88% found this document useful (8 votes)

21K views1 pageRework & Repair Procedure

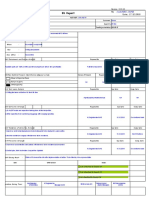

The document outlines a rework/repair procedure that involves receiving a part from production, checking if it can be reworked/repaired, performing those actions according to parameters if possible, making a register entry, submitting to quality checking, scrapping unapproved parts or packaging approved parts.

Uploaded by

Manu SharmaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

88% found this document useful (8 votes)

21K views1 pageRework & Repair Procedure

The document outlines a rework/repair procedure that involves receiving a part from production, checking if it can be reworked/repaired, performing those actions according to parameters if possible, making a register entry, submitting to quality checking, scrapping unapproved parts or packaging approved parts.

Uploaded by

Manu SharmaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd