100% found this document useful (2 votes)

2K views1 pageProcedure: Measurement System Analysis Execution

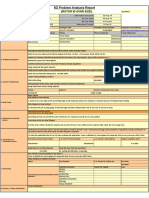

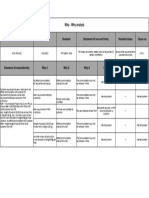

This document establishes guidelines for monitoring supplier performance and the process for determining the quality of procured raw materials and consumables. It involves rating existing suppliers based on quality and delivery over the last six months, with scores between 90-100% considered excellent and 65-79% requiring time-bound improvement plans. If a supplier scores below 65% their approval will be withdrawn, and scores between 65-70% will trigger an audit and corrective action plan submission. Records of data analysis and corrective actions taken are maintained.

Uploaded by

aslamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

2K views1 pageProcedure: Measurement System Analysis Execution

This document establishes guidelines for monitoring supplier performance and the process for determining the quality of procured raw materials and consumables. It involves rating existing suppliers based on quality and delivery over the last six months, with scores between 90-100% considered excellent and 65-79% requiring time-bound improvement plans. If a supplier scores below 65% their approval will be withdrawn, and scores between 65-70% will trigger an audit and corrective action plan submission. Records of data analysis and corrective actions taken are maintained.

Uploaded by

aslamCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Purpose: Establishes the process of monitoring supplier performance in manufacturing quality assessments.

- Resources: Details the resources involved, including specific manuals and technical data.

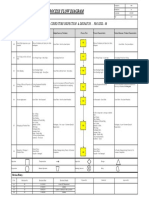

- Method: Describes the method of approval status with a detailed table of scoring criteria and statuses.

- Scope: Defines the boundaries and applicability of the measurement system analysis execution.

- Reference: Lists standards and manuals used as references in the execution of the procedure.

- Responsibility: Outlines the responsibilities of procurement and quality assurance departments in the procedure execution.

- Corrective Action: Specifies actions required in cases of non-compliance to the procedure standards.

- Revision History: Documents the history of revisions made to the procedure, including specific dates and changes.