Professional Documents

Culture Documents

Trendvario: Product Data

Uploaded by

adasjkasdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trendvario: Product Data

Uploaded by

adasjkasdCopyright:

Available Formats

Page 1 of 6

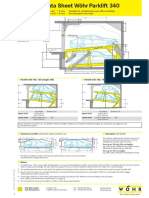

Page 1 Section Dimensions Car data Page 2 Width dimesions

Standard Type 4200

Detail X door dimensions see page 2 Free space 45 Free space

Upper floor (UF)

25

145

30 10

Product Data TrendVario

CONFORMITY

4200

ces eavier g spa h parkin handle Singlegraded to later date! p a u be loads at

le Loadab 0 kg 0 ,6 2 o to up can als

see page 2 Height (H) 1

Seite 3 Width dimesions Rails Tolerances

55

Number of parking spaces:

min. 3 to max. 29 vehicles

Ground floor (GF) Grounding 5

Delimitation 4

Dimensions:

Clear height (DH)

Seite 4 Approach Load plan Free spaces Function Page 5 Electric.data Techn. data To be performed by the customer Page 6 Description

All space requirements are minimum nished dimensions. Tolerances for space requirements +3 0 . Dimensions in cm.

Rail details see page 3 3 120 300 540 +5 0 for vehicle up to 5.00 m = 164 long (560 +5 0 for vehicle up to 5.20 m = 17 long)

Type DH* 4200 160 4200 175 4200 180 4200 185 4200 210 4200 215

* = without car

H 330 345 370 380 405 440

Suitable for: Compact Type 4200 Exclusive Type 4200

UF

Standard passenger car, station wagon/ Van. Height and length according to contur.

Height (H) 1

GF

DH

DH

GF

Height (H) 1

UF

Type 4200 4200 4200 4200 4200 4200

DH 160 175 180 185 210 215

H 330 345 370 380 405 440

car height UF GF 150 150 150 165 170 170 175 175 175 200 205 205

Notes

1 If height H is larger, vehicles with the maximum height as applicable for

width weight 6 wheel load

160

see table 100

190 cm max. 2000/2600 kg max. 500/650 kg

65 145

Standard passenger car the GF can be parked on the UF, otherwise there will be free space available on the ceiling.

2 In order to meet the minimum nished dimensions the tolerances according to

VOB, part C (DIN 18330 and 18331) as well as the DIN 18202 must be observed.

3 Tolerances for the evenness of the carriageway (oor) must be strictly complied with in

15

13

95 500 (520)

125

accordance with DIN (=German Industrial Standard) No. 18202, chart 3, line 3.

4 On the standard version without door, a 10 cm wide yellow-black markings compliant to

Standard station wagon/Van/SUV**

160

see table 105

30

5 Potential equalization from foundation grounding connection to system (provided

15

13

by the customer).

6 Maximum load of 2,600 kg for extra charge.

100 500 (520)

125

General notes

If sprinklers are required make sure to provide the necessary free spaces during the planning stage.

** = Make sure to observe the weights and dimensions!

Klaus Multiparking GmbH Hermann-Krum-Strae 2 D-88319 Aitrach Phone +49-75 65-5 08-0 Fax +49-75 65-5 08-88 E-Mail info@multiparking.com Internet www.multiparking.com

TrendVario 4200 | Code number 585.64.810-001 | Version 10.2010

Standard passenger car, station waggon/ Van/ SUV are vehicles without any sports options such as spoilers, low-prole tyres etc.

95

ISO 3864 must be applied by the customer to the edge of the platform in the access area to mark the danger zone in compliance with DIN EN 14 010 (see Width Dimensions Standard without Door page 2).

92 140

TrendVario 4200 | Code number 585.64.810-001 | Version 10.2010

Page 1 Section Dimensions Car data Page 2 Width dimesions

Page 2 of 6

Widths Detail X for garages without sliding doors (Standard)

Lowering of the platforms: via hold-to-run-device, lifting and shifting of the platforms: automatically. Without door Columns per each grid unit Markings compliant to ISO 3864

(Colors used in this illustration are not ISO 3864 compliant)

Columns every second grid unit 1

RB 10 H1

RB

RB 10

RB 10

RB

RB

RB

Seite 3 Width dimesions Rails Tolerances Seite 4 Approach Load plan Free spaces Function Page 5 Electric.data Techn. data To be performed by the customer Page 6 Description

length 540 (560)

Type 4200 4200 4200 4200 4200 4200 H 330 345 370 380 405 440 DH 160 175 180 185 210 215 H1 210 210 210 210 220 225

20 (B 2) B1 B2 no. of grids x RB + 20

grid unit width usable RB** platform width UF: 230 * GF: 220 250 GF: 230 UF: 240 260 GF: 240 UF: 250 270 GF: 250 UF: 260 280 GF: 260 UF: 270 290

Carriageway in accordance with local regulations

(B 2) B1 B2 no. of grids x RB + 20

grid unit width usable RB** platform width UF: 230 * GF: 220 250 GF: 230 UF: 240 260 GF: 240 UF: 250 270 GF: 250 UF: 260 280 GF: 260 UF: 270 290 B1 500 520 540 560 580

20

B1 250 260 270 280 290

B2 230 240 250 260 270

B2 480 500 520 540 560

Widths Detail X for garages with sliding doors (special model)

Lowering, lifting and shifting of the platforms: automatically. Sliding door behind columns Sliding door between columns 25 1 25 1 Sliding door in front of columns 25 1

H2

H1

length 540 (560)

Type 4200 4200 4200 4200 4200 4200 H 330 345 370 380 405 440 DH 160 175 180 185 210 215 H1 210 210 210 210 220 225

length 540 (560)

Type 4200 4200 4200 4200 4200 4200 H 330 345 370 380 405 440 DH 160 175 180 185 210 215 H2 220 220 220 220 230 235

length 540 (560)

Type 4200 4200 4200 4200 4200 4200 H 330 345 370 380 405 440 DH 160 175 180 185 210 215 H1 210 210 210 210 220 225 H2 220 220 220 220 230 235

Columns per each grid unit

Columns per each grid unit Not available!

Columns per each grid unit

10

20 (B 2) B1 B2 no. of grids x RB + 20

grid unit width usable RB** platform width UF: 230 * GF: 220 250 UF: 240 GF: 230 260 UF: 250 GF: 240 270 UF: 260 GF: 250 280 UF: 270 GF: 260 290

Carriageway in accordance with local regulations B1 250 260 270 280 2 290 B2 230 240 250 260 270

20 (B 6) B5 B6 no. of grids x RB + 20

usable grid unit width platform width RB** UF: 230 * GF: 220 250 UF: 240 GF: 230 260 UF: 250 GF: 240 270 UF: 260 GF: 250 280 UF: 270 GF: 260 290

(25) 1

Carriageway in accordance with local regulations B5 250 260 270 280 290 B6 230 240 250 260 270

RB 10

RB

RB

RB

H1

RB

RB

Columns every second grid unit

Columns every second grid unit

Columns every second grid unit

10 (B 4) B3 B4 no. of grids x RB + 20 20

10

(B 2) B1 B2 no. of grids x RB + 20

grid unit width usable RB** platform width UF: 230 * GF: 220 250 UF: 240 GF: 230 260 UF: 250 GF: 240 270 UF: 260 GF: 250 280 UF: 270 GF: 260 290 B1 500 520 540 560 580

20

Carriageway in accordance with local regulations B2 480 500 520 540 560 grid unit width usable RB** platform width UF: 230 * GF: 220 250 GF: 230 UF: 240 260 UF: 250 GF: 240 270 UF: 260 GF: 250 280 UF: 270 GF: 260 290 B3 500 520 540 560 580 B4 480 500 520 540 560

(B 6) B5 B6 no. of grids x RB + 20

grid unit width usable RB** platform width UF: 230 * GF: 220 250 GF: 230 UF: 240 260 UF: 250 GF: 240 270 UF: 260 GF: 250 280 UF: 270 GF: 260 290 B5 500 520 540 560 580

20

1 = Only applies to manually operated doors.

The electrically driven doors must have 35 cm. * = Standard width (parking space width 230 cm) ** = Grid unit width must strictly conform to dimensions quoted

End parking spaces are generally more difcult to drive into. Therefore we recommended for end parking spaces our wider platforms. Parking on standard width platforms with larger vehicles may make getting into and out of the vehicle difcult. This depends on type of vehicle, approach and above all on the individual drivers skill.

(25) 1

B6 480 500 520 540 560

RB 10

RB

RB

RB

RB

RB

RB

RB

RB

RB

RB

H2 RB

TrendVario 4200 | Code number 585.64.810-001 | Version 10.2010

Page 1 Section Dimensions Car data Page 2 Width dimesions

Page 3 of 6

Widths Detail X for garages with roll doors

Roll door behind columns 15 70 RB 35 10 RB RB Columns per each grid unit

Seite 3 Width dimesions Rails Tolerances Seite 4 Approach Load plan Free spaces Function Page 5 Electric.data Techn. data To be performed by the customer Page 6 Description

20 20 20 DF DF no. of grids x RB + 20

DH

H1

20

length 540 (560)

Type 4200 4200 4200 4200 4200 4200 H 330 345 370 380 405 440 DH 160 175 180 185 210 215 H1 210 210 220 210 220 225 roll door height 263 263 263 263 300 300

Carriageway in accordance with local regulations grid door entrance unit width width RB** DF 250 230 260 240 270 250 280 260 290 270

usable platform width UF: 230 * GF: 220 GF: 230 UF: 240 GF: 240 UF: 250 GF: 250 UF: 260 GF: 260 UF: 270

* = Standard width (parking space width 230 cm) ** = Grid unit width must strictly conform to dimensions quoted End parking spaces are generally more difcult to drive into. Therefore we recommended for end parking spaces our wider platforms. Parking on standard width platforms with larger vehicles may make getting into and out of the vehicle difcult. This depends on type of vehicle, approach and above all on the individual drivers skill.

Rail system

Dependent upon the structural conditions of the garage, several different options are available for installation of the rails: When executing the carriageway, according to raw bottom oor combined with a cement screed or When executing the carriageway with recesses for the rails: The set-up of the rails amounts to 3 cm (height of oor screed 4 cm) After the rails have eventually been laid, the area under the rails must be topped up with concrete by the customer 3 up to max. 5 1,5 6 Note: max. 5 Running rail Direction of parking top edge of finished floor Guide rail 1,5 Running rail 1,5 6 Exact evenness of the carriageway: When exact evenness of the carriageway has successfully been accomplished, the rails may be dowelled onto it 3 Direction of parking top edge of finished floor Guide rail 1,5 10 120 80

1

300

40

300 380

40

Note: Tolerances for the evenness of the carriageway must be strictly complied with in accordance with DIN (= German Industrial Standard) No. 18202, chart 3, line 3.

Evenness and Tolerances (abstract from DIN 18 202, table 3)

The distance between the lower ange of the platforms and the garage ground must therefore not exceed 2 cm. To adhere to the safety regulations and DIN EN 14 010 recommendations and to get the necessary even ground, the tolerances of evenness to DIN 18202, table 3, line 3, must not be exceeded. Therefore exact levelling of the ground by the client is essential.

Column

Vertical measurement as limits in mm with measuring points distances in m to*

Line 2

Reference Unnished to surface of covers, subconcrete and subsoils for higher demands, e.g. as foundation for cast plaster oor, industrial soils, paving tiles and slabstone paving, compund oor paving. Finished surfaces for minor purposes, e.g. warehouses, cellar. Finished grounds, e.g. oor pavement serving as foundation for coverings. Coverings, tile coverings, PVC ooring and glued coverings.

0.1 5

1 8

4 12

10 15

15 20

10

12

15

* = Intermediate values are to be taken out the diagram and must be rounded-off to mm

20 Tolerances in mm 15 10 5 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Distance between measuring points in m 21 22 23 24 25 26 27 28 29 30 Line 2 Line 3

TrendVario 4200 | Code number 585.64.810-001 | Version 10.2010

Page 1 Section Dimensions Car data Page 2 Width dimesions

Page 4 of 6

Approach

The illustrated maximum approach angles must not be exceeded. Incorrect approach angles will cause serious maneouvring & positioning problems on the parking system for which the local agency of Klaus accepts no responsibility. maximum descending slope 3 % maximum ascending slope 5 %

Seite 3 Width dimesions Rails Tolerances Seite 4 Approach Load plan Free spaces Function Page 5 Electric.data Techn. data To be performed by the customer Page 6 Description

Load plan

F1 Height see page 1 F5 F1 F2 F3 F4 165 DH+135 DH+50

F6 F7

DH: see page 1 The dimensions for the points of support are rounded values. If the exact position is required, please contact Klaus Multiparking.

6 540 (560) Load plan top view RB2 F2 F3 F1 RB F4 F3 F1

RB F4 F3 F1

RB F4 F3 F1

RB F4 F3 F1 F2

F5 F6 RB1

usable platform width UF: 230 * UF: 240 UF: 250 UF: 260 UF: 270 RB 250 260 270 280 290

F5 F7 RB

RB1 260 270 280 290 300 RB2 135 140 145 150 155

F5 F7 RB RB1

F1 2 2 F2 9 11 F3 +38 +41 F4 18 22 F5 approx. +0,5 approx. +0,5 F6 +9 7 +12 10 F7 +18 14 +24 20

F7 RB

F7

F6

platform load 2000 kg 2600 kg

* =Standard width

Forces in kN

The system is dowelled to oor and walls. The drilling depth in the oor is approx. 15 cm. The drilling depth in the walls is approx. 12 cm. Floor and walls are to be made of concrete (grade of concrete min. C20/25)!

Longitudinal free space; Standard parking space numbers; Denomination

10 RB 20 Longitudinal free space

Moving direction

Descending to entrance level (standard: Hold-to-rundevice) Transverse repositioning

45

1

Empty space

2 3

4 5

6 7

Entrance level

Upper floor Ground floor

Function of the Parking Automat

e.g. for parking space No. 4: Check rst that all doors are closed, then select No. 4 on operating panel.

2 3

4 5

1 3

2 5

1 3

2 5 4

For driving the vehicle off platform No. 4 the ground oor parking platforms are shifted to the left.

The empty space is now below the vehicle which shall be driven off the platform. The platform No. 4 will be lowered.

The vehicle on platform No. 4 can now be driven off the platform.

TrendVario 4200 | Code number 585.64.810-001 | Version 10.2010

Page 1 Section Dimensions Car data Page 2 Width dimesions

Page 5 of 6

Electrical data

Control box The control box must be accessible at all times from outside! Dimensions approx. 100 x 100 x 30 cm. Cutting through of wall from control box to parking system (contact the local agency of Klaus Multiparking for clarication) Electrical supply to the control box / Foundation earth connector Suitable electrical supply 5 x 2.5 mm2 (3 PH+N+PE) to control box with mains fuse 3 x 16 A slow or over-current cut-out 3 x 16 A trigger characteristic K or C. Suitable electrical supply to the control box must be provided by the customer during installation. The functionality can be monitored on site by our tters together with the electrician. If this cannot be done during installation for some reason for which the customer is responsible, the customer must commission an electrician at their own expense and risk. In accordance with DIN EN 60204 (Safety of Machinery. Electrical Equipment), grounding of the steel structure is necessary, provided by the customer (distance between grounding max. 10 m). Operating device Parking system fully visible from control box Easy-to-survey positioning (e.g. on column). Protection against unauthorized use. May also be recessed in wall if required.

Seite 3 Width dimesions Rails Tolerances Seite 4 Approach Load plan Free spaces Function Page 5 Electric.data Techn. data To be performed by the customer Page 6 Description

Cutting through

Technical data

Range of application Generally, this parking system is not suited for short-time parkers (temporary parkers). Please do not hesitate to contact your local KLAUS agency for further assistance. Available documents wall recess plans maintenance offer/contract declaration of conformity test sheet on airborne and slid-borne sound Sound insulation According to DIN 4109 (Sound insulation in buildings), para. 4, annotation 4, Klaus Multiparkers are part of the building services (garage systems). Normal sound insulation: DIN 4109, para. 4, Sound insulation against noises from building services. Table 4 in para. 4.1 contains the permissible sound level values emitted from building services for personal living and working areas. According to line 2 the maximum sound level in personal living and working areas must not exceed 30 dB (A). Noises created by users are not subject to the requirements (see table 4 , DIN 4109). The following measures are to be taken to comply with this value: Sound protection package according to offer/order (Klaus Multiparking GmbH) Minimum sound insulation of building Rw = 57 dB (to be provided by customer) Increased sound insulation (special agreement): DIN 4109, Amendment 2, Information on planning and execution, proposals for increased sound insulation. Agreement: Maximum sound level in personal living and working areas 25 dB (A). Noises created by users are not subject to the requirements (see table 4 , DIN 4109). The following measures are to be taken to comply with this value: Sound protection package according to offer/order (Klaus Multiparking GmbH) Minimum sound insulation of building Rw = 62 dB (to be provided by customer) Note: User noises are noises created by individual users in our Multiparking systems. These can be noises from accessing the platforms, slamming of vehicle doors, motor and brake noises.

