0% found this document useful (0 votes)

2K views1 pageIQA-Incoming Inspection Flow Chart

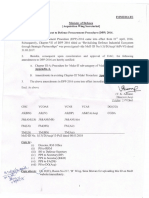

The quality control process flowchart outlines the incoming inspection process. When goods arrive, the receiving department passes the delivery order and material certification to quality assurance. Quality assurance then conducts random sampling inspections according to an AQL level and determines if the goods pass or fail inspection. If goods fail, they are rejected and defect reports are issued. If goods pass, acceptance tags are applied before the purchasing department takes receipt of the items. Quality assurance also generates inspection reports and records.

Uploaded by

mohCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views1 pageIQA-Incoming Inspection Flow Chart

The quality control process flowchart outlines the incoming inspection process. When goods arrive, the receiving department passes the delivery order and material certification to quality assurance. Quality assurance then conducts random sampling inspections according to an AQL level and determines if the goods pass or fail inspection. If goods fail, they are rejected and defect reports are issued. If goods pass, acceptance tags are applied before the purchasing department takes receipt of the items. Quality assurance also generates inspection reports and records.

Uploaded by

mohCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd