100% found this document useful (2 votes)

3K views5 pagesEscalation Process Flow Chart

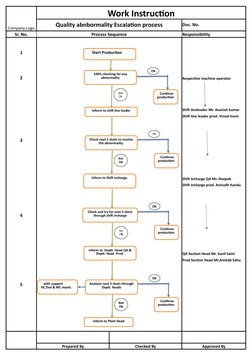

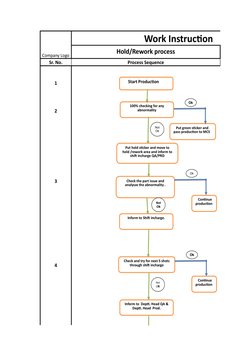

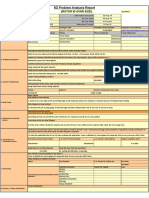

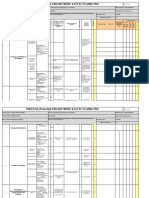

1. The document outlines an escalation process for quality abnormalities at a company.

2. It begins with machine operators checking 100% of production for abnormalities and escalating issues to line leaders, then to shift incharges if unresolved.

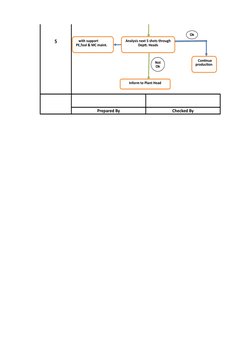

3. If still unresolved, it is escalated to department heads, and finally to the plant head if needed, with support from production engineering, tool maintenance, and machine crews at higher levels.

Uploaded by

VenkatesanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

3K views5 pagesEscalation Process Flow Chart

1. The document outlines an escalation process for quality abnormalities at a company.

2. It begins with machine operators checking 100% of production for abnormalities and escalating issues to line leaders, then to shift incharges if unresolved.

3. If still unresolved, it is escalated to department heads, and finally to the plant head if needed, with support from production engineering, tool maintenance, and machine crews at higher levels.

Uploaded by

VenkatesanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd