Professional Documents

Culture Documents

Supplier Audit - Report Blank

Uploaded by

shobha shelarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supplier Audit - Report Blank

Uploaded by

shobha shelarCopyright:

Available Formats

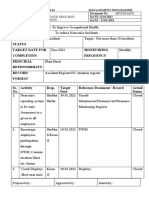

Abbhijeet Techno Plast I Pvt Ltd Supplier Audit Report Page 01 /02

QM-System Audit, Process Audit, Product Audit Audit Date:

Supplier Name & Address: Audit Purpose & Type- 1) Initial,

2) Surveillance,

3) Follow Up

4) To develop the new part

Address:-

General Information

Contact Person Department Contact No Fax No. E-Mail

Quality System : Issued By : Issue Date : Valid upto :

Audit Summary No Business awarded, Grade-D

Audit Information (Highlights)

Score by Section

Total Score

Quality System

100%

80% 100%

60%

Best In Class

40% 0%0%

20% 90%

Sub supplier control 0%0% Process Control confirmation Audit Information (Improvements)

0% 80%

Ok For Business

Storage & Logistics control 70%

60%

Score Area Weightage Score

No Buisiness Awarded Marginally ok for Buisiness

50%

Quality System 40% 0.0% 40%

30%

Process Control confirmation 30% 0.0%

20%

Storage & Logistics control 10% 0.0%

10%

0.00%

0%

Sub supplier control 20% 0.0%

Supplier: Please submit your corrective action plan to the Auditor.

Signatures : Supplier : Auditors :

Distribution : 1- Supplier, 2- Supplier Quality Assurance PUR - F - 16 / Rev.01/01.10.2013

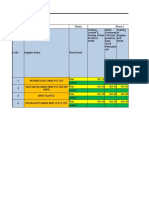

Evaluation Sheet with observation Page 02/02

Supplier Name Date

Auditor Name

Supplier Representative

S. No Criteria Questions to be asked Observation during evaluation Score

A Quality System 0% Section Weightage -40% 0.0% 0

Is the QMS status inline with customer Please show QMS certification you have

1

requirement (IATF)

1) Show the master list of all products

Master list of all parts supplied to supplied to M/s Abhijeet

2

customer available 2) What is frequency of updation of this list.

3) Linkage between latest change level

1) Show Quality objectives

2) Show customer defined target considered

as target in objectives (Wherever

Is Quality objectives are defined &

applicable)

3 reviewed at decided frequency (Check

3) Review frequancy of Objectives

quality targets)

4) Review done by Top managment or Not

5) Agenda of review meeting consist of

Objective points

1) Check with reference to Master list

Are the drawings for all the parts

4 2)Take one assembly of part & check for

including sub components available

child part drawing availability

1) Plan for audit

5 Conduct Internal System Audits 2) Conduction as per plan & Review of NC

with closing

1) Plan for audit

Conduct Internal Process & Product

6 2) Conduction as per plan & Review of NC

Audits

with closing

1) Concern / PPM trend for customer

7 Customer PPM & Concern tracking

2) Analysis of concern

1) All part PPAP

8 Part approval process

2) All part PSW approval

1) Identification of Bottle neck

9 Capacity Analysis 2) Compability of capacity for production

volumes

1) FMEA review

Is the PFMEA reviewed at decided

10 2) Review based on criteria

frequency

3) Rating of SEV, OCC, Det. Based on?

B Process Control confirmation 0% Section Weightage -30% 0.00% 0

Is setting guideline available for every

11 Do you have guideline for set up

set up.

Is the start up condition verified by

12 Show me the start up sheet for m/c

operator & Supervisor.

Does WI contains What , How & Why. 1) Display & Understanding of WI at

13

Does Quality indicators mentioned on WI relevant stages

1) Show the operator is quailified for the

Is the trained operators deployed at operation

14

relevant stage 2) Basis of qualification

3) Upgradation of skill level

Show the rework procedure

15 Rework Procedure

Show the rework records

1) List of FTG

Are the fixtures/gauges identified with

16 3) Identification

calibration due date.

