Professional Documents

Culture Documents

BLD Struct Plan Check List Single Family Residential

BLD Struct Plan Check List Single Family Residential

Uploaded by

Thomas GarciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BLD Struct Plan Check List Single Family Residential

BLD Struct Plan Check List Single Family Residential

Uploaded by

Thomas GarciaCopyright:

Available Formats

CITY OF MILPITAS

Building & Safety Department 455 E. Calaveras Blvd. Milpitas, CA 95035 408-586-3240 www.ci.milpitas.ca.gov

STRUCTURAL PLAN REVIEW CHECKLIST SINGLE FAMILY RESIDENTIAL

(Groups R-3, R-3.1 and U)

The intent of this checklist is to provide a general guideline for the structural plan review. This checklist may not include items related to all possible projects. This checklist may include more items than specific set of structural plans may encompass. Code sections as shown: sec. 301 is referring to 2007 California Building Code MMC II-3-2.04 is referring to 2008 Milpitas Municipal Code

A. GENERAL

Conventional light-frame construction

Buildings are permitted to be constructed in accordance with the provisions of conventional light-frame construction subject to the following limitations per section 2308.2: a. Building shall be limited to a maximum of two stories above grade. b. Bearing wall floor-to-floor height shall not exceed a stud height of 10 feet plus a height of floor framing not to exceed 16 feet. c. Average dead loads shall not exceed 15 psf for combined weight of roof & ceiling, exterior walls, floors & partitions. d. Roof trusses and rafters shall not span more than 40 feet between points of vertical supports.

Structurally Designed Building

1. The design loads and other information pertinent to the structural design required by section 1603.1 through 1603.8 shall be indicated on the construction documents. As a minimum they shall include: a. ROOF : _______PSF DEAD LOAD _______PSF LIVE LOAD FLOOR : _______PSF DEAD LOAD _______PSF LIVE LOAD b. WIND PER ASCE7-05 _______MPH BASIC WIND SPEED (3-SECOND GUST), EXPOSURE CATEGORY _______ c. SEISMIC PER ASCE 7-05 Ss :________ S1 _______ SITE CLASS _______ Sds :________ Sd1 _______ SEISMIC DESIGN CATEGORY _______ R, RESPONSE COEFFICIENT FACTOR_______ 2. Unless the plans are prepared using the requirements of conventional light-frame construction, structural plans must be designed by an Engineer or Architect licensed by the State of California and the final set of plans prepared for permit issuance shall be stamped and signed by the design Engineer or Architect as per section 2308. 3. Projects for all structures located in the hillside area must be prepared and designed by Civil/ Structural Engineer or Architect licensed in the State of California per City Policy BDP-BLG09. 4. All structures and their elements located in the hillside area shall be designed for a 3-second gust minimum wind speed of 95 mph and exposure C per MMC section II-3-2.9.

1 of 6

January 2009

City of Milpitas Building and Safety Department

Structural Plan Review Checklist Single Family Residential

5. All structures located in the hillside shall conform to minimum requirements of 2007 CBC section 2308.10.1 per MMC II-3-2.9. 6. The live load in attic where the maximum clear height between joist and rafter is 42 or more or there are two or more adjacent trusses capable of containing a rectangle 42 high by 2 wide shall be 20 psf per Table 1607.1 of 2007 CBC. 7. Dead load for bottom chord of truss forming an attic shall be the greater of actual dead load or 10 psf per Table 1607.1 of 2007 CBC.

B. CONVENTIONAL FRAMING

1. 2. 3. Indicate sizes and locations of all structural members on plans. Framing details shall be referenced on plans. Sizes, spacing and span for floor joists shall be in accordance with Table 2308.8(1) or (2). Floor girders for single story construction or girders supporting loads from a single floor shall not be less than 4X6 for spans 6 or less provided that girders are spaced not more than 8 on center per section 2308.7. Where a girder is spliced over a support, an adequate tie shall be provided. Not less than 3 of bearing shall be provided when a girder is supported on masonry or concrete per section 2308.7. The ends of joist shall not have less than 1.5 of bearing on wood or metal, or less than 3 on masonry per sec. 2308.8.1. Joists shall be supported laterally at the ends and at each support by solid blocking of not less than 2 thick and full depth of the joist per sec. 2308.8.2. Joist framing from opposite sides of a beam, girder or partition shall be lapped at least 3 per section 2308.8.2. Where the nominal depth to thickness ratio of the framing member exceeds 6 to1, there shall be one line of bridging for each 8 of span per section 2308.8.5. The sizes, height and spacing of studs shall be in accordance with Table 2308.9.1. Not less than three studs shall be installed at each corner of an exterior wall as per section 2308.9.2. Ends of double top plates of bearing and exterior wall studs shall be offset at least 48 and shall be nailed with not less than eight 16d face nails on each side of the joint as per section 2308.9.2.1. Header and its support shall be provided per Table 2308.9.5 over each opening in exterior bearing walls for one and two family dwelling with minimum header bearing of 1.5 X full width of the header as per sections 2308.9.5.1 & 2. Table 2308.9.6 may be used for headers over each opening in interior bearing partition. Where plumbing, heating or other pipes are placed in or partly in a partition, necessitating the cutting of the soles or plates, a metal tie not less than 16 gage and 1.5 wide shall be fastened to each plate across and to each side of the opening with not less than 6-16d nails as per sec. 2308.9.8. In exterior walls and bearing partitions, any wood stud is permitted to be cut or notched to a depth not exceeding 25% of its width as per section 2308.9.10. A hole not greater in diameter than 40% of the stud width is permitted to be bored in any wood stud, 60% of the stud width is permitted, if each bored stud is doubled and not more than 2 such successive doubled studs are so bored as per sec. 2308.9.11. The edge of the bored hole shall not be nearer than 5/8 to the edge of the stud. Bored hole shall not be located at the same section of stud as a cut or notch. Conventional framing details required in section 2308.10 for roof and ceiling framing apply to roofs having a minimum slope of 3 units vertical in 12 units horizontal or greater, otherwise ridge board, hips and valleys shall be designed as beams. 2 of 6 January 2009

4. 5.

6. 7.

8. 9. 10. 11. 12.

13.

14. 15.

16.

City of Milpitas Building and Safety Department

Structural Plan Review Checklist Single Family Residential

17.

Rafters shall be framed directly opposite each other at the ridge. There shall be a ridge board at least 1 nominal thickness at ridges and not less in depth than the cut end of the rafter as per section 2308.10.3. Ceiling joists and rafters shall be nailed to each other and the assembly shall be nailed to the top wall plate per Table 2304.9.1 and 2308.10.1. Ceiling joists shall be continuous or securely joined where they meet over interior partitions and fastened to adjacent rafters in accordance with Tables 2308.10.4.1 & 2304.9.1. Where ceiling joists are not parallel to rafters, an equivalent rafter tie shall be installed in a manner to provide a continuous tie across the building as per section 2308.10.4.1. Notching at the ends of rafters or ceiling joists shall not exceed one-fourth the depth. Notches in the top or bottom of the rafter or ceiling joist shall not exceed one-sixth the depth and shall not be located in the middle one-third of the span. Bored hole diameter in rafters or ceiling joists shall not exceed one-third the depth of the member and not be within 2 of top and bottom per section 2308.10.4.2. Purlin installed to reduce the span of rafters shall not be smaller than the supported rafter and shall be supported by struts to bearing walls. The maximum span of 2X4 and 2X6 purlin is 4 and 6 respectively. Struts shall not be smaller than 2X4 with maximum unbraced length of 8 and the minimum slope shall not be less than 45 degrees from the horizontal as per section 2308.10.5.

18.

19.

20.

C. LATERAL SYSTEM

Conventional Design

1. Indicate type of shear walls and their minimum length on plans to match the design calculations or per the requirements of brace wall in the conventional light-frame construction as per section 2308. 2. Indicate the type/size and locations of hold-downs on the plans. 3. Conventional light-frame construction braced wall panels shall be distributed along the length of the braced wall line and start at not more than 8 from each end of the braced wall line as per section 2308.12.4. 4. The sum of lengths of braced wall panels at each braced wall line shall conform to Table 2308.12.4. (12 wood structural panels for seismic design category D with SDS equal to or greater than 1.0) 5. In conventional light-frame construction, when the wood structural panel bracing of the same material is on two faces of the wall, the minimum length is permitted to be one-half the tabulated value in Table 2308.12.4 and design for uplift is required. 6. In conventional light-frame construction, the minimum length of panel bracing shall have the height to width of brace wall not to exceed 2 to 1 per Table 2308.12.4. 7. The braced wall line spacing between interior and exterior braced wall lines shall not exceed 25 in conventional light-frame construction as per section 2308.12.3. 8. Braced wall lines shall be supported by continuous foundations with the following exceptions as per MMC sec. II3-34: a. One-story buildings with maximum plan dimension not exceeding 50 may have continuous foundations located at exterior braced wall lines only. b. Two-story buildings with a maximum plan dimensions not exceeding 50 may have braced wall lines supported on continuous foundations at the exterior wall only, provided cripple walls do not exceed 4 in height and where the first story is supported on a raised wood framed floor, the interior braced wall panels are directly supported by either doubled joists, continuous 4X blocking or minimum 4X floor beams. 9. Gypsum board, gypsum lath, Portland cement plaster (for over one-story structures) and gypsum sheathing boards may not be used to resist seismic shear in conventional construction as per MMC II-3-34.

3 of 6

January 2009

City of Milpitas Building and Safety Department

Structural Plan Review Checklist Single Family Residential

10. In conventional light-frame construction, the bracing of the wall required by MMC sec. II-3-34 is permitted to be replaced by the alternative bracing per section 2308.9.3.1 as follows: a. In one-story buildings, each panel shall have a length of not less than 2-8, not more than 10 tall. Each panel shall be sheathed on one face with 3/8 minimum thickness wood structural panel sheathing nailed with 8d common or galvanized box nails at 6 on center at edges and 12 on center at intermediate supports. Two anchor bolts shall be provided at each panel. Each panel end stud shall have a tie-down device fastened to the foundation, capable of providing an approved uplift capacity of not less than 1,800 pounds. The foundation shall be reinforced with not less than one no. 4 bar top and bottom. b. In the first story of two-story buildings, each wall panel shall be braced as in one-story buildings except that the wood structural panel sheathing shall be provided on both faces, three anchor bolts shall be placed at one-quarter point, and tie-down device with uplift capacity not less than 3,000 pounds. 11. Portions of structures with one or more conditions described in items 1 through 6 in sec. 2308.12.6 shall be considered irregular and conventional light-framed construction shall not be used. Such irregular portion of structures shall be designed to resist the forces specified in Chapter 16 to the extent such irregular features affect the performance of the conventional framing system.

