Professional Documents

Culture Documents

Mipeg Safe Load Indicator Sagar Kiran Manual m2000nr

Uploaded by

Nanang PhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mipeg Safe Load Indicator Sagar Kiran Manual m2000nr

Uploaded by

Nanang PhCopyright:

Available Formats

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.

06, Page 1 of 34

MIPEG

COMPUTERISED CRANE MONITORING

SYSTEMS

Mipeg 2000NR

Safe Load Indicator System

Operating & Maintenance Manual

SeaTrax

Model 4228 - Offshore Pedestal Crane

Sagar Kiran

ANCHOR ONGC SVR INTERNATIONAL

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 2 of 34

Contents Page

SAFETY NOTES ............................................................................................................................. 4

General Description............................................................................................................................ 5

Operating Instructions ....................................................................................................................... 7

3.1 Brief Description of MIPEG 2000 Operation....................................................................... 7

3.1.1 Verification of Driver's Display Unit......................................................................................................... 7

3.2 Information presented on the Mipeg 2000 display............................................................... 9

3.2.1 Push Buttons on the Display..................................................................................................................... 9

3.2.2 Alarms .................................................................................................................................................... 10

3.3 Error handling...................................................................................................................... 10

3.4 Tare Function ....................................................................................................................... 10

Offline Instructions for Drivers Display Unit (DDU).................................................................... 11

4.1 Introduction........................................................................................................................... 11

4.1.1 Push Buttons in Offline Mode ................................................................................................................ 12

4.2 Calibration of Sensors........................................................................................................... 13

4.2.1 Direct calibration of Sensors................................................................................................................... 14

4.2.1.1 Calibration of sensors.......................................................................................................................... 14

Maintenance ..................................................................................................................................... 15

5.1 Introduction........................................................................................................................... 15

5.2 Scheduled Maintenance ........................................................................................................ 15

5.2.1 Calibration of Sensors............................................................................................................................. 16

5.2.1.1 Calibration of Boom Angle Sensor ....................................................................................................... 17

5.2.1.2 Calibration of Load Hoist Sensors ........................................................................................................ 17

5.2.2 Check and calibration of Pulley Compensation...................................................................................... 18

5.2.3 Set-up of Angle Limits (optional)........................................................................................................... 19

5.2.4 Checking of Crane Operation Inhibit Relays.......................................................................................... 20

5.2.5 Checking Crane Curves .......................................................................................................................... 20

5.3 Unscheduled Maintenance.................................................................................................... 21

5.3.1 Built In Test Equipment.......................................................................................................................... 21

5.3.2 Faults Indicated on Driver's Display....................................................................................................... 21

5.3.3 Faults Not Indicated on Driver's Display................................................................................................ 22

Technical description of the main parts .......................................................................................... 23

6.1 Computer Cabinet................................................................................................................. 23

6.1.1 Master II Card......................................................................................................................................... 24

6.1.1.1 Replacement of the Master II card....................................................................................................... 24

6.1.1.2 Set-up of a new Master II card............................................................................................................. 24

6.1.1.3 Strap J5 for Safe or Ex i ....................................................................................................................... 24

6.1.2 Power Converter Unit ............................................................................................................................. 24

6.2 Driver's Display Unit ............................................................................................................ 25

6.2.1 Introduction............................................................................................................................................. 25

6.2.2 Mipeg 2000 Drivers Display Characteristics......................................................................................... 25

6.3 Sensors.................................................................................................................................... 26

6.3.1 Load Hoist Sensor................................................................................................................................... 26

6.3.2 Boom Angle Sensor ................................................................................................................................ 26

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 3 of 34

APPENDICES Page

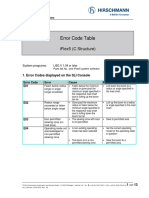

APPENDIX A: MIPEG 2000 ERROR MESSAGES................................................................................................ 27

APPENDIX B: MIPEG SPARE PARTS LISTING................................................................................................... 28

APPENDIX C : MIPEG DOCUMENTATION LISTING.......................................................................................... 28

APPENDIX D : MIPEG CERTIFICATE REFERENCE LIST................................................................................. 28

APPENDIX E: NECESSARY TEST LOADS / DATA FOR CALIBRATION........................................................ 29

APPENDIX F: MIPEG 2000NR CALIBRATION PROTOCOL FORM................................................................ 30

APPENDIX G: BOOM ANGLE / CRANE RADIUS RELATIONSHIP................................................................... 32

APPENDIX H: PROJECT SPECIFICATION........................................................................................................... 33

APPENDIX I : WIRING DIAGRAM........................................................................................................................... 34

FIGURES Page

Figure 2.1: MIPEG 2000 System Configuration ....................................................................................................... 6

Figure 3.1: MIPEG 2000 Driver's Display Unit.......................................................................................................... 8

Figure 3.2: PUSH BUTTONS on Display Unit ....................................................................................................... 12

Figure 3.3: Addressing table for parameters. ........................................................................................................ 13

This document is the property of Aanderaa Data Instruments A.S.

It must not be traced, copied, or exhibited to any third party without permission in writing.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 4 of 34

8ECTON

1

SAFETY NOTES

1. Check and if necessary calibrate the boom angle sensor (Inclinometer) prior to

calibration of the load sensors.

2. Care should be taken when removing the sensor cover to gain access to the

sensor unit and its wiring. The sensor cover should be supported at all times when

the socket head retaining screws are removed. The sensor covers are heavy and if

their weight is allowed to hang on the internal wiring damage to the wires and

sensor could occur. On reassembly it is essential to use the correct torque figure

for the cover retaining screws.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 5 of 34

8ECTON

2

General Description

The MIPEG 2000 crane load indicator system, comprise sensors fitted to the crane, a computer

cabinet and a display located in the crane cabin. Figure 2.1 shows a block diagram of the MIPEG

2000 system.

The load sensors provide frequency modulated electrical signals that are proportional to the

developed loads in the load hoist rope systems of the crane. An inclinometer provides boom angle

information that is used for calculation of the hook radius.

In operation the actual load lifted by the crane are automatically compared with corresponding data

related to the maximum permissible crane loading. The permissible and actual loads, together with

the actual, expressed as a percentage of permissible are displayed. If this percentage exceeds a

pre-set value, alarms and safety functions are activated.

The computer stores the required load-radius curves. These fixed crane parameters are stored in

the main computer's memory while the calibration of the crane is performed using known loads and

boom angle, or known calibration factors. This information is tabulated into the main computer

memory via push buttons on the Display unit.

MIPEG 2000 in standard version comprises the following main parts:

- Computer Cabinet (6.1)

- Driver's Display (6.2)

- Sensors (load and boom angle) (6.3)

A technical description of these main parts is given in Section 6. The numbers in parenthesis are

references to paragraphs for these descriptions.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 6 of 34

Figure 2.1: MIPEG 2000 System Configuration

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 7 of 34

8ECTON

3

Operating Instructions

3.1 Brief Description of MIPEG 2000 Operation

MIPEG 2000 is a computerised crane safety system. It measures load and radius and indicates

safe or hazardous conditions.

It has three main parts; the computer cabinet, the driver's display unit and the sensors. The driver's

display unit is located in the crane driver's cabin, and its layout is shown in Figure 3.1.

MIPEG 2000 interfaces with the crane and prohibits some functions under dangerous conditions.

These crane operation relays and their functions are described in Appendix H. In addition, alarms

are given for loads exceeding the alarm limits of the safe working load.

It is recommended MIPEG 2000 to be constantly powered if possible, even during periods of time

when the crane is not in operation. No warm up time for the system is required, but the load

sensors will need 5-10 minutes after power on to achieve maximum accuracy and stability.

3.1.1 Verification of Driver's Display Unit

Before using the crane: Check that the LEDs back lighting the drivers display panel are illuminated

to show that MIPEG 2000 is powered up.

The back lightning can be adjusted if one keep the AUX button depressed and use the TEST

button to toggle the light intensity. Release the buttons between each setting.

Press the TEST button on the Drivers Display unit and confirm:

Operation of the analogue display of percentage safe working load by allowing the needle to

make at least one complete revolution.

Integrity of the WARNING (Yellow) and ALARM (Red) lamps on DDU - will light continuously.

Operation of display digits. Each segment of each window will show a figure eight with decimal

points being visible between each digit.

If everything is satisfactory proceed, otherwise call maintenance.

Press the 'AUX' button and confirm that the hoisting line is correct for the operating

configuration of the crane.

Confirm that the hoisting line is correct for the operating configuration of the crane. If

not, select correct hosting line by pressing the AUX and 'FALLS' buttons.

Verify that the correct 'Crane curve' is displayed.

If not, select correct crane curve by pressing the CURVE button.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 8 of 34

Figure 3.1: MIPEG 2000 Driver's Display Unit

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 9 of 34

3.2 Information presented on the Mipeg 2000 display

STANDARD LAYOUT

The outer circular analogue scale shows percentage safe working load (%SWL).

The scale is divided into three parts, coloured:

green - for the range 0 - 85/95% SWL,

yellow - for the range 85/95 - 110% SWL, and

red - for the range >110% SWL.

The top Window shows the Hook Load.

This load will vary slightly as the amount of rope paid out varies. It also varies depending on

how the load is lifted; the smoother the lift the less the resultant fluctuation.

The left Window displays the Crane curve selected. See Appendix H for details

The right Window shows the Hook Radius.

The lower Window shows the Safe Working Load that is related to:

operating configuration of the crane

crane curve selected

radius of operation.

ALTERNATIVE INFORMATION

Window Information presented with AUX button depressed

Top Boom angle

Left Not used

Right Number of hoist falls registered in MIPEG

Lower Not used

3.2.1 Push Buttons on the Display

The PUSH BUTTONS have normally the following functions:

BUTTON FUNCTION

ACK Press this button to reset the Mipeg.

Spurious error will be disabled and satisfactory operation will continue.

Pressing this button when an overload will also stop the flashing light on the display.

TEST Press this button to check the function of the needle and LCD's.

AUX Press this button to activate the alternative information on the display.

CURVE Press this button to toggle between the different crane curves (sea curves).

AUX+FALLS Pressing these buttons will change the number of falls in the system.

AUX+TEST The back lighting can be adjusted if one keep the AUX button pressed and use the

TEST button to change the light intensity. Release the buttons between each setting.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 10 of 34

3.2.2 Alarms

The visual and audible alarms warn of approaching danger. The WARNING (Yellow) light on Drivers

Display will flash and the buzzer inside the computer cabinet will sound when the load raised

reaches the warning limit at boom radius, crane curve and operating configuration of the crane. This

means that although a load may have been lifted at a given radius the alarm may come on as the

crane is boomed out beyond that radius and the crane capacity reduces.

To acknowledge an alarm, press the ACK button; the WARNING light will remain constantly lit until

the overload situation has decreased below the warning threshold.

The ALARM (Red) light on Drivers Display will flash when the load raised reaches the alarm. When

the ACK button is pressed; the ALARM light will remain constantly lit until the overload situation has

decreased below the alarm threshold and the WARNING light will remain constantly lit until the

overload situation has decreased below the warning threshold.

3.3 Error handling

If a detectable error occurs the MIPEG 2000 clears the operators display, and blinks an error

message 'ERxx' in top window; "xx" is two digits identifying the error. Operator should press 'ACK on

the Display Unit that then resets MIPEG. If it was a spurious error, satisfactory operation will

continue, otherwise call for maintenance.

See Appendix A for Mipeg 2000 error messages. The two digit error codes have an error explanation

with fault sources and references.

3.4 Tare Function

The zero setting of the hook load may vary due to length of rope payed out or weight of the slings in

use. A tare function has been implemented in the Mipeg 2000 to set the hook load read-out to zero,

prior to lifting operations.

The load read-out may be 'tared' by pressing the 'FALLS' button once. Another push on this button

will deactivate the tare function.

The tare function will only work below +/- 0.5Tonne/1000Lbs. * number of falls calculated from the

last zero calibration. The tare function will not change the zero frequency in the system.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 11 of 34

8ECTON

4

Offline Instructions for Drivers Display Unit (DDU)

4.1 Introduction

The push buttons on the Display Unit are used to select the Offline Mode. When the TEST and

CURVE buttons are pressed simultaneously, the following data is displayed: (Note: This Mode is

disabled by a switch in the computer cabinet).

Window Data

Top Presented value of displayed parameter (Calibration value).

Left Parameter no. which contents presently displayed in upper window. Each parameter

to be displayed/changed in setting mode is tabulated and given a number according

to its position in the table. When change of parameter is required, the number is

found in the table given in figure 3.3 or in the calibration protocol, Appendix F.

Right Off (Offline)

Lower Frequency value read from sensor (for calibration).

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 12 of 34

4.1.1 Push Buttons in Offline Mode

When calibration or inspection of calibration data is required, the offline mode is selected by pressing

TEST and CURVE push buttons simultaneously. The push buttons then get a new function, shown in

Figure 3.2.

The PUSH BUTTONS have the following functions in the Offline Mode:

Button Offline Mode

UP Pressing this button will increase the last digit on the displayed parameter by one.

(ACK) Keeping the button continuously pressed will give a fast change in value. All

alterations are done in the bottom window. The new value will also be displayed in

the top window when accepted.

DOWN Pressing this button will decrease the last digit on the displayed parameter by one.

(TEST) (Details as above)

ENTER Pressing this button will put the changed parameter value into the system.

(AUX)

NEXT Pressing this button will give a step to the next parameter in the table. Its value and

(CURVE) no. are displayed in the upper and left window respectively. When one comes to the

end of the table, the system returns to the first entry, which also is the starting point

when entering offline mode.

READ Pressing these buttons, AUX and then TEST, will read the frequency from the

(AUX+TEST) appropriate sensor and display it in the lower window. This value can then be set in

the system as a calibration value by pressing AUX.

PREVIOUS Pressing this button will give a step to the previous parameter in the table. Its value

(FALLS) and no. are displayed in the upper and left window respectively.

Return to normal operation by pressing ACK and AUX simultaneously.

Figure 3.2: PUSH BUTTONS on Display Unit

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 13 of 34

4.2 Calibration of Sensors

Calibration of the system is performed in the following steps:

Use the TEST and CURVE push buttons to select Offline Mode.

The first parameter is now displayed in the left window and the present value/frequency are

displayed in upper window.

The parameters are organised as follows. See Appendix F for details.

Index number Parameter

1-4 Inclinometer

5-10 Whip Load Sensor

11-34 Main Load Sensor

39-40 Pulley Compensation, Main

41-42 Pulley Compensation, Whip

43-46 Angle limits

Figure 3.3: Addressing table for parameters.

Press the UP (ACK) or DOWN (TEST) button to increase or decrease the last digit on the display by

one.

Press ENTER (AUX) button to set the value in the computer.

Press NEXT (CURVE) or PREVIOUS (FALLS) button to go to another parameter. Ref. the

calibration protocol, Appendix F.

Repeat until all parameters are set as required.

Update all values in the calibration protocol form, Appendix F.

Return to normal mode by use of ACK and AUX push buttons.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 14 of 34

4.2.1 Direct calibration of Sensors

The calibration points are organised as follows:

Cal. Point Load Sensors Inclinometer

0 Empty hook (0) 30

1 100% SWL 80

2 40-60% SWL N/A

Point 2 is the value for the second order calibration and should only be used when required. The second

order calibration is not activated if point 2 is set to zero.

4.2.1.1 Calibration of sensors

To calibrate a Sensor, one must know which Index to use, see Appendix F

Cal. Point 0 - The Zero calibration is done as follows:

Use TEST & CURVE buttons for Offline Mode.

Press CURVE to select the correct Index (see Appendix F).

Press AUX & TEST to read new value from Sensor. Wait.

Press AUX to confirm new calibration.

Press CURVE to go to next Index.

Use ACK (UP) or TEST (DOWN), enter the Y-value (see Appendix E for details):

0 Tonns/Lbs. for Load.

normally 30 degrees for Inclinometer.

Press AUX to confirm new calibration.

The calibration values will be updated.

Press AUX & ACK to go back Online.

Cal. Point 1 - The maximum point (100%) calibration is done as follows:

Use TEST & CURVE buttons for Offline Mode.

Press CURVE to select the correct Index (see Appendix F).

Press AUX & TEST to read new value from Sensor. Wait.

Press AUX to confirm new calibration.

Press CURVE to go to next Index.

Use ACK (UP) or TEST (DOWN), enter the Y-value (see Appendix E for details):

Load lifted in Tonns/Lbs.

normally 80 degrees for Inclinometer.

Press AUX to confirm new calibration.

The calibration values will be updated.

Press AUX & ACK to go back Online.

Cal. Point 2 - The Midpoint (40-60%) calibration is done as follows:

Use TEST & CURVE buttons for Offline Mode.

Press CURVE to select the correct Index (see Appendix F).

Press AUX & TEST to read new value from Sensor. Wait.

Press AUX to confirm new calibration.

Press CURVE to go to next Index.

Use ACK (UP) or TEST (DOWN), enter the Y-value (see Appendix E for details):

Load lifted in Tonns/Lbs.

Press AUX to confirm new calibration.

The calibration values will be updated.

Press AUX & ACK to go back Online.

When the calibration is completed, one should write all calibration values into the Mipeg Calibration Protocol,

Appendix F.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 15 of 34

8ECTON

5

Maintenance

5.1 Introduction

This section describes the maintenance procedures for MIPEG 2000 system. It is divided into two

parts:

- scheduled maintenance (5.2)

- unscheduled maintenance (5.3)

It is recommended that all repair work is performed by Aanderaa Data Instruments A.S, Bergen,

for the aspects of warranty related requirements.

5.2 Scheduled Maintenance

The maintenance schedule and instructions below should be followed rigorously to ensure

correct operation of the MIPEG 2000 system.

FREQUENCY

TASK

PERFORMED BY

INSTRUCTIONS

Prior to

Each shift

Verification of system operation

Crane driver

Perform check detailed in Section

3, 'Operating instructions for

crane driver

3 Monthly

Check calibration of load sensors and

inclinometer

Crane supervisor /

Maintenance engineer

See paragraph 5.2.1. below

Check integrity of crane operation

inhibit relays.

Crane supervisor /

Maintenance engineer

See paragraph 5.2.2. below

6 Monthly

Check crane curves

Crane supervisor /

Maintenance engineer

See paragraph 5.2.3. below

As required

Calibration of pulley compensation

Crane supervisor /

Maintenance engineer

See paragraph 5.2.1.3. below

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 16 of 34

5.2.1 Calibration of Sensors

The sensors of Mipeg 2000 are carefully checked during installation and their initial calibration

constants are semi-permanently kept in the Mipeg 2000 non-volatile memory. Their output might vary

within certain limits due to temperature drift, ageing and changes in environmental conditions. If the

variation is too large, malfunction may occur, and a calibration must be performed.

The zero point drift of the load hoist sensor(s), i.e. the deviation from zero on the display reading with

empty hook is considered to be the most important factor to monitor. It must be kept in mind that the

zero point for this sensor(s) has been defined at 45 degrees boom angle and hook at deck level.

Deviation from zero in a no load condition might be caused by different length of hoisting rope payed

out.

The calibration constants could be set up in two different ways:

1. Normally one would use calibrated test loads or dynamometers for the force sensors and crane

radius marks on the deck for the inclinometer. The frequency is read from the sensor by MIPEG,

while the actual quantity, i.e. weight or angle, is keyed in on the Displays push buttons, as

described in paragraph 4.2.1.

2. It is also possible to enter both the frequency and the actual quantity from the Displays push

buttons. This method is used to enter old calibration constants; giving calibration values to MIPEG

which already are recorded in the calibration protocol, Appendix F. See paragraph 4.2.1.

A compensation for variation caused by an unlinear load sensor arrangement is included in the

MIPEG system. Calibration point 2 is set by the Display Unit buttons during calibration, in the same

way as point 0 and 1. If the compensation is not required, point 2 should be set to zero.

Cal. point 0: Empty hook / No load

Cal. point 1: 100% load

Cal. point 2: 40-60% of full load

The calibration protocol given in Appendix F should be followed whenever possible. Ensure that the

calibration points of the boom angle sensor are checked, and if necessary, calibrated before any other

sensor is calibrated.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 17 of 34

5.2.1.1 Calibration of Boom Angle Sensor

Calibration of the boom angle sensor is recommended if the deviation between the real and the

indicated crane radius is greater than one metre.

It is recommended that two permanent calibration points are used, one at minimum radius using the

boom's end stop, the other point at approximately 30 degrees boom angle, i.e. 87% of maximum

radius. The two points must be marked on the deck as radius in metre.

As Mipeg 2000 always measures boom angle above horizontal, a calibration point at maximum

working radius is not recommended as a small inaccuracy in the radius can cause a significant

inaccuracy in the angle reading. This is because changes in boom angle in the range 0 to 20 degrees

will give a small change in radius of approximately 7%. Radius/angle relationships for calibration

purposes are given in Appendix G.

The calibration procedure for the boom angle sensor is given as follows:

Boom out to the outer radius mark on the deck.

With the hook on this mark, do a calibration of point zero as described in paragraph 4.2.1.

Type in the boom angle according to the table in Appendix G, or according to earlier recorded

data in the calibration protocol.

Boom in to the inner radius mark on the deck.

With the hook on this mark, do a calibration of point one similar to point zero.

Set MIPEG in Online state and check the two calibration points.

If not ok, go back to point a) and/or d) and make adjustments of point zero and/or point one.

If ok, go Offline and read back the new calibration data, see paragraph 4.2.

Make a record in the calibration protocol.

5.2.1.2 Calibration of Load Hoist Sensors

Calibration of the load hoist sensor(s) is recommended if the hook load reading in a no load condition,

i.e. boom angle at 45 degrees and hook at deck level, is outside the following limits:

Whip line: +/- 1Tonne/2000Lbs. (Optional)

Main line, Plural Falls: +/- 2Tonnes/4000Lbs.

Calibration requires calibrated test loads or a calibrated dynamometer to measure the test loads.

Recommended sizes of the test loads are given in Appendix E.

The calibration procedure for the load hoist sensor(s) is as follows:

Boom in/out to the radius that gives a boom angle given in Appendix E. See Appendix G for

radius/angel conversion.

Lower the empty hook to just above deck level.

Do a calibration of point zero as described in paragraph 4.2.1, function 'Calibration of Sensors'.

Type in zero as hook load.

Put on the test load and hoist it just above the deck level.

Do a calibration of point one similar to point zero.

Go back online and check the two calibration points.

Test with approximately 50% of SWL and verify if the Mipeg readout is acceptable. If not

calibration point 2 should be activated.

Do a calibration of point two as above.

Repeat the load test.

If the calibration is acceptable without point 2, the frequency and value for point 2 should be set to

zero.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 18 of 34

5.2.2 Check and calibration of Pulley Compensation

The weight of the pulley on the load hoist sensors could cause a varying output from the load sensors

as the boom angle varies. A compensation for this is implemented on MIPEG. The parameters for this

compensation are stored as calibration parameters according to the following table.

HOIST LINE Index no. PARAMETER

Main 39 Weight parameter

40 Angle for maximum load value

Whip (Optional) 41 Weight parameter

42 Angle for maximum load value

The check of the pulley compensation is done as follows:

Set the values in index 39-42 to zero as described below.

Select Main hoist line first and repeat for Whip hoist line.

With the boom at maximum radius, position the empty hook just above the deck level. Keep

this hoisting line position during this test.

Boom in and note the displayed hook load values for every 5 Metre/15 Foot from maximum to

minimum radius.

Check the variations of the hook load values. If the variation exceeds 0.5Tonne/1000Lbs. for

whip line and 1Tonne/2000Lbs. for main line, a calibration as described above is required.

To disable the pulley compensation, set the Parameters to zero as follows:

Use TEST & CURVE buttons for Offline Mode.

Press CURVE several times to go to the Index 39

Use ACK (UP) or TEST (DOWN) to set to zero

Press AUX to confirm.

Press CURVE to go to Index 40, 41 and 42 and set all to zero

Press AUX & ACK to go back Online.

The calibration of the pulley compensation is done as follows:

The compensation are set in degrees of boom angle and weight of the pulley. Theses values could

be changed from the display unit as described below.

Use TEST & CURVE buttons for Offline Mode.

Press CURVE several times to go to the Index 39

Use ACK (UP) or TEST (DOWN) to adjust the weight parameter values, Index 39 for Main

(and Index 41 for Whip) according to the following formula: Adjustment = (Variation / No. of

falls) / (1 - cos(A)), where: A=Boom angle difference for variation readout

Press AUX to confirm.

Press CURVE to go to Index 40

Use ACK (UP) or TEST (DOWN) to set Index 40 for Main (Index 42 for Whip) to the angle

where the highest load value was during the test.

Press AUX to confirm.

Use TEST & CURVE buttons to return to Offline Mode.

Repeat the test above and if necessary adjust the weight parameter values (Index 39 & 40) until

acceptable read-outs are achieved.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 19 of 34

5.2.3 Set-up of Angle Limits (optional)

'Mipeg 2000 will activate a buzzer and/or output relays if the boom is outside the set angle limits.

See Appendix H for project details. The parameters for these limits are stored as calibration

parameters according to the following table:

LIMIT INDEX NO. Parameter

High Angle-1 43 High limit on

44 Low limit off

Low Angle-1 45 High limit on

46 Low limit off

These limits are set in degrees of boom angle and could be set from the display unit as follows:

Set-up of the High Angle Limits:

Use TEST & CURVE buttons for Offline Mode.

Press CURVE several times to go to the Index 43

Use ACK (UP) or TEST (DOWN) to select the high angle limit, 'on value'

Press AUX to confirm.

Press CURVE to go to Index 44

Use ACK (UP) or TEST (DOWN) to select the high angle limit, 'off value'

Press AUX to confirm.

Press AUX & ACK to go back online.

Set-up of the Low Angle Limits:

Use TEST & CURVE buttons for Offline Mode.

Press CURVE several times to go to select the Index 45

Use ACK (UP) or TEST (DOWN) to select the low angle limit, 'on value'

Press AUX to confirm.

Press CURVE to go to Index 46

Use ACK (UP) or TEST (DOWN) to select the low angle limit, 'off value'

Press AUX to confirm.

Press AUX & ACK to go back online.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 20 of 34

5.2.4 Checking of Crane Operation Inhibit Relays

Checking of the crane operation inhibit relays are recommended to be performed by the crane

supervisor every third month.

To test the overload outputs, one needs a hook load sufficient to create an overload condition. In

order to use a smallest possible load, one can set MIPEG in the highest sea condition. Pick a load

size according to the crane curves. With this load available, the check are done in the following steps:

Lift the load off the ground.

While watching the %SWL readings on the driver's display, boom out until it reaches the warning

limit. The yellow light should be activated. Boom out until it reaches the alarm limit. The red light

and the relay output(s) should now be activated.

Boom in and put the load down.

In addition to this, the output relays may be tested as follows:

MIPEG Nonoperational

Turn MIPEG power off. The horn and overload relays should be activated.

MIPEG Error

Simulate an error condition on MIPEG. The horn and overload relays should now be activated.

5.2.5 Checking Crane Curves

The tables of safe working loads (SWL) are permanently stored in the Mipeg 2000 memory and are

called crane curves. These are thoroughly tested during the commissioning of the crane. One should

therefore not expect any problems with the crane curves during operation, but it is recommended that

the crane supervisor checks the crane curves installed in Mipeg 2000 against the load- radius tables

available in the crane cabin twice a year.

The crane curve checking is done in the following steps:

With no load in the hook, hoist the boom to top position.

Set number of falls to the lowest implemented value.

Set curve to the lowest implemented value.

While reading radius and SWL from driver's display and comparing the readings with the

load-radius tables, lower the boom to maximum radius.

Change the curve to next lowest value and perform point d) while hoisting the boom to top

position.

Go through all crane curves for this number of falls, then change to next number of falls and go

through all curves, and so on until all combinations are checked.

If possibilities for more boom lengths are implemented, change to next boom length, and repeat.

After the checking of the crane curves is finished, set the parameter values for boom length,

number of falls and curve back to the correct values.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 21 of 34

5.3 Unscheduled Maintenance

5.3.1 Built In Test Equipment.

The computer will start to execute once the logic supply (5V) reaches it's working level after power is

turned on to the system.

If the bus or timer checks fails, the program will signalise the fault condition and indicate an error

message on the display, see Appendix A. If all checks are passed the full system software is

initialised and starts its normal execution.

Different checks are continuously performed during normal system execution:

Sensor data limit checks

Processing data evaluation

Processing time control ("watch dog" function)

Evaluation of the crane's parameter set

These tasks are all contained in the software package called the Online BIT-functions. If any of the

checks fail this will lead to an immediate shut down of the system by use of the normal error exit and

indication, see paragraph 5.3.2.

5.3.2 Faults Indicated on Driver's Display

Fault recognised by the Mipeg 2000 system during run-time, will be indicated on the driver's display

by a flashing light in the WARNING and ALARM lamps and an error code in the upper window. The

horn will blow for 10 seconds and overload alarm will be activated.

When the crane driver acknowledges the fault, the fault indications on the driver's display will

disappear and the overload function will be deactivated. If, however, the fault is of a permanent

nature, the same indications will appear over again.