3) Validation of fixtures

1) PFD of all process

17 Control on process 2) Control plan of all parts

3) verification of control plan

1) Internal PPM tracking

18 Internal Rejection

2) Cause analaysis

1) Show me the calibration plan for the

Is the Calibration plan for measuring gauges

19

equipment and gauges available 2) How do you decide the frequency of

calibration

1) Maintenance history sheet

2) Maintenance monitoring - monthly/

Maintenance down time monitored on weekly.

20

weekly/Monthly basis 3) Criticle Spare part list for machine

4) Preventive Maintainance adherance for

machines

C Storage & Logistics control 0% Section Weightage -10% 0.0% 0

Show the Packaging standard agreed with

21 Is the packing approved by customer.

customer

WIP & raw material movement in the 1) FIFO

22

shopfloor 2) Storage condition

1) FIFO

23 FG storage

2) Storage condition

D Sub supplier control 0% Section Weightage -20% 0.0% 0

24 Is there any sustanability initiatives Reuse / Recycle / Reduce / Kaizens / Plans

1) Concent color - Green / Red

2) Hazardous process if ant

25 Review of MPCB concent - Valid upto

3) Membership for Hazardous material

disposal

0.00%

You might also like

- Supplier Audit Checklist Optimizes Risk ManagementDocument13 pagesSupplier Audit Checklist Optimizes Risk ManagementPrakash kumarTripathiNo ratings yet

- QMS Development Checklist AuditDocument4 pagesQMS Development Checklist AuditprashanthNo ratings yet

- Master Sheet Process Audit Check SheetDocument11 pagesMaster Sheet Process Audit Check SheetRakesh S100% (1)

- QAV Checksheet 23.05.2022 LDocument10 pagesQAV Checksheet 23.05.2022 LNikhil SirNo ratings yet

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- SQ Rev 18 03 2015Document72 pagesSQ Rev 18 03 2015nishantNo ratings yet

- Supplier Audit Check Sheet.Document1 pageSupplier Audit Check Sheet.ALI ASGHARNo ratings yet

- ISO 9001 Management Review InputsDocument4 pagesISO 9001 Management Review Inputscesar jntNo ratings yet

- SOP Quality ProceduresDocument28 pagesSOP Quality ProceduresUttam KumarNo ratings yet

- Cost of Poor Quality COPQ CalculatorDocument2 pagesCost of Poor Quality COPQ Calculatorrgrao85No ratings yet

- Competence For Internal AuditorsDocument2 pagesCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- How To Conduct Management ReviewDocument8 pagesHow To Conduct Management ReviewS Seetharaman100% (1)

- NcManagement - SA1 - 2021Document13 pagesNcManagement - SA1 - 2021Nagarajan100% (1)

- WI-824-003 First Article InspectionDocument2 pagesWI-824-003 First Article InspectionAndreas Schlager100% (1)

- Guidelines for Supplier AuditDocument15 pagesGuidelines for Supplier AuditAdi SavaNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- All Departments Monthly Meeting TemplateDocument34 pagesAll Departments Monthly Meeting TemplateSachin RamdurgNo ratings yet

- Supplier Rating CalculatorDocument4 pagesSupplier Rating CalculatorsamcbsivNo ratings yet

- New QMS Tracking SheetDocument21 pagesNew QMS Tracking SheetPrakash kumarTripathiNo ratings yet

- Supplier Self-Assessment: ISO 9001:2015 QMSDocument4 pagesSupplier Self-Assessment: ISO 9001:2015 QMSArieHerdyanto50% (2)

- Mgt Review MinutesDocument6 pagesMgt Review Minutesmgamal1080100% (1)

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- ISO 9001:2008 & ISO/TS 16949 Quality Management RequirementsDocument52 pagesISO 9001:2008 & ISO/TS 16949 Quality Management Requirementssupady5751No ratings yet

- Quality Assessment Tool OptimizedDocument12 pagesQuality Assessment Tool OptimizedGuntur Adi SaputraNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Supplier Audit Check SheetDocument5 pagesSupplier Audit Check SheetMotive Post100% (2)

- Tier-2 Audit ChecksheetDocument17 pagesTier-2 Audit ChecksheetSilambarasan KNo ratings yet

- Lab Testing Services Audit ReportDocument8 pagesLab Testing Services Audit ReportMeghna SharmaNo ratings yet

- Internal Audit Check List MRDocument3 pagesInternal Audit Check List MRGanesh Iyer100% (1)

- Aum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditDocument24 pagesAum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditpraveenNo ratings yet

- In-House Verification or Calibration WI ExampleDocument1 pageIn-House Verification or Calibration WI ExampleSachin RamdurgNo ratings yet

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- ISO-TS 16949 IQA Course MaterialDocument31 pagesISO-TS 16949 IQA Course Materialazadsingh1No ratings yet

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- DK Qap QHS 12-FR 03-R6 - CarDocument1 pageDK Qap QHS 12-FR 03-R6 - CarErlan Gus HermawanNo ratings yet

- Free IATF Audit Checklist For Manufacturing ProcessesDocument14 pagesFree IATF Audit Checklist For Manufacturing ProcessesvidushiNo ratings yet

- Department Quality & FS Objective (Revision2015) - SampleDocument1 pageDepartment Quality & FS Objective (Revision2015) - SampleRachel YapNo ratings yet

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJNo ratings yet

- APQP TrackerDocument10 pagesAPQP TrackerBharathNo ratings yet

- FRM-WS-11 DWM Check Sheet (Weld SHP)Document2 pagesFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalNo ratings yet

- JD KRA LAB TeamDocument27 pagesJD KRA LAB TeamANILNo ratings yet

- AQLChart PDFDocument2 pagesAQLChart PDFAnonymous tv3qpx2No ratings yet

- CQI19 FormsDocument7 pagesCQI19 FormsEmre TekinNo ratings yet

- Supplier Evaluation Checklist F-PU-05 - FILLEDDocument2 pagesSupplier Evaluation Checklist F-PU-05 - FILLEDNav Talukdar100% (1)

- Supplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLDocument38 pagesSupplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLsrkadaliNo ratings yet

- Quality Control Process Chart (Machining)Document7 pagesQuality Control Process Chart (Machining)mani317No ratings yet

- Control PlanDocument1 pageControl Planilaya rajaNo ratings yet

- Control of Non ConformingDocument5 pagesControl of Non ConformingNaveenkumar R100% (1)

- How To Build An Effective Competency Matrix Competency-Matrix/)Document4 pagesHow To Build An Effective Competency Matrix Competency-Matrix/)Anonymous VPJkWfcOQNo ratings yet

- Current Area Item Assembly Process Production Qa CheckingDocument32 pagesCurrent Area Item Assembly Process Production Qa Checkingteresa100% (1)

- Centurion Power Cables (P) LTD.: 1.0 PurposeDocument4 pagesCenturion Power Cables (P) LTD.: 1.0 PurposetriveshNo ratings yet

- Calibration Process Audit ExampleDocument1 pageCalibration Process Audit ExampleMuhammad Alief OthmanNo ratings yet

- Iso 9001:2000 Gap Checklist: 4.0 Quality Management System 4.1 General RequirementsDocument11 pagesIso 9001:2000 Gap Checklist: 4.0 Quality Management System 4.1 General Requirementscover filterNo ratings yet

- VM Checklist - Manufacturing: Peracha Engineering CoDocument2 pagesVM Checklist - Manufacturing: Peracha Engineering CoPeracha EngineeringNo ratings yet

- Supplier Quality Management A Complete Guide - 2020 EditionFrom EverandSupplier Quality Management A Complete Guide - 2020 EditionNo ratings yet

- 5S Audit Form Audit Optimizes Quality DepartmentDocument14 pages5S Audit Form Audit Optimizes Quality Departmentshobha shelarNo ratings yet

- 5S Audit Audit Grinding-Feb 21Document14 pages5S Audit Audit Grinding-Feb 21shobha shelarNo ratings yet

- PLS Office 5S + Safety Audit Form - Draft: Category Criteria Audit Period Scoring SystemDocument15 pagesPLS Office 5S + Safety Audit Form - Draft: Category Criteria Audit Period Scoring SystemMiz MedNo ratings yet

- Workshop Registration FormDocument1 pageWorkshop Registration Formshobha shelarNo ratings yet

- 5S Audit Checklist-Assembly MeenaDocument10 pages5S Audit Checklist-Assembly Meenashobha shelarNo ratings yet

- Reduction in Water Consumption-MP 3Document3 pagesReduction in Water Consumption-MP 3shobha shelarNo ratings yet

- Audit & Cert BodyDocument27 pagesAudit & Cert Bodyshobha shelarNo ratings yet

- OHSAS-MP-1To Reduce Minor Finger InjuriesDocument3 pagesOHSAS-MP-1To Reduce Minor Finger Injuriesshobha shelarNo ratings yet

- 5S Audit Checklist-Store E57Document10 pages5S Audit Checklist-Store E57shobha shelarNo ratings yet

- OHSAS-MP-2 To Reduce Reporatble AccidentsDocument3 pagesOHSAS-MP-2 To Reduce Reporatble Accidentsshobha shelarNo ratings yet

- 5.1 ChecklistDocument1 page5.1 Checklistshobha shelarNo ratings yet

- OHSAS-MP-3 To Reduce Nearmiss IncidentsDocument4 pagesOHSAS-MP-3 To Reduce Nearmiss Incidentsshobha shelarNo ratings yet

- Improve Joint Mounting QualityDocument52 pagesImprove Joint Mounting Qualityshobha shelarNo ratings yet

- 2.3 EPR - EMS Chemical LeakageDocument3 pages2.3 EPR - EMS Chemical Leakageshobha shelarNo ratings yet

- Introduction To Environment - PrintDocument8 pagesIntroduction To Environment - Printshobha shelarNo ratings yet

- Sustainability ChecklistDocument24 pagesSustainability Checklistshobha shelarNo ratings yet

- COPQ Details August 2021 Plant LevelDocument55 pagesCOPQ Details August 2021 Plant Levelshobha shelarNo ratings yet

- 3.2 HIRA Register - BlankDocument3 pages3.2 HIRA Register - Blankshobha shelarNo ratings yet

- Abhijeet Techno-Plast Splash Shields and Automotive Trim PartsDocument301 pagesAbhijeet Techno-Plast Splash Shields and Automotive Trim Partsshobha shelarNo ratings yet

- Process Validation Ensures Quality PartsDocument24 pagesProcess Validation Ensures Quality Partsshobha shelarNo ratings yet

- Roadmap For Supplier Improvement Program 2020-21Document5 pagesRoadmap For Supplier Improvement Program 2020-21shobha shelarNo ratings yet

- Abhijeet Techno-Plast Splash Shields and Automotive Trim PartsDocument301 pagesAbhijeet Techno-Plast Splash Shields and Automotive Trim Partsshobha shelarNo ratings yet

- PUR-LS-01 List of Approved Supplier-11082020Document5 pagesPUR-LS-01 List of Approved Supplier-11082020shobha shelarNo ratings yet

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- Training Need FR 00-2012-2013Document1 pageTraining Need FR 00-2012-2013shobha shelarNo ratings yet

- Transporter Performance MonitoringDocument9 pagesTransporter Performance Monitoringshobha shelarNo ratings yet

- COPQ Details August 2021 Plant LevelDocument55 pagesCOPQ Details August 2021 Plant Levelshobha shelarNo ratings yet

- Abhijeet Techno Plast India PVT Ltd. Standard Operating ProcedureDocument8 pagesAbhijeet Techno Plast India PVT Ltd. Standard Operating Procedureshobha shelarNo ratings yet

- Detection of Wrong Riser FitmentDocument8 pagesDetection of Wrong Riser Fitmentshobha shelarNo ratings yet

