Professional Documents

Culture Documents

Skill evaluation criteria for CED and chrome plating processes

Uploaded by

Dinesh KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Skill evaluation criteria for CED and chrome plating processes

Uploaded by

Dinesh KumarCopyright:

Available Formats

SKILL EVALUATION CRITERIA

CED/Chrome Plating

Process INCOMING INSPECTION CED ( SCADA) FINAL INSEPCTION(CED) FINAL INSEPCTION(HARD CHROME

)

Min Level Required LEVEL-3 LEVEL-3 LEVEL-3 Level-3 Level-3

(LOADING & UNLOADING LEVEL-2)

1.Safety 1.Safety 1.Safety 1.Safety 1.Safety

2.1S,2S 2.1S,2S 2.1S,2S 2.1S,2S 2.1S,2S

3.Basic Knowledge of Tag 3.Basic Knowledge of Tag 3.Basic Knowledge of Tag 3.Basic Knowledge of Tag 3.Basic Knowledge of Tag

4.knowledge of Parts 4.knowledge of Parts 4.knowledge of Parts 4.knowledge of Parts 4.knowledge of Parts

Level 1 5.Basic awareness of operation, 5.Basic awareness of operation, 5.Basic awareness of operation, 5.Basic awareness of operation, 5.Basic awareness of operation,

(Basic Training Provided) 6.Basic awareness of WI 6.Basic awareness of WI 6.Basic awareness of WI 6.Basic awareness of WI 6.Basic awareness of WI

7.Material Handling Bin/Trolley 7.Material Handling Bin/Trolley 7.Material Handling Bin/Trolley 7.Material Handling Bin/Trolley 7.Material Handling Bin/Trolley

L1 + L1 + L1 + L1 + L1 +

1.3S 1.3S 1.3S 1.3S 1.3S

2.Knowledge about traceability 2.Knowledge of WI 2.Knowledge of WI 2.Knowledge about packing standard 2.Knowledge about packing standard

3.Knowledge of visual defect 3.Knowledge of masking 3.Knowledge of masking 3.Knowledge about traceability 3.Knowledge about traceability

4.Knowledge of abnormal situation 4.PART LOADING /UNLOADING 4.PART LOADING /UNLOADING 4.Knowledge of visual defect 4.Knowledge of visual defect

5.Knowledge of WI, 5.Knowledge of abnormal situation , 5.Knowledge of abnormal situation , 5.Knowledge of abnormal situation 5.Knowledge of abnormal situation

Level 2 6.Knowledge of Bins 6.hanger identification , 6.hanger identification , 6.Knowledge of WI, 6.Knowledge of WI,

(Can Work Under Guidance) 7.Knowledge of Bins 7.Knowledge of Bins 7.Knowledge of Bins 7.Knowledge of Bins

8.Ultra sonic Machine & Water Rinsing

L2 + L2 +

1.4S 1.4S

2.KNOWLEDGE defect identify L2 + L2 +

L2 + 3.FIFO, 2.KNOWLEDGE defect identify 1.Visual inspection and limit sample knowledge 1.Visual inspection and limit sample knowledge

1.Visual inspection and limit sample knowledge 2.Thickness Testing 2.Thickness Testing

4.OPERATE SCADA, 3.OPERATE SCADA, 3.Marking on parts 3.Marking on parts

5.Tracebility 4.FIFO, 4.Handling of NG Parts 4.Handling of NG Parts

2.Handling of NG Parts 6.Knowledge of Rework 5.Tracebility 5.4S, 5.4S,

Level 3 3.4S, 7.Daily machine checksheet 6.Knowledge of Rework 6.Knowledge of final inspection standard 6.Knowledge of final inspection standard

4.Similar Part, 7.Daily machine checksheet

(Can Work Independently) 5.Knowledge of rework, 8.BUFFING MACHINE 7.Similar Part, 7.Similar Part,

6.FIFO 8. rework, 8. rework,

9.FIFO 9.FIFO

7.KNOWLEDGE defect identify 10.Defect Identify 10.Defect Identify

L3 + L3 + L3 + L3 + L3 +

Can trained to others about all the topics Can trained to others about all the topics (LEVEL1- Can trained to others about all the topics Can trained to others about all the topics Can trained to others about all the topics

(LEVEL1-3) 3) (LEVEL1-3) (LEVEL1-3) (LEVEL1-3)

1.Help In Chemial Dozing 1.Help In Chemial Dozing 1.PDI Inspection 1.PDI Inspection

Level 4 1.Help in customer complaint handling 2.Help in bath Maintenance 2.Help in bath Maintenance 2.Help in customer complaint handling 2.Help in customer complaint handling

(Can Train Others) 2.Help in SPC Study 3.5s , 3.5s , 3.Help in SPC Study 3.Help in SPC Study

3.5s , 4.IPP, 4.IPP, 4.5s , 4.5s ,

4.IPP,

5.IPC, 5.IPC, 5.IPC, 5.IPP, 5.IPP,

6.4M, 6.4M, 6.4M, 6.IPC, 6.IPC,

7.4M, 7.4M,

PREPARED BY : APPROVED BY:

You might also like

- Year 12 - Chemistry PDFDocument108 pagesYear 12 - Chemistry PDFWill Nguyen100% (2)

- Process Wise Level Wise Skill Req. For Opr.Document1 pageProcess Wise Level Wise Skill Req. For Opr.Prakash kumarTripathiNo ratings yet

- Skill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredDocument2 pagesSkill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredRavi YadavNo ratings yet

- Meenakshi Polymers 4M Change InspectionDocument4 pagesMeenakshi Polymers 4M Change InspectionKaran Malhi100% (1)

- Skill Matrix: 1 - Basic Trg. AcquiredDocument4 pagesSkill Matrix: 1 - Basic Trg. AcquiredDinesh KumarNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- Roles & Responsibilities Job Position: HOD-Quality AssuranceDocument12 pagesRoles & Responsibilities Job Position: HOD-Quality AssurancemuthuselvanNo ratings yet

- Capa - 2Document1 pageCapa - 2Quality DWINo ratings yet

- Customer Complaint RegisterDocument3 pagesCustomer Complaint RegistermuthuselvanNo ratings yet

- In-Process Inspection Report: Date: - / - / - Rev. No.: 01 (11/05/2016)Document4 pagesIn-Process Inspection Report: Date: - / - / - Rev. No.: 01 (11/05/2016)Suraj RawatNo ratings yet

- Defect Control Report FITMENT PROBLEMDocument1 pageDefect Control Report FITMENT PROBLEMamritanshuNo ratings yet

- IT Group Internal Audit Schedules and ReportsDocument11 pagesIT Group Internal Audit Schedules and ReportsBhavin SukhadiyaNo ratings yet

- Management Review Programme (Insert Year) : ISO 9001:2015 QMSDocument2 pagesManagement Review Programme (Insert Year) : ISO 9001:2015 QMSFrench Sarah NeraNo ratings yet

- F MR 20B 4M Criteria NewDocument4 pagesF MR 20B 4M Criteria NewBangali Singh100% (1)

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Point No. 6Document10 pagesPoint No. 6Rohtash fastnerNo ratings yet

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- MTTR & MTBF RecordsDocument6 pagesMTTR & MTBF Recordspraagthish100% (1)

- APQP Time Plan for 150 X 75 Steel Hollow SectionDocument4 pagesAPQP Time Plan for 150 X 75 Steel Hollow SectionRakesh PandeyNo ratings yet

- ISC Termination SheetDocument1 pageISC Termination SheetAjayChaudharyNo ratings yet

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocument6 pagesDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DNo ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- Supplier Name Auditors: Vendor Attendees:: JudgmentDocument4 pagesSupplier Name Auditors: Vendor Attendees:: Judgment3A System SolutionNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- Punch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20Document1 pagePunch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20R KumarNo ratings yet

- Advance Product Quality Planning ProcessDocument6 pagesAdvance Product Quality Planning ProcessBangali Singh100% (1)

- Master TimingDocument4 pagesMaster TimingPk NimiwalNo ratings yet

- Past defect history details root cause analysis formatDocument10 pagesPast defect history details root cause analysis formatRahulNo ratings yet

- MARATHAN MOTOR SOP Recruitment ProcedureDocument4 pagesMARATHAN MOTOR SOP Recruitment Procedurerishi gautamNo ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- Daily Checklist for Quality ToolsDocument4 pagesDaily Checklist for Quality ToolsHarjeet SinghNo ratings yet

- Quality Risk Assesment: Department / Process: Design / EngineeringDocument2 pagesQuality Risk Assesment: Department / Process: Design / EngineeringAlbert NajjarNo ratings yet

- Manufacturing Audit ReportDocument1 pageManufacturing Audit ReportBASAVA ENGINEERINGNo ratings yet

- pure cotton pvt ltd final inspection reportDocument4 pagespure cotton pvt ltd final inspection reportTarun PariharNo ratings yet

- CAPA Incomplete Part MixDocument16 pagesCAPA Incomplete Part MixRohtash fastnerNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- Nikhil Quality 6YOEDocument3 pagesNikhil Quality 6YOENikhil DhimanNo ratings yet

- VSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingDocument1 pageVSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingrakeshNo ratings yet

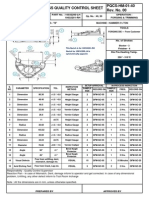

- VCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingDocument1 pageVCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingBalram JiNo ratings yet

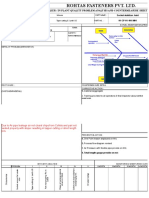

- Rohtas Fasteners Pvt. LTD.: Supplier / In-Plant Quality Problem Analysis and Countermeasure Sheet (5-Rule)Document4 pagesRohtas Fasteners Pvt. LTD.: Supplier / In-Plant Quality Problem Analysis and Countermeasure Sheet (5-Rule)Rohtash fastnerNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- CAPA Burr (TSSR)Document3 pagesCAPA Burr (TSSR)Mohit Singh100% (1)

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- FRM-WS-11 DWM Check Sheet (Weld SHP)Document2 pagesFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- F-QC-05 Deviation NoteDocument1 pageF-QC-05 Deviation NoteKaran MalhiNo ratings yet

- 4M Change Monitoring SheetDocument1 page4M Change Monitoring SheetDinesh KumarNo ratings yet

- Kaga Components (M) SDN BHD: Operator Training ProceduresDocument2 pagesKaga Components (M) SDN BHD: Operator Training Proceduresrajesh sharmaNo ratings yet

- Intimation Sheet Change ReportDocument1 pageIntimation Sheet Change ReportDhananjay Patil100% (1)

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- Cohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NameDocument2 pagesCohrance Audit Summary Report: Date:-Part Name:-PIN BALANCER Part Number: - Customer NamePrakash kumarTripathiNo ratings yet

- Guideline 4M Change MatrixDocument3 pagesGuideline 4M Change MatrixAman JasujaNo ratings yet

- Change Management Matrix for Vendor Updates in May 2022Document1 pageChange Management Matrix for Vendor Updates in May 2022nitin rathoreNo ratings yet

- Problem Solving Report for Rust IssuesDocument2 pagesProblem Solving Report for Rust IssuesMohit SinghNo ratings yet

- FT 35 DC D10447340A Process SheetDocument7 pagesFT 35 DC D10447340A Process SheetSuraj RawatNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMARNo ratings yet

- 8D Report for High Resistance Issue in Coil AssemblyDocument13 pages8D Report for High Resistance Issue in Coil AssemblyAnandha VasanNo ratings yet

- PFMEA Review - MOM FormatDocument2 pagesPFMEA Review - MOM FormatMASU BRAKE PADS QANo ratings yet

- Construction ManualDocument284 pagesConstruction ManualANSARI71No ratings yet

- Poison Test PlanDocument29 pagesPoison Test PlanDinesh KumarNo ratings yet

- Poison Test Sheet: Inspector Name: DateDocument2 pagesPoison Test Sheet: Inspector Name: DateDinesh Kumar100% (4)

- Poison Test PlanDocument29 pagesPoison Test PlanDinesh KumarNo ratings yet

- 4M Change Monitoring SheetDocument1 page4M Change Monitoring SheetDinesh KumarNo ratings yet

- 4M Change Monitoring SheetDocument1 page4M Change Monitoring SheetDinesh KumarNo ratings yet

- Global Automotive Declarable Substance List (GADSL) : Revised February 2018Document13 pagesGlobal Automotive Declarable Substance List (GADSL) : Revised February 2018Paul CadmanNo ratings yet

- RICO 8d FormatDocument4 pagesRICO 8d FormatDinesh KumarNo ratings yet

- SR - No Fire Extinguisher /type Size/Capaci TY Date of Purchasing /refilling Due Date of Inspection/ RefilingDocument6 pagesSR - No Fire Extinguisher /type Size/Capaci TY Date of Purchasing /refilling Due Date of Inspection/ RefilingDinesh KumarNo ratings yet

- Side - Markeddefle Ionpartiale Tensionincompletee Tensioncomplete E TensionDocument1 pageSide - Markeddefle Ionpartiale Tensionincompletee Tensioncomplete E TensionDinesh KumarNo ratings yet

