Professional Documents

Culture Documents

Midget Tractor Plans

Uploaded by

mtullius1234Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Midget Tractor Plans

Uploaded by

mtullius1234Copyright:

Available Formats

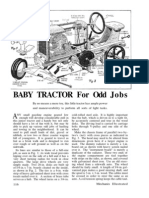

A powerful midget, it shows what you can do with junk-yard bargains, a hacksaw, and a welding outfit. PS photos by W. W .

Morris

OON after Paul E. Matous completed his $50 tractor, a friend's automobile got stuck in the mud. "As a gag, he yelled to me to come and pull him out," says Matous, a building contractor at Orangeburg, N. Y. "He thought I couldn't possibly move the car." Matous was doubtful too. After all, a tractor with a 7-hp. engine is no road-building giant. Another car already had failed to budge the stuck car, even with the

It weighs 450 lbs. One man can easily tip it over. But don't let that fool you about its stability. The builder reports it never "rears up."

MAY 1950 209

Individual brakes make short turns possible. Axle is hooked in notched frame, but U bolts, as in drawing at bottom of page, would be better.

Front-wheel assembly pivots on a boiler-plate "fifth wheel." A " rod through the 2" pipe ties assembly to boiler-plate engine mount.

help of a couple of well-muscled pushers. As Matous hooked on, the pushers winked at each other. But the little tractor buckled down and dragged the car free. Matous then turned to the others. "You guys certainly can push," he grinned. "Push!" one of them said. "We weren't pushing! We were riding!" Matous is a shrewd bargainer, as well as a good craftsman. Otherwise, he couldn't have kept the cost of his doodlebug so low. He paid only $35 for a surplus engine-a single-cylinder, air-cooled, four-cycle Briggs & Stratton. A Ford transmission, Ford steering gear, pre-war Austin rear end, and other parts came from a junk yard. In assembling these, Matous worked mostly with a hacksaw and welding outfit. No machining was required. The Matous tractor doesn't compare in looks with some of the commercial jobs, but its builder offers to bet it will easily outperform at least two famous makes. On that score, Matous argues with some authority. His main job several years ago consisted of repairing agricultural tractors. Matous is proud of the tractor's stability. By experimenting, he produced a nice balance between traction and power. For easy maneuvering, the wheelbase was kept short. But so far Matous has not found a situation that will cause the front wheels to leave the ground. Good weight distribution explains this. The engine rests as far forward on the frame

as he could get it. This shoves the balance point ahead, but there is no loss of traction. The operator's weight helps here. For some jobs, Matous adds about 100 lb. by filling the rear tires with water. Sprockets, countershaft, and chains carry the drive to the Model-A transmission. Speeds are about 10 m.p.h. in high, 4 m.p.h. in second, and 1 m.p.h. in low. A brake-equalizer hanger from a Ford V-8 provided a readymade countershaft bearing. The shaft itself is a 9" length of 7/8" rod, tapped " deep for setscrews that secure the sprockets. Each of the two bearing points was drilled and tapped for a grease fitting. Bolted through slots to its angle-iron mount, the countershaft hanger can be moved to adjust chain tension. When Matous set out to build the tractor, he intended to cut down a Ford rear end. But he decided to forego this job on finding

that an available Austin unit had the 44" tread he wanted. He installed this with considerable misgivings. But despite its lightness it has stood up well. Buick wheels at the rear take 7.00 by 15 mud-grip tires. Inflated to less than 10 lb., these put a large area of rubber on the ground. For some jobs, Matous puts on tire chains. The front tires are 4.00 by 8 (the wheelbarrow type), standing 16" high. These roll on a 1" axle, bent 10 for the proper camber. Welded to the center of the axle is a length of 2" pipe, welded and braced at the upper end to a 10" disk of " boiler plate. In operation, this disk bears against a sheet of " boiler plate that ties together the front end of the channel-iron frame. A " threaded rod, running down through the 2" pipe, holds the wheel assembly to the frame boiler plate. At the lower end, this rod is

MAY 1950 211

Homemade bulldozer attachment hangs on rear axle of tractor. As the sketch shows, Matous

made generous use of junked auto parts when building bulldozer as well as the tractor itself.

bent toward the rear to clear the axle. A nut on its end provides adjustment. The steering assembly came from a Ford V-8. After shortening the shaft to 24", Matous reversed and centered the steering arm. Then he attached the drag link to another steering arm welded to the disk. For the frame, Matous welded together bed-spring angles in channel form. The engine is bolted to the boiler plate that brackets the front end of the frame. For easy starting, the engine is located with the starting pulley overhanging the plate. The tractor has no bumper, but one could easily be added, as suggested in the drawing. At the present time, the lights draw juice directly from a 6-volt battery. The headlamps are back-up lights fitted with 32-candlepower bulbs. Future plans for the tractor include installation of a generator high up under the rear part of the hood. This part

is flat, and for a reason: it makes a convenient spot to lay tools or the gas-can cap. A remote control for varying the tension of the governor spring from the driver's seat is another proposed improvement. A third is a conveniently located toggle switch to stop the engine by shorting out the magneto. About the time Matous built the tractor he also bought a tract of rolling woodland. On this tract, which he refers to as his private Aberdeen proving ground, Matous has made the tractor a real workhorse. Among other jobs, he has used it to snake heavy logs, drag a heavily loaded trailer, and level off the ground with a homemade bulldozer blade. He hasn't yet gotten around to setting it to the routine small-farm and garden chores plowing, cultivating, mowing, and the likebut he feels confident the machine will take all these jobs in good stride. END

A shear pin protects power train. Universal joint was kept only to make assembly easier. Since rear is unsprung, it could be omitted.

A brake-equalizer hanger from a Ford V-8 supports the countershaft. Drive-chain tension is adjusted by moving the hanger in and out.

Clutch linkage is simple. When you press the pedal, a transverse bar pivots forward. Short arm depresses the button, disengaging clutch.

Sprockets and chains carry drive from engine to transmission. Sketch shows power train and clutch linkage from viewpoint directly above.

You might also like

- By Emile Alline: Technical Art by Fred WolffDocument4 pagesBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- Midget Tractor3 PlansDocument6 pagesMidget Tractor3 PlansDanilo RochaNo ratings yet

- Vintage Go Kart Mini Bike Plans-1950sDocument95 pagesVintage Go Kart Mini Bike Plans-1950sJanne FredrikNo ratings yet

- Build MI's Tornado!: by John CapotostoDocument3 pagesBuild MI's Tornado!: by John CapotostoJim100% (1)

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.From EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.No ratings yet

- Plans For Bench GrinderDocument2 pagesPlans For Bench GrinderFernando Morocho100% (1)

- Buildings, Machinery and Tools for a Smallholding - With Information on Economics, Maintenance and Equipment Needed for a Small FarmFrom EverandBuildings, Machinery and Tools for a Smallholding - With Information on Economics, Maintenance and Equipment Needed for a Small FarmNo ratings yet

- Vintage Farm Impliment Plans 1950sDocument91 pagesVintage Farm Impliment Plans 1950sudivljini100% (4)

- Fencing for the Farmstead - Containing Information on the Carpentry Involved in Building FencesFrom EverandFencing for the Farmstead - Containing Information on the Carpentry Involved in Building FencesNo ratings yet

- PowerCycle With SideCarDocument7 pagesPowerCycle With SideCarJim100% (2)

- The Two-Wheel Tractor Handbook: Small-Scale Equipment and Innovative Techniques for Boosting ProductivityFrom EverandThe Two-Wheel Tractor Handbook: Small-Scale Equipment and Innovative Techniques for Boosting ProductivityNo ratings yet

- 3 Wheel Dune BuggyDocument5 pages3 Wheel Dune BuggyyukitadaNo ratings yet

- Car 1901packardDocument8 pagesCar 1901packardDillon Hartsyker100% (1)

- Garden Carpentry - Span, Roof, Greenhouse, Toolshed, Wheelbarrow, Gates, Garden Lights, Summer House, Shelter Etc.From EverandGarden Carpentry - Span, Roof, Greenhouse, Toolshed, Wheelbarrow, Gates, Garden Lights, Summer House, Shelter Etc.No ratings yet

- Super Scooter by Mechanix IllustratedDocument12 pagesSuper Scooter by Mechanix IllustratedJim100% (3)

- The Complete Guide to Building Classic Barns, Fences, Storage Sheds, Animal Pens, Outbuilding, Greenhouses, Farm Equipment, & Tools: A Step-by-Step Guide to Building Everything You Might Need on a Small FarmFrom EverandThe Complete Guide to Building Classic Barns, Fences, Storage Sheds, Animal Pens, Outbuilding, Greenhouses, Farm Equipment, & Tools: A Step-by-Step Guide to Building Everything You Might Need on a Small FarmRating: 4 out of 5 stars4/5 (1)

- SMFeb 56 Roamabout Part 1Document17 pagesSMFeb 56 Roamabout Part 1Jim86% (7)

- YardHorse ScooterDocument9 pagesYardHorse ScooterJim100% (5)

- An Introduction to the Seasoning of Timber: Pergamon Series of Monographs on Furniture and TimberFrom EverandAn Introduction to the Seasoning of Timber: Pergamon Series of Monographs on Furniture and TimberW. J. KapeNo ratings yet

- Homemade Bandsaw From Pipe Fittings and Auto PartsDocument4 pagesHomemade Bandsaw From Pipe Fittings and Auto PartsJan Steinman100% (2)

- The Rocket Powered Oven: how to build your own super-efficient cookerFrom EverandThe Rocket Powered Oven: how to build your own super-efficient cookerNo ratings yet

- Frame Jig Assembly GuideDocument12 pagesFrame Jig Assembly GuideMalcolm DiamondNo ratings yet

- Woodworking on the Farm - With Information on Trees and Lumber, Tools, Sawing, Framing and Various Other Aspects of Farm CarpentryFrom EverandWoodworking on the Farm - With Information on Trees and Lumber, Tools, Sawing, Framing and Various Other Aspects of Farm CarpentryNo ratings yet

- Fee Jee PMFM47Document7 pagesFee Jee PMFM47Jim100% (3)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Wartime ScooterDocument7 pagesWartime ScooterJim100% (5)

- Building Your own Toy Steam Engine - A Guide to Constructing Your own Model Steam Engine and Single Acting Toy EngineFrom EverandBuilding Your own Toy Steam Engine - A Guide to Constructing Your own Model Steam Engine and Single Acting Toy EngineNo ratings yet

- Mite Cycle by Mechanix IllustratedDocument7 pagesMite Cycle by Mechanix IllustratedJim100% (3)

- How to Build Your Own Shed or Outdoor Erection - A Guide for Anybody Handy with a Tool Kit and Wishing to Build Their Own ShedFrom EverandHow to Build Your Own Shed or Outdoor Erection - A Guide for Anybody Handy with a Tool Kit and Wishing to Build Their Own ShedNo ratings yet

- Tote All ScooterDocument7 pagesTote All ScooterJimNo ratings yet

- Handy Farm Devices and How to Make ThemFrom EverandHandy Farm Devices and How to Make ThemRating: 3.5 out of 5 stars3.5/5 (3)

- Homebuilt Wood CarDocument26 pagesHomebuilt Wood Carsjdarkman1930100% (3)

- The Farm Workshop - With Information on Tools and BuildingsFrom EverandThe Farm Workshop - With Information on Tools and BuildingsNo ratings yet

- Foot-Powered Scroll SawDocument8 pagesFoot-Powered Scroll SawJan Steinman100% (1)

- Wood Stove Handbook PDFDocument128 pagesWood Stove Handbook PDFpeter100% (5)

- How-To - Build Your Own Spot Welder - HackadayDocument17 pagesHow-To - Build Your Own Spot Welder - HackadayAndrew McLarenNo ratings yet

- Six Wheeled ATV by Mechanix IllustratedDocument7 pagesSix Wheeled ATV by Mechanix IllustratedJim100% (6)

- More of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideFrom EverandMore of Roy Underhill’s The Woodwright’s Shop Classic Collection, Omnibus Ebook: Includes The Woodwright's Apprentice, The Woodwright's Eclectic Workshop, and The Woodwright's GuideNo ratings yet

- Kid-Powered "Squaris" WheelDocument6 pagesKid-Powered "Squaris" WheelzebrazeroNo ratings yet

- Homemade Ballista - The Oznog's Spruce Moose BallistaDocument13 pagesHomemade Ballista - The Oznog's Spruce Moose BallistaIkkasama NaguenneNo ratings yet

- Patios (UK Only): Designing, building, improving and maintaining patios, paths and stepsFrom EverandPatios (UK Only): Designing, building, improving and maintaining patios, paths and stepsNo ratings yet

- Lathe Cross-Sli Olders.: " DuplexDocument3 pagesLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Brush Buggy, Build An ExcitingDocument5 pagesBrush Buggy, Build An ExcitingJim88% (8)

- Mini-Skat 6-Wheel Plans AssemblyDocument40 pagesMini-Skat 6-Wheel Plans AssemblyВладимир Батманов100% (3)

- Wood Stoves How To Make and Use 1999Document207 pagesWood Stoves How To Make and Use 1999britt1100% (1)

- 1901 TruckDocument10 pages1901 TruckGary B. Watts100% (3)

- Lewis MillDocument9 pagesLewis MillCelso Ari Schlichting100% (2)

- Suitcase PowercycleV2Document13 pagesSuitcase PowercycleV2Jim67% (3)

- Milling Arm For Drill PressDocument4 pagesMilling Arm For Drill PressMartin Ong100% (1)

- Tent Pitching NotesDocument21 pagesTent Pitching NotessnguidemynahNo ratings yet

- FIN323 Project 2021-2022Document6 pagesFIN323 Project 2021-2022saleem razaNo ratings yet

- A Flight Plan in 10 StepsDocument4 pagesA Flight Plan in 10 StepsThar LattNo ratings yet

- OEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Document6 pagesOEM - Fuel Manager Brand Cross Reference P/Ns For Service Filter Elements 99642 - January 2006Miguel RojasNo ratings yet

- Argumentative E-WPS OfficeDocument6 pagesArgumentative E-WPS OfficeoneNo ratings yet

- Quick Commerce:: The Real Last MileDocument9 pagesQuick Commerce:: The Real Last MileChhavi KhandujaNo ratings yet

- Eligibility To Become IAS Officer: Career As A IAS Officer About IAS OfficerDocument4 pagesEligibility To Become IAS Officer: Career As A IAS Officer About IAS Officersamiie30No ratings yet

- 9 PNB V Andrada Electric & Engineering Co., GR No. 142936, April 17, 2002Document9 pages9 PNB V Andrada Electric & Engineering Co., GR No. 142936, April 17, 2002Edgar Calzita AlotaNo ratings yet

- Final Report Air ConditioningDocument42 pagesFinal Report Air ConditioningAzmi Matali73% (11)

- TQM - Juran ContributionDocument19 pagesTQM - Juran ContributionDr.K.Baranidharan100% (2)

- Natural GeotextilesDocument27 pagesNatural GeotextilesDr Muhammad Mushtaq Mangat100% (1)

- Arti ResearchDocument10 pagesArti Researcharti nongbetNo ratings yet

- Road Book - MoroccoDocument28 pagesRoad Book - MoroccoCarrie YangNo ratings yet

- Lynette Hawkins, BMG Awesome InsightDocument2 pagesLynette Hawkins, BMG Awesome Insightawesomei100% (1)

- Kiani v. Bureau of Immigration and Deportation, GR No. 160922, 27 ESCRADocument19 pagesKiani v. Bureau of Immigration and Deportation, GR No. 160922, 27 ESCRAmheritzlynNo ratings yet

- Defining The Audiovisual IndustryDocument20 pagesDefining The Audiovisual IndustryAyoub Ait MahmoudNo ratings yet

- Tapspp0101 PDFDocument119 pagesTapspp0101 PDFAldriel GabayanNo ratings yet

- 03 Zero Emissions and Eco-Town in KawasakiDocument21 pages03 Zero Emissions and Eco-Town in KawasakiAlwi AmarNo ratings yet

- Robert Plank's Super SixDocument35 pagesRobert Plank's Super SixkoyworkzNo ratings yet

- ADM3346A Midterm Fall 2010 SolutionDocument10 pagesADM3346A Midterm Fall 2010 SolutionJohn BecksNo ratings yet

- Cash Management Bank of IndiaDocument52 pagesCash Management Bank of Indiaakalque shaikhNo ratings yet

- Functional Specifications For Purchase Order: 1. Business RequirementsDocument5 pagesFunctional Specifications For Purchase Order: 1. Business RequirementsTom MarksNo ratings yet

- Malik Tcpdump FiltersDocument41 pagesMalik Tcpdump FiltersombidasarNo ratings yet

- Precision Probability Index (Elf)Document20 pagesPrecision Probability Index (Elf)EdsonnSPBrNo ratings yet

- Battlab Report 12 FinalDocument48 pagesBattlab Report 12 FinalLianNo ratings yet

- Pricelist Jan 2023Document7 pagesPricelist Jan 2023Rahmat FadilNo ratings yet

- Biodiversity Management Bureau: Repucjuf The Philippines Department of Environment and Natural ResourcesDocument36 pagesBiodiversity Management Bureau: Repucjuf The Philippines Department of Environment and Natural ResourcesMarijenLeañoNo ratings yet

- VLLAR2019Document81 pagesVLLAR2019Christian MallorcaNo ratings yet

- ZPPF ChallanDocument1 pageZPPF ChallanGunasekhar ReddyNo ratings yet

- Electronics World 1962 11Document114 pagesElectronics World 1962 11meisterwantNo ratings yet

- This Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1Document7 pagesThis Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1HERBERT SITORUS100% (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Endure: How to Work Hard, Outlast, and Keep HammeringFrom EverandEndure: How to Work Hard, Outlast, and Keep HammeringRating: 5 out of 5 stars5/5 (1)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerFrom EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerRating: 4 out of 5 stars4/5 (5)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Endure: How to Work Hard, Outlast, and Keep HammeringFrom EverandEndure: How to Work Hard, Outlast, and Keep HammeringRating: 4.5 out of 5 stars4.5/5 (285)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionFrom EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionRating: 5 out of 5 stars5/5 (2)

- Happy, Happy, Happy: My Life and Legacy as the Duck CommanderFrom EverandHappy, Happy, Happy: My Life and Legacy as the Duck CommanderRating: 5 out of 5 stars5/5 (39)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- Prepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideFrom EverandPrepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideRating: 4.5 out of 5 stars4.5/5 (10)

- Si-cology 1: Tales and Wisdom from Duck Dynasty's Favorite UncleFrom EverandSi-cology 1: Tales and Wisdom from Duck Dynasty's Favorite UncleRating: 4.5 out of 5 stars4.5/5 (16)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)