Professional Documents

Culture Documents

Advanced Control Technologies For 5-Axis Machining: Masako Sudo

Uploaded by

Thirugnanam DhandayuthapaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Control Technologies For 5-Axis Machining: Masako Sudo

Uploaded by

Thirugnanam DhandayuthapaniCopyright:

Available Formats

Sudo, M.

Development Report:

Advanced Control Technologies for 5-Axis Machining

Masako Sudo

Software Research Joint Division, FANUC LTD. 3850 Oshinomura, Yamanashi 401-0597, Japan URL: www.fanuc.com [Received September 6, 2007; accepted October 18, 2007]

Demand for 5-axis machine tools has grown rapidly with the appearance of high-performance machines and growing requirements for high-efciency to enhance competitiveness. To meet market needs, FANUC provides innovative CNCs, including the FS30i-A and FS31i-A5, that control up to 24 axes simultaneously with maximum paths of 10 enabling high-speed and high-precision multiple-axis and path control. FANUCs wide-ranging functions developed for powerful 5-axis machining include tool center point control and tilted working plane command, which enable high-precision complex shape machining minimizing changeover. Nano smoothing, interpolation for generating smooth curves on a nanometer scale, enables high-quality workpiece machining. 3D interference checking enhances the safety of machines whose motion has become increasingly complex. Operability has also been improved to facilitate programming and simulation for 5-axis machining. This report presents the latest control technologies maximizing 5-axis machine tool performance. Keywords: 5-axis machining function, tool center point control, tilted working plane command, nano control, high-quality machining

Using 5-axis machine tools increases the possibility of simultaneously reducing machining time and improving machining precision. The high performance of machine tools and controllers have enabled 5-axis machine tools to evolve dramatically as the reduction in the number of machining processes has reduced manufacturing cost. In keeping with the increasing scope of 5-axis machine tools, functions taking advantage of 5-axis control features have greatly advanced.

2. 5-Axis Machining Functions

Two major trends have emerged in the market 5-axis machining centers based on machining centers and compound machines based on lathes capable of simultaneous 5-axis machining. In principle, the machine type is used based on the shape and type of the workpiece to be machined. Five-axis machine tools based on machining centers are mainly divided into rotary heads (head rotation type), rotary tables (table rotation type), and combined rotary heads and tables (mixed type) (Fig. 1). Compound machines with both workpiece axis and tool axis are rotation axes can be handled as mixed type. Different 5-axis machining functions are applicable to different mechanical congurations. Particularly important functions are tool center point control and tilted working plane command. Tool center point control is used in simultaneous 5-axis machining and tilted working plane command in tilted plane machining (3 2-axis machining), enabling different gures on different 5-axis machines to be machined while changing tools. Using tool center point control and tilted working plane command, programs can be easily changed even if cutting conditions are slightly changed. Using such 5-axis control functions, the number of times of reprogramming using CAM is dramatically reduced, which is expected to increase production efciency.

1. Introduction

The major feature of 5-axis machine tools is their integration of machining, conventionally divided into multiple processes, into processes with a single setup thanks to their capacity for complex operation. Reducing setup enables the following: - Reduced interprocess wait and machining time. - Improved machining precision due to eliminating mounting error due to setup changeover. Because the tool axis can be controlled at any angle to the machining surface: - The cutting tool angle to the machining surface can be controlled to be constant, it can improve surface roughness. - Tool rigidity is improved by machining with short tool projection, thereby increasing the machining feed rate. 108

3. Tool Center Point Control

Tool center point control makes it possible to program gures that conventionally must be specied with minute

Int. J. of Automation Technology Vol.1 No.2, 2007

Advanced Control Technologies for 5-Axis Machining

Head rotationtype

Table rotationtype

Fig. 1. Three mechanical congurations.

Mixed type

Control points (machine coordinates)

Machine position

Control point path with tool Control point path with tool 2

Program commands at TCP

Cutting points (programmed commands)

Fig. 3. Tool movement paths with cutting point commands. Fig. 2. Tool center point control.

Selecting the TWP Command type from the menu by moving cursor with graphic guidance Then the individual data input screen is displayed

line segments, using the same concept as an axis orthogonal to three axes as in linear interpolation, circular interpolation, etc. (Fig. 2). This has the following advantages: - The number of program steps decreases, reducing cycle time. - The CNC interpolates directly, increasing gure precision. - The program is easy to understand intuitively, making it easy to make minute modications in the eld. - The tool center point speed is specied, so the machining feed rate at the tool center point is made constant, improving surface precision. The two types of tool center point control are type I, in which angular displacement of the rotary axis is specied directly to the rotary axis, and type II, in which it is specied with a vector. Using tool center point control type II enables the same program to be used regardless of the mechanical conguration (head rotation, table rotation, or compound). For ball-end mills, machining should be at a constant point on the tool tip with good precision/efciency machining. With type II, it is easy to create data vertical to the machining surface because tool directions are specied with vectors as I, J, and K. (1) Cutting point command The cutting point on the machining path can be directly specied in the program. The control point used with the actual machine move command is automatically calculated from the cutting point, corner rounding compensation, cutter compensation, and tool length compensation to control the tool movement path. Even when the tool gure, tool radius, or tool length changes, the program need not be basically modied. Even when the tool is changed, Int. J. of Automation Technology Vol.1 No.2, 2007

Fig. 4. Tilted working plane guidance screen.

the same program can be used, increasing programming efciency (Fig. 3). (2) Tool positioning control By interpolating the attitude of the tool from the tool direction at the start point to the tool direction at the end point, a plane can be machined with the side face of the tool during Tool center point control. When the tool passes near a singular point, however, the rotary axis becomes unstable, it may cause a large rotation. The tool must therefore be made to pass through a singular point while avoiding passing near the singular point and to keep the rotary axis from unstable operation by inverting the rotary axis sign. The travel distance and direction of movement of the entire block must be checked for whether the block is supposed to pass through a singular point and, if so, to modify the block command so that the block does so.

4. Tilted Working Plane

The tilted working plane command is used for free machining on a tilted plane. Simply by creating a machining 109

You might also like

- VISI Machining MANUALDocument158 pagesVISI Machining MANUALThirugnanam Dhandayuthapani90% (10)

- HW3 Spring19Document2 pagesHW3 Spring19Alex Williams0% (1)

- Report CNC MillingDocument16 pagesReport CNC Millingharislukman100% (5)

- CNC Milling MachineDocument15 pagesCNC Milling Machinenajieyuya91% (11)

- CNC Programming Workbook Mill Generic SampleDocument43 pagesCNC Programming Workbook Mill Generic SampleThirugnanam Dhandayuthapani100% (1)

- Exercises Marine Engineer + Internal Combustion EnginesDocument3 pagesExercises Marine Engineer + Internal Combustion EnginesGeorge GaneaNo ratings yet

- Lee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LDocument3 pagesLee's Disc Apparatus (Theory) Heat & Thermodynamics Virtual LReddyvari VenugopalNo ratings yet

- 5 Steps To A 5 AP Physics C 2017 - McGraw-HillDocument299 pages5 Steps To A 5 AP Physics C 2017 - McGraw-HillRishit Kalra100% (1)

- Comparison of Manufacturing Data Analysis For 5 3Document6 pagesComparison of Manufacturing Data Analysis For 5 3Joss JossNo ratings yet

- 13 - F30i A (E) 01Document24 pages13 - F30i A (E) 01Guillermo RamirezNo ratings yet

- CNC Turning Centre GuideDocument10 pagesCNC Turning Centre GuideArun100% (1)

- B Axis For Complete Mill-Turn IntegrationDocument7 pagesB Axis For Complete Mill-Turn IntegrationArtur Pereira LeiteNo ratings yet

- The Task of 5-Axis Milling: Peter Pokorný, Jozef Peterka, Štefan VáclavDocument4 pagesThe Task of 5-Axis Milling: Peter Pokorný, Jozef Peterka, Štefan VáclavNatalie WyattNo ratings yet

- Automatic Centerless Grinder Changeover Keeps Contact Points ConstantDocument1 pageAutomatic Centerless Grinder Changeover Keeps Contact Points ConstantNatKThNo ratings yet

- AI Nano CNC For High-Speed, High-Accuracy MachiningDocument24 pagesAI Nano CNC For High-Speed, High-Accuracy MachiningarashNo ratings yet

- Experiment 3 Contracer - Contour Measureing Machine: Mechatronic Engineering Advanced ProgramDocument10 pagesExperiment 3 Contracer - Contour Measureing Machine: Mechatronic Engineering Advanced ProgramCao KhảiNo ratings yet

- Tugas Bahasa Inggris Artikel Mesin Kelas ME 1 C: Jurusan Teknik Mesin Politeknik Negeri Semarang 2010Document11 pagesTugas Bahasa Inggris Artikel Mesin Kelas ME 1 C: Jurusan Teknik Mesin Politeknik Negeri Semarang 2010Ryand Adhi PNo ratings yet

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiNo ratings yet

- EML 342/2 Lab Report on CNC MachiningDocument9 pagesEML 342/2 Lab Report on CNC MachiningMark SelvanNo ratings yet

- CIM Notes TypedDocument9 pagesCIM Notes TypeditzgayaNo ratings yet

- Mitsubishi m700 CNC BrochureDocument13 pagesMitsubishi m700 CNC BrochureDmitryNo ratings yet

- Automation in Machining Case StudyDocument10 pagesAutomation in Machining Case StudyspicykeyurNo ratings yet

- CH 3Document14 pagesCH 3abdullah 3mar abou reashaNo ratings yet

- CNC NoteDocument7 pagesCNC Note21UME003 TUSHAR DEBNo ratings yet

- CNC Milling Instruction ManualDocument92 pagesCNC Milling Instruction ManualPraveen Raj100% (1)

- CNC Milling ReportDocument6 pagesCNC Milling ReportMuhazman DinNo ratings yet

- CNC Milling Lab GuideDocument21 pagesCNC Milling Lab GuideDinie Abdullah ZamawiNo ratings yet

- MCU EtcDocument22 pagesMCU EtcAjay Kumar BathulaNo ratings yet

- Key Concept Number Three: You Must Understand The Motion Types Available On Your CNC MachineDocument4 pagesKey Concept Number Three: You Must Understand The Motion Types Available On Your CNC MachineGowtham RamakrishnanNo ratings yet

- Name: Rahul Goraksha PRN No:22070148009 Experiment 2 ObjectiveDocument3 pagesName: Rahul Goraksha PRN No:22070148009 Experiment 2 ObjectiveRahul GorakshaNo ratings yet

- Materi 1. Dasar Mesin CNC, Jenis Mesin CNCDocument48 pagesMateri 1. Dasar Mesin CNC, Jenis Mesin CNCndyaudinaNo ratings yet

- 4951 6365 1 SMDocument6 pages4951 6365 1 SMbartosznikusNo ratings yet

- Chapter - 1Document20 pagesChapter - 1nagappa talawarNo ratings yet

- Computer Aided Manufacturing Lab ReportDocument40 pagesComputer Aided Manufacturing Lab ReportDinesh Kumar JdNo ratings yet

- CNC Lathe2Document41 pagesCNC Lathe2Ruby SmithNo ratings yet

- CNC Ipme 710Document73 pagesCNC Ipme 710vajram1No ratings yet

- 1Document27 pages1saranyakathiravanNo ratings yet

- 09 Chapter1 PDFDocument12 pages09 Chapter1 PDFbilbobaggingsNo ratings yet

- What Is A Machine?: Conventional MachinesDocument48 pagesWhat Is A Machine?: Conventional MachinesKranthi KumarNo ratings yet

- 1.0 Introduction of CNC Turning MachineDocument9 pages1.0 Introduction of CNC Turning Machineeizhar50% (4)

- Machining Centre Programming Lab ExperimentDocument6 pagesMachining Centre Programming Lab ExperimentLee RockNo ratings yet

- CNC Machines and Programming GuideDocument76 pagesCNC Machines and Programming GuideAlexandru Precup100% (1)

- Machine Tool Design Lab ManualDocument40 pagesMachine Tool Design Lab ManualRohitGupta100% (1)

- CNC 8055Document16 pagesCNC 8055Aloisio GonzagaNo ratings yet

- Machine Tool Design Lab ManualDocument40 pagesMachine Tool Design Lab ManualRohitGupta100% (2)

- Hari Om Summer Training PPT CNCDocument44 pagesHari Om Summer Training PPT CNCAbhay TiwariNo ratings yet

- Numerical ControlDocument36 pagesNumerical ControlsaishvNo ratings yet

- CamDocument52 pagesCamGaurav DabhekarNo ratings yet

- CNC CimDocument16 pagesCNC CimAbdulhmeed MutalatNo ratings yet

- Intelligent Design of Reconfigurable Machines: Majid Tolouei-RadDocument5 pagesIntelligent Design of Reconfigurable Machines: Majid Tolouei-RadBaitoiu George-MariusNo ratings yet

- 5 AXIS MachiningDocument17 pages5 AXIS Machiningsarangponnamparambath1No ratings yet

- 9.pmat M-01Document94 pages9.pmat M-01mailtome126100% (1)

- Cutting Tool (Milling Machine) PerformanceDocument12 pagesCutting Tool (Milling Machine) PerformanceLashawn de MelNo ratings yet

- CNC Machines GuideDocument23 pagesCNC Machines GuideAshish KumarNo ratings yet

- CNC Part ProgrammingDocument40 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- CNC Part ProgrammingDocument53 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- Chapter 1Document17 pagesChapter 1shubhanshuNo ratings yet

- Bro Hypermill Mill Turn Machining enDocument12 pagesBro Hypermill Mill Turn Machining enErtan DurNo ratings yet

- CNC Section:-: High End Prosthesis Shop MachinesDocument12 pagesCNC Section:-: High End Prosthesis Shop MachinesRishabh PandeyNo ratings yet

- Rotary Table For Radial Drilling MachineDocument30 pagesRotary Table For Radial Drilling Machinehardish_trivedi7005No ratings yet

- CNC TURNING MachineDocument14 pagesCNC TURNING MachineFaiz AhmedNo ratings yet

- Classification of CNC Machine Tools (1) Based On The Motion Type ' Point-To-Point & Contouring SystemsDocument14 pagesClassification of CNC Machine Tools (1) Based On The Motion Type ' Point-To-Point & Contouring SystemsKalyan SinghNo ratings yet

- Thread Milling TutorialDocument9 pagesThread Milling TutorialThirugnanam DhandayuthapaniNo ratings yet

- Setup SheetsDocument4 pagesSetup SheetsThirugnanam DhandayuthapaniNo ratings yet

- Introduction To Multiaxis Toolpaths PDFDocument52 pagesIntroduction To Multiaxis Toolpaths PDFJesus MedinaNo ratings yet

- Helicoil Plus GBDocument51 pagesHelicoil Plus GBThirugnanam DhandayuthapaniNo ratings yet

- NC-Programming Manual For Turning Centers With Fanuc 30 Series ControlsDocument129 pagesNC-Programming Manual For Turning Centers With Fanuc 30 Series ControlsThirugnanam Dhandayuthapani100% (1)

- NX MULTI AXIS MACHINING ConceptDocument22 pagesNX MULTI AXIS MACHINING ConceptMATHI KRISHNAN100% (1)

- SolidWorks+SolidCAM EDU Training Course PDFDocument233 pagesSolidWorks+SolidCAM EDU Training Course PDFThirugnanam Dhandayuthapani100% (1)

- 5 Axis Siemens PDFDocument114 pages5 Axis Siemens PDFAnas AsifNo ratings yet

- Tap Drill Chart 3Document1 pageTap Drill Chart 3Thirugnanam DhandayuthapaniNo ratings yet

- 5-Axis Savings WorksheetDocument3 pages5-Axis Savings WorksheetThirugnanam DhandayuthapaniNo ratings yet

- Engineering Curves and CAGDDocument62 pagesEngineering Curves and CAGDThirugnanam DhandayuthapaniNo ratings yet

- PostProcessing BruyereDocument45 pagesPostProcessing BruyereThirugnanam DhandayuthapaniNo ratings yet

- Professional Courseware Mastercam X Mill 4/5 AxisDocument15 pagesProfessional Courseware Mastercam X Mill 4/5 Axisapi-26042865No ratings yet

- Milling With SINUMERIKDocument114 pagesMilling With SINUMERIKThirugnanam DhandayuthapaniNo ratings yet

- Locking Style Index PinsDocument2 pagesLocking Style Index PinsPeter KingNo ratings yet

- Machine ShopDocument12 pagesMachine ShopArman MalikNo ratings yet

- Hidden PageDocument440 pagesHidden PageThirugnanam DhandayuthapaniNo ratings yet

- PAES 303-2000roller Chains and Sprockets For Agricultural Machines - SpecificDocument30 pagesPAES 303-2000roller Chains and Sprockets For Agricultural Machines - SpecificYanYan CustodioNo ratings yet

- Hlep / Vsax: High Performance Cryogenic Reciprocating PumpsDocument4 pagesHlep / Vsax: High Performance Cryogenic Reciprocating Pumpsbarun1977No ratings yet

- Steel Strips Sheaths For Pre-Stressing TendonsDocument8 pagesSteel Strips Sheaths For Pre-Stressing TendonsAbdullahNo ratings yet

- ANSYS-CFD Analysis of Condensation Process Occurring Inside High Efficiency BoilersDocument20 pagesANSYS-CFD Analysis of Condensation Process Occurring Inside High Efficiency Boilerskulov1592No ratings yet

- CAMON C8 Rotavator PowerSafe DiagramDocument16 pagesCAMON C8 Rotavator PowerSafe DiagramDomNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Metsec Engineering Forms the FutureDocument24 pagesMetsec Engineering Forms the Futureshashank adigaNo ratings yet

- Peake and Tobak 3D SeparationDocument25 pagesPeake and Tobak 3D SeparationPablitox84No ratings yet

- CHAPTER 6 - Design of Knuckle Joint, Sleeve and Cotter JointDocument34 pagesCHAPTER 6 - Design of Knuckle Joint, Sleeve and Cotter JointVignesan MechNo ratings yet

- Honda GX 630 - 660 - 690Document79 pagesHonda GX 630 - 660 - 690joao mariaNo ratings yet

- Injectors. Adaptations. Coding - Bimmerprofs - Com - NOx Emulator NOXEM 129 - 130 - 402 Developed For BMW N43 & N53 Series EnginesDocument27 pagesInjectors. Adaptations. Coding - Bimmerprofs - Com - NOx Emulator NOXEM 129 - 130 - 402 Developed For BMW N43 & N53 Series EnginesMiguelNo ratings yet

- Induction Motor Load Test AnalysisDocument6 pagesInduction Motor Load Test AnalysisCønstäh Van Der WüppertälärîanskíhNo ratings yet

- Government of India Ministry of Railways: DraftDocument26 pagesGovernment of India Ministry of Railways: DraftraveenNo ratings yet

- Hydraulic Pressure TestDocument4 pagesHydraulic Pressure TestBola AdelNo ratings yet

- pc200 7 Main Pump Test MethodDocument26 pagespc200 7 Main Pump Test Methodalfred100% (1)

- VW Fluid Capacity Chart 2001Document5 pagesVW Fluid Capacity Chart 2001WILLIAM ROMERONo ratings yet

- PEM Economy Gauge 1Document5 pagesPEM Economy Gauge 1kprasannanNo ratings yet

- Flowfit CPA250: Technical InformationDocument8 pagesFlowfit CPA250: Technical Informationknightfelix12No ratings yet

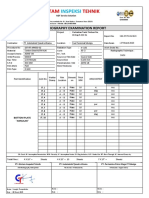

- Pt. Gintam Tehnik: InspeksiDocument5 pagesPt. Gintam Tehnik: Inspeksirizky youlandaNo ratings yet

- Finite Element Analysis of Unreinforced Masonry Walls: MahammedDocument14 pagesFinite Element Analysis of Unreinforced Masonry Walls: MahammedSaad HneidiNo ratings yet

- Design of Drag-Link Mechanisms With Optimum Transmission AngleDocument5 pagesDesign of Drag-Link Mechanisms With Optimum Transmission AngleNigussie AdemNo ratings yet

- Self-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMDocument219 pagesSelf-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMblue4882No ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- CAT 320/323GC Electrical DiagramDocument33 pagesCAT 320/323GC Electrical DiagramSammyNo ratings yet

- Product Information: Diesel Extra LD 15W40Document2 pagesProduct Information: Diesel Extra LD 15W40movie hunterNo ratings yet

- Owners manual for Maveric GK-32A go kartDocument18 pagesOwners manual for Maveric GK-32A go kartedgar santanaNo ratings yet