TWI

CSWIP VISUAL INSPECTION OF WELDS

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Terminology

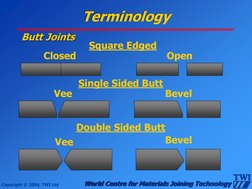

Butt Joints

Closed Square Edged Open

Vee

Single Sided Butt

Bevel

Double Sided Butt Bevel Vee

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Terminology

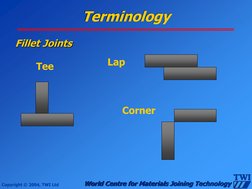

Fillet Joints

Tee

Lap

Corner

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Terminology

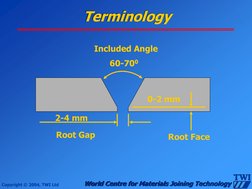

Included Angle

60-700

0-2 mm

2-4 mm Root Gap

Root Face

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

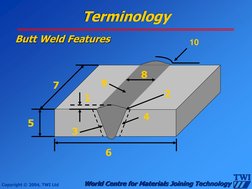

�Terminology

Butt Weld Features

8 2 4 3 6

Copyright 2004, TWI Ltd

10

1

5

World Centre for Materials Joining Technology

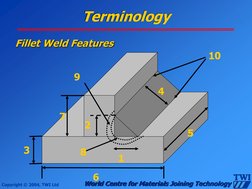

�Terminology

Fillet Weld Features

10 9

4

7 3 2 8 6 1

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

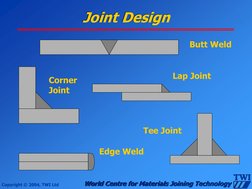

�Joint Design

Butt Weld

Corner Joint

Lap Joint

Tee Joint Edge Weld

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

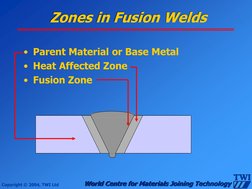

�Zones in Fusion Welds

Parent Material or Base Metal Heat Affected Zone Fusion Zone

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

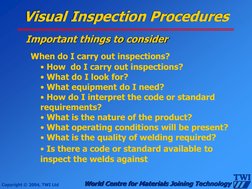

�Visual Inspection Procedures

Important things to consider

When do I carry out inspections? How do I carry out inspections? What do I look for? What equipment do I need? How do I interpret the code or standard requirements? What is the nature of the product? What operating conditions will be present? What is the quality of welding required? Is there a code or standard available to inspect the welds against

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Checklist

Before Welding Commences

Documentation Materials Weld preparations Fit up for welding Welding equipment

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Checklist

During Welding

Correct parameters WPS at the work place Inter run cleanliness and quality Interpass temperature Consumable control Maintenance of preheat Process control NDE regime Weld records and maintenance of weld maps

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Checklist

Welding Completion

Visual inspection and records NDE PWHT Final testing Cleaning, painting, preservation, packing Final documentation

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Butt welds - Size

Weld cap width

Excess weld metal height

Root penetration Root bead width

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Fillet welds - Size

Excess weld metal

Actual throat thickness

Minimum and maximum leg length size

Design throat thickness

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Importance of Fillet weld leg length Size

(a)

(b) 8mm 6mm 4mm

4mm

What size is the Throat thickness of (a) What size is the Throat thickness of (b)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Importance of Fillet weld leg length Size

(a)

(b) 6mm 4mm 6mm

4mm

How much bigger is (a) in volume than (b)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

(a) 4mm 4mm (a) volume = 4 x 4 = 8mm2 2 6mm 6mm (b) volume = 6 x 6 = 18mm2 2 (b)

The volume of (b) is over double the volume of (a) Without the extra reinforcement being added

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Fillet welds - Size & Shape

Convex Mitre

Concave

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Fillet welds - Toe Blend

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

EFFECTIVE THROAT THICKNESS

a = Nominal throat thickness s = Effective throat thickness

Deep throat fillet welds from FCAW & SAW etc

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Butt welds - Profile

x x

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Butt welds - Toe Blend

x x

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Features to Consider

Butt welds - Weld Width

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�A Weld : Definitions

BS 499

A union between pieces of metal at faces rendered plastic or liquid by heat,pressure or both.

NASA

A continuous defect surrounded by parent material

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welds

An ideal weld must give a strong bond between materials with the interfaces disappearing

To achieve this Smooth,flat or matching surfaces Surfaces shall be free from contaminants Metals shall be free from impurities Metals shall have identical crystalline structures

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Electric Arc Welding

Electrode

Power supply Work piece

Clamp(Earth)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Electric Arc Welding

Electric discharge produced between cathode and anode by a potential difference (40 to 60 volts) Discharge ionises air and produces -ve electrons and +ve ions

Electrons impact upon anode, ions upon cathode

Impact of particles converts kinetic energy to heat (7000o C) and light Amperage controls number of ions and electrons, Voltage controls their velocity

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Manual Metal Arc Welding

Shielding provided by decomposition of flux covering Electrode consumable Manual process Welder controls Arc length Angle of electrode Speed of travel Amperage settings

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Manual Metal Arc Welding

POWER SOURCE

POWER SOURCE:Input 240v (single phase) or 415v ( 2 live phases of 3 phase supply) Output AC (O.C.V. 80v) or DC (O.C.V. 50v) or both. AC for Shop

DC for site work as it is SAFER (lower OCV). Also for shop work..

Current adjustment control

TYPES:-

Transformers AC only Transformer/Rectifiers AC and DC Petrol or Diesel driven Generators Site work DC Inverters AC and DC

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Manual Metal Arc Welding

Power control panel Electrode oven Electrodes Power return cable Safety visor (With dark lens) *

Copyright 2004, TWI Ltd

Power source. Transformer/ Rectifier Heated quiver Inverter power source Electrode holder Power cable

World Centre for Materials Joining Technology

�Manual Metal Arc (MMA)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Tungsten Inert Gas (TIG)

Power control panel Power return cable Torch assemblies Tungsten electrodes Transformer/ Rectifier Inverter power source Power control panel Power cable Flow-meter

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Tungsten Inert Gas (TIG)

POWER SOURCE

POWER SOURCE 440v 50Hz 3 phase or 240v single phase input TORCH TORCH HOSE RETURN LEAD INERT GAS SUPPLY (Cylinder & regulator) FLOWMETER (graduated in ltr/min) Transformers for AC aluminium alloys Rectifiers for DC - steels Transformer/rectifier for AC/DC Inverters for AC/DC more portable - expensive Sizes/types vary depending on current/application Flexible may carry current, gas, cooling water. Note that current actually flows from this lead Correct type for application.(ar, he, ar/he mixture) Argon/hydrogen for austenitic stainless steel To deliver correct gas flow (velocity) depending on welding position and joint configuration.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Tungsten Inert Gas (TIG)

TORCH WELDING LEAD + GAS SUPPLY NORMALLY DC-VE METERS (OPTIONAL) VARIABLE CURRENT CONTROLLER GAS SUPPLY

ARC

OUTPUT 80 OCV MAX

THE POWER SOURCE

AC/DC CONSTANT CURRENT

ARC STRIKING DEVICE

I N E R T G A S

+

RETURN LEAD

EARTH*

Copyright 2004, TWI Ltd

*CHECK WITH HSE GUIDANCE NOTE

World Centre for Materials Joining Technology

�Tungsten Inert Gas (TIG)

Tungsten housing Fitted ceramic shielding cup On/Off switch Split collet Gas diffuser Spare ceramic shielding cup * Torch body

Tungsten electrodes Ceramic shield cup

Gas lens

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Tungsten Inert Gas (TIG)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Metal Inert Gas (MIG)

External wire feed unit Transformer/ Rectifier

Internal wire feed system Power control panel

Power cable & hose assembly

Liner for wire 15kg wire spool Power return cable* Welding gun assembly

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Metal Inert Gas (MIG)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Submerged Arc

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Cracks

Classified by Shape Longitudinal Transverse Branched Chevron Classified by Position HAZ Centreline Crater Fusion zone Parent metal

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Cracks

4 Crack Types Solidification cracks Hydrogen induced cracks Lamellar tearing Reheat cracks

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Cracks

Solidification Occurs during weld solidification process Steels with high sulphur content (low ductility at elevated temperature) Requires high tensile stress Occur longitudinally down centre of weld e.g. Crater cracking

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Solidification Cracking

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Deeper and narrow weld beads are prone to solidification cracking (depth to width ratio over 2:1) In order to avoid solidification cracking, reduce penetration and increase bead width (depth to width ratio 0,5:1)

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Cracks

Hydrogen Induced Requires susceptible grain structure, stress and hydrogen Hydrogen enters via welding arc Hydrogen source - atmosphere or contamination of preparation or electrode Moisture diffuses out into parent metal on cooling Most likely in HAZ

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Hydrogen Cracking

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Hydrogen Cracking

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Cracks

Lamellar Tearing Step like appearance Occurs in parent material or HAZ Only in rolled direction of the parent material Associated with restrained joints subjected to through thickness stresses on corners, tees and fillets Requires high sulphur or non-metallic inclusions

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Lamellar Tearing

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Lamellar Tearing

Restraint High contractional stress Lamellar tear

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Lamellar Tearing

Grind and infill with ductile weld metal

Control restraint Re-design weld

For critical work a forged T piece may be used

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

Forged T Piece

�Welding Defects

Cracks

Re-Heat Cracking Occurs mainly in HAZ of low alloy steels during post weld heat treatment or service at elevated temperatures Occurs in areas of high stress and existing defects Prevented by toe grinding, elimination of poor profile material selection and controlled post weld heat treatment

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Incomplete root penetration

Causes Too small a root gap Arc too long Wrong polarity Electrode too large for joint preparation Incorrect electrode angle Too fast a speed of travel for current

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

a) Excessively thick root face

b) Too small a root gap c) Misplaced welds d) Power input too low

e) Arc (heat) input too low

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Too large diameter electrode

Smaller (correct) diameter electrode

Lack of sidewall fusion due to arc deflection

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Incomplete root Fusion

Causes Too small a root gap Arc too long Wrong polarity Electrode too large for joint preparation Incorrect electrode angle Too fast a speed of travel for current

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Root concavity

Causes Root gap too large Insufficient arc energy Excessive back purge TIG

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Excess Root Penetration

Causes Excessive amperage during welding of root Excessive root gap Poor fit up Excessive root grinding Improper welding technique

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Root undercut

Causes Root gap too large Excessive arc energy Small or no root face

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Cap Undercut

Causes Excessive welding current Welding speed too high Incorrect electrode angle Excessive weave Electrode too large

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Overlap

Excess weld

metal

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Welding Defects

Lack of fusion

Causes Contaminated weld preparation Amperage too low Amperage too high (welder increases speed of travel)

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Welding Defects

Incompletely Filled Groove & Lack of Side wall Fusion

Causes Insufficient weld metal deposited Improper welding technique

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Inter run Incompletely Filled Groove

Causes Insufficient weld metal deposited Improper welding technique

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Gas pores / Porosity

Causes Excessive moisture in flux or preparation Contaminated preparation Low welding current Arc length too long Damaged electrode flux Removal of gas shield

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Gas pores / Porosity

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Inclusions - Slag

Causes

Insufficient cleaning between passes Contaminated weld preparation Welding over irregular profile Incorrect welding speed Arc length too long

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Welding Defects

Inclusions - Slag

Causes

Insufficient cleaning between passes Contaminated weld preparation Welding over irregular profile Incorrect welding speed Arc length too long

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Welding Defects

Poor (convex) weld bead profile resulted in pockets of slag being trapped between the weld runs

Smooth weld bead profile allows the slag to be readily removed between runs

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Inclusions - Tungsten

Causes Contamination of weld Caused by tungsten touching weld metal or parent metal during welding using the TIG welding process

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Burn Through

Causes Excessive amperage during welding of root Excessive root grinding Improper welding technique

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Spatter

Causes Excessive arc energy Excessive arc length Damp electrodes Arc blow

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Welding Defects

Arc Strikes

Causes

Electrode straying onto parent metal Electrode holder with poor insulation

Poor contact of earth clamp

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Mechanical Damage

Chisel Marks Chisel Marks Pitting Corrosion Grinding Marks

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Welding Defects

Non-alignment of two abutting edges

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Page 1 of 3 Name: [Block capitals] Mr. I C Plenty Code/Specification used: TWI 09-09-03 Welding position: Flat /PA MEASURE FROM Copyright 2004, TWI Ltd THIS DATUM EDGE

EXAMPLE PLATE REPORT

Signature:

I C Plenty

Test piece ident:

001

Welding process:

MMA/SMAW

Joint type: Single V Butt Date 22/08/2003

Length & thickness of plate: 300mm x 10 mm

WELD FACE

Lack of sidewall fusion

B

Gas pore 1.5

230

C

Undercut smooth 1.5 max 236 30

87

22

51

153

40 Arc Strike 241

Slag inclusion

NOTES:

Centreline crack

Cap height : 4mm. Weld width: 12-14mm Toe blend: Poor Misalignment: 2mm Angular Distortion 3mm in 50mm Spatter along weld length or scale on the plate surface

World Centre for Materials Joining Technology

�Page 2 of 3

EXAMPLE PLATE REPORT

Copyright 2004, TWI Ltd

MEASURE FROM THIS DATUM EDGE

WELD ROOT

Root concavity 2 deep

B

LACK OF ROOT FUSION

247 20

23

10

128

50

Incomplete root penetration

NOTES: Penetration height :

Linear Misalignment: Angular Distortion: Any scale on plate surface

4mm. 2mm 3mm in 50mm

World Centre for Materials Joining Technology

�EXAMPLE WELD INSPECTION REPORT/SENTENCE SHEET

PRINT FULL NAME I C Plenty 001

Defects Noted Code or Specification Reference

SPECIMEN NUMBER

EXTERNAL DEFECTS

Defect Type

Pipe/Plate Section 1

Accumulative Total 2 4mm Poor blend 22mm NONE 1x 8mm long 1.5mm depth 1.5mm 40mm

Maximum Allowance 3 3mm Smooth None -----------2mm 1mm 1mm NONE

Section/ Table No 4

Accept/Reject 5 Reject Reject Reject Accept Reject Reject Reject Reject*

Excess weld metal height Excess weld metal appearance Incomplete filling Inadequate weld width Slag Inclusions Undercut Surface Porosity Cracks/Crack-like defects

AC

A-C A-C A-C A-C A-C A-C A-C

15

19 8 ---------3 11 2 1

Lack of fusion

Arc strikes Mechanical damage Laps/Laminations Misalignment (Linear) Longitudinal seams

A-C

A-C A-C A-C A-C A-C

22mm

30x25 NONE NONE 2mm NONE

NONE

---------------------------------2mm ------------

5

12 ------------------9 ----------

Reject

Seek advise*** Accept Accept Accept Accept

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Root Defects

Misalignment A-C 2mm 2mm 9 Accept

Excessive Root Penetration Incomplete Root Penetration Lack of Root Fusion Root Concavity Root Undercut Cracks/Crack-like defects Slag inclusions Porosity Laps/Laminations

A-C A-C A-C A-C A-C A-C A-C A-C A-C

4mm 50mm 20mm 2mm depth NONE NONE NONE NONE NONE

2mm NONE NONE 1mm --------------------------------------------------------

16 6 5 20 ----------------------------------------------

Reject Reject Reject Reject Accept Accept Accept Accept Accept

This *pipe/plate has been examined to the requirements of code/specification TWI 09-09-03 ......................................... and is accepted/rejected accordingly. Comments: * Request MPI testing to confirm crack and length. ** Large amount of spatter on weld face. Recommend this is removed and re inspected. *** Recommend arc strikes are ground flush prior to MPI testing for crack detection.

Signature......................................................... *Delete which is not applicable.

I C Plenty

Date................................................. .................................... Use the other side for any comments.