Corrosion protection See separate sheet regarding corrosion protection. Environmental conditions Environmental conditions for the area of multiparking systems: Temperature range 10 to + 40 C. Relative humidity 50 % at a maximum outside temperature of + 40 C. If lifting or lowering times are specied, they refer to an environmental temperature of + 10 C and with the system set up directly next to the hydraulic unit. At lower temperatures or with longer hydraulic lines, these times increase. Electrically driven doors In accordance with ZH 1/494 commercially used power-driven doors must be subjected to annual inspections. We urgently recommend concluding a maintenance agreement that includes this service for the entire system. Numbering The standard numbering of the parking spaces is to be taken from page 3. Different numbering is only possible at extra cost. Please take note of the following specications: In general, the empty space must be arranged to the left. The numbers must be provided 8 10 weeks before the delivery date.

To be performed by the customer

Safety fences Any constraints that may be necessary according to DIN EN ISO 13857 in order to provide protection for the park pits for pathways directly in front, next to or behind the unit. This is also valid during construction. Numbering of parking spaces Consecutive numbering of parking spaces. Building services Lighting, ventilation, re extinguishing and re alarm systems. Marking According to DIN EN 14 010, a warning that identies this danger area must be placed in the entrance area that conforms to ISO 3864. This must be done according to EN 92/58/EWG for systems without a pit 10 cm from the edge of the platform. Wall cuttings Any necessary wall cuttings. Door shields Door shields that may be necessary. If desired, they can be ordered from Klaus Multiparking for an additional charge. Rails A bed should be installed and concrete should be poured around the rails installed by the manufacturer throughout their entire length. Tolerances The tolerances for levelness of the driving surface must conform to DIN 18202, tab. 3, line 3. If the following are not included in the quotation, they will also have to be provided / paid for by the customer: Costs for nal technical approval by an authorized body Electrical supply to the control box / Foundation earth connector Suitable electrical supply to the control box must be provided by the customer during installation. The functionality can be monitored on site by our tters together with the electrician. If this cannot be done during installation for some reason for which the customer is responsible, the customer must commission an electrician at their own expense and risk. In accordance with DIN EN 60204 (Safety of Machinery. Electrical Equipment), grounding of the steel structure is necessary, provided by the customer (distance between grounding max. 10 m).

