Professional Documents

Culture Documents

Iso 9001:2000 Gap Checklist: 4.0 Quality Management System 4.1 General Requirements

Uploaded by

cover filterOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso 9001:2000 Gap Checklist: 4.0 Quality Management System 4.1 General Requirements

Uploaded by

cover filterCopyright:

Available Formats

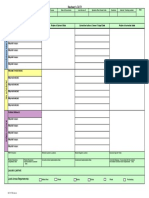

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

4.0 Quality Management System

4.1 General Requirements

4.1 Has a quality management system been established, documented,

maintained and continually improved in accordance with the

requirements ISO 9001:2000?

Does the organization:

a) Identify the processes needed for the quality management system

and their application throughout the organization?

b) Determine the sequence and interaction of these processes?

c) Determine criteria and methods needed to ensure that both the

operation and control of these processes are effective?

d) Ensure the availability of resources and information necessary to

support the operation and monitoring of these processes?

e) Monitor, measure and analyse these processes?

f) Implement actions necessary to achieve planned results and

continual improvement of these processes?

Is evidence available confirming that all outsourced processes affecting

product conformance with requirements have been identified and

controlled within the quality management system?

4.2 Documentation Requirements

4.2.1 General

4.2.1 Does the quality management system documentation include:

a) Documented quality policy and objectives?

b) A quality manual?

c) Documented procedures required by ISO 9001:2000?

d) Documents needed to ensure effective planning, operation and

control of processes?

e) Quality records required by ISO 9001:2000 ? (see 4.2.4)

4.2.2 Quality Manual

4.2.2 Has a quality manual been established and maintained that includes the

following:

a) The scope of the quality management system, including details of,

and justification for, any exclusions?

b) Do all exclusions meet Clause 1.2, "Application" of ISO 9001:2000?

c) Documented procedures for the quality management system or

reference to them?

d) A description of the interaction between the processes of the quality

management system?

4.2.3 Control of Documents

4.2.3 Have all documents required for the quality management system been

placed under control?

Are records controlled in accordance with the requirements of 4.2.4?

Is there a documented procedure for control of documents, which

addresses all requirements of 4.2.3?

Are documents approved for adequacy prior to use?

Are documents reviewed, updated and reapproved as necessary?

Are changes and the current revision status of documents identified?

Are the relevant versions of applicable documents available at points of

use?

Are the documents legible and readily identifiable?

Are documents of external origin identified and their distribution

controlled?

Are controls in place to prevent the unintended use of obsolete

documents, and to apply suitable identification to them if they are

retained for any purpose?

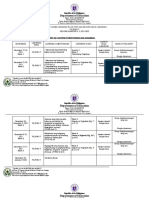

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

4.2.4 Control of Records

4.2.4 Do quality records provide evidence of conformance to requirements

and the effective operation of the quality management system?

Has a documented procedure been established for the identification,

storage, retrieval, protection, retention time and disposition of quality

records?

Are quality records legible, readily identifiable and retrievable?

5.0 Management Responsibility

5.1 Management Commitment

5.1 Can top management demonstrate evidence of commitment to the

development, implementation and improvement of the effectiveness of

the quality management system by:

a) Communicating to the organization the importance of meeting

customer requirements?

b) Establishing the quality policy?

c) Ensuring that quality objectives are established?

d) Conducting management reviews?

e) Ensuring the availability of resources?

5.2 Customer Focus

5.2 Does top management ensure that customer requirements are

determined and are met with the aim of enhancing customer

satisfaction?

5.3 Quality Policy

5.3 Does top management ensure that the quality policy:

a) Appropriate to the organization?

b) Includes a commitment to comply with requirements and continually

improve the effectiveness of the quality management system?

c) Provides a framework for establishing and reviewing quality

objectives?

d) Is communicated and understood throughout the organization?

e) Is reviewed for continuing suitability?

5.4 Planning

5.4.1 Quality Objectives

5.4.1 Is top management able to demonstrate how they ensure that quality

objectives, including those needed to meet requirements for product

are established at relevant functions and levels within the organization?

Are the quality objectives measurable and consistent with the quality

policy?

5.4.2 Quality Management System Planning

5.4.2 Is top management able to demonstrate how they ensure:

a) Quality management system planning is carried out in order to meet

the requirements given in 4.1 and the quality objectives?

b) The integrity of the quality management system is maintained when

changes to the quality management system are planned and

implemented?

5.5 Responsibility, Authority, and Communication

5.5.1 Responsibility and Authority

5.5.1 Is top management able to demonstrate how they ensure that the

responsibilities, authorities and their interrelation are defined and

communicated within the organization?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

5.5.2 Management Representative

5.5.2 Has top management appointed one or more members of management

to serve as the management representative?

Does the management representative’s authority and responsibility,

irrespective of other responsibilities include:

a) Ensuring that processes for the quality management system are

established, implemented and maintained?

b) Reporting to top management the performance of the quality

management system including needs for improvement?

c) Promoting awareness of customer requirements throughout the

organization?

5.5.3 Internal Communication

5.5.3 Is top management able to demonstrate how they ensure that

appropriate communication processes are established within the

organization, and that communication takes place regarding the

effectiveness of the quality management system?

5.6 Management Review

5.6.1 General

5.6.1 Does top management review the quality management system at

planned intervals to ensure its continuing suitability, adequacy and

effectiveness?

Does management review evaluate the need for changes to the quality

management system, including the quality policy and quality objectives?

Are the results of management review recorded?

5.6.2 Review Input

5.6.2 Do the inputs to management review include information on the

following:

a) Results of audits?

b) Customer feedback?

c) Process performance and product conformance?

d) Status of preventative and corrective actions?

e) Follow-up actions from earlier management reviews?

f) Planned changes that could affect the quality management system?

g) Recommendations for improvement?

5.6.3 Review Output

5.6.3 Do the outputs from management review include decisions and actions

related to:

a) Improvement of the effectiveness of the quality management system

and its processes?

b) Improvement of product related to customer requirements?

c) Resource needs?

6.0 Resource Management

6.1 Provision of Resources

6.1 Does the organization determine and provide the resources needed to:

a) Implement, and maintain and continually improve the quality

management system?

b) Enhance customer satisfaction by meeting requirements?

6.2 Human Resources

6.2.1 General

6.2.1 Is evidence available that personnel performing work affecting product

quality are competent on the basis of appropriate education, training,

skills and experience?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

6.2.2 Competence, Awareness and Training

6.2.2 Has the necessary competence for personnel performing work affecting

product quality been determined?

Has Training been provided or other actions taken to satisfy

competency needs?

Is the Training provided or other actions taken evaluated for

effectiveness in meeting the competency needs?

Are Personnel aware of the relevance and importance of their activities

and how they contribute to the achievement of the quality objectives?

Are appropriate records of education, training, skills and experience

maintained?

6.3 Infrastructure

6.3 Does the organization determine, provide and maintain the

infrastructure needed to achieve conformity to product requirements?

Does infrastructure include, as applicable:

a) Buildings, workspace and associated utilities?

b) Process equipment including hardware and software?

c) Supporting services such as transport or communication?

6.4 Work Environment

6.4 Does the organization determine and manage the work environment

needed to achieve conformity to product requirements?

7.0 Product Realization

7.1 Planning of Product Realization

7.1 Does the organization plan and develop the processes needed for

product realization?

Is planning of product realization processes consistent with the

requirements of the other processes of the quality management system

Is the following determined, as appropriate, during product realization

planning:

a) Quality objectives and requirements for the product?

b) The need to establish processes, documents and provide resources

specific to the product?

c) The need to establish verification, validation, monitoring, inspection

and test activities specific to the product and criteria for product

acceptance?

d) Records needed to provide evidence that realization processes and

resulting product fulfill requirements?

Is the output of this planning in a form suitable for the organization’s

method of operations?

7.2 Customer-Related Processes

7.2.1 Determination of Requirements Relate to the Product

7.2.1 Does the organization determine:

a) Customer specified requirements including delivery and post-

delivery?

b) Requirements not stated by the customer but necessary for specified

or intended use when known?

c) Statutory and regulatory requirements related to the product?

d) Any additional requirements determined by the organization?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

7.2.2 Review of Requirements Related to the Product

7.2.2 Are Requirements related to the product reviewed prior to the

commitment to supply a product to the customer?

Does the review activity ensure:

a) Product requirements are defined?

b) Contract or order requirements differing from those previously

expressed are resolved?

c) The organization’s ability to meet defined requirements?

Are records of the results of review and actions arising from review

activity maintained?

Where the customer provides no documented statement of requirement,

are requirements confirmed by the organization before acceptance?

Where product requirements are changed, does the organization

ensure that relevant documents are amended?

Does the organization ensure that relevant personnel are made aware

of the changed requirements?

7.2.3 Customer Communication

7.2.3 Do effective arrangements exist for customer communication related to:

a) Product information?

b) Inquiries, contracts, order handling and amendments?

c) Customer feedback and customer complaints?

7.3 Design and Development

EXCLUDED

7.4 Purchasing

7.4.1 Purchasing Process

7.4.1 Does the organization ensure that purchased product conforms to

specified purchase requirements?

Are the type and extent of control applied to the supplier and the

purchased product dependent upon the effect of the purchased product

on subsequent product realization or final product?

Does the organization evaluate and select suppliers based on their

ability to supply product in accordance with the organization’s

requirements?

Are criteria for selection, evaluation and re-evaluation established?

Are records of the results of evaluations and any necessary actions

arising from the evaluation maintained?

7.4.2 Purchasing Information

7.4.2 Does purchasing information describe the product to be purchased,

including where appropriate:

a) Requirements for approval of product, procedures, processes and

equipment?

b) Requirements for qualification of personnel?

c) Quality management system requirements?

Is the adequacy of specified purchase requirements ensured prior to

their communication to the supplier?

7.4.3 Verification of Purchased Product

7.4.3 Have inspection or other activities necessary for ensuring that

purchased product meets specified purchase requirements been

established and implemented?

7.4.3

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

When the organization or the customer performs verification at the

supplier’s premises, has the organization stated the intended

verification arrangements and the method of product release in the

purchasing information?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

7.5 Production and Service Provision

7.5.1 Control of Production and Service Provision

7.5.1 Are production and service operations carried out under controlled

conditions?

Do controlled conditions include, as applicable:

a) The availability of information that describes the characteristics of the

product?

b) The availability of work instructions?

c) The use of suitable equipment?

d) The availability and use of monitoring and measurement devices?

e) The implementation of monitoring and measurement?

f) The implementation of release, delivery and post-delivery activities?

7.5.2 Validation of Processes for Production and Service Provision

7.5.2 Are production and service processes validated where the resulting

output cannot be verified by subsequent monitoring or measurement

validated?

Does this include any processes where deficiencies become apparent

only after the product is in use or the service has been delivered?

Does the organization establish arrangements for these processes

including, as applicable:

a) Defined criteria for review and approval of the processes?

b) Approval of equipment and qualification of personnel?

c) Use of specific methods and procedures?

d) Requirements for records?

e) Re-validation?

7.5.3 Identification and Traceability

7.5.3 Is product identified, as appropriate, by suitable means throughout

product realization?

Is product status identified with respect to measuring and monitoring

requirements?

Is traceability a specified requirement? If so, is unique identification of

the product controlled and recorded?

7.5.4 Customer Property

7.5.4 Does the organization exercise care with customer property while it is

under the organization’s control or being used by the organization?

Does the organization identify, verify, protect and safeguard customer

property provided for use or incorporation into the product?

Is lost, damaged, or unsuitable product reported to the customer and

records maintained?

7.5.5 Preservation of Product

7.5.5 Does the organization preserve the conformity of product during internal

processing and delivery to the intended destination?

Does this preservation include identification, handling, packaging,

storage and protection?

Is preservation also applied to the constituent parts of a product?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

7.6 Control of Monitoring and Measuring Devices

7.6 Has the organization determined the monitoring and measurement to be

undertaken, and the monitoring and measurement devices needed to

provide evidence of conformity to determined requirements?

Are processes established which ensure monitoring and measurement

is carried out in a manner consistent with measuring and monitoring

requirements?

Where necessary to ensure valid results, is measuring equipment:

a) Calibrated or verified at specified intervals, or prior to use, against

measurement standards traceable to international or national

measurement standards? Where no such standards exist, is the basis

used for calibration or verification recorded?

b) Adjusted or re-adjusted as necessary?

c) Identified to enable calibration status to be determined?

d) Safeguarded from adjustments that would invalidate the

measurement result?

e) Protected from damage and deterioration during handling,

maintenance and storage?

Does the organization assess and record the validity of the previous

measuring results when the equipment is found not to conform to

requirements?

Does the organization take appropriate action on the equipment and

any product affected?

Are records of the results of calibration and verification maintained?

Is computer software used in the measuring and monitoring of specified

requirements?

If so, is the ability of computer software to satisfy the intended

application confirmed prior to initial use and re-confirmed as necessary?

8.0 Measurement, Analysis, and Improvement

8.1 General

8.1 Are monitoring, measurement, analysis and improvement processes

planned and implemented as needed to:

a) Demonstrate conformity of the product?

b) Ensure conformity of the quality management system?

c) Continually improve the effectiveness of the quality management

system?

d) Determine applicable methods including statistical techniques and

the extent of their use?

8.2 Monitoring and Measurement

8.2.1 Customer Satisfaction

8.2.1 Is information relating to customer perception to whether the

organization has fulfilled customer requirements monitored?

Are the methods for obtaining and using this information determined?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

8.2.2 Internal AuditI

8.2.2 Have the responsibilities and requirements for planning and conducting

audits, reporting results and maintaining records been defined in a

documented procedure?

Does the organization conduct internal audits at planned intervals to

determine whether the quality management system:

a) Conforms to planned arrangements?

b) Conforms to ISO 9001:2000?

c) Conforms to quality management system requirements established

by the organization?

d) Is effectively implemented and maintained?

Is evidence available to confirm that internal audits are conducted at

planned intervals based upon:

a) The status and importance of the processes and areas to be

audited?

b) The results of previous audits?

Have audit criteria, scope, frequency and methods been defined?

Is evidence available to confirm that auditors and the conduct of audits

ensure objectivity and impartiality of the audit process?

Is evidence available to confirm that auditors do not audit their own

work?

Does the management responsible for the area being audited ensure

that actions are taken without undue delay to eliminate detected

nonconformities and their causes?

Do the nonconformity follow-up activities include the verification of the

actions taken and the reporting of verification results?

8.2.3 Monitoring and Measurement of Processes

8.2.3 Does the organization apply suitable methods for monitoring, and where

applicable, measurement of the quality management system

processes?

Do these methods demonstrate the ability of the processes to achieve

planned results?

When planned results are not achieved, is correction and corrective

action taken, as appropriate, to ensure conformity of the product?

8.2.4 Monitoring and Measurement of Product

8.2.4 Does the organization monitor and measure the characteristics of the

product to verify that product requirements have been met?

Is this carried out at appropriate stages of the product realization

process in accordance with the planned arrangements?

Is evidence of conformity with the acceptance criteria maintained?

Do records indicate the person(s) authorizing release of product?

Does the organization ensure that product release and service delivery

does not proceed until all the planned arrangements have been

satisfactorily completed, unless otherwise approved by a relevant

authority and, where applicable, by the customer?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

8.3 Control of Nonconforming Product

8.3 Does the organization ensure that product which does not conform to

product requirements is identified and controlled to prevent unintended

use or delivery?

Are the controls and related responsibilities and authorities for dealing

with nonconforming product defined in a documented procedure?

Is evidence available that nonconforming product is dealt with by one or

more of the following ways:

a) By taking action to eliminate the detected nonconformity

b) By authorizing its use, release or acceptance under concession by a

relevant authority, and where applicable by the customer

c) By taking action to preclude its original intended use or application

Are records of the nature of nonconformities and any subsequent

actions taken, including concessions maintained?

Is evidence available that corrected nonconforming product is subject to

re-verification to demonstrate conformity to the requirements?

Are actions appropriate to the effects, or potential effects of

nonconforming product taken when nonconforming product is detected

after delivery or use has started?

8.4 Analysis of Data

8.4 Does the organization determine, collect and analyse appropriate data

to:

a) Demonstrate the suitability and effectiveness of the quality

management system?

b) Evaluate where continual improvement of the quality management

system can be made?

Does this include data generated as a result of monitoring and

measurement and from other relevant sources?

Does the data analysis provide information relating to:

a) Customer satisfaction?

b) Conformance to product requirements?

c) Characteristics and trends of processes and products?

d) Opportunities for preventative action?

e) Suppliers?

8.5 Improvement

8.5.1 Continual Improvement

8.5.1 Is it demonstrated that the effectiveness of the quality management

system is being continually improved?

Is it demonstrated that the following are being used to improve the

effectiveness of the quality management system?

a) Quality policy?

b) Quality objectives?

c) Audit results?

d) Analysis of data?

e) Corrective actions?

f) Preventative actions?

g) Management review?

ISO 9001:2000 GAP CHECKLIST

ISO REF # REQUIREMENTS NOTES

8.5.2 Corrective Action

8.5.2 Is action taken to eliminate the cause of nonconformities in order to

prevent recurrence?

Are the Corrective actions taken appropriate to the effects of the

nonconformities encountered?

Does a documented procedure define requirements for:

a) Reviewing nonconformities (including customer complaints)?

b) Determining the cause of nonconformities?

c) Evaluating the need for action to ensure that nonconformities do not

recur?

d) Determining and implementing action needed?

e) Recording results of the action taken?

d) Reviewing corrective action taken?

8.5.3 Preventive Action

8.5.3 Is action is taken to eliminate the causes of potential nonconformities in

order to prevent their occurrence?

Are the Preventative actions taken appropriate to the effects of the

potential problems?

Does a documented procedure define requirements for:

a) Determining potential nonconformities and their causes?

b) Evaluating the need for action to prevent occurrence of

nonconformities?

c) Determining and implementing action needed?

d) Recording results of the action taken?

e) Reviewing preventative action taken?

You might also like

- SBI Online Registration Form for CINB SaralDocument1 pageSBI Online Registration Form for CINB Saralamitjainis60% (5)

- Quality Audit Checklist FOR ISO 9001:2000Document10 pagesQuality Audit Checklist FOR ISO 9001:2000MAdrianRumayarNo ratings yet

- HOSHIZAKI SERVICE MANUAL Logic Board Settings E1ck-811 PDFDocument118 pagesHOSHIZAKI SERVICE MANUAL Logic Board Settings E1ck-811 PDFLeo50% (2)

- Audit Checklist Process ApproachDocument7 pagesAudit Checklist Process Approachsrinivas8587100% (3)

- ISO 9001:2008 & ISO/TS 16949 Quality Management RequirementsDocument52 pagesISO 9001:2008 & ISO/TS 16949 Quality Management Requirementssupady5751No ratings yet

- Frequency Distribution For Categorical DataDocument6 pagesFrequency Distribution For Categorical Databakhtawar soniaNo ratings yet

- Lab Testing Services Audit ReportDocument8 pagesLab Testing Services Audit ReportMeghna SharmaNo ratings yet

- Documented - Information para Iso9001-2015Document5 pagesDocumented - Information para Iso9001-2015jrodangarNo ratings yet

- Construction Quality AssuranceDocument8 pagesConstruction Quality AssuranceMalek AlhussienNo ratings yet

- ISO 9001 - 2015 - 2020 - October - Management Review - Last DayDocument59 pagesISO 9001 - 2015 - 2020 - October - Management Review - Last DayMatt Andrew Baquiano100% (1)

- Astm E1557 09 (2020)Document45 pagesAstm E1557 09 (2020)Patrick LitteeNo ratings yet

- Final AssignmentDocument6 pagesFinal Assignmentmhk665No ratings yet

- ISO 9001 Basic FundamentalDocument35 pagesISO 9001 Basic FundamentalIstimawan_Bagus100% (2)

- 7.1.4 Transfer of Work Worksheet Template and Checklists 1OCT2016Document12 pages7.1.4 Transfer of Work Worksheet Template and Checklists 1OCT2016cover filterNo ratings yet

- Process Control ProcedureDocument12 pagesProcess Control ProcedureGrazel MDNo ratings yet

- Ims MRM Input 2015Document2 pagesIms MRM Input 2015venkatesanNo ratings yet

- Cost of QualityDocument21 pagesCost of QualitymaherkamelNo ratings yet

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 pagesSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWNo ratings yet

- Quality Manual 9001-2008 Elsmar 1Document13 pagesQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzNo ratings yet

- Internal Audit - 19!08!2022-GP ISO 17025 SlidesDocument33 pagesInternal Audit - 19!08!2022-GP ISO 17025 Slidesmuhammad imran azizNo ratings yet

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJNo ratings yet

- Quality Management - ISO 9001 - 2015 Mandatory Documented Information - Documents and RecordsDocument6 pagesQuality Management - ISO 9001 - 2015 Mandatory Documented Information - Documents and RecordsSithanandan GanapathyNo ratings yet

- Quality Manual: For Carolina Precision Manufacturing, LLC IndexDocument27 pagesQuality Manual: For Carolina Precision Manufacturing, LLC IndexhjgajjarNo ratings yet

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- Happy Forgings EMS PerformanceDocument3 pagesHappy Forgings EMS Performancemool raj100% (1)

- BTD Quality System Policy ManualDocument19 pagesBTD Quality System Policy ManualPinaki DasNo ratings yet

- Managemnet Review SOP & RecordsDocument3 pagesManagemnet Review SOP & RecordsPritam MitraNo ratings yet

- Roles and Resposiblity-SampleDocument7 pagesRoles and Resposiblity-SampleELANTHENDRALNo ratings yet

- Audit Report of SRF Date 16.9.11Document6 pagesAudit Report of SRF Date 16.9.11yash272No ratings yet

- Quality Management PresentationDocument8 pagesQuality Management PresentationLok SewaNo ratings yet

- CH 2Document18 pagesCH 2suresh84123No ratings yet

- Quality Management System Checklist Iso 9001Document13 pagesQuality Management System Checklist Iso 9001Ayman Hamed MalahNo ratings yet

- Iso 9001-2015 Clause 7 SupportDocument14 pagesIso 9001-2015 Clause 7 SupportalexrferreiraNo ratings yet

- ISO 9001 Implementation Plan & TimelineDocument2 pagesISO 9001 Implementation Plan & TimelineVictoriaNo ratings yet

- ISO PresentationDocument64 pagesISO PresentationManu Madaan100% (2)

- Quality Management Systems StandardsDocument41 pagesQuality Management Systems StandardspradeepNo ratings yet

- ISO 9001:2015 Audit ChecklistDocument4 pagesISO 9001:2015 Audit ChecklistyuniNo ratings yet

- Scope of The QMSDocument2 pagesScope of The QMSVictor100% (1)

- ISO SOP Procedure ControlDocument4 pagesISO SOP Procedure ControlPINTU RAJNo ratings yet

- QMS DocumentationDocument11 pagesQMS Documentationaji ibrahimNo ratings yet

- List of Contents: Process-And Product AuditDocument6 pagesList of Contents: Process-And Product AuditiresendizNo ratings yet

- Vertical Turbine Pumps Engineering Data: Effective April 1, 2003Document11 pagesVertical Turbine Pumps Engineering Data: Effective April 1, 2003Israel CastilloNo ratings yet

- What Is The ISO 9001:2008 Audit Checklist?Document38 pagesWhat Is The ISO 9001:2008 Audit Checklist?John SoaresNo ratings yet

- 9001 Audit Checklist - Quality Planning and DesignDocument14 pages9001 Audit Checklist - Quality Planning and DesignAmer RahmahNo ratings yet

- KerepeanDocument12 pagesKerepeansyeila_elmiaNo ratings yet

- Guidelines for Supplier AuditDocument15 pagesGuidelines for Supplier AuditAdi SavaNo ratings yet

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 pagesISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- Self Audit Checklist PresentationDocument20 pagesSelf Audit Checklist Presentationnashwan mustafaNo ratings yet

- Iso9001 2015 Quality Manual Template 1 1024Document1 pageIso9001 2015 Quality Manual Template 1 1024Adhi GunantoNo ratings yet

- Pub100373 PDFDocument12 pagesPub100373 PDFedgelcer100% (1)

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- ISO 9001 Internal Audit ChecklistDocument14 pagesISO 9001 Internal Audit ChecklistEsterNTNo ratings yet

- ISO 9001 Lead AuditorDocument20 pagesISO 9001 Lead AuditorAmer MakenNo ratings yet

- APG InternalAudit2015 PDFDocument4 pagesAPG InternalAudit2015 PDFBulmaro SanchezNo ratings yet

- 9001 ExcerciseDocument5 pages9001 ExcerciseMohamed Fouad100% (1)

- Quality Process Audit TitleDocument42 pagesQuality Process Audit TitlephamtienkhangNo ratings yet

- Auditing Integrated Management System (ISO 9001:2015, ISO 14001:2015 & BS OHSAS 18001:2007)Document50 pagesAuditing Integrated Management System (ISO 9001:2015, ISO 14001:2015 & BS OHSAS 18001:2007)Junaid Mir100% (1)

- In Southeast Asia Poised For Rapid Growth: AUGUST 2019Document8 pagesIn Southeast Asia Poised For Rapid Growth: AUGUST 2019Nguyễn Vũ HoàngNo ratings yet

- CPA Compliance ChecklistDocument25 pagesCPA Compliance ChecklistFizz FirdausNo ratings yet

- ISO 9001 Awareness PDFDocument1 pageISO 9001 Awareness PDFAnand Chavan Projects-QualityNo ratings yet

- Alabama Specialty Products, Inc.Document24 pagesAlabama Specialty Products, Inc.qmicertificationNo ratings yet

- The Program of QmsDocument16 pagesThe Program of QmsHamza Sharif AdamNo ratings yet

- AS9100 Rev D TransitionDocument104 pagesAS9100 Rev D TransitionSudhagarNo ratings yet

- 9001 Planning Checklist - Production ProcessDocument14 pages9001 Planning Checklist - Production ProcessMowheadAdelNo ratings yet

- PMBody of Knowledge (Quality) Leangroup OrgDocument55 pagesPMBody of Knowledge (Quality) Leangroup Orgكنز knzNo ratings yet

- TM-638500090 42Document1 pageTM-638500090 42cover filterNo ratings yet

- 2055IATF BDocument8 pages2055IATF BHelton MotaNo ratings yet

- 7.3.2 Risk Management Storyboard Content 01 APR 2014Document38 pages7.3.2 Risk Management Storyboard Content 01 APR 2014BharathNo ratings yet

- 001-DP Master PDFDocument2 pages001-DP Master PDFAles esaamNo ratings yet

- A Strategy For Performance ExcellenceDocument27 pagesA Strategy For Performance Excellencejosan777No ratings yet

- 5S Routine Audit Form AuditDocument7 pages5S Routine Audit Form Auditadnan iqbalNo ratings yet

- 3 Legged 5 Why Picture of Current State Corrective Actions / Owner / Target Date Picture of Corrected StateDocument1 page3 Legged 5 Why Picture of Current State Corrective Actions / Owner / Target Date Picture of Corrected Statecover filterNo ratings yet

- Study of IT Systems at Ashok LeylandDocument3 pagesStudy of IT Systems at Ashok LeylandSiddhant SalilNo ratings yet

- Condor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) ADocument2 pagesCondor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) AEldar IsgenderovNo ratings yet

- The Ultimate Guide To WaterjetDocument9 pagesThe Ultimate Guide To WaterjetNsidibe Michael EtimNo ratings yet

- FAQ 690p Flash FirmwareDocument1 pageFAQ 690p Flash FirmwareRicardo Pimenta de CarvalhoNo ratings yet

- Mode of Grouped Data and MidrangeDocument16 pagesMode of Grouped Data and Midrangesfjs/olfdNo ratings yet

- Candle Power Stirling Engine PDFDocument4 pagesCandle Power Stirling Engine PDFFodor EmericNo ratings yet

- Example 8: Masonry Wall: Starting A New StructureDocument16 pagesExample 8: Masonry Wall: Starting A New StructureHENRY MICHELNo ratings yet

- Department of Education: Republic of The PhilippinesDocument4 pagesDepartment of Education: Republic of The PhilippinesTotoy AbnoyNo ratings yet

- Iso 19731-2017Document6 pagesIso 19731-2017Borja Arrizabalaga UriarteNo ratings yet

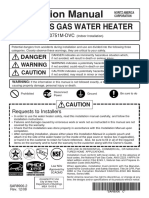

- Installation Manual: Tankless Gas Water HeaterDocument26 pagesInstallation Manual: Tankless Gas Water HeateralanNo ratings yet

- HP Compaq 6910p Compal LA-3261p UMA Rev 1A SchematicDocument55 pagesHP Compaq 6910p Compal LA-3261p UMA Rev 1A Schematicbbbbbb1987No ratings yet

- EN14181 Asig Calitatii CEMSDocument45 pagesEN14181 Asig Calitatii CEMSbrctlnNo ratings yet

- GSMA What Is SIM SwapDocument1 pageGSMA What Is SIM SwapLeon PejićNo ratings yet

- JBoss Enterprise Application Platform-5-Performance Tuning Guide-En-USDocument75 pagesJBoss Enterprise Application Platform-5-Performance Tuning Guide-En-USvali07No ratings yet

- Developing Web Applications Using Microsoft Visual Studio 2008Document23 pagesDeveloping Web Applications Using Microsoft Visual Studio 2008Guillermo Pardos VázquezNo ratings yet

- Urban Transit For Livable Cities: ReferencesDocument3 pagesUrban Transit For Livable Cities: ReferencesVismitha RamaiahNo ratings yet

- Algebra Terms and DefinitionsDocument6 pagesAlgebra Terms and DefinitionssNo ratings yet

- Catalogo VPFT 4535Document91 pagesCatalogo VPFT 4535PRISCILA FAGUNDESNo ratings yet

- Inglés Técnico 01Document23 pagesInglés Técnico 01Stefany DulkaNo ratings yet

- Tutorial Wirecut PDFDocument77 pagesTutorial Wirecut PDFmfitri83No ratings yet

- Power BI Vs Excel 1694801413Document1 pagePower BI Vs Excel 1694801413LifeNo ratings yet

- Manage project cost reportDocument6 pagesManage project cost reportMonique Marcolin BugeNo ratings yet

- Business PlanDocument49 pagesBusiness Plandanie krisyaNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument4 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceJagdeep Singh DeepiNo ratings yet