Professional Documents

Culture Documents

Drum Level Control

Drum Level Control

Uploaded by

Saurabh SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drum Level Control

Drum Level Control

Uploaded by

Saurabh SinghCopyright:

Available Formats

Application Guide

Drum Level Control Systems in the Process Industries

Drum Level Control Systems are used extensively throughout the process industries and the Utilities to control the level of boiling water contained in boiler drums on process plant and help provide a constant supply of steam. If the level is too high, flooding of steam purification equipment can occur. If the level is too low, reduction in efficiency of the treatment and recirculation function. Pressure can also build to dangerous levels. A drum level control system tightly controls the level whatever the disturbances, level change, increase/ decrease of steam demand, feedwater flow variations.

Suitable ABB products for use in Drum Level Control systems are: COMMANDER 300 Controller (for single-element systems) COMMANDER 1900 Controller (for single, two and three-element systems) MOD 30ML (for single, two and three-element systems) MODCELL

ABB Instrumentation

Drum Level Control Systems in the Process Industries

Drum Level Control Systems

In the process industries, boiling water to make steam is a very important procedure. The control of water level is a major function in this process and it is achieved through a water steam interface established in a cylindrical vessel called the drum which is usually lying on its side and located near the top of the boiler. Providing tight water level control in a drum is accomplished by utilizing one of three types of drum level control: single-element, two-element, or three-element. All three types of control strategies can be provided for utilizing one MOD 30ML Controller and supporting field products such as ABB electronic differential pressure transmitters (type 621D) and WEDGE flow elements.

The Boiler Drum

Maintaining the correct water level in the drum is critical for many reasons. A water level that is too high causes flooding of the steam purification equipment; resulting in the carry over of water and impurities into the steam system. A water level that is too low results in a reduction in efficiency of the treatment and recirculation function. It can even result in tube failure due to overheating from lack of cooling water on the boiling surfaces. Normally drum level is expected to be held within 2 to 5cm of the set-point with some tolerance for temporary load changes.

Components Affecting Drum Water Level

Under boiling conditions, steam supporting field products such as bubbles exist below the water/steam level interface. These bubbles have volume and therefore displace water to create a misrepresentation of the true water level in the drum. Another effect upon drum level is pressure in the drum. Because steam bubbles compress under pressure (if the drum pressure changes due to load demands), the steam bubbles expand or contract respective to these pressure changes. A higher steam demand will cause the drum pressure to drop, and the steam bubbles to expand to give the appearance of a water level higher than it truly is. This fictitious higher water level causes the feedwater input to be shut down at a time when more water is really required. A surge in water level as a result of the drum pressure decreasing is called 'swell'. A water level decrease due to drum pressure increase is called 'shrink'.

Level Control Strategies

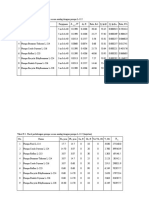

Figure 1 depicts three types of drum level control strategies with typical applications for each. While single-element drum level control is acceptable for steady boiler load conditions; as load changes become more frequent, unpredictable, or severe; this type of level control cannot respond quickly enough to compensate. More information must be included and processed to predetermine the amount of water to be added to the drum to compensate for load changes. The addition of elements (flow and transmitter devices) enables the controller to predict the amount of water added to the drum to maintain drum level set-point.

System Classification Single-element Two-element Load Change Capabilities Magnitude Rate Moderate Moderate Slow Typical Applications Institutional and industrial heating plants Steady process conditions Industrial plants with essentially continuous type processes and good feedwater pressure regulation Combination of batch and continuous type operations such that plant steam load characteristics varies continuously and usually unpredictably. Most industrial power applications fall into this category.

Moderate

Three-element

Wide Fast

Figure 1 Application Chart for Drum Level Control System

Drum Level Control Systems in the Process Industries

Single-Element Drum Level Control

Figure 2 depicts the control scheme for single-element drum level control. In this configuration, only the water level in the drum is being measured (hence the term " single element" ) . LT- 1 is an electronic differential pressure transmitter with a high static pressure range. The high side of the transmitter is connected to the bottom of the drum. Because of the drum's static pressure, the low side of the transmitter is connected to the top of the drum above the water/steam interface. This provides a reference for the transmitter by cancelling the static pressure effect and allowing only the water hydrostatic head to be measured. A constant head reservoir is required to maintain a consistent head in the reference leg of the transmitter. This is often referred to as a ''wet leg" The output of the electronic DP transmitter is the process Input for the MOD 30ML Controller, (LC-1), and the output is then compared to a drum level set-point. Any discrepancy between setpoint and drum level causes an output from the MOD 30ML controller in compensation. Because controller action is reverse, as the drum level Increases, a resultant output signal will decrease to close the feedwater control valve. The output of the Controller is fed to the feedwater control valve (FCV-1). If the feedwater valve is pneumatic, an lP (current-to-pressure) converter is required to change the Controller current output to accommodate the pneumatic valve. Note that the response from the controller to the feedwater control valve is reactive; i.e. feedwater is added only in response to a drop in drum level. This type of control is acceptable if steam load changes are not dramatic because the controller can respond well to steady demands. In applications where steam load changes become frequent and unpredictable, a reactive strategy is better suited. This type of system requires more field devices for input.

Steam

LX 1

Constant Head Reservoir

Water/Steam Interface

LT 1

Drum Level Transmitter Drum Level Controller

Water with Steam Bubbles

Boiler Drum

LC 1 FCV 1 FK 1

A M Feedwater

Feedwater Control Valve

Figure 2 Single-element drum level control system

Drum Level Control Systems in the Process Industries

Two-Element Drum Level Control System

A two-element drum level control system is capable of providing close adherence of drum level to its set-point under steady-state conditions as well as being capable of providing the required tight control during a transient. Its performance during transient conditions permits its use on many industrial boiler applications. Such applications are characterized by adequately-sized drums used with load changes of moderate rate and degree. These characteristics are usually found in plants with continuous-type processes, and those with mixed heating and processing demands. Caution should be exercised in its use on systems without reasonably constant feedwater pressure. The term 'two-element' is derived from two variables: steam flow and drum level influence on the feedwater valve position. It is often classified as a combination 'feed-forward-feedback' system because the steam flow demand is fed forward as the primary index of the feedwater valve position. The drum level signal becomes the feedback which is used to constantly trim the accuracy of the feed-forward system and provide final control of the water/steam interface in the drum. Refer to Figure 3 for the control scheme of a two-element drum level control. Note the left side of the doted line is identical to that used in single-element control. Additional equipment required for two-element drum level control consists of a steam flow measuring device, a differential pressure transmitter, a square root extractor, a feedwater flow computer and a feedwater flow mode transfer station. At first this may appear like a large investment in order to gain stable drum level control, but as you will see this is not necessarily true. How it works: Steam flow is measured by the steam flow transmitter (FT-1), its signal is fed to the feedwater flow computer (FC-1) after processing through the square root extractor (FY-1). As in the single-element level control, the drum level is measured by the level transmitter (LT-1) and its signal is transmitted to the drum level controller (LC1). In the drum level controller, the process signal is compared to the drum level setpoint, where a required corrective output signal to maintain the drum level is produced. This corrective signal is sent to the feedwater flow computer. The feedwater flow computer combines the signal from the two variables, and produces an output signal to the feedwater control valve (FCV-1). Auto/Manual transfer of the feedwater control valve is accomplished via FK-1. Nearly all of the load change work is done by the feed-forward system, for example, a pound of feedwater change is made for every pound of steam flow change. The drum level control system is used for compensation only. It is expected that the drum level will be maintained very closely to the set-point value. This is true in spite of the low-to-moderate volume/throughput ratio and a wide operating range. As a result, integral response (reset) is a necessary function in the drum level controller. Using one MOD 30ML Controller, four of the functions in the two-element control scheme are accomplished: level control (LC-1), square root extraction (FY-1), feedwater flow computation (FC-1), and feedwater flow mode transfer (FK-1). The MOD 30ML Controller is a multi-functional controller providing level control for LC-1. Utilizing the linearization block in the ML will provide the required square root function to obtain a linear signal from the steam flow transmitter. A math block in the Controller enables feedwater flow computations. Finally, a feedwater flow transfer

Drum Level Control Systems in the Process Industries

Two-Element Drum Level Control System

station is easily provided for with an operator-accessible Auto/Manual button on the Controller display. Once in manual, the controller output is ramped up or down by an operator using keys on the controller display. Should a totalized steam flow be required, the MOD 30ML Controller provides an eight-digit display of the totalized value. FT-1 is an ABB electronic transmitter providing accuracy of 0.2% and is rugged enough to handle static pressures up to 6000 PSI.

FE 1

Steam Steam Constant Head Reservoir

LX 1 FT 1

Flow Transmitter

Water/Steam Interface Water with Steam Bubbles Boiler Drum

Drum Level Transmitter

LT 1 LC 1

FY 1

Square Root Extractor

Drum Level Controller

A M

FC 1 FK 1

Feedwater Flow Computer

Feedwater Flow Mode Transfer Station

FCV 1

Feedwater Feedwater Control Valve

Figure 3 Two-element drum level control system

Drum Level Control Systems in the Process Industries

Three-Element Drum Level Control System

In most drum level control applications, the two-element drum level control will maintain the required water/steam interface level even under moderate load changes. However, If an unstable feedwater system exists exhibiting a variable feed header-to-drum pressure differential, or if large unpredictable steam demands are frequent, a three-element drum level control scheme should be considered. As implied from the previous information, this control strategy supplies control of feedwater flow in relationship to steam flow. The performance of the three-element control system during transient conditions makes it very useful for general industrial and utility boiler applications. It handles loads exhibiting wide and rapid rates of change. Plants which exhibit load characteristics of this type are those with mixed, continuous, and batch processing demands. It is also recommended where normal load characteristics are fairly steady; but upsets can be sudden, unpredictable and/or a significant portion of the load. How it works: Figure 4 shows the control scheme for three-element drum level control. To the left of the dotted line, the instrumentation is the same as that for the two-element drum level control, with one exception: the output of the feedwater flow computer now becomes the set-point of the feedwater flow controller (FIC-2). Equipment required to complete our three-element drum level control scheme includes an additional flow device (FE-2) and differential pressure transmitter (FT-2). The area to the left of the dotted line in figure 4 functions the same as that of a twoelement drum level control. We can pick up the operation for this scheme where the output signal of the feedwater flow computer (the combination of steam flow and drum level) enters the feedwater controller (FIC-2). This in effect becomes the set-point to this controller. Feedwater flow Is measured by the transmitter (FT-2). The output signal of the feedwater flow transmitter is linearized by the square root extractor, (FY-2). This signal is the process variable to the feedwater controller and is compared to the output of the feedwater flow computer (set-point). The feedwater flow controller produces the necessary corrective signal to maintain feedwater flow at its set-point by the adjustment of the feedwater control valve (FCV-1). As in the two-element drum level control scheme, nearly all of the work necessary to compensate for load change is done by the feed-forward system (i.e. a pound of feedwater change is made for every pound of steam flow change). The drum level portion of the control scheme is used only in a compensating role. Despite low-tomoderate volume/ throughput ratio and a wide operating range, it is expected the drum level will be maintained very close to set-point. Achieving this requires use of the integrating response and reset in both the drum level and feedwater controllers. This application may suggest that an additional controller is required for the feedwater flow controller, however this Is not true. The MOD 30ML Controller is a multi-loop unit. An easily-configured feed-forward command in the MOD 30ML means no additional wiring is required to have the drum level controller and feedwater controller working together. Feedwater flow computations are effortlessly done in the maths block of the controller, all square root functions are performed within. The feedwater flow element (FE-2), is an ABB WEDGE unit. A reliable, rugged, yet accurate measuring device that will be in service for many years. Many models include the option of mounting the transmitter on the WEDGE itself, thus eliminating the need for expensive lead lines, valves and flanges.

Drum Level Control Systems in the Process Industries

Three-Element Drum Level Control System

The feedwater flow transmitter (FT-2), is an ABB electronic differential pressure transmitter. If the system is appropriately designed. FT-1. FT-2, and LT-1 may be the same type of transmitter. This means stocking only one type of transmitter In the case of a transmitter failure.

FE 1

Steam Steam Constant Head Reservoir

FT 1

LX 1

Flow Transmitter

Water/Steam Interface Water with Steam Bubbles Boiler Drum

Drum Level Transmitter

LT 1 LC 1

FY 1

Square Root Extractor

FY 2

Drum Level Controller

FY 3

FIC 2 FCV 1

FT 2

Flow Transmitter

Feedwater Flow Computer

A M

FK 1

Feedwater Flow Mode Transfer Station

Feedwater Feedwater Control Valve

FE 2

Feedwater Flow Element

Figure 4 Three-element drum level control system

ABB 1997

(8.97)

ABB Kent-Taylor Ltd. St. Neots Cambs. England, PE19 3EU Tel: +44 (0) 1480 475321 Fax: +44 (0) 1480 217948

ABB Instrumentation Inc. PO Box 20550, Rochester New York 14602-0550 USA Tel: +1 716 292 6050 Fax: +1 716 273 6207

ABB Kent-Taylor SpA 22016 Lenno Como Italy Tel: +39 (0) 344 58111 Fax: +39 (0) 344 56278

AG/DLC

The Company's policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice.

Issue A

DLC#_1GG.pdf

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Technical Proposal of BoilerDocument20 pagesTechnical Proposal of Boilermichael100% (1)

- Super Critical Boiler BasicsDocument105 pagesSuper Critical Boiler BasicsAnkit GaraiNo ratings yet

- Oer BoosterDocument8 pagesOer Boosteredison58100% (1)

- Paper Plant Energy Audit ReportDocument77 pagesPaper Plant Energy Audit ReportAnubhav Gupta100% (2)

- Heat PinchDocument6 pagesHeat PinchYeeXuan TenNo ratings yet

- Advance Boiler Control SystemDocument44 pagesAdvance Boiler Control SystemJeEJyZaNo ratings yet

- DAE Mechanical Technology 3rd Year PDFDocument116 pagesDAE Mechanical Technology 3rd Year PDFShahid JehanNo ratings yet

- TVN Series Trim and Pressure Build VaporizersDocument2 pagesTVN Series Trim and Pressure Build Vaporizersaakhyar_2100% (1)

- Superheated SteamDocument51 pagesSuperheated SteamMiguel Loera BaronaNo ratings yet

- Rina B. InggrisDocument9 pagesRina B. InggrisRidwan Alfian NoorNo ratings yet

- AqudDocument5 pagesAqudch0k3 iiiNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- Belajar KaznaeDocument277 pagesBelajar KaznaewahyuNo ratings yet

- Module 2aDocument33 pagesModule 2aGenesis MedelNo ratings yet

- GGHGLGLLGDocument20 pagesGGHGLGLLGInder RatheeNo ratings yet

- Coaching Set 4 PinkDocument7 pagesCoaching Set 4 Pinkjoe1256No ratings yet

- Naval Engineers Journal Volume 77 Issue 6 1965 (Doi 10.1111 - j.1559-3584.1965.tb05596.x) DR. F. BAHGAT - MARINE BOILER FURNACE DIMENSIONSâ "A STANDARDIZAT PDFDocument8 pagesNaval Engineers Journal Volume 77 Issue 6 1965 (Doi 10.1111 - j.1559-3584.1965.tb05596.x) DR. F. BAHGAT - MARINE BOILER FURNACE DIMENSIONSâ "A STANDARDIZAT PDFAnonymous knICaxNo ratings yet

- Coupling Power Generation With Syngas-Based Chemical Synthesis A Process Chain Evaluation From A Power Plant ViewpointDocument167 pagesCoupling Power Generation With Syngas-Based Chemical Synthesis A Process Chain Evaluation From A Power Plant ViewpointGiovana GhasaryNo ratings yet

- Lecture 16 - Evaporation and ConcentrationDocument14 pagesLecture 16 - Evaporation and ConcentrationSrishti UpadhyayNo ratings yet

- Abubakar Tafawa Balewa UniversityDocument62 pagesAbubakar Tafawa Balewa UniversityIsrael Apeh100% (1)

- Modeling of Fire Tube BoilerDocument16 pagesModeling of Fire Tube BoilerVignesh AlagesanNo ratings yet

- US Maritime Service Training Manual - Engineering Branch TrainingDocument152 pagesUS Maritime Service Training Manual - Engineering Branch Trainingmihalikj2190No ratings yet

- AMSCO Evolution - Technical InformationDocument13 pagesAMSCO Evolution - Technical InformationNimsi AstiviaNo ratings yet

- Extraction of Essential OilsDocument9 pagesExtraction of Essential OilsBhaby ForevherNo ratings yet

- 600 MW Subcritical Boiler Operation RulesDocument162 pages600 MW Subcritical Boiler Operation Rulesjust_4_u_dear_in9549No ratings yet

- Medical Sterilization Methods - LemoDocument52 pagesMedical Sterilization Methods - LemoPedro GomesNo ratings yet

- Problem Sheet No 5Document2 pagesProblem Sheet No 5mahad ashfaq33% (3)

- Dobijanje Etericnih UljaDocument34 pagesDobijanje Etericnih UljaMile VeljovicNo ratings yet

- Understanding Installation of Steam Tracing For Long-Term Application SuccessDocument31 pagesUnderstanding Installation of Steam Tracing For Long-Term Application SuccessDương HoàngNo ratings yet

- Viadrus U22 Upute Za Ugradnju I KorištenjeDocument28 pagesViadrus U22 Upute Za Ugradnju I KorištenjevladoNo ratings yet