Professional Documents

Culture Documents

Process Audit - Sheet New ......

Uploaded by

MUKESH KUMAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Audit - Sheet New ......

Uploaded by

MUKESH KUMARCopyright:

Available Formats

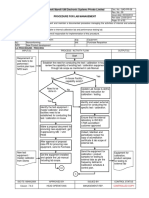

Doc. No.

F/QA/13

Rev. No. 00

PROCESS AUDIT CHECKSHEET Date 01.07.2016

Part Name/No. : Date :

S.No. PROCESS PARAMETERS SPECIFICATIONS OBSERVATIONS REMARKS

1 Are previous audit observations closed ? Should be closed

Is operator working as per Operation

2 standard Should be follow

3

Verify the Process Flow Chart / Process Process sequence must be as per

Sequence of the Running Component PFD.

Check the availability of Process Control PCS / Control Plan / Operation

4 Standards (Operation Standard/WI's) on Standard must be Displayed /

machine Available on line

Verify the process parameters as per All the process parameters must be

5 Control Plan / Operation Standard on within specification limit

machine

Recording must be as per specified

6

Check the records as mentioned in Control frequency and in defined format &

Plan / Operation Standard by competent person as defined

Verify that all the measuring instruments/ Calibration reports of the

7 Gauges are calibrated & check the Instruments / Gauges

validity / Expiry date.

Verify that the machine check sheet is

8 properly filled Check sheets must be upto date

9

Check for Legibility / Visibility of all the All the Displays must be Visible &

Displayed documents Legible

Check for the availability of Master

10 samples / Limit Samples / FOP samples FOP & Master /Limit Samples must

exist

etc.

Verify proper disposition of Non Rework / Scrap Notes &

11 Countermeasure reports must be

Conforming products produced

Check the competency of Operator /

12

Inspector Verify Skill / Competence Matrix

Verify the effective implementation

13 Verify the Countermeasures of problems of Countermeasures & awareness

(Internal & External)

among concerned peoples

Check & Verify the Machine / Tool / Jig / All the Machines / tools must have

14 Fixture conditions (Maintenance of been maintained as per plan

Production Equipments/ Machine/ Tool)

15

Verify the effective implementation / Poka-Yoke mechanism must be

functioning of Poka-Yoke Mechanism functioning well

All the parts must be properly

16 Check for identification & traceability identified & traceable

( Identification Tags )

Quality check record must be

17 Verification of Change Management. maintained for upexpected

/abnormal change & ECN must be

properly implemented

PPEs (Goggles, Gloves , Aprons,

18

Verify the implementation of Safety Nose masks , Shoes ,Ear Plugs etc.)

measures in the shop floor must be effectively used in shop

floor

Check the availability of Red/Yellow/Ok

19 Bins at shop floor. should be available

Remarks for any Improvement/Suggestion :

Sign of Auditor : Sign Of Audittee :

You might also like

- Operator observation sheet reviewDocument1 pageOperator observation sheet review25aprilNo ratings yet

- Layered Audit Check SheetsDocument5 pagesLayered Audit Check Sheetsdeepak sharma100% (1)

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Operator Observance ChecklistDocument2 pagesOperator Observance Checklistrajesh sharma100% (1)

- Operator Observance SheetDocument5 pagesOperator Observance SheetEr Avinash Kumar100% (2)

- Manufacturing Audit ReportDocument1 pageManufacturing Audit ReportBASAVA ENGINEERINGNo ratings yet

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (1)

- Meenakshi Polymers 4M Change InspectionDocument4 pagesMeenakshi Polymers 4M Change InspectionKaran Malhi100% (1)

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDocument1 page14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNo ratings yet

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- F MR 20B 4M Criteria NewDocument4 pagesF MR 20B 4M Criteria NewBangali Singh100% (1)

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- Advance Product Quality Planning ProcessDocument6 pagesAdvance Product Quality Planning ProcessBangali Singh100% (1)

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- ISC Termination SheetDocument1 pageISC Termination SheetAjayChaudharyNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P2Document2 pagesQAD Procedure - Control of Non-Conforming Products P2sumanNo ratings yet

- Cohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NameDocument2 pagesCohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NamePrakash kumarTripathiNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

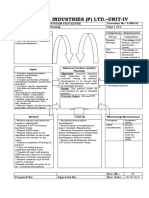

- Chopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureDocument5 pagesChopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureShankar ChowdhuryNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

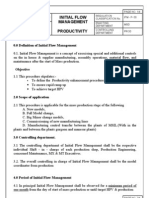

- Inital Flow Management Productivity ProcedureDocument4 pagesInital Flow Management Productivity Procedureshaggyrahul100% (3)

- Manufacturing Process Audit ScorecardDocument1 pageManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- AE-QA-02 - First Piece Inspection ReportDocument1 pageAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanNo ratings yet

- Skill evaluation criteria for CED and chrome plating processesDocument1 pageSkill evaluation criteria for CED and chrome plating processesDinesh KumarNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- DS-09-02 R0 Change Implementation MatrixDocument3 pagesDS-09-02 R0 Change Implementation MatrixDhinakaran100% (1)

- NC Management Procedure..Document8 pagesNC Management Procedure..shobha shelarNo ratings yet

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Change Management Matrix for Vendor Updates in May 2022Document1 pageChange Management Matrix for Vendor Updates in May 2022nitin rathoreNo ratings yet

- Automotive customer requirement checklistDocument2 pagesAutomotive customer requirement checklistmahesk_dmNo ratings yet

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- 4M Change MatrixDocument1 page4M Change MatrixAnkit SainiNo ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- W.I - Abnormal SituationDocument1 pageW.I - Abnormal Situation25april100% (2)

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaNo ratings yet

- Poison Test PlanDocument29 pagesPoison Test PlanDinesh KumarNo ratings yet

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- WI For 4M Change ManagementDocument2 pagesWI For 4M Change ManagementSwagatNo ratings yet

- Guideline 4M Change MatrixDocument3 pagesGuideline 4M Change MatrixAman JasujaNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Control of Documents ProcedureDocument1 pageControl of Documents ProcedureZharel AhmadNo ratings yet

- COMP-OPP-01 Procedure For Control and Validation of ProductionDocument4 pagesCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINo ratings yet

- Manufacturing Process Audit: RatingDocument3 pagesManufacturing Process Audit: Ratingrajesh.bNo ratings yet

- Manufacturing Process Audit ResultsDocument1 pageManufacturing Process Audit Resultsmurilocabrini100% (1)

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- VCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingDocument1 pageVCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingBalram JiNo ratings yet

- Procedure For ApqpDocument19 pagesProcedure For ApqpRaja RehaNo ratings yet

- Manufacturing Process Audit Report SummaryDocument1 pageManufacturing Process Audit Report SummaryNaresh kumarNo ratings yet

- Layered Process Audit ChecklistDocument1 pageLayered Process Audit ChecklistMuniyappan TNo ratings yet

- Combined Orders (SAP Library - Production Planning and Control)Document3 pagesCombined Orders (SAP Library - Production Planning and Control)Rashid KhanNo ratings yet

- Transfer Price MechanismDocument5 pagesTransfer Price MechanismnikhilkumarraoNo ratings yet

- Measuring Marketing Performance A Critique of Empirical LiteratureDocument10 pagesMeasuring Marketing Performance A Critique of Empirical LiteratureAsma TahaNo ratings yet

- S141 Advanced DSP-based Servo Motion ControllerDocument8 pagesS141 Advanced DSP-based Servo Motion ControllersharkeraNo ratings yet

- Customer Guide Electrical Service Information FormDocument2 pagesCustomer Guide Electrical Service Information FormRyder BergerudNo ratings yet

- Maslows TheoryDocument9 pagesMaslows TheoryPratik ThakkarNo ratings yet

- Tata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Document3 pagesTata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Mahendra SinghNo ratings yet

- German Truck CheatDocument3 pagesGerman Truck Cheatdukagold11No ratings yet

- Nurarihyon No Mago Season 3 Sub Indo PDFDocument3 pagesNurarihyon No Mago Season 3 Sub Indo PDFLgn StruggleNo ratings yet

- The Stock Market For Dummies PDFDocument2 pagesThe Stock Market For Dummies PDFJoe D100% (1)

- International Auditing Overview: Principles of Auditing: An Introduction To International Standards On Auditing - Ch. 1Document36 pagesInternational Auditing Overview: Principles of Auditing: An Introduction To International Standards On Auditing - Ch. 1Almi HafizNo ratings yet

- Jess 303Document22 pagesJess 303Santanu Saha100% (1)

- Reverse Traversal HomeworkDocument3 pagesReverse Traversal Homeworkabhi74No ratings yet

- Tugas Kelompok Pend.b.asing 3Document5 pagesTugas Kelompok Pend.b.asing 3Akun YoutubeNo ratings yet

- Bank TellerDocument3 pagesBank Tellerapi-3701112No ratings yet

- AarushDocument88 pagesAarushCgNo ratings yet

- 809kW Marine Propulsion Engine SpecificationsDocument2 pages809kW Marine Propulsion Engine SpecificationsRoberto StepankowskyNo ratings yet

- Philips Gemini TF 64 Preferred Room LayoutDocument3 pagesPhilips Gemini TF 64 Preferred Room Layoutahmed_galal_waly1056No ratings yet

- Al-Cu Phase DiagramDocument4 pagesAl-Cu Phase DiagramSandeep YadavNo ratings yet

- Omnidirectional Condenser Lavalier Microphone U.S. Atr Series Lifetime Limited End-User WarrantyDocument2 pagesOmnidirectional Condenser Lavalier Microphone U.S. Atr Series Lifetime Limited End-User WarrantyEduardito De Villa CrespoNo ratings yet

- Ian Thompson - A Critique of Valuation Methods For Exploration PropertiesDocument12 pagesIan Thompson - A Critique of Valuation Methods For Exploration PropertiesZhuu Ming AngNo ratings yet

- Essay On Causes of Corruption and Its RemediesDocument30 pagesEssay On Causes of Corruption and Its Remediesanoos04100% (2)

- Buses and PortsDocument3 pagesBuses and PortsHuma Rashid80% (5)

- Understanding marketing conceptsDocument19 pagesUnderstanding marketing conceptsMOST SUBSCRIBER WITHOUT A VIDEO50% (2)

- Economics of The Environment - Theory and Policy (PDFDrive)Document328 pagesEconomics of The Environment - Theory and Policy (PDFDrive)danysubash100% (1)

- HR Functions and ProceduresDocument7 pagesHR Functions and ProceduresSandeep KumarNo ratings yet

- Final E-Portfolio AssignmentDocument7 pagesFinal E-Portfolio Assignmentapi-302594281No ratings yet

- English Form 01Document21 pagesEnglish Form 01setegnNo ratings yet

- Court of Appeals decision on Batara family land disputeDocument19 pagesCourt of Appeals decision on Batara family land disputeKhanini GandamraNo ratings yet

- EPM-Sxxx - I-O System 1000 System Manual - v8-0 - ENDocument1 pageEPM-Sxxx - I-O System 1000 System Manual - v8-0 - ENilli206No ratings yet