SQ Checksheet Part1Document50 pagesWorksheet in SQ Checksheet Part1Jetesh Devgun100% (1)

- CP St. Assy Upp 12.04.24Document92 pagesCP St. Assy Upp 12.04.24Hemant GuptaNo ratings yet

- Machining Control PlanDocument1 pageMachining Control PlanGARIMA CASTINGS, JAIPURNo ratings yet

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- Litotriptor Intracorporeo NeumaticoDocument4 pagesLitotriptor Intracorporeo NeumaticoJuan VasquezNo ratings yet

- 78EZDM Product Specifications Conector para Cable de 7 OctavosDocument4 pages78EZDM Product Specifications Conector para Cable de 7 OctavosEdwin Santiago QuispeNo ratings yet

- How To Plant Thoughts in Her Mind Ross Jeffries: TranscriptDocument12 pagesHow To Plant Thoughts in Her Mind Ross Jeffries: TranscriptAlcajNo ratings yet

- Visibility of NursesDocument17 pagesVisibility of NursesLuke ShantiNo ratings yet

- 1250kva DG SetDocument61 pages1250kva DG SetAnagha Deb100% (1)

- 2023 The Eighth Dimension of Applied Behavior AnalysisDocument15 pages2023 The Eighth Dimension of Applied Behavior AnalysisFranciele PinheiroNo ratings yet

- Impacts of Extracurricular Activities On The Academic Performance of Student AthletesDocument3 pagesImpacts of Extracurricular Activities On The Academic Performance of Student AthletesKarlo VillanuevaNo ratings yet

- A Priori and A Posteriori Knowledge: A Priori Knowledge Is Knowledge That Is Known Independently of Experience (That IsDocument7 pagesA Priori and A Posteriori Knowledge: A Priori Knowledge Is Knowledge That Is Known Independently of Experience (That Ispiyush_maheshwari22No ratings yet

- كتالوج وصفي للعملات الرومانية النادرة وغير المحررة من الفترة الأولى للعملات المعدنية الرومانية إلى انقراض الإمبراطورية تحت حكDocument570 pagesكتالوج وصفي للعملات الرومانية النادرة وغير المحررة من الفترة الأولى للعملات المعدنية الرومانية إلى انقراض الإمبراطورية تحت حكFayza MaghrabiNo ratings yet

- Intro To StarsDocument37 pagesIntro To StarsENo ratings yet

- Pertemuan Ke 12 - The Passive VoiceDocument5 pagesPertemuan Ke 12 - The Passive VoiceZarNo ratings yet

- Understanding EarsDocument1 pageUnderstanding EarsmerkyworksNo ratings yet

- Answerkey Precise ListeningDocument26 pagesAnswerkey Precise ListeningAn LeNo ratings yet

- Alup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENDocument2 pagesAlup Allegro 37 AC IE3 400V 4-13bar 50Hz Metric Technical Data ENBosznay ZoltánNo ratings yet

- Radar & Satellite Communication SystemDocument1 pageRadar & Satellite Communication SystemSyed Viquar AhmedNo ratings yet

- Bubbles in Transformer Oil Dynamic Behavior Internal Discharge and Triggered Liquid BreakdownDocument9 pagesBubbles in Transformer Oil Dynamic Behavior Internal Discharge and Triggered Liquid BreakdownMuhammad Irfan NazhmiNo ratings yet

- Group 6G Revised Research Manuscript 1Document57 pagesGroup 6G Revised Research Manuscript 1Mc Rollyn VallespinNo ratings yet

- ESET TechnologyDocument21 pagesESET TechnologyValentin SalcianuNo ratings yet

- Instability of Slender Concrete Deep BeamDocument12 pagesInstability of Slender Concrete Deep BeamFrederick TanNo ratings yet

- Aurora National High School: Report On AttendanceDocument2 pagesAurora National High School: Report On AttendanceLimuel CaringalNo ratings yet

- AspenTech Awareness & Workshop Ebook - 2020 PDFDocument20 pagesAspenTech Awareness & Workshop Ebook - 2020 PDFĐậu BắpNo ratings yet

- Case Analysis: A Simple Strategy at Costco: Informative Background InformationDocument15 pagesCase Analysis: A Simple Strategy at Costco: Informative Background InformationFred Nazareno CerezoNo ratings yet

- Review Problems Chapter 6Document8 pagesReview Problems Chapter 6Yue FeiNo ratings yet

- Organizational Behavior Exam 2 Practice QuestionsDocument1 pageOrganizational Behavior Exam 2 Practice QuestionsSydney EverettNo ratings yet

- Lesson Plan Entre P Dec 7Document12 pagesLesson Plan Entre P Dec 7yannie isananNo ratings yet

- Geography Grade 11 ANotes and Worksheet On Topography Associated With Horozontally Layered RocksDocument13 pagesGeography Grade 11 ANotes and Worksheet On Topography Associated With Horozontally Layered RocksTheo MolotoNo ratings yet

- Math 2 MakilingDocument28 pagesMath 2 MakilingAnnabelle Poniente HertezNo ratings yet

- Classification by Depth Distribution of Phytoplankton and ZooplanktonDocument31 pagesClassification by Depth Distribution of Phytoplankton and ZooplanktonKeanu Denzel BolitoNo ratings yet

- Tata Steel LTD.: Elements Unit Min Max RemarksDocument2 pagesTata Steel LTD.: Elements Unit Min Max RemarksPavan KumarNo ratings yet