22nd August 2003

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Inspection Practice Specification Number TWI 09-09-03

All dimensions are given in mm

Comments

Confirm with penetrant testing Individual pore Non metallic. Individual size Metallic. Individual size Side wall/Root/Inter-run

No

1 2 3 4 5

Imperfection

Cracks Porosity Solid Inclusions Solid Inclusions Lack of Fusion

Allowance

Not permitted Maximum 1mm Maximum 1mm Not permitted Not permitted

6

7 8 9 10 11 12

Incomplete Root Penetration

Overlap/Cold lap Incompletely filled groove Linear Misalignment Angular Misalignment Undercut Arc Strikes Smoothly blended Area to be tested by MPI Weld face/Root

Not permitted

Not permitted Not permitted 0.2t Maximum 4mm Maximum 10 10%t Maximum d 1mm Seek advice

13

14 15 16 17 18 19 20

Laminations

Mechanical Damage Cap Height Penetration Bead Toe Blend Spatter Weld Appearance Root concavity Clean & Re-inspect All runs shall blend smoothly Shall fall below plate surface

Not permitted

Not permitted 0 3mm h Maximum 0 2mm h Maximum Smooth Refer to manufacturer Regular 10%t Maximum

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Visual Inspection of Welds Using the Cambridge Multi-Purpose Welding Gauge:

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Angle of preparation:

This scale reads from 00 to 600 in steps of 50. The angle is read against the chamfered edge of the plate or pipe.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Linear Misalignment:

The gauge may be used to measure misalignment of members by placing the edge of the gauge on the lower member and rotating the segment until the pointed finger contacts the higher member.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Excess Weld Metal/Root penetration:

The scale is used to measure excess weld metal or root penetration, by placing the edge of the gauge on the plate and rotating the segment until the pointed finger contacts the excess weld metal or root bead at its highest point.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Undercut / mechanical damage (grinding etc)

The gauge may be used to measure the depth of undercut by placing the edge of the gauge on the plate and rotating the segment until the pointed finger contacts the lowest depth of the undercut. The reading is taken on the scale to the left of the zero mark in mm or inches.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Fillet Weld Actual Throat Thickness:

The small sliding pointer reads up to 20mm, or inch. When checking the throat you measure the actual throat thickness also note! that there is a nominal design throat thickness,

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�TWI CAMBRIDGE MULTI-PURPOSE WELDING GAUGE:

Fillet Weld Leg Length:

The gauge may be used to measure fillet weld leg lengths of up to 25mm, as shown on left.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�CSWIP 3.0 INSPECTION OF FILLET WELDS

TWI

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

CSWIP 3.0 Fillet Welded T Joint

F 123

Part of the CSWIP 3.0 examination is to inspect & assess a Fillet welded Tee for its size & visual acceptance to the applicable code.

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Fillet Weld Inspection

1. The plate reference number must be recorded in the top left hand corner of the report sheet, then the thickness of the plate must be measured and entered in the top right hand corner of the report sheet in the boxes provided.

Specimen Number F123 Material thickness: 6mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

2) Both the Vertical and Horizontal fillet weld leg lengths must be measured to find the minimum and maximum sizes. These values are entered in the boxes provided on the report sheet. Use the gauge as shown below:

Fillet Weld Leg Length: The gauge may be used to measure fillet weld leg lengths up to a maximum of 25mm, as shown on left.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

3) The minimum and maximum throat thickness are measured and entered in the boxes provided on the report sheet. These values are measured as shown below:

Fillet Weld Throat Thickness:

The small sliding pointer reads up to 20mm, or inch. When measuring the throat it is supposed that the fillet weld has a nominal throat thickness, as an effective throat thickness cannot be measured in this manner.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

Having made all the above measurements they can be assessed to a set of values that may be simply calculated from the plate thickness. a) The minimum leg length size is the plate thickness b) The maximum leg length size is: The plate thickness + 3mm c) The minimum throat thickness is: The plate thickness x 0.7 d) The maximum throat thickness is: The plate thickness + 0.5mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

For example if the plate thickness is 6mm then the following will apply:

6mm

F 123

a) The minimum leg length size is 6mm (Plate thickness) b) The maximum leg length size is 9mm (Plate thickness + 3mm) c) The minimum throat thickness is 4.2mm (Plate thickness x 0.7) d) The maximum throat thickness is 6.5mm (Plate thickness + 0.5mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

This means that the measurements taken must fall inside BOTH the tolerances calculated i.e. Leg lengths must be between 6mm 9mm Throat thickness must be between 4.2 and 6.5mm If all the values are within these tolerances they are acceptable. If any of the values fall outside of the calculated tolerances then it becomes unacceptable. It is important to remember that any change in thickness will change the acceptance values calculated above.

World Centre for Materials Joining Technology

Copyright 2004, TWI Ltd

�Fillet Weld Inspection

Vertical Leg Length Lowest leg measurement 7mm Highest leg measurement 8mm Actual Throat Thickness Lowest throat measurement 4.5mm Highest throat measurement 8mm Horizontal Leg Length Lowest leg measurement 5mm Highest leg measurement 10mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

Practical Exam Report Sheet

Specimen Number F123 Material thickness: 6mm

1) Measure and record the following details: VERTICAL LEG LENGTH (Max & Min) HORIZONTAL LEG LENGTH (Max & Min) = Max 8mm Min 7mm

= Max 10mm Min 5mm Min 4.5mm

DESIGN THROAT THICKNESS (Max & Min) = Max 8mm

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

2) Sentence the fillet weld dimensions using the following design criteria: MINIMUM LEG LENGTH: Material thickness (6mm) MAXIMUM LEG LENGTH: Material thickness + 3mm (9 mm) MINIMUM THROAT THICKNESS: Material thickness x 0.7 (4.2 mm) MAXIMUM THROAT THICKNESS: Material thickness + 0.5mm (6.5 mm)

The VERTICAL LEG LENGTH Please state: ACCEPT The HORIZONTAL LEG LENGTH Please state: REJECT The THROAT THICKNESS Please state: REJECT

Copyright 2004, TWI Ltd

ACCEPT or REJECT?

ACCEPT or REJECT?

ACCEPT or REJECT?

World Centre for Materials Joining Technology

�Fillet Weld Inspection

Having assessed the weld for its size an inspection can then be made on the surface to locate any imperfections. Firstly; the report sheet requests the inspector to indicate the number of locations that the following imperfections occur, if any? 3) The number of places that they occur should now be entered in the box as follows: UNDERCUT APPEAR? OVERLAP APPEAR? LACK OF FUSION APPEAR? CRACKS APPEAR? POROSITY APPEAR? SOLID INCULSIONS? MISC: [ARC STRIKES etc] 3 places None None None 2 Areas 1 Slag Inclusion Spatter

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

4) For the defects recorded state: MAXIMUM length (and DEPTH if applicable) of each defect UNDERCUT: OVERLAP: LACK OF FUSION: CRACKS: POROSITY: SOLID INCLUSIONS: Length: 15 mm Depth: Smooth 1.0mm Length: -------- Depth: --------Length: -------- Depth: --------Length: -------- Depth: --------Length: 6mm Length: 4mm Depth: Maximum Depth: ---------

MISC:[ ARC STRIKES] Length: Spatter Depth: --------Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

5) Then, assess the levels of imperfections allowed by the applicable code which is provided: UNDERCUT: OVERLAP: LACK OF FUSION: CRACKS: POROSITY: SOLID INCLUSION: MISC: [ARC STRIKES] ACCEPT ACCEPT ACCEPT ACCEPT REJECT REJECT REJECT* (Accept (Accept (Accept (Accept (Accept (Accept (Accept or Reject?) or Reject?) or Reject?) or Reject?) or Reject?) or Reject?) or Reject?)

* All spatters should have been removed prior to submission for inspection

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology

�Fillet Weld Inspection

6) Finally accept or reject the weld used for your visual inspection as follows: IS THE WELD ACCEPTABLE? Signature: Name: Date: I C Plenty I C Plenty 01-01-04 NO YES/NO?

This now completes the Fillet Welded T Joint Inspection Assessment.

Copyright 2004, TWI Ltd

World Centre for Materials Joining Technology