TrendVario 4200 | Code number 585.64.810-001 | Version 10.2010

Page 1 Section Dimensions Car data Page 2 Width dimesions

Page 6 of 6

Description

General description Multiparking system providing independent parking spaces for cars, one on top of the other and side by side. Dimensions are in accordance with the underlying dimensions of height and width. The parking bays are accessed horinzotally (installation deviation 1 %). Along the complete width of the parking automat an approach lane (driving lane in accordance with local regulations) must be available. Parking spaces are arranged on two different levels, one level on top of the other. The platforms of the upper oor (UF) are moved vertically, the platforms on the ground oor (GF) horizontally. At approach level (GF) there is always one parking space less available. This vacant space is used for shifting the ground oor (GF) parking spaces sideways, thus enabling the upper platform (UF) parking space located above to be lowered to approach/ground level. Consequently, a unit of three parking spaces (1 on the ground oor, 2 on the upper oor) is the smallest unit available for this parking system. The TrendVario 4200 allows parking of passenger cars and station wagons. All necessary safety devices are installed. Safety devices mainly consist of chain monitoring system and locking levers for the upper platforms. Standard delivery is made without doors. The approach/entrance area to the parking automat is monitored via light barriers. If the light barrier is interrupted, the parking system stops moving instantly. A steel framework mounted to the oor consisting of: Seriated supports Steel pillars with sliding platform supports Cross and longitudinal members running rails for the transversely movable ground oor (GF) platforms Side members Cross members Platform base sections 1 wheel stop (on the right per parking space) Screws, small parts, etc. Hydraulic cylinder with solenoid valve Chain wheels Chains Limit switches The platforms are suspended on four points and guided along the supports using plastic sliding bearings Laterally movable doors Size Sliding door, dimensions: approx. 2500 mm x 2000 mm (width x height). Frame Frame construction with vertical centre stay bar made from extruded aluminium proles (anodized, layer thickness approx. 20 m) To open the doors a recessed grip is integrated in the aluminium prole. A rubber lip is used for the nishing of the closing edge to the building. Standard door panel Perforated steel plate Thickness 1 mm, RV 5/8, galvanized, layer thickness: approx. 20 m Ventilation cross-section of the panel approx. 40 % Not suitable for outdoor garages Alternative door panel Perforated aluminium plate Thickness 2 mm, RV 5/8 E6/EV1, anodized, layer thickness: approx. 20 m Ventilation cross-section of the panel approx. 40 % Beaded steel plate Thickness 1 mm, galvanized, layer thickness: approx. 20 m. additional power coating, layer thickness: approx. 25 m on the outside and approx. 12 m on the inside Colour options for the outside (building view): RAL 1015 (light ivory), RAL 3003 (ruby), RAL 5014 (pigeon blue), RAL 6005 (moss green), RAL 7016 (charcoal grey), RAL 7035 (light grey), RAL 7040 (window grey), RAL 8014 (sepia), RAL 9006 (white aluminium), RAL 9016 (trafc white) Inside of the gates in light grey Plain aluminium sheet Thickness 2 mm, E6/EV1, anodized, layer thickness: approx. 20 m Wooden panelling Nordic spruce in grade A vertical tongue and groove boards preimpregnated colourless Laminated safety glass Laminated safety glass made from single pane safety glass 8/4 mm Running rails The running gear of each doors consists of 2 twin-pair rolling gadgets, adjustable in height The running rails of the doors are xed to brackets or the concrete lintel, or on a building-specic door suspension using ceiling ttings The guide consists of 2 plastic rollers mounted to a base plate, which is dowelled to the oor Running rails, ceiling ttings and guide roller base plate are hot-dip galvanized Door actuation Standard: Manually, i.e. the door is opened and closed by hand Alternatively: Electric drive via electric motor mounted to the rail system at the turning point of the sliding doors. The drive pinion engages into the chain mounted to the door. For safety reasons the movement of the platforms is always made behind locked doors. Position sensing, i.e. door open and door closed is effected by electric signalers. Separation (if necessary): Upon request Please note: Door panels (on the side, cover for running rails, etc.) and door suspensions are not included in the standard version but can be delivered against surcharge as special equipment. Important! Systems in outside areas (not an underground garage): If doors are not installed and the system can be freely accessed, this presents a danger, for example for children playing, for which we will not be held liable. If the TrendVario 4200 is ordered without doors, the customer expressly accepts full liability without limitations and frees the supplier from all claims. In individual cases, we reserve the right to not accept the order. Additionally, wetness, cold, ice and snow can cause problems when driving into and out of parking spaces. The weather conditions listed previously can cause lasting damaTherefore, we recommend closed doors (not doors with wire mesh lling).

Seite 3 Width dimesions Rails Tolerances Seite 4 Approach Load plan Free spaces Function Page 5 Electric.data Techn. data To be performed by the customer Page 6 Description

Platforms consisting of:

Lifting device for upper oor (UF) platforms:

Drive unit of transversely movable platforms on the ground oor (GF): Gear motor with chain wheel Running and guide rollers (low-noise) Power supply via cable chain Hydraulic unit consisting of: Hydraulic power unit (low-noise, installed onto a console with a rubber-bonded-to-metal mounting) Hydraulic oil reservoir Oil lling Internal geared wheel pump Pump holder Clutch 3-phase-AC-motor (3.0 kW, 230/400 V, 50 Hz) Motor circuit breaker Test manometer Pressure relief valve Hydraulic hoses (which reduce noise transmission onto the hydraulic pipe Hold-to-run-device (standard): Operation on a central control panel (operating device) All movements are latched automatically, except for downward movement of an OG parking space, for which the start button must be continually pressed Electric wiring is made from the electric cabinet by the manufacturer Automatic control system (special design): Central control panel (operating device) used to select the desired parking space Here, it is necessary that a door system is installed in the entrance area. The doors are operated manually for a series system. If desired, this can also be done using electric motors. Electric wiring is made from the electric cabinet by the manufacturer

We reserve the right to change this specication without further notice

The Klaus company reserves the right in the course of technical progress to use newer or other technologies, systems, processes, procedures or standards in the fulllment of their obligations other than those originally offered provided the customer derives no disadvantage from their so doing.

You might also like

- Parking Automat Passable: Product DataDocument6 pagesParking Automat Passable: Product DatapoopoopoopooabcdNo ratings yet

- Basement Parking PDFDocument6 pagesBasement Parking PDFShameel PtNo ratings yet

- Page 1 Section Dimensions Car dataDocument5 pagesPage 1 Section Dimensions Car dataAlexandra SterescuNo ratings yet

- Stack Parker G61 Product DataDocument5 pagesStack Parker G61 Product DataDamian OvidiuNo ratings yet

- Whoer Hydr Car ParkDocument45 pagesWhoer Hydr Car ParkHeri SetyantoNo ratings yet

- Data Sheet for Wöhr Combilift 552 Parking SystemDocument6 pagesData Sheet for Wöhr Combilift 552 Parking SystemSima ViorelNo ratings yet

- Klaus MultiParkingDocument7 pagesKlaus MultiParkingLiviu ManescuNo ratings yet

- Single Unit 2 Cars Suitable For Condominium and Office Buildings. Double Unit 4 Cars For Permanent Use Only!Document6 pagesSingle Unit 2 Cars Suitable For Condominium and Office Buildings. Double Unit 4 Cars For Permanent Use Only!axel_ppNo ratings yet

- Ascensor MitsubishiDocument6 pagesAscensor MitsubishiRicardo ZapataNo ratings yet

- Tender Specification Klaus Multiparking Multibase 2072I Eb / Multibase 2072I DBDocument6 pagesTender Specification Klaus Multiparking Multibase 2072I Eb / Multibase 2072I DBama29No ratings yet

- SITE BOOK Quantity Take Off Details PDFDocument20 pagesSITE BOOK Quantity Take Off Details PDFkumaravajiraNo ratings yet

- Chassis Hookloader FMX 6x4Document10 pagesChassis Hookloader FMX 6x4Juan Manuel Villanueva uraccahuaNo ratings yet

- v2 EngDocument6 pagesv2 Engsharryjean balaneNo ratings yet

- Mobile Drilling Rig SpecsDocument52 pagesMobile Drilling Rig SpecsGregory StewartNo ratings yet

- Dependent Parking For Permanent User Only! : Function Width DimensionsDocument2 pagesDependent Parking For Permanent User Only! : Function Width DimensionsEduardo PujolNo ratings yet

- Blown Film CatalogueDocument12 pagesBlown Film CatalogueMohammad-reza NabavinezhadNo ratings yet

- 0 34 Chain Conveyor RL and RMDocument1 page0 34 Chain Conveyor RL and RMFlamingorosadoNo ratings yet

- Container SpecificationsDocument46 pagesContainer SpecificationsPARALELO10100% (1)

- Re76111 2007-08Document6 pagesRe76111 2007-08Pablo Flor ArgosNo ratings yet

- SB07 Quantity Take Off Details 04Document20 pagesSB07 Quantity Take Off Details 04Praveen SalindaNo ratings yet

- Series 500 NRA Specification For Road Works Drainage & Service DuctsDocument35 pagesSeries 500 NRA Specification For Road Works Drainage & Service DuctsJuanjo GonzalezNo ratings yet

- 3F Condulet Single Gang Cast Device Boxes: With and Without Mounting Lugs For Threaded Rigid and IMC ConduitDocument6 pages3F Condulet Single Gang Cast Device Boxes: With and Without Mounting Lugs For Threaded Rigid and IMC ConduitHenry MichaelNo ratings yet

- Demag Vinç BilgileriDocument28 pagesDemag Vinç BilgileriZahid ArıcıNo ratings yet

