Professional Documents

Culture Documents

Product Safety Procedure Summary

Uploaded by

GANESH BORUDEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Safety Procedure Summary

Uploaded by

GANESH BORUDECopyright:

Available Formats

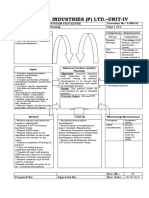

QMS PROCEDURE

DEPARTMENT: QUALITY

PROCEDURE FOR: PRODUCT SAFETY

Procedure No. P-1 Issue No.01 Rev. No. 00 Page: 1

Clause No.: 4.4.1.2 Issue Dt. 01.03.2021 Rev. Dt. - Of: 2

Approved by MR

Purpose: Management of product-safety- related to products and manufacturing processes.

Scope: Applicable to all products, for all customers, which are identified during incoming, in process, final

inspection as well as customer end fitment, To assure safety of the products.

Responsibilities: All concerns including external provider.

Procedures:

Reference

Sr. No. Activity Responsibility Record

Document

When an enquiry received from the

customer. Manufacturing feasibility

review is done to verify the given

parameters are. AS <SC> , <CC>,

<CAP> AND make a list of safety Marketing Customer Drawing Feasibility review report

a)

parameters From customer to Head/NPD Head

customer the symbols used for

critical parameter are different for

that ref Symbol conversion table or

Symbol is given in “Control Plan"

Identification of the statutory and

regulatory product safety Statutory and Regulatory

b) All concerns -

requirements and customer Records

notification

Identification of product safety- Identification of SC & CC

c) All concerns -

related characteristics. Characteristics

Identification and control of safety – FPA/In-process

d) related characteristics of product and QA In-charge Inspection Report/SPC

at the point of manufacture. Report/Control Plan

NPD

Approval of Control plan and

e) Head/Production - Control Plan & PFMEA

PFMEA

I/C

Reaction plan and escalation process

f) QA In-charge Control Plan

if any acceptance criteria not met

QMS PROCEDURE

PROCEDURE FOR: TRAINING

PROCEDURE FOR: PRODUCT SAFETY

Procedure No. P-1 Issue No.01 Rev. No. 00 Page: 2

Clause No.:

Issue Dt. 01.03.2021 Rev. Dt. - Of: 2

Approved by MR 4.4.1.2

Conti.

Reference

Sr. No. Activity Responsibility Record

Document

Defined responsibility, definition of

escalation process and flow of

Control Plan / Organization

g) information, including top QA In-charge -

chart

management and customer

notification.

Training identification by the

organization or customer for

h) personnel involved in product-safety All concerns - Training record

related product and associated

manufacturing process.

Changes of product or process shall

be approved prior to implementation, Team Feasibility

Development

i) including evaluation of potential - Commitment For ECN/

Head

effect on product safety from process ECN Tracker

and product changes

Transfer of requirement with regards

to product safety throughout the

j) QA In-charge - -

supply chain, including designated

source.

Product traceability manufactured lot Store & Dispatch

k) - Identification label / FIFO

throughout the supply chain in-charge

Lesson learned for new product

l) NPD - -

introduction.

You might also like

- Product Safety ProcessDocument4 pagesProduct Safety Processdhir.ankurNo ratings yet

- Management of Product Safety: 6) Esclation Process & Information FlowDocument2 pagesManagement of Product Safety: 6) Esclation Process & Information FlowrajarajanNo ratings yet

- Chopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureDocument5 pagesChopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureShankar ChowdhuryNo ratings yet

- How To Conduct Management ReviewDocument8 pagesHow To Conduct Management ReviewS Seetharaman100% (1)

- IATF Road MapDocument1 pageIATF Road MapGANESH BORUDENo ratings yet

- APQP & PPAP Training ProgramDocument1 pageAPQP & PPAP Training Programbalakumar rajaram100% (1)

- IATF Audit Observation 21.06.2021-23.06.2021Document6 pagesIATF Audit Observation 21.06.2021-23.06.2021Karan MalhiNo ratings yet

- SUPPLIER - Manual - Rev - H (Commercial String & Tool Company)Document18 pagesSUPPLIER - Manual - Rev - H (Commercial String & Tool Company)Jahmia CoralieNo ratings yet

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- 5.1.1.2 - Process Effectiveness EfficiencyDocument1 page5.1.1.2 - Process Effectiveness EfficiencyPrakash kumarTripathiNo ratings yet

- 16 - Procedure For Control of Production Provisions (Machine Shop I &II)Document6 pages16 - Procedure For Control of Production Provisions (Machine Shop I &II)rockyNo ratings yet

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- ISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingDocument7 pagesISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingSudhagarNo ratings yet

