Professional Documents

Culture Documents

QAD Procedure - Control of Inspection, Measuring & Test Equipment P2

Uploaded by

sumanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAD Procedure - Control of Inspection, Measuring & Test Equipment P2

Uploaded by

sumanCopyright:

Available Formats

Magneti Marelli UM Electronic Systems Private Limited Doc. No.

: QAD-PR-02

Rev. No.: 01

PROCEDURE FOR CONTROL OF MONITORING & MEASURING

Issue date: 03/03/2010

EQUIPMENT Page: 02 of 02

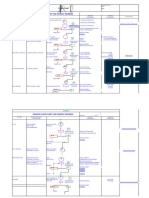

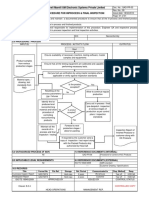

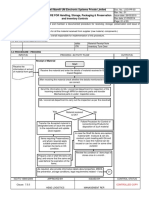

5.0 PROCEDURE / PROCESS

INPUT(S) PROCESS / ACTIVITY FLOW OUTPUT(S)

C1

No Within Reqd. Yes

Accuracy?

Calibrated

Can be Yes Send calibrated Instrument Equipment with

repaired? provided with Calibration status to user

Status to User Dept department

No

Get the equipment

repaired and re-

Discuss with Head QA calibrated

& user for its use in

other desired location.

Either Reject instrument and / or Identify need of new / repair of

Instruments based on Product / Process Tolerances, Resolution,

Operating Range and required accuracy. Inform User Dept

Review the calibration frequency of such equipment and if required

increase the frequency of calibration.

Update the history card & next due date of calibration in annual schedule

In case of a breakdown in equipment, jig, gauge, 20 % parts are to be

quarantined and reverified, In case one found NG all the quarantined

material to be rework Δ

End

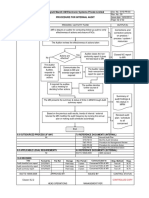

6.0 OUTSOURCED PROCESS (IF ANY) 7.0 REFERENCE DOCUMENTS (INTERNAL)

External Calibration Services QAD-PR-07 Procedure for MSA

QAD-PR-08 Procedure for Lab Management

Master list of Monitoring & measuring Equip

Internal Laboratory Scope

8.0 APPLICABLE LEGAL REQUIREMENTS 9.0 REFERENCE DOCUMENTS (EXTERNAL)

Nil ISO/TS 16949:2009 QMS standard

10.0 RECORDS

Title Format No. File Ref. Storage Ret. Period Communicated to Disp. Method Resp.

External Cal. Report --- Cal-01 Hard copy 3 years User Department Tear off HOD QA

ISO/TS 16949:2009 APPROVED BY ISSUED BY CONTROL STATUS

Clause: 7.6 CONTROLLED COPY

HEAD OPERATIONS MANAGEMENT REP.

You might also like

- QAD Procedure - Control of Inspection, Measuring & Test Equipment P1Document1 pageQAD Procedure - Control of Inspection, Measuring & Test Equipment P1sumanNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P2Document2 pagesQAD Procedure - Control of Non-Conforming Products P2sumanNo ratings yet

- FRM QUA 506 Process Audit Sheet 1Document2 pagesFRM QUA 506 Process Audit Sheet 1Ravi javaliNo ratings yet

- QP-QA-01-Receiving InspectionDocument2 pagesQP-QA-01-Receiving InspectionDebkanta DasNo ratings yet

- QAD Procedure - Corrective Action P2Document1 pageQAD Procedure - Corrective Action P2sumanNo ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- HRD Procedure - Employee Motivation & Empowerment P2Document1 pageHRD Procedure - Employee Motivation & Empowerment P2sumanNo ratings yet

- Check List - Product Realisation ProcessDocument4 pagesCheck List - Product Realisation ProcessDisha ShahNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- MSP ProceduresDocument18 pagesMSP ProcedurestarunNo ratings yet

- 1635 - 03 Control of Non Conforming Products Rev. 01Document5 pages1635 - 03 Control of Non Conforming Products Rev. 01Senthilkumar NarayananNo ratings yet

- 5 APQP 1 of 3Document3 pages5 APQP 1 of 3P G SumanNo ratings yet

- Chopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureDocument5 pagesChopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureShankar ChowdhuryNo ratings yet

- NC Management Procedure..Document8 pagesNC Management Procedure..shobha shelarNo ratings yet

- Production QA Process AuditDocument9 pagesProduction QA Process AuditDhananjay Patil100% (1)

- QAD Procedure - Control of Non-Conforming Products P1Document1 pageQAD Procedure - Control of Non-Conforming Products P1sumanNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Initial Product Quality Control ProcessDocument3 pagesInitial Product Quality Control ProcessSameer SaxenaNo ratings yet

- QG-QSP-08 Procedure For Control of Non-Conformance Product.Document5 pagesQG-QSP-08 Procedure For Control of Non-Conformance Product.omprakash yadavNo ratings yet

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMARNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- Control of Non-Conforming Products ProcedureDocument10 pagesControl of Non-Conforming Products ProcedureSachin KumbharNo ratings yet

- Audit ComplianceDocument1 pageAudit ComplianceNitin SharmaNo ratings yet

- TMT Procedure - Management Review P2Document1 pageTMT Procedure - Management Review P2sumanNo ratings yet

- IT Group Internal Audit Schedules and ReportsDocument11 pagesIT Group Internal Audit Schedules and ReportsBhavin SukhadiyaNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Control of Non-ConformanceDocument5 pagesControl of Non-ConformanceLawzy Elsadig SeddigNo ratings yet

- TMT Procedure - Management ReviewP1Document1 pageTMT Procedure - Management ReviewP1sumanNo ratings yet

- ISO 9001:2008 & ISO/TS 16949 Quality Management RequirementsDocument52 pagesISO 9001:2008 & ISO/TS 16949 Quality Management Requirementssupady5751No ratings yet

- Control of Records ProcedureDocument1 pageControl of Records ProcedureZharel AhmadNo ratings yet

- Roles & Responsibilities Job Position: HOD-Quality AssuranceDocument12 pagesRoles & Responsibilities Job Position: HOD-Quality AssurancemuthuselvanNo ratings yet

- Safety: A) Machine Safety SystemDocument5 pagesSafety: A) Machine Safety SystemSagar DaundNo ratings yet

- Quality System Procedure: Corrective Action 1.0 PurposeDocument4 pagesQuality System Procedure: Corrective Action 1.0 PurposeNaveenkumar RNo ratings yet

- QA & QC Organization Chart PDFDocument1 pageQA & QC Organization Chart PDFFashion MangoNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Customer Complaint RegisterDocument3 pagesCustomer Complaint RegistermuthuselvanNo ratings yet

- Anexo 06 - PA - Process Audit v1.1Document19 pagesAnexo 06 - PA - Process Audit v1.1BalajiNo ratings yet

- QM 01 ANNEX II Key Busines ProcessDocument4 pagesQM 01 ANNEX II Key Busines ProcessVinod SaleNo ratings yet

- Maruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingDocument3 pagesMaruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingAnkush Chourasia100% (1)

- RQMS - IRIS - Stake Holder Analysis SheetDocument6 pagesRQMS - IRIS - Stake Holder Analysis Sheetabhisheksen.asindNo ratings yet

- PPAP Production Part Approval ProcessDocument7 pagesPPAP Production Part Approval ProcessXionNo ratings yet

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Control PlanDocument4 pagesControl PlanRakesh PandeyNo ratings yet

- Road Map For IATF 16949 R-6 UpdatedDocument1 pageRoad Map For IATF 16949 R-6 UpdatedRavi javali100% (1)

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Minutes of Management Review MeetingDocument5 pagesMinutes of Management Review Meetingwinston11No ratings yet

- APQP Final ProcedureDocument9 pagesAPQP Final ProcedurePk NimiwalNo ratings yet

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- Process flow chart for primary structural steel fabricationDocument3 pagesProcess flow chart for primary structural steel fabricationmadhu krishnaNo ratings yet

- Control of Monitoring & Measuring DevicesDocument10 pagesControl of Monitoring & Measuring DevicesRamesh mudunuriNo ratings yet

- MRM PlanDocument2 pagesMRM Plang.kannan100% (1)

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1EduardNo ratings yet

- QAD Procedure - Corrective Action P2Document1 pageQAD Procedure - Corrective Action P2sumanNo ratings yet

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- QAD Procedure - Corrective Action P1Document1 pageQAD Procedure - Corrective Action P1sumanNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P1Document1 pageQAD Procedure - Control of Non-Conforming Products P1sumanNo ratings yet

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- LOG Procedure - Finished Product Despatch & DeliveryDocument1 pageLOG Procedure - Finished Product Despatch & DeliverysumanNo ratings yet

- Control Drawing & Engineering SpecificationsDocument1 pageControl Drawing & Engineering SpecificationssumanNo ratings yet

- R&D Procedure - Product - Development - HandbookDocument45 pagesR&D Procedure - Product - Development - HandbooksumanNo ratings yet

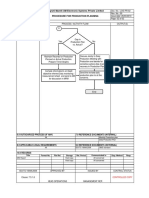

- LOG Procedure - Production Planning and Control P2Document1 pageLOG Procedure - Production Planning and Control P2sumanNo ratings yet

- LOG Procedure - Material Planning & Procurement - P1Document1 pageLOG Procedure - Material Planning & Procurement - P1sumanNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- LOG Procedure - Handling Storage Packaging Preservation and Inventory Control P1Document1 pageLOG Procedure - Handling Storage Packaging Preservation and Inventory Control P1sumanNo ratings yet

- TMT Procedure - Management Review P2Document1 pageTMT Procedure - Management Review P2sumanNo ratings yet

- Internal Audit ProcedureDocument1 pageInternal Audit ProceduresumanNo ratings yet

- ICT Procedure - System Support and Maintenance P1Document1 pageICT Procedure - System Support and Maintenance P1sumanNo ratings yet

- TMT Procedure - Management ReviewP1Document1 pageTMT Procedure - Management ReviewP1sumanNo ratings yet

- SYS Procedure - Internal Quality Audit P1Document1 pageSYS Procedure - Internal Quality Audit P1sumanNo ratings yet

- HRD Procedure - Employee Motivation & Empowerment P2Document1 pageHRD Procedure - Employee Motivation & Empowerment P2sumanNo ratings yet

- HRD Procedure - Competance, Awareness & Training P2Document1 pageHRD Procedure - Competance, Awareness & Training P2sumanNo ratings yet

- GFORM 015 Risk Assessment QualityDocument4 pagesGFORM 015 Risk Assessment QualitysumanNo ratings yet

- HRD Procedure - Competance, Awareness & Training P1Document2 pagesHRD Procedure - Competance, Awareness & Training P1sumanNo ratings yet

- GFORM - 015 Risk Assessment - Production, Store, Purchase & Maint.Document4 pagesGFORM - 015 Risk Assessment - Production, Store, Purchase & Maint.sumanNo ratings yet

- Certification ProcedureDocument1 pageCertification ProceduresumanNo ratings yet

- GFORM - 015 Risk Assessment - Engineering - 1Document5 pagesGFORM - 015 Risk Assessment - Engineering - 1sumanNo ratings yet

- How to Use the Risk Management TemplateDocument4 pagesHow to Use the Risk Management TemplatesumanNo ratings yet

- LEC 5 Elements of An Offence and Their QualificationsDocument27 pagesLEC 5 Elements of An Offence and Their QualificationsEliezer Charles Ngahyoma67% (3)

- Toshiba 40rv52u LCD TV SMDocument18 pagesToshiba 40rv52u LCD TV SMRomell Estaba SalazarNo ratings yet