- Monopoly: Imba Nccu Managerial Economics Jack WuDocument26 pagesMonopoly: Imba Nccu Managerial Economics Jack WuMelina KurniawanNo ratings yet

- PO GCWS G85012 To MIDocument6 pagesPO GCWS G85012 To MIandika bukopinNo ratings yet

- Marketing ManagementDocument6 pagesMarketing ManagementMohammad Fajar SidikNo ratings yet

- Sip Project RutujaDocument16 pagesSip Project Rutujapsourabh638No ratings yet

- Strategic AnalysisDocument6 pagesStrategic AnalysisAnil KumarNo ratings yet

- Scientific ManagementDocument24 pagesScientific Managementdipti30No ratings yet

- Company Profile: Kayempee Foods Pvt. LimitedDocument8 pagesCompany Profile: Kayempee Foods Pvt. LimitedrajareenaNo ratings yet

- 11 Appendix J B 1st-31st March 2020 - 2Document2 pages11 Appendix J B 1st-31st March 2020 - 2Adita DayNo ratings yet

- Bescom GSTN No: 29Aaccb1412G1Z5Document2 pagesBescom GSTN No: 29Aaccb1412G1Z5RajkiranaNo ratings yet

- Inventory Mgt: Concepts, Motives & ObjectivesDocument5 pagesInventory Mgt: Concepts, Motives & ObjectivesEKANSH DANGAYACH 20212619No ratings yet

- DPI Programme GoalsDocument11 pagesDPI Programme GoalsGodfrey KakalaNo ratings yet

- The Greatest Options Strategy Ever MadeDocument14 pagesThe Greatest Options Strategy Ever MadeAnkur DasNo ratings yet

- Old Exam AEDocument12 pagesOld Exam AEaaaaaNo ratings yet

- Introduction and Chapter 1 - 1Document42 pagesIntroduction and Chapter 1 - 1Ntsikelelo MosikareNo ratings yet

- The Economic & Business Environment WorksheetsDocument13 pagesThe Economic & Business Environment WorksheetsKareem AghaNo ratings yet

- Quiz Pas 33 EpsDocument2 pagesQuiz Pas 33 EpsApol AsusNo ratings yet

- WorkSheet Capital GainDocument12 pagesWorkSheet Capital GainakshatkharcheNo ratings yet

- Project On Online e PayDocument49 pagesProject On Online e PayAmaan RazviNo ratings yet

- U4A1 AssignmentDocument1 pageU4A1 AssignmentDrippy SnowflakeNo ratings yet

- Barrons 10.july.2023Document103 pagesBarrons 10.july.2023mariuscsmNo ratings yet

- Format CBFT - Pagos ExteriorDocument9 pagesFormat CBFT - Pagos ExteriorCarlos PasosNo ratings yet

- Rekha V.V.I. Commerce (Hons.) Part-2Document13 pagesRekha V.V.I. Commerce (Hons.) Part-2NewshibeNo ratings yet

- Pump-Dump Manipulation AnalysiDocument15 pagesPump-Dump Manipulation Analysihedrywan8No ratings yet

- Catalogo Guarda OrdumeDocument11 pagesCatalogo Guarda OrdumeJúlio Cézar CastroNo ratings yet

- Presentation - HDFC Dividend Yield FundDocument27 pagesPresentation - HDFC Dividend Yield FundRitesh ChatterjeeNo ratings yet

- Final Black Book GST in ResturentsDocument66 pagesFinal Black Book GST in Resturentsirfan khan100% (2)

- Resources and CapabilitiesDocument12 pagesResources and CapabilitiesKeith NavalNo ratings yet

- Black BookDocument26 pagesBlack BookYash soshteNo ratings yet

- MBA Multiple Choice Assessment 1Document18 pagesMBA Multiple Choice Assessment 1Yasiru MahindaratneNo ratings yet

- US DOE Pathways To Commercial Liftoff - Carbon ManagementDocument54 pagesUS DOE Pathways To Commercial Liftoff - Carbon ManagementFreyrVoNo ratings yet