The fault may of course be located in the computer (and be of a major kind, ref. paragraph 5.3.1

above) or the cabling to the display may be damaged both of which will display a normal error

indication.

The error code will assist the maintenance engineer in locating the fault. Appendix A gives a list of

error codes with the probable fault source(s). When fault tracing, reference should be made into the

technical description where further details may found.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 22 of 34

5.3.3 Faults Not Indicated on Driver's Display

Prior to faultfinding on this level, the Mipeg 2000 system should be given a power reset by turning power

off/on. These faults normally fall into the following categories:

FAULT

"Dead system", a typical power supply problem

Faults located in the Driver's Display prohibiting

normal error indication

Erratic behaviour, where parts of the system do

not operate properly or as specified.

The system does not follow the input switches

Horn or other outputs not functioning

FAULT SOURCE :

Trace the input power through fuses on TR1. If

24V dc present, check fuse located on the Master

II card.

If the error is strictly located to the display unit,

error indication by the use of the horn will still be

maintained. If not, reference to paragraph 5.3.1

should be made.

If a malfunction is established and no fault found

in the cabling a replacement of the display or

cards may be necessary, see paragraph 6.1.

Check the cabling of the switch or eventually

replace the Master II card, see paragraph 6.1

Check the cabling of the item or eventually

replace the Master II card, see paragraph 6.1

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 23 of 34

8ECTON

6

Technical description of the main parts

MIPEG 2000 in standard version comprises the following main parts:

Computer Cabinet (6.1)

Driver's Display Unit (6.2)

Sensors (load and boom angle) (6.3)

A technical description of these main parts is given in this section.

6.1 Computer Cabinet

The Computer Cabinet houses the Mipeg computer, zener barriers (EEx nC only), relays and terminal

rows for external cable connection.

EEx nC Certificated systems:

The cabinet is certified EEx nC and sealed to IP66. Dimensions: 380*380*210 mm. Weight:

approximately 30 kgs.

The computer cabinet has been found to comply with the IEC 79-15 1987 standard and has

successfully met the type verification and test requirements of this standard.

Systems in safe areas:

The cabinet is sealed to IP66. Dimensions: 380*300*210 mm. Weight: approximately 15 kg. The

computer cabinet has been found to comply with the IEC 79-15 1987 standard and has successfully

met the type verification and test requirements of this standard.

There are three fuses in the system:

Supply Location Fuse type

24 Vs Master II Card 1.0 A / 250V - 5*20 mm

24 Vs TR1 - no. 3 3.15 A / 250V - 5*20 mm

85-240 V ac TR1 - no. 1 2.0 A / 250V - 5*20 mm (in safe area)

85-240 V ac TR1 - no. 1 8.0 A / 250V - 5*20 mm (certificated systems)

WARNING:

FOR CONTINUED PROTECTION AGAINST FIRE

REPLACE WITH SAME TYPE AND RATING OF FUSES

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 24 of 34

6.1.1 Master II Card

The computer is built in microprocessor technology located on the Master II card. The Master II card

also contains power, sensor and interface logic. The cards are connected to the terminal rail through

connectors on the cards. These connectors can be split to make a quick replacement of cards.

The Master II card contains the following electronics:

microprocessor with program memory

volatile memory used to store the crane's parameter set

timing circuits

interface for three S-sensors

interface for the inclinometer

DC/DC converter for generation of the galvanic isolated power supply 5V, 12V

level detection circuits on logic (5V) and input (24V) power,

power protection circuits

fuse: 1A/250V - 5*20mm

6.1.1.1 Replacement of the Master II card

When replacement of the Master II card is found to be necessary one should always continue with the

same program unless this circuit (EPROM) is proven damaged.

The EPROM containing the program is found in socket U37. To remove this socket inserted

component, gentle insert a small screwdriver under the component and twist until component is free.

Insert carefully onto spare Master II card.

6.1.1.2 Set-up of a new Master II card

Prior to operation of the Mipeg 2000 system, a new Master II card has to be reset with default values

from the system program and old calibration values should be entered:

Reset the Prom parameters (please contact Aanderaa Data Instruments for this procedure)

Enter old calibration values from the Calibration protocol, ref. paragraph 4.2.

6.1.1.3 Strap J5 for Safe or Ex i

Due to the use of Zener barriers for Exi systems, the strap J5 on the Master II card has to be set in

different positions for a safe or Ex i.

SAFE: strap J5 in position towards the crystal

Ex i : strap J5 in position towards J14

6.1.2 Power Converter Unit

The Power Converter Unit is included inside the computer cabinet. The unit is a switching power

supply, coping with input voltage from 85 - 264 Vac. The output from the power unit to the Mipeg

2000 Master II card is nominal 24 Vdc.

The unit is in accordance with UL,CSA, TUV and VDE (IEC950). Noise terminal voltage is

conforming to FCC class B and VDE0871 class B. Proof pressure AC 3000V.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 25 of 34

6.2 Driver's Display Unit

6.2.1 Introduction.

The Mipeg 2000 Driver's Display is a microprocessor controlled display designed for use in harsh

environment.

Information is presented by four LCDs and by an analogue needle. All LCDs and the display facia are

backlit by LEDs. The unit incorporates two alarm indicators (LEDs). Information to be visualised on

the display is transmitted from the computer on a serial interface line.

The Display Unit consists of three major parts all housed in an enclosure supplied with a cable

entry through a gland and terminal row:

A printed circuit board including the front plate and electronic components of the display.

A push-button panel mounted on the front plate. This panel consists of five push-buttons.

A connector for the PTU connection mounted on the bottom plate of the enclosure.

The back-light can be adjusted if one keep the AUX button pressed and use the TEST button to

change the light intensity. Release the buttons between each setting.

The display is mounted on a bracket fitting which enables the unit to be tilted in both the vertical and

horizontal planes. Selica Gel should be included inside the enclosure to prevent condensation of

water on the display front glass.

It is recommended that the Driver's Display is serviced by Aanderaa Data Instruments personnel.

6.2.2 Mipeg 2000 Drivers Display Characteristics.

Physical characteristics

Outer size: 225 x 200 x 60 millimetre

Overall weight: Approximately 3 kgs

Housing material: Aluminium given an epoxy resin finish.

Electrical characteristics

Supply Voltage: Nom. 7.5 Vdc

Supply current: Nom. 152 mA

External connections

Two pairs connected to a terminal row.

DC supply: DD+/-.

Serial communications line to/ from display: RS485 A/B

Environmental characteristics

Operating/Storage temperature: -20, +40 C

Sealing: to IP65

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 26 of 34

6.3 Sensors

MIPEG 2000 sensors are used to measure the following:

Loads in the hoisting lines, main and whip (optional)

Boom inclination relatively to horizontal plane

A technical description of each of the sensors is given in the following paragraphs.

6.3.1 Load Hoist Sensor

The load hoist primary sensor(s) is of S-band type. This primary sensor is MIG-welded to a

suspension part that also carries a pulley for the load sensing. The sensor measures the material

stress in the suspension part, which is proportional to the line load.

The output from the sensor is a frequency signal in the range 350-450 Hz. The resolution is typically

5Hz/tonne for one fall configuration. The sensor has two wire power/signal connection and is not

damaged by short or open circuits.

The primary sensor may be overloaded 5-10 times the nominal working range. This is far above the

yield strength of the material. The primary sensor is temperature compensated. The primary sensor is

sealed hermetically to SEN431614-k (MIL-STD-883A).

The sensor cover is sealed to protection index IP67. The sensor has been examined against the

requirements of the CENELEC standards EN50 014 and EN50 018 for flameproof enclosures and has

been approved for use in hazardous areas and to bear the marking EEx d IIB T6. The sensor cover

mounted on the sensor with four socket screws. These are tightened with a torque wrench to a torque

of 5 Nm. The flame gap area must be filled with an 'EExd' approved protection matter/grease, e.g. of

mark PBC.

To verify correct/undamaged cabling and sensor, a resistance measurement from the terminal row in

the computer cabinet can be done. Between disconnected cores, the resistance shall be

approximately 6 ohms (3 ohms in sensor plus cable). There shall be open circuits between cores and

drain, and between drain and chassis earth.

The load hoist sensor(s) has to be replaced as a complete unit.

6.3.2 Boom Angle Sensor

The Boom Angle Sensor is an inclinometer mounted in an EX d enclosure at the boom foot. The

inclinometer gives a voltage output in proportion to the boom angle (BAS+). Voltage supply to the unit

is 12Vdc (BAR+). The Inclinometer has a typical resolution of 30-35 mV/degree boom angle. The

sensor is not damaged by shorts or open circuits.

The unit is manually set to give approximately 4 Volt dc at zero degree boom angle if the unit is

installed facing towards the left hand side of the crane. At minimum radius the voltage will then be

approximately 7 Volts.

If the unit is installed facing towards the right hand side of the crane, it should manually be set to give

approximately 7 Vdc at zero degree boom angle. At minimum radius the voltage would then be

approximately 4 Volts.

Aanderaa Data Instruments Document W-130 H00 623, Date 26.06.06, Page 27 of 34

APPENDIX A: MIPEG 2000 ERROR MESSAGES

CODE

Error Explanation, (fault sources & references)

19

Sensor fault, Moment sensor out of range.

(Cabling, sensor, Master II card).

20

Sensor fault, Whip hoist sensor out of range.

(Cabling, sensor, Master II card)

21

Sensor fault, Main Hoist sensor out of range.

(Cabling, sensor, Master II card).

23

Sensor fault, Inclinometer out of range.

(Cabling, sensor, Master II card).

25

Computer fault, Initializing error. (Master II card).

28

Computer fault, SWL-parameter error. (Master II card).

30

Computer fault, EEPROM/RTC read/write error (Master II Card)

31

Computer fault, EEPROM overflow (Master II Card)

50

Crane identity does not correspond to parameter set.

51

Both or none of the Main and Whip inputs selected.

9509

Or

0210

No communication between the computer cabinet and the display.

(Cabling, Display, Master II Card)

Datainstrument document W-130 H00 623, Date 26.06.06 Page 28 of 34

APPENDIX B: MIPEG SPARE PARTS LISTING

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

Part Name Part no.

COMPUTER CABINET

Master II Card DI-130 P01 001

MIPEG 2000 DRIVER'S DISPLAY

Display Box/Front DI-130 P02 000

Mounting Bracket DI-130 P02 005

SENSORS

Main Hoist Sensor DI-112 P05 239

Whip Hoist Sensor DI-112 P01 225

Boom Angle Sensor DI-130 P05 003

APPENDIX C : MIPEG DOCUMENTATION LISTING

COMPUTER CABINET

S - 123 B01 002 Block Schematic, Master II card

DISPLAY

A-130 M02 000 General Assembly, Mipeg 2000 Driver's Display

SENSORS

I - 112 M05 239 General Assembly, Main Hoist Sensor

I - 112 M01 225 General Assembly, Whip Hoist Sensor

I - 130 M05 005 General Assembly, Inclinometer

APPENDIX D : MIPEG CERTIFICATE REFERENCE LIST

MIPEG Part Marking Certificate no.

Main Load Sensor Ex II 2 GD EEx d IIB T6 NEMKO 03 ATEX 304

Whip Load Sensor Ex II 2 GD EEx d IIB T6 NEMKO 03 ATEX 302X

Inclinometer Ex II 2 GD EEx d IIB T6 NEMKO 03 ATEX 303X

Datainstrument document W-130 H00 623, Date 26.06.06 Page 29 of 34

APPENDIX E: NECESSARY TEST LOADS / DATA FOR CALIBRATION

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

The following test loads/data are recommended for calibration:

Sensor

Number

of Falls

Calibration

Point

Cal. at

Degrees

Test value

Inclinometer

-

0

1

30

80

No test load

Whip Hoist

1

0

1

45

0 Lbs

11 800 Lbs

Main Hoist

2

0

1

50

0 Lbs

27 000 Lbs

Main Hoist

4

0

1

75

0 Lbs

56 000 Lbs

Main Hoist

6

0

1

80

0 Lbs

85 000 Lbs

Datainstrument document W-130 H00 623, Date 26.06.06 Page 30 of 34

APPENDIX F: MIPEG 2000NR CALIBRATION PROTOCOL FORM page 1 of 2

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

CRANE: ______________________________ Calibrated - Date/Sign. : _________________________

SENSOR

No. of Falls

Cal.

Point

Index

no.

Calibration

Parameters

Frequency / value

0

1

Volt

INCLINOMETER

-

0

2

Degrees

1

3

Volt

1

4

Degrees

0

5

Hz

0

6

Lbs

LOAD HOIST,

1

7

Hz

Whip

1

1

8

Lbs

2

9

Hz

2

10

Lbs

0

11

Hz

0

12

Lbs

LOAD HOIST,

1

13

Hz

Main

2

1

14

Lbs

2

15

Hz

2

16

Lbs

0

17

Hz

0

18

Lbs

LOAD HOIST,

1

19

Hz

Main

4

1

20

Lbs

2

21

Hz

2

22

Lbs

0

23

Hz

0

24

Lbs

LOAD HOIST,

1

25

Hz

Main

6

1

26

Lbs

2

27

Hz

2

28

Lbs

Datainstrument document W-130 H00 623, Date 26.06.06 Page 31 of 34

APPENDIX F: MIPEG 2000NR CALIBRATION PROTOCOL FORM page 2 of 2

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

CRANE: ______________________________ Calibrated - Date/Sign. : _________________________

PULLEY COMP.

-

0

39

Lbs

( Main )

0

40

Degrees

PULLEY COMP.

-

0

41

Lbs

( Whip )

0

42

Degrees

ANGLE LIMITS

-

0

43

Degrees

( High Angle-1 )

0

44

Degrees

ANGLE LIMITS

-

0

45

Degrees

(Low Angle-1 )

0

46

Degrees

Datainstrument document W-130 H00 623, Date 26.06.06 Page 32 of 34

APPENDIX G: BOOM ANGLE / CRANE RADIUS RELATIONSHIP

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

RADIUS = Distance from Centre of Pedestal to Jib Pin (+ Sheave radius for 1 Fall)

+ Boom Length * cos(@) + Offset Centerline * sin(@)

RADIUS for Whip line = 3.75 + 0.60 + 122.32 * cos(@) + 3.52 * sin(@)

RADIUS for Main line = 3.75 + 118.80 * cos(@) + 1.50 * sin(@)

Boom lengths:

Whip

1 fall

122.32

Main

2or> falls

118.8

Angle Radius Radius

0 126.7 122.6

5 126.5 122.2

10 125.4 121

15 123.4 118.9

20 120.5 115.9

25 116.7 112.1

30 112 107.4

35 106.6 101.9

40 100.3 95.7

45 93.3 88.8

50 85.7 81.3

55 77.4 73.1

60 68.6 64.4

65 59.2 55.3

70 49.5 45.8

75 39.4 35.9

80 29.1 25.9

85 18.5 15.6

90 7.9 5.2

Datainstrument document W-130 H00 623, Date 26.06.06 Page 33 of 34

APPENDIX H: PROJECT SPECIFICATION

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

Crane specification

BOOM LENGTH: 118.80 Feet

LOAD SENSORS: Whip Line 1 Fall

Main Line 2, 4 & 6 Falls

MIPEG 2000 Non Recording System

LOAD CURVES: PLF(Static) & SEA(Dynamic)

WARNING LIMIT: 95% SWL

UNITS: Lbs / Ft

COMPUTER CABINET: Rittal AE1030, Safe area.

POWER SUPPLY: 85 - 240V ac

DIGITAL INPUT SIGNALS to MASTER II CARD

J13-2 INP#a : ON / OFFLINE SWITCH (in TR1)

J13-1 INP#b : spare

DIGITAL OUTPUT SIGNALS from MASTER II CARD

J13-3 OUT#10 : 95% SWL & Angle Limits - BUZZER

J13-4 OUT#11 : 110% SWL Horn & BOI - R1

J15-6 OUT#12 : High Boom Angle - R2

J15-7 OUT#13 : Low Boom Angle - R3

Datainstrument document W-130 H00 623, Date 26.06.06 Page 34 of 34

APPENDIX I : WIRING DIAGRAM

Cranes: SeaTrax Model 4228 : ONGC Sagar Kiran

You might also like

- Calibration of The Mipeg SystemDocument32 pagesCalibration of The Mipeg SystemJeneesh Shanmughan100% (2)

- Mipeg 2000 Installation GuideDocument17 pagesMipeg 2000 Installation GuideSatheesh VagiNo ratings yet

- zoomlion-truck-QY100 HDocument16 pageszoomlion-truck-QY100 Hالبديري بهاءNo ratings yet

- Pat Load Moment IndicatorDocument79 pagesPat Load Moment IndicatorWilson torresNo ratings yet

- I3000 RAYCOWYLIE Hyd RCI Cal PDFDocument59 pagesI3000 RAYCOWYLIE Hyd RCI Cal PDFraul80% (5)

- SLI ManualDocument142 pagesSLI ManualAnonymous 1ykzuaxWgY100% (1)

- NomenclatureDocument100 pagesNomenclaturejairsegura100% (4)

- XCMG QY50K Operation ManualDocument10 pagesXCMG QY50K Operation ManualElxan ShaheliyevNo ratings yet

- WTL-A700 LMI System Introduction For Crawler CraneDocument5 pagesWTL-A700 LMI System Introduction For Crawler Crane劉功暹No ratings yet

- Robway SLI ManualDocument135 pagesRobway SLI ManualBatagor H. Isan100% (1)

- I3000 Hyd RCI Cal PDFDocument59 pagesI3000 Hyd RCI Cal PDFLuis Arturo Arenales Mayta100% (1)

- Test Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Document3 pagesTest Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Ranil KanchanaNo ratings yet

- Crane SmartDocument60 pagesCrane SmartDatNo ratings yet

- W376 LMI ManualDocument33 pagesW376 LMI ManualAnonymous yjK3peI7100% (1)

- Pedestal Crane SpecDocument21 pagesPedestal Crane SpecYinka Akinkunmi100% (1)

- Mark 4E2 OperatorsDocument22 pagesMark 4E2 OperatorsRajan Mullappilly100% (2)

- Rt551 Lmi Greer 1Document40 pagesRt551 Lmi Greer 1George JhonsonNo ratings yet

- Rci-8510 A3 Graphical Cable-Based Display ManualDocument30 pagesRci-8510 A3 Graphical Cable-Based Display ManualMgc ElektronikNo ratings yet

- LMI Operators ManualDocument33 pagesLMI Operators ManualsobirinNo ratings yet

- Greer RCI510 Operators W450273ADocument33 pagesGreer RCI510 Operators W450273AAndres Florentin Pizarro LazarteNo ratings yet

- GROVE RT550E Operation ManualDocument530 pagesGROVE RT550E Operation Manualprashanth sreedharanNo ratings yet

- LSI LMI Calibration GuideDocument26 pagesLSI LMI Calibration GuideHussein BeqaiNo ratings yet

- Terex Rough Terrain Cranes Spec 77ad4a PDFDocument212 pagesTerex Rough Terrain Cranes Spec 77ad4a PDFGunawan WijayaNo ratings yet

- Crawler CraneDocument2 pagesCrawler CraneFarukBasyoriNo ratings yet

- Demag Ac 535 All Terrain CraneDocument20 pagesDemag Ac 535 All Terrain CranePamela Courson100% (1)

- 2-5 New Error Codes PDFDocument13 pages2-5 New Error Codes PDFdacem torres cruz100% (1)

- Load Chart GRT 880 - 236006-1Document18 pagesLoad Chart GRT 880 - 236006-1mohamedNo ratings yet

- Liebherr LTM1080-1 Load ChartDocument73 pagesLiebherr LTM1080-1 Load ChartBane Radovic100% (1)

- KATO NK 250 Ev PDFDocument3 pagesKATO NK 250 Ev PDFzam11050% (4)

- IFLEX2 ISCOUT Grove RT TM Service Manual English 1Document64 pagesIFLEX2 ISCOUT Grove RT TM Service Manual English 1Mohamed Rashed100% (1)

- PAT LMI System DS350GM Troubleshooting ManualDocument56 pagesPAT LMI System DS350GM Troubleshooting ManualCarlos E. Delius Sciaroni75% (4)

- CC2800 Hydraulic InteractivDocument31 pagesCC2800 Hydraulic InteractivDemian Leiva100% (2)

- Lmi OperationDocument24 pagesLmi OperationMohamed Rashed100% (2)

- Vessel Pedestal Crane Student ManualDocument19 pagesVessel Pedestal Crane Student Manualfafejaya1350% (2)

- Iflex5 XCMG Operators Manual English PDFDocument42 pagesIflex5 XCMG Operators Manual English PDFpurnomo100% (2)

- 21-Crane Inspection Check ListDocument2 pages21-Crane Inspection Check ListKhuda Buksh100% (1)

- FA150 Manrider Winch MHD56234 - Ed3Document69 pagesFA150 Manrider Winch MHD56234 - Ed3Riaz SpNo ratings yet

- Pat Iflex5Document83 pagesPat Iflex5aren_mendoza100% (3)

- 180 Ton LTM 1160-1 LiebherrDocument13 pages180 Ton LTM 1160-1 Liebherrcornel_lupuNo ratings yet

- Load Moment Indicator: iFLEX5Document44 pagesLoad Moment Indicator: iFLEX5Bhola BholaNo ratings yet

- Zcc800hcg Operating ManualDocument319 pagesZcc800hcg Operating Manualमुकेश कुमार झाNo ratings yet

- Product Advantages Mobile Crane LTM 1150/1Document5 pagesProduct Advantages Mobile Crane LTM 1150/1Liebherr100% (2)

- Sumitomo LS 248RH 5 PDFDocument22 pagesSumitomo LS 248RH 5 PDFJorge Barcelo0% (1)

- Cranes IntroductionDocument55 pagesCranes Introductiondsn_sarmaNo ratings yet

- Model m25 Free Fall Service ManualDocument44 pagesModel m25 Free Fall Service ManualManuel Rodriguez100% (1)

- Hitachi Sumitomo SCX2800 2 PDFDocument64 pagesHitachi Sumitomo SCX2800 2 PDFD Rider Casanova100% (1)

- MPH Crane Owners ManualDocument62 pagesMPH Crane Owners ManualVagabond HuynhNo ratings yet

- APE - Manual For200, 200T & 200-6-ADocument41 pagesAPE - Manual For200, 200T & 200-6-ALuis gamboa corderoNo ratings yet

- Link Belt Rough Terrain Cranes Spec 9d470bDocument96 pagesLink Belt Rough Terrain Cranes Spec 9d470bMauro BatalhaNo ratings yet

- UNIC Crane Maintenance Manual PDFDocument38 pagesUNIC Crane Maintenance Manual PDFMel Aliping100% (2)

- Crane Test ProgramDocument17 pagesCrane Test ProgramSONNo ratings yet

- Amphion Maintenance Student ManualDocument515 pagesAmphion Maintenance Student Manualmohamed mohsenNo ratings yet

- Training Program On Crane Basic: Module No: CHSEE-TM-39-L2Document78 pagesTraining Program On Crane Basic: Module No: CHSEE-TM-39-L2rR2CcNo ratings yet

- Drilling Rig PDFDocument464 pagesDrilling Rig PDFfranciscocarvajal15659267% (3)

- PAT DS 350G GW Service ManualDocument64 pagesPAT DS 350G GW Service Manualddedaniel100% (7)

- Mpi-540 Insobs v105 GBDocument212 pagesMpi-540 Insobs v105 GBBenet George VadakkemulanjanalNo ratings yet

- SCM-SCC Operations ManualDocument61 pagesSCM-SCC Operations ManualDaniel CastleNo ratings yet

- 14NL013-MNL-1410 (FT)Document144 pages14NL013-MNL-1410 (FT)hyarub9No ratings yet

- 3RG7843 enDocument62 pages3RG7843 enRaj ChavanNo ratings yet

- SUP-153 (EN) (Earthmoving) 22-185 PQDocument1 pageSUP-153 (EN) (Earthmoving) 22-185 PQNanang PhNo ratings yet

- Asme B30.9 Interpretations-1997Document20 pagesAsme B30.9 Interpretations-1997Nanang PhNo ratings yet

- HDDWFC Confirmed: Contact: Mr. Nanang Puji H Phone: 6282257555989Document1 pageHDDWFC Confirmed: Contact: Mr. Nanang Puji H Phone: 6282257555989Nanang PhNo ratings yet

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupDocument14 pagesPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhNo ratings yet

- Your Electronic Ticket Receipt MR HENDRA Y 2 NOV PDFDocument2 pagesYour Electronic Ticket Receipt MR HENDRA Y 2 NOV PDFNanang PhNo ratings yet

- Pressure Test in Accordance With The Standard Din en 13445: Inspecta GroupDocument14 pagesPressure Test in Accordance With The Standard Din en 13445: Inspecta GroupNanang PhNo ratings yet

- API 510 Study PlanDocument7 pagesAPI 510 Study Plankoib789100% (2)

- API 510 Study PlanDocument7 pagesAPI 510 Study Plankoib789100% (2)

- API ICP Contacts and FeedbackDocument1 pageAPI ICP Contacts and FeedbackNanang PhNo ratings yet

- Basics of Imperative Programming ParadigmDocument21 pagesBasics of Imperative Programming ParadigmShabari PrakashNo ratings yet

- Computational ThinkingDocument176 pagesComputational Thinkingazuanr830100% (1)

- Telit at Commands Reference Guide r12Document559 pagesTelit at Commands Reference Guide r12SidhuNo ratings yet

- MC-Module 3 - Written CommunicationDocument13 pagesMC-Module 3 - Written CommunicationCherianXavierNo ratings yet

- Handout For Technical English I IT ISCIM 19hhhDocument63 pagesHandout For Technical English I IT ISCIM 19hhhcornelio marcelinoNo ratings yet

- Alternador Honda LineasDocument2 pagesAlternador Honda LineasJames JonesNo ratings yet

- B.Tech. Engineering VII Semester (New Syllabus Wef 2018-19)Document4 pagesB.Tech. Engineering VII Semester (New Syllabus Wef 2018-19)kunalmotianNo ratings yet

- Concurrent DX 200Document359 pagesConcurrent DX 200AsuvathNo ratings yet

- Dell Service ManualDocument220 pagesDell Service ManualYeik ThaNo ratings yet

- Feynman Lectures On ComputationDocument324 pagesFeynman Lectures On Computationwhyatepie93% (44)

- CNC Macros PDFDocument91 pagesCNC Macros PDF27b7m2100% (6)

- INSTRUCTION: Please Choose The Letter of Your Answer and Encircle The Letter of Your AnswerDocument2 pagesINSTRUCTION: Please Choose The Letter of Your Answer and Encircle The Letter of Your AnswerMark Angelo CastanaresNo ratings yet

- C# - ClassesDocument207 pagesC# - Classesrogerkirk1100% (2)

- Computer Hardware Servicing NC II ExamDocument10 pagesComputer Hardware Servicing NC II ExamKristine CapaoNo ratings yet

- Bartending NC II CGDocument27 pagesBartending NC II CGMj Ortiz100% (1)

- How To Think Like A Computer Scientist - Learning With Python 3 PDFDocument354 pagesHow To Think Like A Computer Scientist - Learning With Python 3 PDFJerry Waxman100% (2)

- Programming and Data Structures: Debasis SamantaDocument63 pagesProgramming and Data Structures: Debasis SamantavittalNo ratings yet

- Information SystemDocument296 pagesInformation SystemSelamawit MekonnenNo ratings yet

- Strategic Renewal of OrganizationsDocument15 pagesStrategic Renewal of OrganizationsMichael LeungNo ratings yet

- Cloud ComputingDocument6 pagesCloud Computingsaurabh_maurya_5No ratings yet

- Pre Mechanicak PDFDocument52 pagesPre Mechanicak PDFCrazy MeNo ratings yet

- Chap 4 Internal ControlDocument23 pagesChap 4 Internal ControlAkash GuptaNo ratings yet

- A To Z Computer Abbreviations - Full Forms For Exams PDF DownloadDocument19 pagesA To Z Computer Abbreviations - Full Forms For Exams PDF DownloadrthrshhdNo ratings yet

- MarkDocument17 pagesMarkMutaawe MMarkNo ratings yet

- Chapter 12 Implications of Information Technology For The Audit ProcessDocument32 pagesChapter 12 Implications of Information Technology For The Audit ProcessYasmine MagdiNo ratings yet

- Basic Parts of A Computer SystemDocument34 pagesBasic Parts of A Computer SystemAMNo ratings yet

- The Information AgeDocument20 pagesThe Information AgeQuinne EstabilloNo ratings yet

- Computing Essentials 2017 26th Edition Oleary Test BankDocument33 pagesComputing Essentials 2017 26th Edition Oleary Test Bankvictoriaperkinsrzksfyjacx100% (33)

- Bachelor in Computer Science PDFDocument4 pagesBachelor in Computer Science PDFKiyanga MbodoNo ratings yet

- How Humor HealsDocument3 pagesHow Humor HealsJohn Michael RacelisNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- Design Research Through Practice: From the Lab, Field, and ShowroomFrom EverandDesign Research Through Practice: From the Lab, Field, and ShowroomRating: 3 out of 5 stars3/5 (7)