- Cased Hole LoggingDocument131 pagesCased Hole LoggingEbenezer Amoah-Kyei100% (1)

- Department of Labor: ls-200Document2 pagesDepartment of Labor: ls-200USA_DepartmentOfLaborNo ratings yet

- DRM Act 2015Document52 pagesDRM Act 2015Gail HoadNo ratings yet

- FliesDocument14 pagesFliesaguilarmvzNo ratings yet

- TS Ewk 2Document14 pagesTS Ewk 2bodale vergaNo ratings yet

- Continuity of Education in the New NormalDocument2 pagesContinuity of Education in the New NormalMon Agulto LomedaNo ratings yet

- IJST - Vol (7) - No (4) December 2012Document153 pagesIJST - Vol (7) - No (4) December 2012Taghreed hashim AlnoorNo ratings yet

- Root-Knot and Root-Lesion Nematode SuppressionDocument6 pagesRoot-Knot and Root-Lesion Nematode SuppressionRAMIRO H.S.No ratings yet

- The McKenzie Method Powerpoint - 2008Document57 pagesThe McKenzie Method Powerpoint - 2008aslooclt100% (2)

- HB Synthesis, Degradation, Jaundice, Iron Metabolism by Dr. RoomiDocument23 pagesHB Synthesis, Degradation, Jaundice, Iron Metabolism by Dr. RoomiMudassar Roomi100% (1)

- Topic 3. Ecosystems (4 Marks) : Q. No. Option I Option II Option III Option IV Answer KeyDocument2 pagesTopic 3. Ecosystems (4 Marks) : Q. No. Option I Option II Option III Option IV Answer KeysakshiNo ratings yet

- What Is Newborn ScreeningDocument2 pagesWhat Is Newborn ScreeningroksanmiNo ratings yet

- Carte Tehnica Masina de Spalat HM270-670 en NEWDocument53 pagesCarte Tehnica Masina de Spalat HM270-670 en NEWniki2530No ratings yet

- Case Study 2 MNTDocument11 pagesCase Study 2 MNTapi-242547654No ratings yet

- Trophy Winners 2019Document10 pagesTrophy Winners 2019blackguard999No ratings yet

- Data Sheet - BS6231 PVC Tri-Rated Flexible Cable - Cleveland CableDocument2 pagesData Sheet - BS6231 PVC Tri-Rated Flexible Cable - Cleveland CableCalum MartinNo ratings yet

- 1 - KSU Research Methodology Overview (A Mandil, Oct 2009)Document25 pages1 - KSU Research Methodology Overview (A Mandil, Oct 2009)Fatamii IiiNo ratings yet

- Astm E1973 - 1 (En)Document4 pagesAstm E1973 - 1 (En)Dinesh SaiNo ratings yet

- Long-Term Memory - ProcessDocument30 pagesLong-Term Memory - ProcessALEXANDRA SAN PEDRONo ratings yet

- Perfume Notes & FamiliesDocument24 pagesPerfume Notes & Familiesmohamed tharwatNo ratings yet

- Chemistry Ssc-I: Answer Sheet No.Document7 pagesChemistry Ssc-I: Answer Sheet No.Mohsin SyedNo ratings yet

- Inflammatory Bowel DiseaseDocument27 pagesInflammatory Bowel DiseaseMihai VladescuNo ratings yet

- Benefits of HobbiesDocument6 pagesBenefits of HobbiesAdam YapNo ratings yet

- 3 Novec™ 1230 Fire Protection Fluid Data SheetDocument4 pages3 Novec™ 1230 Fire Protection Fluid Data SheetL ONo ratings yet

- Ultra-low Profile Dome Key Adds Single-key TypeDocument3 pagesUltra-low Profile Dome Key Adds Single-key TypeMuhamad PriyatnaNo ratings yet

- Presented by M. Hassan ShafiqDocument25 pagesPresented by M. Hassan ShafiqMadiha Amna AndrabiNo ratings yet

- Road Kill Cafe MenuDocument1 pageRoad Kill Cafe MenuwjannuschNo ratings yet