- Coherence PlanDocument2 pagesCoherence PlanAman JasujaNo ratings yet

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaNo ratings yet

- Assessment Manual ExamDocument19 pagesAssessment Manual ExamSaurabhNo ratings yet

- Bureau Veritas India (Iatf 16949) (Page 3 of 6) OptionalDocument9 pagesBureau Veritas India (Iatf 16949) (Page 3 of 6) Optionalashish mehtaNo ratings yet

- IATF 16949 Transition Audit - Off Site Document Review WorksheetDocument5 pagesIATF 16949 Transition Audit - Off Site Document Review WorksheetDuho ConsultoresNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- IATF 16949 Documentation Toolkit GuideDocument4 pagesIATF 16949 Documentation Toolkit GuideRahul SharmaNo ratings yet

- Evidences To Be Maintained As Per APQP For PMDocument3 pagesEvidences To Be Maintained As Per APQP For PMSachin RamdurgNo ratings yet

- Competence For Internal AuditorsDocument2 pagesCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (1)

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Roles and Resposiblity-SampleDocument7 pagesRoles and Resposiblity-SampleELANTHENDRALNo ratings yet

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNo ratings yet

- Komathi Engineering Works Performance Evaluation ProcedureDocument3 pagesKomathi Engineering Works Performance Evaluation ProcedurePINTU RAJNo ratings yet

- How To Build An Effective Competency Matrix Competency-Matrix/)Document4 pagesHow To Build An Effective Competency Matrix Competency-Matrix/)Anonymous VPJkWfcOQNo ratings yet

- ISO/TS 16949 and VDA 6.1 Quality Standard ComparisonDocument22 pagesISO/TS 16949 and VDA 6.1 Quality Standard ComparisonTarunaiNo ratings yet

- 4M Change Control Management Work InstructionDocument2 pages4M Change Control Management Work InstructionSameer Saxena100% (2)

- ISO 9001:2008 & ISO/TS 16949 Quality Management RequirementsDocument52 pagesISO 9001:2008 & ISO/TS 16949 Quality Management Requirementssupady5751No ratings yet

- Contigency Planning IATFDocument1 pageContigency Planning IATFDhananjay Patil100% (2)

- TMT Procedure - Management ReviewP1Document1 pageTMT Procedure - Management ReviewP1sumanNo ratings yet

- Poison Test PlanDocument29 pagesPoison Test PlanDinesh KumarNo ratings yet

- Layered Audit Check SheetsDocument5 pagesLayered Audit Check Sheetsdeepak sharma100% (1)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- VSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingDocument1 pageVSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingrakeshNo ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- Escalation Procedure Updated 020915Document30 pagesEscalation Procedure Updated 020915Joezel Juaman Maglajos100% (1)

- Bgl-Fm-Qa - Red Bin Analysis RuleDocument1 pageBgl-Fm-Qa - Red Bin Analysis RuleMohit SinghNo ratings yet

- IQA Checklist - SmpleDocument16 pagesIQA Checklist - SmpleHarits As Siddiq100% (1)

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- IATF 16949 - 2016-Exam Paper With AnswersDocument11 pagesIATF 16949 - 2016-Exam Paper With Answersrashwin singhNo ratings yet

- 7.2.3 A List of Internal Auditors QMSDocument2 pages7.2.3 A List of Internal Auditors QMSPrakash kumarTripathiNo ratings yet

- Vendor System Audit Report (Final) - Technico Ind., Bawal (T043)Document17 pagesVendor System Audit Report (Final) - Technico Ind., Bawal (T043)Ankit SainiNo ratings yet

- Minutes of MRM: STANDARD: IATF 16949: 2016Document7 pagesMinutes of MRM: STANDARD: IATF 16949: 2016Raja Durai100% (1)

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- IATF 16949 Mandatory DocumentsDocument2 pagesIATF 16949 Mandatory DocumentsLuis AlejandroNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- OCP of HR Process-03Document2 pagesOCP of HR Process-03sathyabalaramanNo ratings yet

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMARNo ratings yet

- Woxevekototaporilube PDFDocument2 pagesWoxevekototaporilube PDFharish puNo ratings yet

- PPAP Process Checklist / Sign Off Sheet InstructionsDocument7 pagesPPAP Process Checklist / Sign Off Sheet InstructionsSantosh TiwariNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- TS ClausesDocument3 pagesTS Clausesgarvmonu100% (2)

- Ipsas 35 SummaryDocument6 pagesIpsas 35 SummaryWilson Mugenyi KasendwaNo ratings yet

- Anckar - On The Applicability of The Most Similar Systems Design and The Most Different Systems Design in Comparative ResearchDocument14 pagesAnckar - On The Applicability of The Most Similar Systems Design and The Most Different Systems Design in Comparative ResearchA0% (1)

- Young and Crative PDFDocument230 pagesYoung and Crative PDFHoward W ArevaloNo ratings yet

- JCSOS REV Chapter6 PDFDocument23 pagesJCSOS REV Chapter6 PDFcollinmandersonNo ratings yet

- Computer Network Applications and UsesDocument31 pagesComputer Network Applications and Usessandhya bhujbalNo ratings yet

- Liveloud SongsheetDocument20 pagesLiveloud SongsheetMhay Lee-VillanuevaNo ratings yet

- Solutions Guide: Please Reword The Answers To Essay Type Parts So As To Guarantee That Your Answer Is An Original. Do Not Submit As Your OwnDocument6 pagesSolutions Guide: Please Reword The Answers To Essay Type Parts So As To Guarantee That Your Answer Is An Original. Do Not Submit As Your OwnSkarlz ZyNo ratings yet

- MINOR PPT 5th SEM-4Document22 pagesMINOR PPT 5th SEM-4parthasharma861No ratings yet

- ProCapture-T User Manual V1.1 - 20210903 PDFDocument65 pagesProCapture-T User Manual V1.1 - 20210903 PDFahmad khanNo ratings yet

- Adam Arvidsson Brands, Meaning and Value in Media Culture.Document2 pagesAdam Arvidsson Brands, Meaning and Value in Media Culture.Silvina Tatavitto0% (1)

- The Path of Kriya Yoga: An IntroductionDocument7 pagesThe Path of Kriya Yoga: An IntroductionGowthamanBalaNo ratings yet

- Checklist For Construction and Rehabilitation of Small Dams: Social & Environmental Management Unit (Semu)Document10 pagesChecklist For Construction and Rehabilitation of Small Dams: Social & Environmental Management Unit (Semu)Muhammad imran LatifNo ratings yet

- SARFAESI Act PDFDocument36 pagesSARFAESI Act PDFvarshneyankit1100% (5)

- As 2214-2004 Certification of Welding Supervisors - Structural Steel WeldingDocument8 pagesAs 2214-2004 Certification of Welding Supervisors - Structural Steel WeldingSAI Global - APAC50% (2)

- Slide Show On Kargil WarDocument35 pagesSlide Show On Kargil WarZamurrad Awan63% (8)

- The Divine ServitorDocument55 pagesThe Divine ServitorlevidinizNo ratings yet

- Starbucks - Company AnalysisDocument12 pagesStarbucks - Company AnalysisVisakh VigneshNo ratings yet

- IBAs in Timor-Leste Low ResDocument90 pagesIBAs in Timor-Leste Low ResInug WaeNo ratings yet

- Calculate Market Price and Amortization of Bonds Issued at a DiscountDocument5 pagesCalculate Market Price and Amortization of Bonds Issued at a DiscountKris Hazel RentonNo ratings yet

- Rate Analysis m25Document2 pagesRate Analysis m25Biswajit Sinha100% (4)

- Leonardo MercadoDocument1 pageLeonardo Mercadoemmanuel esmillaNo ratings yet

- In The Court of Hon'Ble District Judge Pune, at Pune CAVEAT APPLICATION NO. - OF 2012Document2 pagesIn The Court of Hon'Ble District Judge Pune, at Pune CAVEAT APPLICATION NO. - OF 2012AniketNo ratings yet

- ABDULLAH BOZKURT - Iran Plays Subversive Role in Turkey PDFDocument4 pagesABDULLAH BOZKURT - Iran Plays Subversive Role in Turkey PDFAnonymous Bbxx7Z9No ratings yet

- Mariolis y Tsoulfidis (2016) Modern Classical Economics and RealityDocument253 pagesMariolis y Tsoulfidis (2016) Modern Classical Economics and RealityJesús Moreno100% (1)

- Tom Barry - International Skateboarder!: Lesson 2 HomeworkDocument1 pageTom Barry - International Skateboarder!: Lesson 2 HomeworkMr TrungNo ratings yet

- Landrith, Lipari V Chief Justice Roberts Plaintiff's Second Motion For Electronic Filing (PDF Version)Document6 pagesLandrith, Lipari V Chief Justice Roberts Plaintiff's Second Motion For Electronic Filing (PDF Version)Bret LandrithNo ratings yet

- Hometown Brochure DesignDocument2 pagesHometown Brochure DesignTiffanymcliu100% (1)

- DevOps All in OneDocument29 pagesDevOps All in OneABUZARNo ratings yet

- Assessing The Environmental Impact of Data Centres Part 1: Background, Energy Use and MetricsDocument10 pagesAssessing The Environmental Impact of Data Centres Part 1: Background, Energy Use and Metricsmarf123No ratings yet

- Mobility Consulting Engineer - Job DescriptionDocument2 pagesMobility Consulting Engineer - Job DescriptionEdwin BrandNo ratings yet