0% found this document useful (0 votes)

4K views5 pagesSupplier QMS Audit Checklist

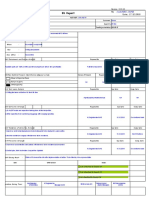

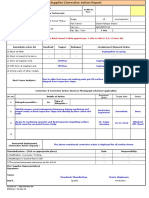

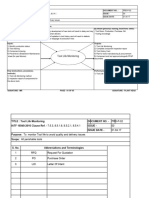

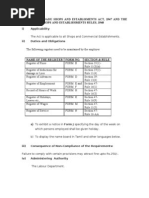

The document is a supplier quality management system audit checklist that contains 7 sections evaluating different areas of the supplier's quality system, including general requirements, specific requirements, purchasing, incoming material control, production, final product control, and maintenance. Each section contains several audit criteria rated on a scale of 1 to 4. The checklist is used to assess conformance to the supplier's quality management system and identify any nonconformities requiring corrective action.

Uploaded by

vishvendanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

4K views5 pagesSupplier QMS Audit Checklist

The document is a supplier quality management system audit checklist that contains 7 sections evaluating different areas of the supplier's quality system, including general requirements, specific requirements, purchasing, incoming material control, production, final product control, and maintenance. Each section contains several audit criteria rated on a scale of 1 to 4. The checklist is used to assess conformance to the supplier's quality management system and identify any nonconformities requiring corrective action.

Uploaded by

vishvendanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd