0% found this document useful (0 votes)

1K views3 pagesQuality System Procedure

Uploaded by

Subrat barikCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views3 pagesQuality System Procedure

Uploaded by

Subrat barikCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

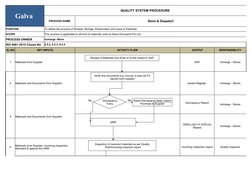

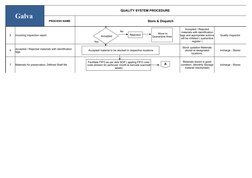

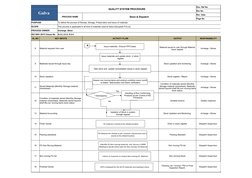

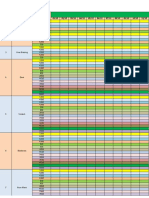

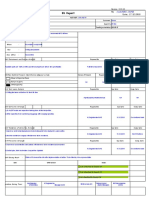

- Activity Flow and Key Inputs

- Store & Dispatch Purpose and Scope

- Incoming Inspection Analysis

- Store & Dispatch Procedure Steps