Professional Documents

Culture Documents

PFMEA Review - MOM Format

Uploaded by

MASU BRAKE PADS QACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFMEA Review - MOM Format

Uploaded by

MASU BRAKE PADS QACopyright:

Available Formats

PFMEA Review - Minutes Of Meeting Doc.

no : WI/NPD/01- Annex-01

Mrs. Sasireka,Mr.Ranjeet Singh,Mr. TS Kohli, Mr.Ankul, Mr.Anuj,Mr. Jitender Yadav,Mr.Dinesh, Mr. Rohit, Mr. Jitender

Members Sharma,Mr. Sandeep,Mr. Anil,Mr. Narender,Mr.Arvind,Mr.Shreekant Chahal,Mr.Krishan.Production respecrive operator & Last Reviewed Date : 01.03.2022

supervisor

Inprocess rejection Based on control plan revision

Based on Process Flow Diagram

Internal NC's

revision

Customer concerns Process audit observations

Customer complaints Poka yoke implementation

Customer line return Any 4M change

Review Agenda

DFMEA input Machine improvements

Audit Feedback Customer visit learnings / inputs

Changes in the process design Field failures

Changes in the product design New product learnings

`

Based on risk analysis

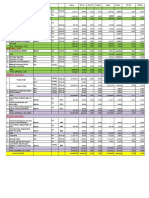

S.NO Points Discussed Resp. Target Date Status

Fresh Release for Prelaunch

0 CFT MEMBER 20.02.2016 COMPLETE

Fresh Release for Production ALL PROCESS

1 OWNER 25.03.2016 COMPLETE

Work Instruction made for die cleaning ALL PROCESS

2 OWNER 12.08.2016 COMPLETE

(Acc. Fitting ) Add selection of die plates process added , ALL PROCESS

3 Visual inspection inhanced at after various operation such as OWNER 12.10.2016 COMPLETE

grinding, printing

Weighing poka yoke implemented ALL PROCESS

4 OWNER 15.12.2016 COMPLETE

(Powder coating) Temperature controller poka yoke ALL PROCESS

5 implemented OWNER 19.01.2017 COMPLETE

(Printing) printing machine process add ALL PROCESS

6 (Shim Pasting) Shim Pasting Process add OWNER 15.03.2017 COMPLETE

(Packing ) Add shrink wrapping process in packing ALL PROCESS

7 OWNER 15.08.2017 COMPLETE

Auto & Manual process combined . ALL PROCESS

8 OWNER 28.08.2017 COMPLETE

New adhesive machine process add ALL PROCESS

9 OWNER 25.12.2017 COMPLETE

100% pull off test and quality checking dot mark introduced at ALL PROCESS

10 final inspection OWNER 22.04.2018 COMPLETE

Auto taping (packing ) machine added ALL PROCESS

11 OWNER 24.05.2018 COMPLETE

100% rivert damage defect visual inspection WI ALL PROCESS

12 OWNER 01.06.2018 COMPLETE

Sensor locking system (printing)(internal failure) ALL PROCESS

13 OWNER 25.06.2018 COMPLETE

Grinding stage chipping (internal failure) ALL PROCESS

14 OWNER 13.07.2018 COMPLETE

Daily checklist add for vibrator function verfied(internal failure) ALL PROCESS

15 OWNER 08.08.2018 COMPLETE

Rework process included in Printing ALL PROCESS

16 OWNER 22.08.2018 COMPLETE

Internal Review and added control document & Auto moulding

nozzle cleaning frequency add in DM & PM check sheet ALL PROCESS

17 OWNER 10.09.2018 COMPLETE

(internal failure)

New adhesive conveyer oven process added (Process added) ALL PROCESS

18 & Temperature Poke Yoke Introduced at Moulding OWNER 16.10.2018 COMPLETE

Adhesive Oven temperature Poke Yoke Introduced ALL PROCESS

19 OWNER 22.11.2018 COMPLETE

Acc. Fitting Pressure Low Poke Yoke Introduced ALL PROCESS

20 OWNER 11.12.2018 COMPLETE

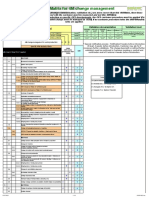

Potential failure of Back plate thickness,height and length

added in process no.60, hardness, compressibility, accetone,

shear strength, coverage and density added in process no. ALL PROCESS

21 OWNER 08.01.2019 COMPLETE

120, Revit damage added in process no. 190,

Selection of wrong shear blade added to potential cause of

failure for coverege less than 80% in process no.120 and

ALL PROCESS

22 simultaneously current process control prevention & detection OWNER 01.04.2019 COMPLETE

updated.

Burr issue -Customer complaint :- uncleaned die,High

pressure,gap b/w cavity insert and backplate slot added to

potential cause of failure for flash/burr in process no 110 & ALL PROCESS

23 simultaneously current process control prevention & detection OWNER 03.05.2019 COMPLETE

updated.

Current process control prevention In process no. 20,

Incoming Inspection of Accessories or Clip / Shim / Back Plate ALL PROCESS

24 OWNER 15.09.2019 COMPLETE

use rustprevention oil.

Current process control prevention In process no. 210B, added

ALL PROCESS

25 the check point in FPA. OWNER 06/12/2019 COMPLETE

Auto moulding process has been removed from process. ALL PROCESS

26 OWNER 30.01.2020 COMPLETE

Shim gap customer complaint - failure mode and controls

ALL PROCESS

27 added in powder coating process 17.03.2020 COMPLETE

OWNER

New identification failure of dispatch and blister cause. find

ALL PROCESS

28 nnd blue layer coating add. 10.02.2021 COMPLETE

OWNER

Auto shrink wrapping machine introduced to avoid loose

ALL PROCESS

29 packing due to manual - Failure mode and control added 17.02.2021 COMPLETE

OWNER

Pressing time inadequate in shim pasting - Failure mode

ALL PROCESS

30 identified and control pressing time increased based on study 24.03.2021 COMPLETE

OWNER

Air pressure low failure mode identified in accessories fitting

ALL PROCESS

31 and control 19.05.2021 COMPLETE

OWNER

Improper seating on conveyor in blue strip process identified

ALL PROCESS

32 and control introduced - Cavity type conveyor changed 12.06.2021 COMPLETE

OWNER

New failure mode - Shim logo orientation wrong added in shim

ALL PROCESS

33 bonding 29.06.2021 COMPLETE

OWNER

Drill hole offset - improper seating of pad failure mode added

ALL PROCESS

34 and control fixture introduced 19.08.2021 COMPLETE

OWNER

Levelling tool introduced in moulding to improve the mix

ALL PROCESS

35 spreading to reduce the poor compression rejection 07.09.21 COMPLETE

OWNER

Edge damage - failure mode and control added in final

ALL PROCESS

36 inspection process (Trolley design changed) 13.09.2021 COMPLETE

OWNER

Blister rejection due to mix moisture high - Mix bin cover -

ALL PROCESS

37 countermeasure added in moulding process 08.10.2021 COMPLETE

OWNER

On Printing machine , sensor stand to be fixed with machine

ALL PROCESS

38 not rest on floor, Review done for recommended action & 05.11.2021 COMPLETE

OWNER

same is added

To be Replaced the auto electric sensor to optical fiber sensor

ALL PROCESS

39 for better sense the printing location 01.12.2021 COMPLETE

OWNER

Shim Pressing machined covered & tray defined with qty.

ALL PROCESS

40 fitted in machine with automatic start button 05.01.2022 COMPLETE

OWNER

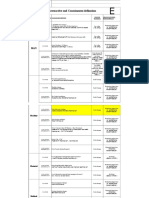

Air knife system installed for removing polythene from shim

after that eliminate shim adhesive sticking out issue &

ALL PROCESS

41 improper shim pasting issue (Review done for recommended OWNER 10.01.2022 COMPLETE

action & same is added)

Slider angle and length modified to eliminate adhesive glue

overlapping & Uniformity in Adhesive Spread on back plate

ALL PROCESS

42 (Review done for recommended action & same is added) OWNER 13.01.2022 COMPLETE

L-Shape Levelling tool introduced to improve the spreading

of material to reduce the poor compression rejection (Review

ALL PROCESS

43 done for recommended action & same is added) OWNER 02.02.2022 COMPLETE

(Red Layer & Blue Strip) Poka-yoke introduced for

temperature high/low with alarm & light system (Review done ALL PROCESS

44 for recommended action & same is added) OWNER 01.03.2022 COMPLETE

Prepared By: Reviewed By:

Approved By:

You might also like

- Roles & Responsibilities Job Position: HOD-Quality AssuranceDocument12 pagesRoles & Responsibilities Job Position: HOD-Quality AssurancemuthuselvanNo ratings yet

- 1 - Supplier Rating - Including Premium Freight1Document1 page1 - Supplier Rating - Including Premium Freight1RAJESH DHOKALENo ratings yet

- COQ Elements Data Source Value Percentage Contribution Per AH Percentage SalesDocument10 pagesCOQ Elements Data Source Value Percentage Contribution Per AH Percentage SalesmuthuselvanNo ratings yet

- Tool Life Monitoring RecordDocument4 pagesTool Life Monitoring RecordMani ManishNo ratings yet

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- In-Process Inspection Report: Date: - / - / - Rev. No.: 01 (11/05/2016)Document4 pagesIn-Process Inspection Report: Date: - / - / - Rev. No.: 01 (11/05/2016)Suraj RawatNo ratings yet

- HR Managers Roles & ResponsibilitiesDocument4 pagesHR Managers Roles & ResponsibilitiesManu SharmaNo ratings yet

- APQP Responsibility MatrixDocument3 pagesAPQP Responsibility MatrixSuraj RawatNo ratings yet

- Amendment Record Delite Technoplast: Date Doc. No. Rev. No. Details of Change Eff, Date MR NEW RevDocument2 pagesAmendment Record Delite Technoplast: Date Doc. No. Rev. No. Details of Change Eff, Date MR NEW RevSaurabhNo ratings yet

- Butterworth Feedmill SDN BHD: Toolbox Meeting RecordsDocument1 pageButterworth Feedmill SDN BHD: Toolbox Meeting RecordsNurul NatashaNo ratings yet

- Master list of special part characteristicsDocument2 pagesMaster list of special part characteristicsSafety DeptNo ratings yet

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- QMS Cross Audit 18Document4 pagesQMS Cross Audit 18rajesh sharmaNo ratings yet

- Paretto (Defect Wise) FEB-2022Document2 pagesParetto (Defect Wise) FEB-2022Bangali SinghNo ratings yet

- 8D Report for High Resistance Issue in Coil AssemblyDocument13 pages8D Report for High Resistance Issue in Coil AssemblyAnandha VasanNo ratings yet

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocument6 pagesDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DNo ratings yet

- F MR 20B 4M Criteria NewDocument4 pagesF MR 20B 4M Criteria NewBangali Singh100% (1)

- KS Munjal Industries responds to customer complaint about dull zinc platingDocument1 pageKS Munjal Industries responds to customer complaint about dull zinc platingKaramjit SinghNo ratings yet

- APQP Time Plan for 150 X 75 Steel Hollow SectionDocument4 pagesAPQP Time Plan for 150 X 75 Steel Hollow SectionRakesh PandeyNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementDamodaran RajanayagamNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- DS-09-02 R0 Change Implementation MatrixDocument3 pagesDS-09-02 R0 Change Implementation MatrixDhinakaran100% (1)

- Point No. 6Document10 pagesPoint No. 6Rohtash fastnerNo ratings yet

- F.disp.01 Schedule V-S Dispatch PlanDocument6 pagesF.disp.01 Schedule V-S Dispatch PlanSaurabhNo ratings yet

- PFMEA - 4th Edition PFMEA RankingDocument2 pagesPFMEA - 4th Edition PFMEA RankingDjurdjina PetkovicNo ratings yet

- DWM FormatDocument4 pagesDWM Formatdharmendra ChaurasiaNo ratings yet

- IATF Awareness Training ParticipantsDocument124 pagesIATF Awareness Training ParticipantsDisha ShahNo ratings yet

- IT Group Internal Audit Schedules and ReportsDocument11 pagesIT Group Internal Audit Schedules and ReportsBhavin SukhadiyaNo ratings yet

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- 5M Change SheetDocument7 pages5M Change SheetPk NimiwalNo ratings yet

- 02 Manufacturing Process Design InputsDocument3 pages02 Manufacturing Process Design InputsRaja DuraiNo ratings yet

- Tool Preventive Maintenance Plan Year - 2018Document3 pagesTool Preventive Maintenance Plan Year - 2018Saurabh100% (1)

- Management Review Programme (Insert Year) : ISO 9001:2015 QMSDocument2 pagesManagement Review Programme (Insert Year) : ISO 9001:2015 QMSFrench Sarah NeraNo ratings yet

- Tool Development PlanDocument3 pagesTool Development PlanTrivesh SharmaNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- Prepared by Approved by Department Status Saurabh Kumar Praguman Verma Biw VqaDocument2 pagesPrepared by Approved by Department Status Saurabh Kumar Praguman Verma Biw VqaScientific KingNo ratings yet

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapNo ratings yet

- Format No - Qf-As-02 - Daily Production Log BookDocument2 pagesFormat No - Qf-As-02 - Daily Production Log BookDisha ShahNo ratings yet

- Sundram Fasteners LTD, Autolec Division. Apqp Timing Plan - XXXXXXXXXXX (1111111) Date: XX - XX.XXXXDocument2 pagesSundram Fasteners LTD, Autolec Division. Apqp Timing Plan - XXXXXXXXXXX (1111111) Date: XX - XX.XXXXUdhayakumarNo ratings yet

- Customer Satisfaction Survey ProcedureDocument1 pageCustomer Satisfaction Survey ProcedureAnkur GuptaNo ratings yet

- Ilu Skill ChartDocument5 pagesIlu Skill ChartNavindran SubramaniamNo ratings yet

- Calibration ProcedureDocument5 pagesCalibration ProcedureManu SharmaNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Managerial skill matrixDocument1 pageManagerial skill matrixKarthi ThiyagarajanNo ratings yet

- 4 M Change LatestDocument8 pages4 M Change LatestVikas KashyapNo ratings yet

- Cii Erode: 1S PresentationDocument19 pagesCii Erode: 1S PresentationsathyabalaramanNo ratings yet

- Cable bracket manufacturing processDocument2 pagesCable bracket manufacturing processBASAVA ENGINEERINGNo ratings yet

- Past defect history details root cause analysis formatDocument10 pagesPast defect history details root cause analysis formatRahulNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- FT 35 DC D10447340A Process SheetDocument7 pagesFT 35 DC D10447340A Process SheetSuraj RawatNo ratings yet

- Trouble HistoryDocument7 pagesTrouble HistoryShahzaibUsmanNo ratings yet

- pure cotton pvt ltd final inspection reportDocument4 pagespure cotton pvt ltd final inspection reportTarun PariharNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- Turner End Yoke Development Plan IssuesDocument85 pagesTurner End Yoke Development Plan IssuesrohitbaggaNo ratings yet

- DS-09-01 R0 Communication During ChangeDocument1 pageDS-09-01 R0 Communication During ChangeDhinakaranNo ratings yet

- PFD - Example..Document4 pagesPFD - Example..lalit GuptaNo ratings yet

- Supplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .Document50 pagesSupplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .muthuselvanNo ratings yet

- 4M Change RecordDocument6 pages4M Change RecordRAHUL SINGHNo ratings yet

- GM FMEA DoneDocument12 pagesGM FMEA DoneSuraj RawatNo ratings yet

- QAV-2 Step-5 Audit check sheet-PDFDocument6 pagesQAV-2 Step-5 Audit check sheet-PDFRajNo ratings yet

- Masu Brake Pads PVT LTD, Unit - Ii: F/LAB/03 Rev No: 00Document1 pageMasu Brake Pads PVT LTD, Unit - Ii: F/LAB/03 Rev No: 00MASU BRAKE PADS QANo ratings yet

- Masu Brake Pads PVT LTD, Unit - Ii: Master List of Monitoring and Measuring EquipmentsDocument1 pageMasu Brake Pads PVT LTD, Unit - Ii: Master List of Monitoring and Measuring EquipmentsMASU BRAKE PADS QANo ratings yet

- Customer Complaint ResolutionDocument3 pagesCustomer Complaint ResolutionMASU BRAKE PADS QANo ratings yet

- Integrated System Change Management ProceduresDocument3 pagesIntegrated System Change Management ProceduresMASU BRAKE PADS QANo ratings yet

- Packing Standard Masu U-2Document15 pagesPacking Standard Masu U-2MASU BRAKE PADS QANo ratings yet

- Thermal Mapping - Powder CoatingDocument2 pagesThermal Mapping - Powder CoatingMASU BRAKE PADS QANo ratings yet

- Customer Service Report: Parameters Actuals ResponseDocument2 pagesCustomer Service Report: Parameters Actuals ResponseMASU BRAKE PADS QANo ratings yet

- Machine List With SupplierDocument29 pagesMachine List With SupplierMASU BRAKE PADS QANo ratings yet

- Maintain Machinery with Planned MaintenanceDocument5 pagesMaintain Machinery with Planned MaintenanceMASU BRAKE PADS QANo ratings yet

- PM EFFECTIVENESSDocument2 pagesPM EFFECTIVENESSMASU BRAKE PADS QANo ratings yet

- F - HRD - 08 Competency Matrix For Middle ManagementDocument16 pagesF - HRD - 08 Competency Matrix For Middle ManagementMASU BRAKE PADS QANo ratings yet

- List of Plant Machines & Utilities Under AMCDocument1 pageList of Plant Machines & Utilities Under AMCMASU BRAKE PADS QANo ratings yet

- PPAP Checklist: SL No Activity Description Status Responsibility RemarkDocument2 pagesPPAP Checklist: SL No Activity Description Status Responsibility RemarkMASU BRAKE PADS QANo ratings yet

- MTTR & MTBF TrendDocument2 pagesMTTR & MTBF TrendMASU BRAKE PADS QANo ratings yet

- Illustrative-Problem-2 (Normal and Abnormal Losses)Document22 pagesIllustrative-Problem-2 (Normal and Abnormal Losses)rei biatchNo ratings yet

- Eni Grease SLL 00Document1 pageEni Grease SLL 00ranjanguptNo ratings yet

- Assignment On Production AnalysisDocument2 pagesAssignment On Production AnalysisShaira Mae Delos ReyesNo ratings yet

- Rid and Clean Safety DataDocument1 pageRid and Clean Safety DataElizabeth GraceNo ratings yet

- WET PCB Fabrication ProcessDocument14 pagesWET PCB Fabrication Processwebip33713100% (1)

- Effect of Mercerization On The Mechanical and Thermal Response of Hybrid - 2019Document7 pagesEffect of Mercerization On The Mechanical and Thermal Response of Hybrid - 2019bakhrul ilmiNo ratings yet

- MP1 M3 Short NotesDocument34 pagesMP1 M3 Short NotesRadhika GandhiNo ratings yet

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleNo ratings yet

- CORE PROPERTIES AND PERMEABILITYDocument30 pagesCORE PROPERTIES AND PERMEABILITYNavya Nova ChandaliaNo ratings yet

- Skill MatrixDocument33 pagesSkill MatrixJOAI BITANANo ratings yet

- PAC Metal Roofing Wall and Trim Catalog 2023Document48 pagesPAC Metal Roofing Wall and Trim Catalog 2023THIS IS AWESOMENo ratings yet

- Plastic InjectionmoldingDocument21 pagesPlastic InjectionmoldingSumanth UNo ratings yet

- Ceramic Liner Products and FeaturesDocument9 pagesCeramic Liner Products and FeaturesrezandriansyahNo ratings yet

- CISCRYL-DS50 (Duct Sealant)Document2 pagesCISCRYL-DS50 (Duct Sealant)ajeet soniNo ratings yet

- RAB Monopole 30M Jabar Area OkkDocument2 pagesRAB Monopole 30M Jabar Area OkkAsep ZamhajiNo ratings yet

- Cementatious Waterproofing - KousterDocument3 pagesCementatious Waterproofing - KousterRaed HaloubNo ratings yet

- ASTM D3418-21 (Redline)Document11 pagesASTM D3418-21 (Redline)Parom WaikasikarnNo ratings yet

- Performance Packaging CodesDocument2 pagesPerformance Packaging CodesErrezaHardianNo ratings yet

- DFM ForgingDocument24 pagesDFM Forgingsaikrishnaps31No ratings yet

- Mammoth Breakout Wrench Catalogue - Web v2Document30 pagesMammoth Breakout Wrench Catalogue - Web v2WalissonNo ratings yet

- NyconXLSheet042015-macro FibrillatedDocument2 pagesNyconXLSheet042015-macro Fibrillateduğur alparslanNo ratings yet

- Tle 7 - Q3 - Week 3Document17 pagesTle 7 - Q3 - Week 3Mahaleah Fiabla PasanaNo ratings yet

- GEV 2022 Company Presentation & Application - ENGDocument33 pagesGEV 2022 Company Presentation & Application - ENGSunil R HasabnisNo ratings yet

- The Cyclone / Chip Separator From The HR-D/V-D Series: Waste Disposal With A SystemDocument2 pagesThe Cyclone / Chip Separator From The HR-D/V-D Series: Waste Disposal With A SystemJohn Lester Padilla-DacanayNo ratings yet

- Rolling Mill Guide: Types and Metal Forming ProcessDocument2 pagesRolling Mill Guide: Types and Metal Forming Processnanda rizkyNo ratings yet

- Chapter 9 Process CostingDocument16 pagesChapter 9 Process CostingAlexsandra GarciaNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- Plant Mass Flow-50080091 - A4-P - 5.0 - ENDocument9 pagesPlant Mass Flow-50080091 - A4-P - 5.0 - ENHassan raufNo ratings yet

- CWB Level 2 MODULE 7 RESIDUAL STRESS & DISTORTION Flashcards - Quizlet - PDF (CWB 2)Document17 pagesCWB Level 2 MODULE 7 RESIDUAL STRESS & DISTORTION Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedNo ratings yet

- FMEA-INJECTION-MOLDING - Breakout SessionDocument4 pagesFMEA-INJECTION-MOLDING - Breakout Sessiongobu269104No ratings yet