- Global Automotive Declarable Substance List (GADSL)Document26 pagesGlobal Automotive Declarable Substance List (GADSL)Dinesh KumarNo ratings yet

- Statistical Process Control Study: Data Collection: - d2 A2 D4Document2 pagesStatistical Process Control Study: Data Collection: - d2 A2 D4Dinesh KumarNo ratings yet

- Rubric in Poster Making PDFDocument1 pageRubric in Poster Making PDFSerolf IanNo ratings yet

- CS 70 Discrete Mathematics and Probability Theory Spring 2016 Rao and Walrand Note 2 1 ProofsDocument8 pagesCS 70 Discrete Mathematics and Probability Theory Spring 2016 Rao and Walrand Note 2 1 ProofsAyesha NayyerNo ratings yet

- Vinamilk - Group 5Document13 pagesVinamilk - Group 5trinhhai09062003No ratings yet

- IPv4 - IPv4 Header - IPv4 Header Format - Gate VidyalayDocument15 pagesIPv4 - IPv4 Header - IPv4 Header Format - Gate VidyalaySakshi TapaseNo ratings yet

- Emmanuel Oneka - CV-3Document3 pagesEmmanuel Oneka - CV-3Emmanuel OnekaNo ratings yet

- University of Abuja School of Posgraduate StudiesDocument6 pagesUniversity of Abuja School of Posgraduate StudiesAdamu Yusufu100% (1)

- Reg0000007635187Document2 pagesReg0000007635187Amal JimmyNo ratings yet

- Nucor at A Crossroads: Group-2, Section - BDocument8 pagesNucor at A Crossroads: Group-2, Section - BHimanshiNo ratings yet

- Organizational Learning, Innovation, and ChangeDocument37 pagesOrganizational Learning, Innovation, and Changejaypee pengNo ratings yet

- Y12 - Hand - Book - 2019 2Document22 pagesY12 - Hand - Book - 2019 2tiagoNo ratings yet

- Operation and Maintenance of Power Plant PDFDocument31 pagesOperation and Maintenance of Power Plant PDFwonderstrikeNo ratings yet

- CSA Recap-8.8 Test 1Document72 pagesCSA Recap-8.8 Test 1Gokul BakkiyarasuNo ratings yet

- Chapter 3 Case Study - Not Sold OutDocument1 pageChapter 3 Case Study - Not Sold OutSagarika SinhaNo ratings yet

- Creo Simulate Components for Stress and Strain QuantitiesDocument1 pageCreo Simulate Components for Stress and Strain QuantitiesSebastiao SilvaNo ratings yet

- Transfer Taxes and Basic SuccessionDocument59 pagesTransfer Taxes and Basic SuccessionARC SVIORNo ratings yet

- Partial Molar PropertiesDocument6 pagesPartial Molar PropertiesNISHTHA PANDEYNo ratings yet

- Firelights PDFDocument2 pagesFirelights PDFEFG EFGNo ratings yet

- Journal of Ethnopharmacology: Trilobata (L.) Pruski Flower in RatsDocument7 pagesJournal of Ethnopharmacology: Trilobata (L.) Pruski Flower in RatsHeriansyah S1 FarmasiNo ratings yet

- Model Question Papers SolutionDocument39 pagesModel Question Papers SolutionVinayaka Gombi100% (2)

- PBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Document45 pagesPBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Ramdas KambleNo ratings yet

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet

- Project management software and techniquesDocument2 pagesProject management software and techniquesbinduannNo ratings yet

- EZPC/SC FAQ Covers Installation and Use of Smart Card ReadersDocument7 pagesEZPC/SC FAQ Covers Installation and Use of Smart Card ReadersDjuroLjPosticNo ratings yet

- Library ClassificationDocument10 pagesLibrary ClassificationKakeembo NasiifuNo ratings yet

- Antioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. LeavesDocument7 pagesAntioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. Leavespasid harlisaNo ratings yet

- Translation Task 1Document5 pagesTranslation Task 1Beatrice FontanaNo ratings yet

- Digital Marketing - Scope Opportunities and Challenges - IntechOpen PDFDocument31 pagesDigital Marketing - Scope Opportunities and Challenges - IntechOpen PDFPratsNo ratings yet

- Breaking Into Software Defined Radio: Presented by Kelly AlbrinkDocument40 pagesBreaking Into Software Defined Radio: Presented by Kelly AlbrinkChris Guarin100% (1)

- Gathering Materials: Presentation Skills MPU 2113Document18 pagesGathering Materials: Presentation Skills MPU 2113ila2nabilaNo ratings yet