Professional Documents

Culture Documents

QMP-18 Initial Production Control

Uploaded by

om cncCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QMP-18 Initial Production Control

Uploaded by

om cncCopyright:

Available Formats

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No: QMP-18

Issue/Rev. No.: 1.0/1.0

AQMS PROCEDURE

Date: 30.03.2019

Page 1 of 5

INITIAL PRODUCTION CONTROL

ASWINI GROUP

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No: QMP-18

Issue/Rev. No.: 1.0/1.0

AQMS PROCEDURE

Date: 30.03.2019

Page 2 of 5

INITIAL PRODUCTION CONTROL

ASWINI GROUP

EFFECTIVE

NAME SIGNATURE DATE

DATE

PREPARD & N.KARTHIKEYAN

30.03.2019

RELEASED BY (MR)

30.03.2019

APPROVED H.GIRI

30.03.2019

BY (CEO)

REVISION CONTROL

The Revision Control format given below is used for updating revisions in the Procedures and issued

along with the document.

DETAILS

REV. REV. ISSUE

TOTAL NO. REVIEW DATE

NO. DATE DESCRIPTION OF REVIEW NO.

OF PAGES PAGE NO.

0.0 08.03.18 3 All New release 1.0 08.03.18

1.0 30.03.19 3 3 IPC Quantity updated 1.0 08.03.18

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No: QMP-18

Issue/Rev. No.: 1.0/1.0

AQMS PROCEDURE

Date: 30.03.2019

Page 3 of 5

ASWINI GROUP

INITIAL PRODUCTION CONTROL

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No: QMP-18

Issue/Rev. No.: 1.0/1.0

AQMS PROCEDURE

Date: 30.03.2019

Page 4 of 5

INITIAL PRODUCTION CONTROL

ASWINI GROUP

1.0 PURPOSE

Supply after sample approval considered as INITIAL SUPPLY. This is confident built

process and involves of monitoring & additional controls in the processes by taking

precautionary & prevention actions, during the initial period of mass production of a new

product.

2.0 SCOPE

The Initial supply control is applicable Initial product:-

Initial product is,

• A new designed parts

• Any major design change in existing parts

Material change

Dimension / specification change

Safety / performance / regulatory requirement

• Process change

3.0 REFERENCE

IATF 16949:2016 Clause 8.3.4, 8.3.5 (8.3.5.1, 8.3.5.2)

4.0 DEFINITION / ABBREVIATIONS

NPD – New Product Development, APQP – Advanced Product Quality Planning, PPAP – Production

Part Approval Process, ECN – Engineering Change Note, PFMEA – Process Failure Mode and

Effects Analysis, CP – Control Plan, PFD – Process Flow Diagram, WI – Work Instruction, MSA –

Measurement System Analysis, OEM – Original Equipment Manufacturer, CFT – Cross Functional

Team, QA – Quality Assurance, UOM – Unit of Measurement, SC – Significant Characteristics, CC

– Critical Characteristics, SOP – Standard Operating Procedure, MFR – Manufacturing Feasibility

Report .

5.0 RESPONSIBILITY

Head - Quality is authorized for approval and issue of this initial production control are

responsible for implementation of this procedure.

6.0 INPUT – PROCESS – OUTPUT

Input Process (Activity) Output

Initial period of mass

Extra Care & Control of initial

production of a new Initial production control supply

product

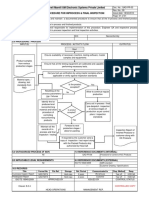

6.1 INITIAL PRODUCTION CONTROL

Input Control Plan- Activity Output Nos. for

3 Months/15000

New products, 1

Month/5000 Nos. for

Major change &

15Days/2500 Nos. for

Minor change

AUTOMOTIVE QUALITY MANAGEMENT SYSTEM Ref No: QMP-18

Issue/Rev. No.: 1.0/1.0

AQMS PROCEDURE

Date: 30.03.2019

Page 5 of 5

INITIAL PRODUCTION CONTROL

ASWINI GROUP

New product Duration of Initial Supply Control of mass

development production is decided by CFT (After start of

Approved PPAP production at customer end)

document

Determine Special controls (increased Special control plan,

Pre-launch control Inspection reports,

inspection, increased sample size etc. at all

plan Process audit & Cpk

stages - incoming, in-process & final)

Initial production

Start date (from SOP

Visual display control (Regulation for Initial control period,

at vendor's end) and

production control) Minimum quantity

end date (after SOP at

and Persons

customer end)

responsible for

start/end

Special control plan, Implementation of initial production control Inspection reports, Cpk

and defect rate PPM

SOP Special tags (Locked

(In-house & Customer end)

area)

Cpk and defect rate

PPM (In-house & Termination conditions for control items Countermeasure

Customer end) report (If not met)

TGW & TGR (Things

Gone Wrong & Right)

Initial supply control NG OK Initial control check

period continuous to Result of initial

terminated, if no (Initial

repeat from date of NG supply control? supply control period

month & Sign of extended as customer

specified) & Sign off

Problems reported Efectiveness of countermeasures taken for Summary in PDCA

during IPC problems reported during development sheet

Communication of initial production control

information to other departments.

7.0 Further Reference

7.1 Documented Information

As per List of Documented Information to be maintained – RD-ASW-01

As per List of Documented Information to be retained – RD-ASW-02

You might also like

- QMP-10 New Product DevelopmentDocument15 pagesQMP-10 New Product Developmentom cnc100% (1)

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- QMP-13 Production ControlDocument9 pagesQMP-13 Production Controlom cncNo ratings yet

- 2.procedures Initial Supply Control UpdatedDocument3 pages2.procedures Initial Supply Control UpdatedKapil Karhana100% (1)

- QMP 15 Identification and TraceabilityDocument6 pagesQMP 15 Identification and Traceabilityom cncNo ratings yet

- QMP-06 - Preventive ActionDocument5 pagesQMP-06 - Preventive Actionom cnc100% (1)

- QMP-05 - Corrective ActionDocument5 pagesQMP-05 - Corrective Actionom cnc100% (1)

- QMP 07 TrainingDocument10 pagesQMP 07 Trainingom cncNo ratings yet

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- Inital Flow Management Productivity ProcedureDocument4 pagesInital Flow Management Productivity Procedureshaggyrahul100% (3)

- Initial Supply ControlDocument3 pagesInitial Supply ControlKuldeep Chauhan100% (1)

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDocument1 page14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNo ratings yet

- Operator Observation SheetDocument1 pageOperator Observation Sheet25aprilNo ratings yet

- T2 VSA With RequirementDocument8 pagesT2 VSA With RequirementSandeep K Malhotra100% (3)

- Evidences To Be Maintained As Per APQP For PMDocument3 pagesEvidences To Be Maintained As Per APQP For PMSachin RamdurgNo ratings yet

- IATF 16949 DocumenDocument1 pageIATF 16949 Documenpunitg_2No ratings yet

- Operator Observance SheetDocument5 pagesOperator Observance SheetEr Avinash Kumar100% (2)

- 4M Change MatrixDocument1 page4M Change MatrixAnkit SainiNo ratings yet

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditSachin Kumbhar100% (1)

- W.I - Abnormal SituationDocument1 pageW.I - Abnormal Situation25april100% (2)

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Operator Observance SheetDocument2 pagesOperator Observance Sheetrajesh sharma100% (1)

- Product Audit Check SheetDocument3 pagesProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- .013-00-Checking AidsDocument3 pages.013-00-Checking Aidsdaniel_sasikumarNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- Top Management, Stores and DispatchDocument4 pagesTop Management, Stores and DispatchBibhudutta mishraNo ratings yet

- System Audit RequirementDocument37 pagesSystem Audit Requirementavinashbatra171% (7)

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayNo ratings yet

- IATF Objective Data Analysis - Quality - ExampleDocument1 pageIATF Objective Data Analysis - Quality - ExampleSachin RamdurgNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Iatf-Qm-08 - Operation 8.5.1.1Document22 pagesIatf-Qm-08 - Operation 8.5.1.1SATISH HALGEKARNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (4)

- P13-Process For APQPDocument6 pagesP13-Process For APQPBangali Singh100% (1)

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNo ratings yet

- 4M Change Procedure - PED 02Document2 pages4M Change Procedure - PED 02sathyabalaraman87% (23)

- Red Bin Analysis ProcedureDocument4 pagesRed Bin Analysis ProcedureVenkatesan92% (12)

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaNo ratings yet

- Rework & Repair ProcedureDocument1 pageRework & Repair ProcedureManu Sharma100% (4)

- Product Audit FormDocument2 pagesProduct Audit Formcong da0% (1)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- APQP MatrixDocument2 pagesAPQP Matrixkumar QA100% (2)

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlieNo ratings yet

- NC Closure 5 Why AnalysiDocument26 pagesNC Closure 5 Why AnalysiKaran MalhiNo ratings yet

- Process Audit - Sheet New ......Document1 pageProcess Audit - Sheet New ......MUKESH KUMARNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoDocument10 pagesFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapNo ratings yet

- NPD Procedure & Apqp FormatDocument132 pagesNPD Procedure & Apqp FormatKaramjit Singh100% (2)

- QAF12 Process Audit Rev 09Document4 pagesQAF12 Process Audit Rev 09ukavathekarNo ratings yet

- Supplier 4M Change Request FormatDocument1 pageSupplier 4M Change Request FormatManoj KumarNo ratings yet

- Department: CNC SHOP Auditee: AuditorDocument33 pagesDepartment: CNC SHOP Auditee: AuditormuthuselvanNo ratings yet

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- QMP-02 - Control of RecordDocument5 pagesQMP-02 - Control of Recordom cncNo ratings yet

- Quality Assurance Manual Oct-18Document176 pagesQuality Assurance Manual Oct-18Ayush SharmaNo ratings yet

- 03 LC of Semi Auto Cap Filling Machine 03Document2 pages03 LC of Semi Auto Cap Filling Machine 03Ravi YadavNo ratings yet

- Sop SeDocument60 pagesSop SemanttupandeyNo ratings yet

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- QMP 07 TrainingDocument10 pagesQMP 07 Trainingom cncNo ratings yet

- QMP-02 - Control of RecordDocument5 pagesQMP-02 - Control of Recordom cncNo ratings yet

- QMP-05 - Corrective ActionDocument5 pagesQMP-05 - Corrective Actionom cnc100% (1)

- RD ASW 22 Masterlist of APQPDocument1 pageRD ASW 22 Masterlist of APQPom cncNo ratings yet

- QMP-06 - Preventive ActionDocument5 pagesQMP-06 - Preventive Actionom cnc100% (1)

- Xods G8D1Document75 pagesXods G8D1om cncNo ratings yet

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- 703 Fmea m3 LatestDocument24 pages703 Fmea m3 Latestom cncNo ratings yet

- Customer ComplientDocument1 pageCustomer Complientom cncNo ratings yet

- 703 Fmea m3 LatestDocument24 pages703 Fmea m3 Latestom cncNo ratings yet

- Top 3 Rejections: Rejected Qty Rej %Document1 pageTop 3 Rejections: Rejected Qty Rej %om cncNo ratings yet

- AVEVA LFM - Data Summary v2Document6 pagesAVEVA LFM - Data Summary v2Joshua HobsonNo ratings yet

- EDAG0007Document5 pagesEDAG0007krunalNo ratings yet

- Lesson 1 Concepts About Educational TechnologyDocument17 pagesLesson 1 Concepts About Educational TechnologyMarvin ContigaNo ratings yet

- Swift As A MisanthropeDocument4 pagesSwift As A MisanthropeindrajitNo ratings yet

- Economics - Economics - Cheat - SheetDocument1 pageEconomics - Economics - Cheat - SheetranaurNo ratings yet

- Macros and DirectiveDocument7 pagesMacros and DirectiveAbdul MoeedNo ratings yet

- All Nobel Prizes in LiteratureDocument16 pagesAll Nobel Prizes in LiteratureMohsin IftikharNo ratings yet

- Essay On Stem CellsDocument4 pagesEssay On Stem CellsAdrien G. S. WaldNo ratings yet

- The Ethics of Peacebuilding PDFDocument201 pagesThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- Class InsectaDocument4 pagesClass InsectaLittle Miss CeeNo ratings yet

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocument64 pagesUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091No ratings yet

- Unilever PakistanDocument26 pagesUnilever PakistanElie Mints100% (3)

- CrimDocument29 pagesCrimkeziahmae.bagacinaNo ratings yet

- Handout Waste Catch BasinDocument2 pagesHandout Waste Catch BasinJonniel De GuzmanNo ratings yet

- Using Your Digital Assets On Q-GlobalDocument3 pagesUsing Your Digital Assets On Q-GlobalRemik BuczekNo ratings yet

- Ec 0301Document25 pagesEc 0301Silvio RomanNo ratings yet

- Very Hungry Caterpillar Clip CardsDocument5 pagesVery Hungry Caterpillar Clip CardsARTGRAVETO ARTNo ratings yet

- Immobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingDocument7 pagesImmobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingSahar IrankhahNo ratings yet

- Writing About Graphs, Tables and DiagramsDocument68 pagesWriting About Graphs, Tables and DiagramsLangers BastasaNo ratings yet

- Gandhi and The Non-Cooperation MovementDocument6 pagesGandhi and The Non-Cooperation MovementAliya KhanNo ratings yet

- Assessment - UK Forestry Data ICT THEORY For CAT1Document13 pagesAssessment - UK Forestry Data ICT THEORY For CAT1Joanna AchemaNo ratings yet

- RS2 Stress Analysis Verification Manual - Part 1Document166 pagesRS2 Stress Analysis Verification Manual - Part 1Jordana Furman100% (1)

- Midterm ReviewerDocument20 pagesMidterm ReviewerJonnafe IgnacioNo ratings yet

- Chapter 3 Extension - Game Theory-StDocument25 pagesChapter 3 Extension - Game Theory-StQuynh Chau TranNo ratings yet

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocument3 pagesWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinNo ratings yet

- Training Design SprintDocument11 pagesTraining Design Sprintardi wiantoNo ratings yet

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFDocument10 pagesFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaNo ratings yet

- Rosewood Case AnalysisDocument5 pagesRosewood Case AnalysisJayant KushwahaNo ratings yet

- FIGMADocument22 pagesFIGMACessNo ratings yet

- UpdateJul2007 3julDocument10 pagesUpdateJul2007 3julAnshul SinghNo ratings yet