Engineered Design

1. The basic lateral and vertical seismic force-resisting system shall conform to one of the types indicated in Table 12.2-1 of the ASCE 7-05. The structural system used shall be in accordance with the seismic design category and height limitations indicated in ASCE 7-05 Table 12.2-1. The appropriate response modification coefficient, R, system overstrength factor, omega, and deflection amplification factor, Cd, indicated in ASCE 7-05 Table 12.2-1 shall be used in determining the base shear, element design forces and design story drift. 2. When the soil properties are not known in sufficient detail to determine the site class, site class D shall be used as per section 1613.5.2, 2007 CBC & 11.4.2 of ASCE 7-05. 3. When using alternative basic load combinations in allowable stress design that includes wind or seismic loads, allowable stresses are permitted to be increased or load combinations reduced where permitted by the material chapter of this code or the referenced standards per section 1605.3.2, 2007 CBC. 4. Where different seismic force-resisting systems are used in combination to resist seismic forces in the same direction of the structural response, the more stringent system limitation contained in ASCE 7-05 Table 12.2-1 shall apply. Resisting elements are permitted to be designed using the least value of R for the different structural systems found in each independent line of resistance if the following three conditions are met (sec.12.2.3 & 12.2.3.2 of ASCE 7-05.): a. Occupancy Category I or II building. b. Two stories or less in height, and c. Use of light-frame construction or flexible diaphragms. However, the value of R used for design of diaphragms in such structures shall not be greater than the least value for any of the systems utilized in that same direction and the deflection amplification factor, Cd, and the system overstrength factor, omega, in the direction under consideration at any story shall not be less than the largest value of this factor for the R factor used in the same direction being considered. 5. R, Cd, and omega values for vertical combinations: The value of the response modification coefficient, R, used for design at any story shall not exceed the lowest value of R that is used in the same direction at any story above that story. The deflection amplification factor, Cd, and the system over strength factor, omega, used for the design at any story shall not be less than the largest value of this factor that is used in the same direction at any story above that story, except for rooftop structures not exceeding two stories in height and 10% of the total structure weight, other supported structural systems with a weight equal to or less 10% of the weight of the structure and detached one and two family dwellings of light-frame construction as per sec.12.2.3.1 of ASCE 705. 6. Single-story steel ordinary moment frames and intermediate moment frames in structures assigned to seismic design category D or E are permitted up to a height of 65 where the dead load supported by and tributary to the

4 of 6

January 2009

City of Milpitas Building and Safety Department

Structural Plan Review Checklist Single Family Residential

roof does not exceed 20 psf. Dead loads tributary to the moment frame, of the exterior wall more than 35 above the base shall not exceed 20 psf as per sec.12.2.5.6 of ASCE 7-05. 7. Other steel ordinary moment frames in structures assigned to seismic design category D or E not meeting the limitations set forth in section 12.2.5.6 are permitted within light-frame construction up to a height of 35 where neither the roof nor the floor dead load supported by and tributary to the moment frames exceeds 35 psf, the dead load of the exterior walls tributary to the moment frame shall not exceed 20 psf as per sec. 12.2.5.7 of ASCE 705. 8. Redundancy factor for structures assigned to seismic design category D through F shall be equal to 1.3 unless one of the two conditions in sec.12.3.4.2 of ASCE 7-05 is met, whereby the redundancy factor is permitted to be taken as 1.0. 9. Columns, beams, trusses, or slabs supporting discontinuous walls or frames of structures having horizontal irregularity type 4 of ASCE 7-05 Table 12.3-1 or vertical irregularity type 4 of ASCE 7-05 Table 12.3-2 shall have the design strength to resist the maximum axial force that can develop in accordance with the load combinations with overstrength factor of section 12.4.3.2. 12.3.3.3 of ASCE 7-05. 10. Where allowable stress design is used for load combinations with overstrength, allowable stresses are permitted to be determined using allowable stress increase of 1.2 per ASCE 7-05 sec. 12.4.3.3. This increase shall not be combined with increases in allowable stresses or load combination reductions otherwise permitted by the ASCE standard or the material reference document except that combination with the duration of load increases permitted in NDS is permitted. 11. In structures assigned to seismic design category C, D, E or F, collector elements, splices, and their connections to resisting elements shall resist the load combinations with overstrength factor of ASCE 7-05 sec. 12.4.3.2, except in structures or portions thereof braced entirely by light-frame shear walls per ASCE 7-05 sec. 12.10.2.1. 12. Any smaller portion of the structure shall be tied to the remainder of the structure with elements having a design strength capable of transmitting a seismic force of 0.133 times SDS, times the weight of the smaller portion or 5 percent of the portions weight, whichever is greater as per ASCE 7-05 sec. 12.1.4. 13. In structures assigned to seismic design category D, E & F, horizontal cantilever structural components shall be designed for a minimum net upward force of 0.2 times the dead load in addition to applicable load combinations of ASCE 7-05 sec. 12.4 per sec. 12.4.4. 14. Periodic special inspection is required for nailing, bolting, anchoring and other fastening of components within the seismic-force-resisting system, including wood shear walls, wood diaphragm, drag struts, braces, shear panels and hold-downs, except where the fastener spacing of the sheathing is more than 4 on center as per sec. 1707.3. 15. The height, h, and the width, w, ratio of wood structural panels shall not exceed 2 to 1. For design to resist seismic forces, shear wall height-width ratio greater than 2 to 1, but not exceeding 3.5 to 1 are permitted provided the allowable shear values in Table 2306.4.1 are multiplied by 2w/h as per section 2305.3.4 & Table 2305.3.4.

D. FOUNDATION

1. All new foundations required due to building additions to existing occupancies shall be the same type of foundation system as the existing structure per MMC II-3-2.13 A soil report is required for both new residences and additions to residences in hillside areas per MMC II-32.13. Concrete in footings shall have a specified compressive strength fc of not less than 2,500 psi at 28 days as per section 1805.4.2.1. The assumed frictional resistance developed by any pier or uncased case-in-place piles shall not exceed onesixth of the bearing value of the soil material at minimum depth set forth in Table 1804.2, up to maximum of 500 psf as per sec. 1804.2. 5 of 6 January 2009

2.

3.

4.

City of Milpitas Building and Safety Department 5.

Structural Plan Review Checklist Single Family Residential

Addition to R-3 occupancies without an available soils report and where the existing foundation system is a standard T type or a pier and grade beam type, may be constructed per MMC II-3-2.13 and in accordance with Table 1805.4.2 of 2007 CBC at the option of the property owner. Special inspection shall not be required for isolated spread footing of buildings three stories or less in height that are fully supported on earth or rock, where the structural design of the footing is based on a specified compressive strength fc no greater than 2,500 psi per MMC II-3-2.12. Special inspection shall not be required for continuous concrete footing supporting walls of buildings three stories or less in height that are fully supported on earth or rock, where the footing supports walls of lightframe construction and is designed in accordance with Table 1805.4.2 and based on specified compressive strength fc no greater than 2,500 psi, regardless of the compressive strength specified in the construction documents or used in the footing construction as per MMC II-3-2.12. Sill plate on concrete or masonry slab that is in direct contact with earth shall be of naturally durable or preservative-treated wood as per section 2304.11.2.4 Wood framing members, including wood sheathing, that rest on exterior foundation walls shall be 8 from exposed earth unless they are of naturally durable or preservative treated wood as per section 2304.11.2.2. Where wood joists or the bottom of a wood structural floor without joists are closer than 18 or wood girders are closer than 12 to the exposed ground in crawl spaces or unexcavated areas located within the perimeter of the building foundation, the floor assembly (including posts, girders, joists and sub-floor) shall be of naturally durable or preservative treated wood as per section 2304.11.2.1. Sill plates resisting a design load greater than 350 plf using allowable stress design shall not be less than a 3 nominal member. Sill plate is permitted to be 2 nominal member in shear walls where the design load is greater than 350 plf but less than 600 plf using allowable stress design, if the sill plate is anchored by two times the number of bolts required by design as per section 2305.3.11. Foundation plates or sills shall be bolted or anchored to the foundation with not less than 0.5 diameter steel bolts or approved anchors. Bolts shall be embedded at least 7 into concrete or masonry, and spaced not more than 6 apart. There shall be a minimum of two bolts or anchor straps per piece with one bolt or anchor strap located not more than 12 or less than 4 from each end of each piece as per section 2308.6. Sill anchorage of braced wall shall conform to section 2308.6 except that such anchors shall be spaced at not more than 4 on center for structures over two stories in height as per section 2308.3.3 Anchor bolts for shear walls shall include steel plate washers, a minimum 0.229 by 3 square between the sill plate and nut as per section 2305.3.11. Fasteners for preservative-treated and fire-retardant-treated wood shall be of hot dipped zinc-coated galvanized steel, stainless steel silicon bronze or copper as per section 2304.9.5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

6 of 6

January 2009

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Architectural Woodwork Standards 2nd EditionDocument510 pagesArchitectural Woodwork Standards 2nd Edition36O2100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Free Deer Stand PlansDocument10 pagesFree Deer Stand PlansloktakwahNo ratings yet

- Splay No More: Seating PlansDocument64 pagesSplay No More: Seating PlansАлексей Жук100% (2)

- Chap 13 Hoisting and RoofingDocument6 pagesChap 13 Hoisting and RoofingAbhishekNo ratings yet

- Robert D. Johnson Building InspectionDocument18 pagesRobert D. Johnson Building InspectionMelissa Van Der StadNo ratings yet

- CPCCCA3007 - Student Guide V1.0Document65 pagesCPCCCA3007 - Student Guide V1.0sharma SoniaNo ratings yet

- Padonat Pwa4 CBLMDocument30 pagesPadonat Pwa4 CBLMginalynpadonat2No ratings yet

- Wood JointsDocument3 pagesWood JointsNhatz Gallosa MarticioNo ratings yet

- Door DoorAndFrame 20190514Document10 pagesDoor DoorAndFrame 20190514BeatrizLlamasNo ratings yet

- Scope of Work Material Unit I. Facilities: Group MembersDocument5 pagesScope of Work Material Unit I. Facilities: Group MembersAganon AristotleNo ratings yet

- Types of Drill BitsDocument3 pagesTypes of Drill BitsShameema FarjanNo ratings yet

- Module 4 - Masonry MaterialDocument6 pagesModule 4 - Masonry MaterialCa Lop100% (1)

- Reading 1 - P19 - B2Document2 pagesReading 1 - P19 - B2no noNo ratings yet

- Vimana Q1 UpdatedDocument10 pagesVimana Q1 UpdatedOrlyn DanielsNo ratings yet

- A Father That Learn A Lesson From His SonDocument1 pageA Father That Learn A Lesson From His SonFarahdilaNo ratings yet

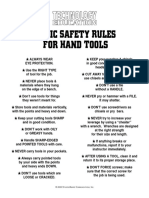

- Hand Tool SafetyDocument1 pageHand Tool SafetymardyNo ratings yet

- Tools List PDFDocument6 pagesTools List PDFAkash RockNo ratings yet

- Flooring Material SurveyDocument51 pagesFlooring Material SurveyUnnati Thapa100% (1)

- IKEA KItchen CatalogueDocument30 pagesIKEA KItchen CatalogueASNo ratings yet

- Folk Architecture: Submitted By: Kristine Mae PalaoDocument15 pagesFolk Architecture: Submitted By: Kristine Mae Palaozeno phyxxNo ratings yet

- Technical Specifications: Site Works 1. RequirementsDocument13 pagesTechnical Specifications: Site Works 1. RequirementsThomasNo ratings yet

- High Speed Precision Lathe Machine With DRODocument1 pageHigh Speed Precision Lathe Machine With DRObipindimri2014No ratings yet

- Supplier: Alu General Merchandise: Wall MaterialsDocument9 pagesSupplier: Alu General Merchandise: Wall MaterialsMelanie CabforoNo ratings yet

- Seat of The First Philippine Republic: Management Plan For The Barasoain Church Historical LandmarkDocument18 pagesSeat of The First Philippine Republic: Management Plan For The Barasoain Church Historical LandmarkJia GalanNo ratings yet

- Sikkens BrochureDocument10 pagesSikkens BrochuremainpersonNo ratings yet

- Machine Shop Safety RulesDocument1 pageMachine Shop Safety RulesSyed Wajih Ul HassanNo ratings yet

- Technical Specifications Construction of Fire StationDocument11 pagesTechnical Specifications Construction of Fire Stationp.viloriaNo ratings yet

- Product List Onetouch PDFDocument5 pagesProduct List Onetouch PDFGouse BujjiNo ratings yet

- Description of Mechanical Workshop Layout and Machine DetailsDocument7 pagesDescription of Mechanical Workshop Layout and Machine DetailshasnainNo ratings yet

- Basic Tech Jss3Document1 pageBasic Tech Jss3Anthony IsraelNo ratings yet