Professional Documents

Culture Documents

Types of Information: G Codes

Uploaded by

Cad CamacademyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Types of Information: G Codes

Uploaded by

Cad CamacademyCopyright:

Available Formats

G codes

http://westone.wa.gov.au/toolbox8/furniture/toolbox/shared/resource...

There are four main types of information you need to enter into the computer:

Types of information

Information Mechanical The mechanical actions required. Direction The direction of each movement. Dimensions The distance each movement travels. Example Turning on the spindle or the vacuum pump. Code M codes (machine functions) eg M93, M06 Cartesian (rectangular) co-ordinates expressed as axes (X,Y,Z) Expressed as millimetres and contain a decimal point eg X345.67 G codes (preparatory functions) eg G01, G02, G03, G00

Movement left or right, back or forward, up and down.

Appears after every axis designation

Movements A straight line, clockwise and The way movements take place. anti-clockwise curves and rapid feed.

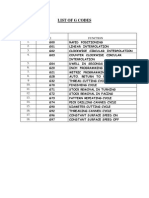

In this section we will look at Movements. There are many possible programmable movements using a CNC machine. Generally, they are either linear (straight line) or rotary (circular). G codes are used to determine the way movements take place. Below is a sample list of G codes. You can also find a more detailed list of G codes here. G code G00 G01 G02 G03 G04 G09 G17 G18 G19 G28 G40 G41 G42 07 00 02 00 01 Group Function Rapid positioning Linear interpolation (straight line) Circular interpolation CW (clockwise) Circular interpolation CCW (counter clockwise) Dwell Exact stop check XY plane selection XZ plane selection YZ plane selection Return to reference point Cutter compensation cancel Cutter compensation left Cutter compensation right

1 of 3

10/04/2013 05:57 PM

G codes

http://westone.wa.gov.au/toolbox8/furniture/toolbox/shared/resource...

G43 G44 G49 G61 G62 G64 G90 G91 G92 03 00 15 08

Tool length compensation + direction Tool length compensation direction Tool length compensation cancel Exact stop check mode Automatic corner over-ride effective Cutting mode Absolute programming Incremental programming Programming of absolute zero point

Each G code has three characters, so usually G1 must be expressed as G01. However, newer controllers will accept two characters such as G0, G1, G2, G3.

No two codes from the same group can be used on the same program line. For example, the codes G90 and G91 are for identifying absolute and incremental measurements and only one type can be selected. One code tells the computer to measure from a fixed point (G90, absolute) and the other code tells the computer to measure from the tool's current position (G91, incremental).

Whether using absolute or incremental modes, it is necessary to begin each program cycle with the table and carriage in the home (or zero) position on the CNC machine.

G codes may differ on each CNC machine. It is vital that you become familiar with the list specific to the machine you are working with. Below is a brief explanation of each group G00 to G03 G04 and G09 G17 to G19 G28 G40 to G42 G43, G44 and G49 G61 and G64 G90 and G91 G92 tool movement codes pause codes plane selection codes a return code used at the end of program tool radius codes tool length codes allow for continuous or stop each line movement identify absolute and incremental measurements will set a zero or start point

2 of 3

10/04/2013 05:57 PM

G codes

http://westone.wa.gov.au/toolbox8/furniture/toolbox/shared/resource...

You should always refer to your machine manual as G codes may vary on different machines.

3 of 3

10/04/2013 05:57 PM

You might also like

- Standard G and M Codes for CNC ProgrammingDocument2 pagesStandard G and M Codes for CNC ProgrammingRamesh PariharNo ratings yet

- G Codes and M CodesDocument10 pagesG Codes and M CodesHarsh YadavNo ratings yet

- Getting Started With CNC GcodeDocument7 pagesGetting Started With CNC Gcodeleonard1971No ratings yet

- CNC CodesDocument8 pagesCNC CodesKevin DebryuneNo ratings yet

- Code Description Milling (M) Turning (T) Corollary InfoDocument11 pagesCode Description Milling (M) Turning (T) Corollary InfoDilshad MalikNo ratings yet

- CNC Unit 3Document39 pagesCNC Unit 3rahul bhattNo ratings yet

- CNC Programming FundamentalsDocument26 pagesCNC Programming Fundamentalsmohamed alsalhyNo ratings yet

- Specific Codes: Letter AddressesDocument16 pagesSpecific Codes: Letter AddressesVijay KumarNo ratings yet

- 2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Document59 pages2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Srinivas YadavNo ratings yet

- Code Description Milling (M) Turning (T) Corollary InfoDocument5 pagesCode Description Milling (M) Turning (T) Corollary InfoivtrubeljaNo ratings yet

- (G-Codes Vary From Machine To Machine) : Standard G Code Chart For LathesDocument8 pages(G-Codes Vary From Machine To Machine) : Standard G Code Chart For LathesTeguh Dc100% (1)

- G-Code Table Explains Numerical Control AddressingDocument3 pagesG-Code Table Explains Numerical Control AddressingBradley VidañaNo ratings yet

- 3.1 G and M Codes On The Emco Compact 5 CNC Lathes: 3.4.1 Summary of CommandsDocument17 pages3.1 G and M Codes On The Emco Compact 5 CNC Lathes: 3.4.1 Summary of CommandsFilipe RosaNo ratings yet

- LAB 5 - Coding LectureDocument16 pagesLAB 5 - Coding LectureHusnain AliNo ratings yet

- CNC Machine Language G Code ListDocument3 pagesCNC Machine Language G Code ListJules OlivierNo ratings yet

- G and M Codes For CNC LatheDocument8 pagesG and M Codes For CNC LatheLuis Gonzalo Castañeda GalindoNo ratings yet

- New Microsoft Word DocumentDocument19 pagesNew Microsoft Word DocumentŤhåýğųŢjNo ratings yet

- G-Code For CNC MachineDocument13 pagesG-Code For CNC MachinezokiplusNo ratings yet

- Listă G Codu UriDocument30 pagesListă G Codu UriAlexdruNo ratings yet

- Basic Information of CNC ProgramDocument16 pagesBasic Information of CNC Programjawad khalidNo ratings yet

- Me 473 - Unit 4 - 1Document70 pagesMe 473 - Unit 4 - 1Ama Serwaa YeboahNo ratings yet

- G-Code - Wikipedia, The Free EncyclopediaDocument6 pagesG-Code - Wikipedia, The Free EncyclopediajoydeepNo ratings yet

- G Code CommandsDocument6 pagesG Code CommandsFida HussainNo ratings yet

- Generalni CNC KodoviDocument2 pagesGeneralni CNC KodoviLeo MilosevNo ratings yet

- Axis positions, feedrates, tool offsets and more for CNC machiningDocument13 pagesAxis positions, feedrates, tool offsets and more for CNC machiningzokiplusNo ratings yet

- Yashwant InternshipDocument17 pagesYashwant InternshipGoku RocksNo ratings yet

- List of G Codes: SR - NO. Code Function 1. 2. 3. 4Document28 pagesList of G Codes: SR - NO. Code Function 1. 2. 3. 4pmagrawal100% (1)

- G CodesDocument24 pagesG CodesJohn Gilbert CalixtoNo ratings yet

- CNC Codes and LettersDocument48 pagesCNC Codes and LettersJag DeshNo ratings yet

- A New PetrolDocument9 pagesA New PetrolMariano Escobar AvilaNo ratings yet

- Experiment P3 CNC Machining: ObjectiveDocument13 pagesExperiment P3 CNC Machining: ObjectivePhạm Ngọc HòaNo ratings yet

- Lathe GCode ProgrammingDocument89 pagesLathe GCode ProgrammingluisNo ratings yet

- Jm201 - CNC MillingDocument24 pagesJm201 - CNC MillingMuhd Zulhusni Ag Jaludin100% (1)

- CNC ProgDocument38 pagesCNC ProgPoornima JoshiNo ratings yet

- CADCAM Intro1Document10 pagesCADCAM Intro1Yousef AshryNo ratings yet

- Turning: Chapter ObjectivesDocument78 pagesTurning: Chapter ObjectivesDany EscobarNo ratings yet

- Manufacturing Technology - CNC Machining and Other CNC ApplicationsDocument46 pagesManufacturing Technology - CNC Machining and Other CNC ApplicationsDhanis ParamaguruNo ratings yet

- G-code Programming Language GuideDocument16 pagesG-code Programming Language GuideArnold NagyNo ratings yet

- G Code WikiDocument19 pagesG Code WikiShaukat Ali ShahNo ratings yet

- CNC Part Programming IDocument9 pagesCNC Part Programming IRajendra Kumar YadavNo ratings yet

- Mach4 Mill GCode ManualDocument60 pagesMach4 Mill GCode Manualsahiljain_146No ratings yet

- Mach4 Mill GCode Manual PDFDocument60 pagesMach4 Mill GCode Manual PDFDao - Ngoc LamNo ratings yet

- My Summer Internship (Autosaved)Document15 pagesMy Summer Internship (Autosaved)Akarsh DaradNo ratings yet

- Mach4 G and M Code Reference ManualDocument81 pagesMach4 G and M Code Reference ManualMegi Setiawan SNo ratings yet

- G CodesDocument8 pagesG Codesdinesh2705No ratings yet

- Mach4 G and M Code Reference ManualDocument60 pagesMach4 G and M Code Reference ManualRAKESH PRAJAPATI100% (1)

- 5 PPDocument48 pages5 PPPatel NikhilNo ratings yet

- Lecture Cad CamDocument84 pagesLecture Cad Camismail_69No ratings yet

- CAM Lab Manual Expereiment - 10-13 - CAMDocument9 pagesCAM Lab Manual Expereiment - 10-13 - CAMmilanmottaNo ratings yet

- G-Code - Wikipedia, The Free EncyclopediaDocument21 pagesG-Code - Wikipedia, The Free Encyclopediabeta2009No ratings yet

- Fanuc BasicDocument0 pagesFanuc BasicMarco A. Miranda RamírezNo ratings yet

- Nota What Is CNCDocument5 pagesNota What Is CNCKebal BostNo ratings yet

- 240 Basic G CodesDocument11 pages240 Basic G CodesFranklin EstévezNo ratings yet

- NC PRGDocument9 pagesNC PRGNAGU2009No ratings yet

- CNC Programming Turning GuideDocument9 pagesCNC Programming Turning GuideG. Dancer GhNo ratings yet

- Chapter 6Document56 pagesChapter 6gashawletaNo ratings yet

- Haas TM-1P CNC Machining Center Peck Drilling ProgramDocument3 pagesHaas TM-1P CNC Machining Center Peck Drilling ProgramSabir AliNo ratings yet

- Cutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryFrom EverandCutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryRating: 2 out of 5 stars2/5 (1)

- Autocad PDFDocument35 pagesAutocad PDFHarsh SharmaNo ratings yet

- Building Drawing - 1Document6 pagesBuilding Drawing - 1Vigneshwaran SrinivasanNo ratings yet

- Autocad Work BookDocument163 pagesAutocad Work BookCad CamacademyNo ratings yet

- How to solve probability and math word problemsDocument89 pagesHow to solve probability and math word problemsAbhijeet DhendeNo ratings yet

- Cad - CamDocument10 pagesCad - CamCad Camacademy100% (1)

- Types of Information: G CodesDocument3 pagesTypes of Information: G CodesCad CamacademyNo ratings yet