Professional Documents

Culture Documents

IBE Mount Rev2

IBE Mount Rev2

Uploaded by

Carlos RamirezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IBE Mount Rev2

IBE Mount Rev2

Uploaded by

Carlos RamirezCopyright:

Available Formats

KDN Tool & Automation Engineering Co. LLC 34 Church Street West Warwick, RI 02893 401-615-0267 www.kdntool.com sales@kdntool.

com kdntool@cox.net

X2-IB/E High Speed Spindle Mount

A simple and effective enhancement to the X2 mini mill that allows the attachment of a Proxxon IB/E professional grinder for use as a high speed spindle. This product extends the capabilities of the X2 by allowing small diameter cutters to be used at their recommended rotational speed for maximum material removal and life. Example uses are: Fine Engraving Work Mechanical Circuit Board Etching Jewelry Wax Machining Highly Detailed Wood Carving

Why Choose the Proxxon IB/E?

Proxxons noted reputation for quality tools 100 watts of cutting power in an extremely compact size 5000-20,000 RPM variable spindle speed Continuous duty rating with forced air-cooling Die-cast aluminum mounting surface and nose bearing seat Super quiet operation even at 20,000 RPM Excellent run-out characteristics Compact size allowed a mere 2.7 offset from stock spindle centerline 6 collet sizes and a variety of included bits

This enhancement lends itself to both manually operated and CNC controlled machines with either a MT3 or R-8 spindle.

KDN Tool & Automation Engineering Co. LLC will not be held responsible for injuries sustained while operating CNC machinery retrofit by us or with one of our kits.

1 7/19/06

KDN Tool & Automation Engineering Co. LLC 34 Church Street West Warwick, RI 02893 401-615-0267 www.kdntool.com sales@kdntool.com kdntool@cox.net

X2 IB/E MOUNT

GENERAL INSTALLATION:

1. Gather all necessary components and tools for the installation. You will need the following hex keys (allen wrenches) to complete the installation: 4mm, 9/64, and 3/16. 2. Raise the head-stock to allow access to the under-side of the spindle box. 3. Locate and remove the three 5mm socket head cap screws that retain the lower spindle bearing cover. You will need the 4mm allen wrench 4. Remove the bearing cover.

5. Position the bearing cover onto and inline with, the base-plate mounting holes and install one of the supplied M5 X 30mm socket head cap screws.

6. Position the base-plate and cover together onto the underside of the spindle box and finger tighten the M5 X 30mm socket head cap screw.

KDN Tool & Automation Engineering Co. LLC will not be held responsible for injuries sustained while operating CNC machinery retrofit by us or with one of our kits.

2 7/19/06

KDN Tool & Automation Engineering Co. LLC 34 Church Street West Warwick, RI 02893 401-615-0267 www.kdntool.com sales@kdntool.com kdntool@cox.net

7. Install the two remaining M5 X 30mm socket head cap screws.

8. Tighten all three M5 X 30mm socket head cap screws with a 4mm allen wrench.

9. Position the clamp bracket with the counter-bores facing down towards the machine table and align it with the corresponding mounting holes in the baseplate. 10. Install four #8-32 X socket head cap screws and tighten fully with a 9/64 allen wrench.

11. Insert the Proxxon IB/E professional grinder into the 20mm bore in the clamp bracket and tighten the -20 clamp socket head cap screw with a 3/16 allen wrench.

12. If necessary, shim between the base-plate and the spindle box to align the IB/E spindle with the mill spindle.

KDN Tool & Automation Engineering Co. LLC will not be held responsible for injuries sustained while operating CNC machinery retrofit by us or with one of our kits.

3 7/19/06

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gasturbine Engines For Model AircraftDocument104 pagesGasturbine Engines For Model AircraftSaransiri Wongsiri94% (16)

- Actuator BrochureDocument6 pagesActuator BrochureCarlos Ramirez100% (1)

- MDX650 Rotary TutorialDocument17 pagesMDX650 Rotary TutorialCarlos RamirezNo ratings yet

- 2008 CatalogDocument99 pages2008 CatalogCarlos RamirezNo ratings yet

- Techniques of Helmet Removal From Injured Patients: April 1997Document2 pagesTechniques of Helmet Removal From Injured Patients: April 1997Carlos RamirezNo ratings yet

- 2006 Taper BitDocument1 page2006 Taper BitCarlos RamirezNo ratings yet

- Torno t400 BrochureDocument4 pagesTorno t400 BrochureCarlos RamirezNo ratings yet

- Waterjet CutterDocument4 pagesWaterjet CutterCarlos RamirezNo ratings yet

- MDX650 Rotary TutorialDocument17 pagesMDX650 Rotary TutorialCarlos RamirezNo ratings yet

- Acme Ball ScrewsDocument27 pagesAcme Ball ScrewsCarlos Ramirez100% (1)

- Zeroing Xyz On MillDocument1 pageZeroing Xyz On MillCarlos RamirezNo ratings yet

- 17 ActuatorDocument1 page17 ActuatorCarlos RamirezNo ratings yet

- Process Control Servo System SD 1664 Stepper Motor Training UnitDocument1 pageProcess Control Servo System SD 1664 Stepper Motor Training UnitCarlos RamirezNo ratings yet

- mf70 PKGDocument19 pagesmf70 PKGCarlos RamirezNo ratings yet

- Torchmate Catalog 11-8-04Document29 pagesTorchmate Catalog 11-8-04Carlos RamirezNo ratings yet

- The Art of Motion Control - SubcategoryDocument2 pagesThe Art of Motion Control - SubcategoryCarlos RamirezNo ratings yet

