Professional Documents

Culture Documents

Disinfection of Sterile Area

Uploaded by

Ali KureishiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disinfection of Sterile Area

Uploaded by

Ali KureishiCopyright:

Available Formats

Standard Operating Procedure for Cleaning mopping and disinfection Prepared by: Microbiologist Approved by: Q. C.

Manager Reference: USP / SOP Guidelines

SOP #. Effective Date: Rev. #: Rev. Date: Page 1 of 3

Purpose

To lay down a standard procedure for Sterile Area Disinfection.

Scope

This procedure provides a standard method for routine cleaning of sterile area using Disinfectants to ensure the area is completely free from micro organisms.

Responsibility

Senior Chemist - Production Microbiologist, Supervisor - Production House keeping

Procedure

Remove all glass pieces if any, from sterile area after completion of the filling. Clean the filling Machine, SS parts, filling table and floor with distilled water. Use hot distilled water to remove the strain if present. Then use following disinfectants as per the schedule.

After cleaning, dry the sterile area for half an hour. The Machine, table, laminar airflow should be wiped with decontaminating solution: Decontaminating solution contains: Liquid phenol 5% w/v Formaldehyde 8% v/v IPA 75% v/v Distilled water QS Spray the hydrogen peroxide solution 20% w/v after cleaning and wiping. Finally, fumigate by using Formaldehyde and Potassium permanganate.

Record

Log Book

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Expense Detail AprilDocument2 pagesExpense Detail AprilAli KureishiNo ratings yet

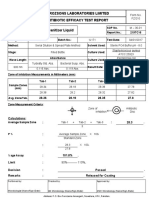

- Ferozsons Laboratories Limited Antibiotic Efficacy Test Report 707 Hand Sanitizer LiquidDocument2 pagesFerozsons Laboratories Limited Antibiotic Efficacy Test Report 707 Hand Sanitizer LiquidAli KureishiNo ratings yet

- Cam VDocument3 pagesCam VAli KureishiNo ratings yet

- Designing Air Flow SystemsDocument37 pagesDesigning Air Flow SystemsAli KureishiNo ratings yet

- Compressed Air Qualification Gaps Standard Requirement: 1) Dew Point SensorDocument2 pagesCompressed Air Qualification Gaps Standard Requirement: 1) Dew Point SensorAli KureishiNo ratings yet

- LD 50 For SLS Is 1288 MG / KG: MACO of SLS 128860SF BS / MDDDocument1 pageLD 50 For SLS Is 1288 MG / KG: MACO of SLS 128860SF BS / MDDAli KureishiNo ratings yet

- I Would Like To Bring To Your Notice That For The Last 2Document1 pageI Would Like To Bring To Your Notice That For The Last 2Ali KureishiNo ratings yet

- 25 09 2014Document4 pages25 09 2014Ali KureishiNo ratings yet

- DRAP of ChecklistDocument61 pagesDRAP of ChecklistAli KureishiNo ratings yet

- Swab Test of Micbrobial Analysis For Cleaning ValidationDocument4 pagesSwab Test of Micbrobial Analysis For Cleaning ValidationAli KureishiNo ratings yet

- Ferozsons Laboratories Limited: Quotation of Different Supplier of Culture MediaDocument1 pageFerozsons Laboratories Limited: Quotation of Different Supplier of Culture MediaAli KureishiNo ratings yet

- FP 658Document9 pagesFP 658Ali KureishiNo ratings yet

- Biocontamination Control Techniques For Purified Water SystemDocument4 pagesBiocontamination Control Techniques For Purified Water SystemAli KureishiNo ratings yet

- AcrDocument1 pageAcrAli KureishiNo ratings yet

- Work Instruction For EntryDocument3 pagesWork Instruction For EntryAli KureishiNo ratings yet

- Water Test ReportDocument1 pageWater Test ReportAli KureishiNo ratings yet

- Clean Room SpecificationsDocument2 pagesClean Room SpecificationsAli KureishiNo ratings yet