- Hormann Technical Manual For Industrial Sectional DoorDocument24 pagesHormann Technical Manual For Industrial Sectional Doorszeesther100% (1)

- 23 Cb2000 Ls Varmeca enDocument10 pages23 Cb2000 Ls Varmeca enFlying2eagleNo ratings yet

- 38mm Flooring Structural PerformanceDocument2 pages38mm Flooring Structural PerformancealpogaltreeNo ratings yet

- End Carriage DFW Bas LEDocument12 pagesEnd Carriage DFW Bas LEcutenganNo ratings yet

- RIG SPECS - 330 FT Independent Leg Jack-Up - NtyDocument32 pagesRIG SPECS - 330 FT Independent Leg Jack-Up - Ntycarlosfelix81No ratings yet

- Prezentare 2015-KlausDocument4 pagesPrezentare 2015-KlaussourcoufNo ratings yet

- ProductSupportGuide A2238CDocument20 pagesProductSupportGuide A2238CRicoh Company LtdNo ratings yet

- Guidelines For VNA (Very Narrow Aisle) Forklift and Racking System PDFDocument42 pagesGuidelines For VNA (Very Narrow Aisle) Forklift and Racking System PDFtuonghai67% (3)

- Manual DEMAG de Gruas Puente PDFDocument20 pagesManual DEMAG de Gruas Puente PDFDiego Lopez SolorzanoNo ratings yet

- V20 LaunchedDocument147 pagesV20 LaunchedNguyễn Viết HùngNo ratings yet

- Ladder and Self Closing Gate For Storage TankDocument15 pagesLadder and Self Closing Gate For Storage TankAkshat JainNo ratings yet

- Hydraulic Cylinder Mill Type: RE 17334/10.07 Replaces: 09.05Document44 pagesHydraulic Cylinder Mill Type: RE 17334/10.07 Replaces: 09.05Cristianovici RasinarNo ratings yet

- Cat 8L E Conductor Cables and Fittings PDFDocument28 pagesCat 8L E Conductor Cables and Fittings PDFMohamed MagdyNo ratings yet

- P-250iA™ Series Paint Robot: Basic DescriptionDocument4 pagesP-250iA™ Series Paint Robot: Basic DescriptionLuis LópezNo ratings yet

- Mechanistic Pavement Design Using IRC & AI MethodsDocument39 pagesMechanistic Pavement Design Using IRC & AI MethodsAmit Ruchi Yadav100% (1)

- Flexible Pavement Design For: No Thickness Adjustments Required Stabilized Base/Subbase Are RequiredDocument25 pagesFlexible Pavement Design For: No Thickness Adjustments Required Stabilized Base/Subbase Are RequiredJose Miguel Jimenez LopezNo ratings yet

- Vayu PDFDocument6 pagesVayu PDFYuppy KanalNo ratings yet

- TS - Lohata-Bhadoi 39 KM DoublingDocument125 pagesTS - Lohata-Bhadoi 39 KM DoublinggotosudNo ratings yet

- SingleVario2061 Product DataDocument13 pagesSingleVario2061 Product DataPetru CordosNo ratings yet

- Pavement Design PDFDocument8 pagesPavement Design PDFchandru187No ratings yet

- VayuDocument6 pagesVayuelangeeranNo ratings yet

- Daf Fa LF55 E15Document4 pagesDaf Fa LF55 E15javierluis83No ratings yet

- TrelleborgDocument10 pagesTrelleborgrofiqq4No ratings yet

- Bridge Model Estimate With Well FoundationDocument47 pagesBridge Model Estimate With Well Foundationsivabathy50% (6)

- Beams: Fittings & Technical GuideDocument20 pagesBeams: Fittings & Technical Guideohomele4424No ratings yet

- Multi V 3Document128 pagesMulti V 3giobuarNo ratings yet

- Automatic Horizontal Sliding Car Door: Residential Low Commercial Low Service LiftsDocument8 pagesAutomatic Horizontal Sliding Car Door: Residential Low Commercial Low Service LiftsSuresh SubbaiyanNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Exploring BeagleBone: Tools and Techniques for Building with Embedded LinuxFrom EverandExploring BeagleBone: Tools and Techniques for Building with Embedded LinuxRating: 4 out of 5 stars4/5 (2)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)