- Machine Data Sheet: Model G0519 Mill/Drill/Tapping MachineDocument2 pagesMachine Data Sheet: Model G0519 Mill/Drill/Tapping MachineCarlos RamirezNo ratings yet

- KH56KDocument2 pagesKH56KCarlos RamirezNo ratings yet

- Process Control Servo SystemDocument16 pagesProcess Control Servo SystemCarlos RamirezNo ratings yet

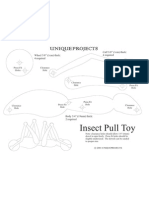

- Insect Pull Toy: Wheel 3/8" (1cm) Thick: 4 Required Calf 3/8" (1cm) Thick: 4 RequiredDocument1 pageInsect Pull Toy: Wheel 3/8" (1cm) Thick: 4 Required Calf 3/8" (1cm) Thick: 4 RequiredCarlos RamirezNo ratings yet

- Cutter GuideDocument1 pageCutter GuideCarlos RamirezNo ratings yet

- Gencata 4 LDocument74 pagesGencata 4 LCarlos RamirezNo ratings yet

- Flying ShearDocument5 pagesFlying ShearCarlos RamirezNo ratings yet

- Grizzly g0463 MDocument40 pagesGrizzly g0463 MCarlos RamirezNo ratings yet

- FM Global 2Document28 pagesFM Global 2Suciu MariusNo ratings yet

- Din en 408-2004Document31 pagesDin en 408-2004TaraNo ratings yet

- Desmi Pumps SparesDocument174 pagesDesmi Pumps SparesThomas Irwin DsouzaNo ratings yet

- Cem - Lecture - 4. - Bricks (2) - 2Document59 pagesCem - Lecture - 4. - Bricks (2) - 2sufyanNo ratings yet

- Cisco IPSEC High Availability Solution - Stateful Failover For IPsecDocument16 pagesCisco IPSEC High Availability Solution - Stateful Failover For IPsecBehnam BagheriNo ratings yet

- Urban Problems: Done By: Afif (Leader) Ahsanudin NazirulDocument18 pagesUrban Problems: Done By: Afif (Leader) Ahsanudin NazirulHemantNo ratings yet

- Ammonia NH3Document9 pagesAmmonia NH3Nikhil TanwarNo ratings yet

- En15273-1 Cen FVDocument208 pagesEn15273-1 Cen FVSamuel Carlos Sanjuán TorresNo ratings yet

- Defecte Directie2Document59 pagesDefecte Directie2Goranka Bulatovic IlicNo ratings yet

- N2qv-Wu2x-N5dx CQ Magazine May 2018Document6 pagesN2qv-Wu2x-N5dx CQ Magazine May 2018Tariq Mundiya0% (1)

- Lifting Guidance For DN 2000 DN 2200 and DN 2400 Pipes PD38Document4 pagesLifting Guidance For DN 2000 DN 2200 and DN 2400 Pipes PD38sosi2020No ratings yet

- Service Manual For X-Ray Collimator: Model Nk202Document17 pagesService Manual For X-Ray Collimator: Model Nk202Wael Fuad AL-MaktariNo ratings yet

- FY2200S Series Communication ProtocolDocument5 pagesFY2200S Series Communication ProtocolxoltrialNo ratings yet

- Cloverads Credentials 2017Document44 pagesCloverads Credentials 2017CloverAdsNo ratings yet

- Brake Lining MeasureDocument2 pagesBrake Lining MeasureAnil yucebasNo ratings yet

- Application Letter PGO Siquijor Supply OfficerDocument1 pageApplication Letter PGO Siquijor Supply OfficerMariss MondarteNo ratings yet

- Polymer Optic FibersDocument33 pagesPolymer Optic FibersHeo QuayNo ratings yet

- Bar Bending Schedule Basic Formulas - Cutting Length Formulas - BBS Calculation - Quantity Surveying - YouTubeDocument5 pagesBar Bending Schedule Basic Formulas - Cutting Length Formulas - BBS Calculation - Quantity Surveying - YouTubedggfchchNo ratings yet

- DIC SyllabusDocument1 pageDIC SyllabusSneha NargundkarNo ratings yet

- Flight Control BacksteppingDocument126 pagesFlight Control BacksteppingAnoop SreeNo ratings yet

- Tifase Midas: Customer StatementDocument15 pagesTifase Midas: Customer Statementganiukoredetifase09No ratings yet

- CA TPX User Enu r5.3Document105 pagesCA TPX User Enu r5.3borisg3No ratings yet

- Mod ADocument128 pagesMod AAsma AlmansouriNo ratings yet

- Christos Savvides CVDocument3 pagesChristos Savvides CVboom1234No ratings yet

- Siemens Switchgear Price List 2019Document48 pagesSiemens Switchgear Price List 2019rajabharath12No ratings yet

- Enhance The Heat Transfer Rate of Finned Tube Heat Exchanger: A ReviewDocument6 pagesEnhance The Heat Transfer Rate of Finned Tube Heat Exchanger: A ReviewEditor IJRITCCNo ratings yet

- Top Gun 140Document2 pagesTop Gun 140Haresh BhavnaniNo ratings yet

- WEG w22 Three Phase Motor Technical Australia New Zealand Market 50025541 BR - Mo - W22technical Catalogue - BSC Brochure English PDFDocument40 pagesWEG w22 Three Phase Motor Technical Australia New Zealand Market 50025541 BR - Mo - W22technical Catalogue - BSC Brochure English PDFMohammad Mahdi BozorgzadehNo ratings yet

- BPM Technology TaxonomyDocument55 pagesBPM Technology TaxonomyKan FB100% (1)

- OR Module All (Sublitted)Document133 pagesOR Module All (Sublitted)DararaNo ratings yet