0% found this document useful (0 votes)

2K views9 pagesWi-Stores & Production

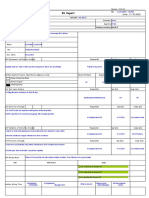

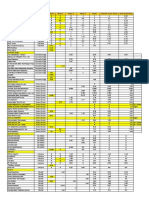

1. The documents describe Fontus Water Private Limited's procedures for receiving, storing, and issuing materials at their facility.

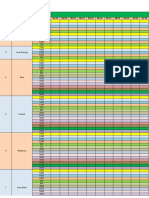

2. Key steps include checking incoming materials against purchase orders, segregating approved and rejected items, updating stock registers and bin cards, and informing other departments about shortages or excess deliveries.

3. Materials are stored in designated areas with minimum and maximum levels defined, physical verifications are carried out monthly, and inventory reports are generated. Materials are issued based on requisition slips and orders, and registers are updated to track usage.

Uploaded by

Ranjit SinghCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views9 pagesWi-Stores & Production

1. The documents describe Fontus Water Private Limited's procedures for receiving, storing, and issuing materials at their facility.

2. Key steps include checking incoming materials against purchase orders, segregating approved and rejected items, updating stock registers and bin cards, and informing other departments about shortages or excess deliveries.

3. Materials are stored in designated areas with minimum and maximum levels defined, physical verifications are carried out monthly, and inventory reports are generated. Materials are issued based on requisition slips and orders, and registers are updated to track usage.

Uploaded by

Ranjit SinghCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd