Professional Documents

Culture Documents

7 Waste

Uploaded by

vijay2101Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Waste

Uploaded by

vijay2101Copyright:

Available Formats

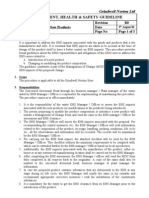

Eliminating The Seven Wastes

Internal, Rework, Supplier, Final Test, Inspection, Out of Control Process, Lack of skill, training and on the job support, Inaccurate design and engineering, Machine inaccuracy

7. Defects

Material Shortages, Un-level Demand, Build to stock, Economic Lot Sizes, Batching, Bottleneck processes, Unbalanced capacities, Quality problems, Long change-over times, Building Earlier than needed, Poor logistics, Poor layout, Poor machine reliability, Emphasis on keeping machines busy opposed to keeping material busy.

1. Over Production 2. Inventory

Buffers , Excess WIP, Supplier inventories for long lead time, Stock, Production Schedule not even, inaccurate forecasting, excessive downtime / setup. Poor work design, Ergonomic Design, Travel time, Tool & Material access, Inadequate Operating Procedure, Poor Housekeeping, Inadequate Training

Excessive testing, Install, Reconfiguration, Material variability/over design, Lack of operating procedures

6. Over Processing

3. Motion

5. Transporta tion

4. Waiting

Movement between buildings/sites, Premium, Freight, Distribution, Network, Plant Layout, Unnecessary material handling

Materials Shortages, Un-level Demand, Startup, Vendor Predictability, Scheduling Conflicts, Lack of flexibility in personnel or equipment, Downtime/Breakdown, Ineffective planning, Design or Quality issues, Transportation, Unnecessary material handling

L. Pennington

Predefined methodology to identify and eliminate waste.

www.AQSN.com

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 15 Propositie Service Logistiek WP SL FinalDocument92 pages15 Propositie Service Logistiek WP SL Finalvijay2101No ratings yet

- Principles of Management - BbaDocument3 pagesPrinciples of Management - Bbavijay21010% (1)

- SC - MGMT - Scientific ManagementDocument22 pagesSC - MGMT - Scientific Managementvijay2101No ratings yet

- ch9R PMDocument18 pagesch9R PMvijay2101No ratings yet

- High Strength Steel - ATOS 80, DOMEX 650Document1 pageHigh Strength Steel - ATOS 80, DOMEX 650vijay2101No ratings yet

- Quality Management: Mcgraw-Hill/Irwin © 2006 The Mcgraw-Hill Companies, Inc., All Rights ReservedDocument35 pagesQuality Management: Mcgraw-Hill/Irwin © 2006 The Mcgraw-Hill Companies, Inc., All Rights Reservedvijay2101No ratings yet

- COPQ QueriesDocument3 pagesCOPQ Queriesvijay2101No ratings yet

- 6 Sigma HistoryDocument16 pages6 Sigma HistoryArmando Delgado PedrozaNo ratings yet

- 5S BasicsDocument26 pages5S Basicsvijay2101No ratings yet

- 1st Page Six SigmaDocument2 pages1st Page Six Sigmavijay2101No ratings yet

- Six Sigma Systems Principles, Module 2.1Document11 pagesSix Sigma Systems Principles, Module 2.1Adeniyi RotimiNo ratings yet

- Chpt01 Principles of ManagementDocument23 pagesChpt01 Principles of Managementvijay2101No ratings yet

- GNO-New Product Procedure For EHSDocument3 pagesGNO-New Product Procedure For EHSvijay2101No ratings yet

- 6 Sigma HistoryDocument16 pages6 Sigma HistoryArmando Delgado PedrozaNo ratings yet

- 7 WasteDocument1 page7 Wastevijay2101No ratings yet

- 1st Page Six SigmaDocument2 pages1st Page Six Sigmavijay2101No ratings yet

- Poka Yoka ExercisesDocument1 pagePoka Yoka Exercisesvijay2101No ratings yet

- AnovaDocument11 pagesAnovavijay2101No ratings yet

- AnovaDocument11 pagesAnovavijay2101No ratings yet

- Articles - CPK PPKDocument10 pagesArticles - CPK PPKvijay2101100% (1)

- FrequentlyDocument3 pagesFrequentlyvijay2101No ratings yet

- 1st Page Six SigmaDocument2 pages1st Page Six Sigmavijay2101No ratings yet

- One-way ANOVA and Tukey Post Hoc TestDocument11 pagesOne-way ANOVA and Tukey Post Hoc Testvijay2101No ratings yet

- AnovaDocument11 pagesAnovavijay2101No ratings yet

- AnovaDocument11 pagesAnovavijay2101No ratings yet

- AnovaDocument11 pagesAnovavijay2101No ratings yet

- 1st Page Six SigmaDocument2 pages1st Page Six Sigmavijay2101No ratings yet

- One-way ANOVA and Tukey Post Hoc TestDocument11 pagesOne-way ANOVA and Tukey Post Hoc Testvijay2101No ratings yet

- Gentlemen, Start Your Gages: R&R and Variability: Gagepack Gordon ConstableDocument4 pagesGentlemen, Start Your Gages: R&R and Variability: Gagepack Gordon Constablevijay2101No ratings yet

- 7 WasteDocument1 page7 Wastevijay2101No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)