Professional Documents

Culture Documents

Sample of Procedure Qualification Record (PQR) : Joint Details

Uploaded by

hancur_27Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample of Procedure Qualification Record (PQR) : Joint Details

Uploaded by

hancur_27Copyright:

Available Formats

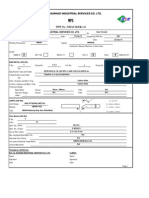

Sample of PROCEDURE QUALIFICATION RECORD (PQR)

1. Procedure Qualification COMPANY NAME PQR No. PQR REV. No. SUPPORTING WPS Nos. WELDING PROCESS(ES) JOINTS JOINT TYPE or 2. Procedure Verification BY DATE REV. DATE TYPE

Manual, Semi-Automatic, Automatic, Robotic

Joint Details

BACKING BACKING MATERIAL (TYPE) GROOVE ANGLE ROOT OPENING RADIUS (U or J) ROOT FACE BACKGOUGING (YES or NO) BACKGOUGING METHOD

Sketches, production drawings, welding symbols, or written description should show the general arrangement of the parts to be welded. Where applicable, the root spacing details of the weld groove may be specified.

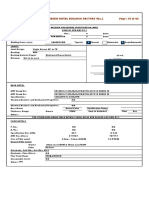

M-No. GROUP No. SPECIFICATION TYPE AND GRADE TO SPECIFICATION TYPE AND GRADE THICKNESS RANGE OF BASE METAL GROOVE PIPE DIA. RANGE GROOVE OTHER FILLER METAL F-No. AWS CLASSIFICATION WELD METAL ANALYSIS A-No. FILLER METAL SIZE ELECTRODE-FLUX (CLASS) FLUX TRADE NAME CONSUMABLE INSERT OTHER

BASE METAL(S) OR TO M-No.

GROUP No.

FILLET FILLET FILLER METALS OTHER AWS SPECIFICATION OTHER

POSITION(S) OF GROOVE POSITION(S) OF FILLET PREHEAT TEMPERATURE TEMPERATURE

POSITIONS WELD PROGRESSION PREHEAT INTERPASS TEMPERATURE POSTWELD HEAT TREATMENT TIME

Sample PQR Form (continued) Shielding Gas(es) Composition Flow Rate FLUX Yes No

PQR NUMBER (Page 2) SHIELDING Backing Trailing

FLUX TYPE / TRADE NAME

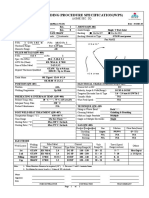

ELECTRICAL CHARACTERISTICS & WELDING PARAMETERS CURRENT TYPE AND POLARITY PULSING (YES OR NO) CURRENT (RANGE) VOLTAGE (RANGE) WIRE FEED SPEED (RANGE) TRAVEL SPEED (RANGE) TUNGSTEN ELECTRODE SIZE AND TYPE PULSING PARAMETERS OTHER OTHER VARIABLES CUP OR NOZZLE SIZE CLEANING METHOD NUMBER OF ELECTRODES OTHER VISUAL TEST RESULTS COLLET BODY or GAS LENS TECHNIQUE Stringer or Weave NUMBER OF PASSES PER SIDE TEST RESULTS

TENSILE TESTS Specimen No. Width Thickness Area Yield Load Results Yield Tensile Strength Load Tensile Strength Failure Type and Location

Guided Bend Tests Type and Figure Number Results

WELDERS NAME: TESTS CONDUCTED BY:

ID or SS No. LAB TEST No.

We the undersigned certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of AWS D18.3. MANUFACTURER OR CONTRACTOR DATE BY

Please Print Signature

You might also like

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- WPS Blank FormDocument4 pagesWPS Blank FormAhmet SerdengectiNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS 11A Welding ProcedureDocument1 pageWPS 11A Welding ProcedureM. R. Shahnawaz KhanNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)Document1 pageWPQP 6gr Smaw API 5lx52 Od6inch 14mm 18mm (Approved)ufomskiNo ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- Welding Coordinator WeldMap Weld Data SheetDocument1 pageWelding Coordinator WeldMap Weld Data Sheetquocphong199No ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- WPS Indosol 001 (ASME) RDocument2 pagesWPS Indosol 001 (ASME) RDoni HardiNo ratings yet

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- OSD Welding ProcedureDocument6 pagesOSD Welding ProcedureVijayakumar Chandran100% (1)

- Aws PQR FormDocument3 pagesAws PQR Formndi101No ratings yet

- Weld Procedure Specification RecordDocument2 pagesWeld Procedure Specification RecordNur WijiantoNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- QAP For PQR'S - For Impact TestingDocument3 pagesQAP For PQR'S - For Impact TestingDries VandezandeNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Fitup ReportDocument2 pagesFitup ReportMohd SaffririzalNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocument1 pageIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNo ratings yet

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Transformer-WPS OfficeDocument19 pagesTransformer-WPS OfficeVinaya kumar BGNo ratings yet

- Welding Procedure Specification (WPS) FormDocument2 pagesWelding Procedure Specification (WPS) FormEarl Harbert0% (2)

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- OlDocument5 pagesOlArun KumarNo ratings yet

- The Heat Affected ZoneDocument24 pagesThe Heat Affected ZoneRatan PanditNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Essential Variables for Welder QualificationDocument12 pagesEssential Variables for Welder QualificationMahmoud Alwasif100% (2)

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Rationalise List Welding ConsumablesDocument19 pagesRationalise List Welding ConsumablesMayank SadaniNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- La Ko Sure Unsa NiDocument3 pagesLa Ko Sure Unsa NiJeromeNo ratings yet

- WPS For Shaft of TG-9 ImpellerDocument17 pagesWPS For Shaft of TG-9 ImpellerRaymond de WeeverNo ratings yet

- PQR welding procedure recordDocument3 pagesPQR welding procedure recordCatalina Sorina ParfeneNo ratings yet