100% found this document useful (2 votes)

3K views1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)

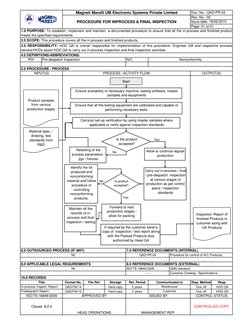

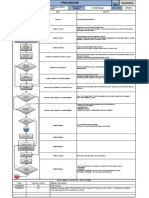

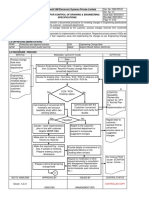

This document establishes a procedure for in-process and final inspection to ensure products meet specifications. It defines responsibilities for quality assurance personnel to perform inspections at various production stages according to control plans. Inspection reports are generated and sent to the warehouse or customer along with conforming products. Nonconforming products are handled per the procedure for controlling nonconforming products. Quality assurance is responsible for maintaining inspection records for two years.

Uploaded by

sumanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

3K views1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)

This document establishes a procedure for in-process and final inspection to ensure products meet specifications. It defines responsibilities for quality assurance personnel to perform inspections at various production stages according to control plans. Inspection reports are generated and sent to the warehouse or customer along with conforming products. Nonconforming products are handled per the procedure for controlling nonconforming products. Quality assurance is responsible for maintaining inspection records for two years.

Uploaded by

sumanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Procedure for Inprocess & Final Inspection: Details the steps and responsibilities associated with inprocess and final inspection procedures within the manufacturing process, including position-specific responsibilities and control measures.