Professional Documents

Culture Documents

31 Brinker Proposed Design Standard For Towers

31 Brinker Proposed Design Standard For Towers

Uploaded by

silvereyes18Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

31 Brinker Proposed Design Standard For Towers

31 Brinker Proposed Design Standard For Towers

Uploaded by

silvereyes18Copyright:

Available Formats

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

ANSI/TIA STANDARD DESIGN SUPPLEMENT

Design Supplement for Small Wind Turbine Support Structures

TIA-222-G-DS1

Draft 3-29-2011 Rev 0

TELECOMMUNICATIONS INDUSTRY ASSOCIATION

TR14.7 Sub-committee tiaonline.org

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

NOTICE OF COPYRIGHT

This document is copyrighted by the TIA.

Reproduction of these documents either in hard copy or soft copy (including posting on the web) is prohibited without copyright permission. For copyright permission to reproduce portions of this document, please contact TIA Standards Department or go to the TIA website (www.tiaonline.org) for details on how to request permission. Details are located at: http://www.tiaonline.org/standards/catalog/info.cfm#copyright OR Telecommunications Industry Association Standards & Technology Department 2500 Wilson Boulevard, Suite 300 Arlington, VA 22201 USA +1(703)907-7700 Organizations may obtain permission to reproduce a limited number of copies by entering into a license agreement. For information, contact: IHS 15 Inverness Way East Englewood, CO 80112-5704 or call U.S.A. and Canada (1-800-525-7052) International (303-790-0600)

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

NOTICE OF DISCLAIMER AND LIMITATION OF LIABILITY The document to which this Notice is affixed (the Document) has been prepared by one or more Engineering Committees or Formulating Groups of the Telecommunications Industry Association (TIA). TIA is not the author of the Document contents, but publishes and claims copyright to the Document pursuant to licenses and permission granted by the authors of the contents. TIA Engineering Committees and Formulating Groups are expected to conduct their affairs in accordance with the TIA Engineering Manual (Manual), the current and predecessor versions of which are available at http://www.tiaonline.org/standards/procedures/manuals/ TIAs function is to administer the process, but not the content, of document preparation in accordance with the Manual and, when appropriate, the policies and procedures of the American National Standards Institute (ANSI). TIA does not evaluate, test, verify or investigate the information, accuracy, soundness, or credibility of the contents of the Document. In publishing the Document, TIA disclaims any undertaking to perform any duty owed to or for anyone. If the Document is identified or marked as a project number (PN) document, or as a standards proposal (SP) document, persons or parties reading or in any way interested in the Document are cautioned that: (a) the Document is a proposal; (b) there is no assurance that the Document will be approved by any Committee of TIA or any other body in its present or any other form; (c) the Document may be amended, modified or changed in the standards development or any editing process. The use or practice of contents of this Document may involve the use of intellectual property rights (IPR), including pending or issued patents, or copyrights, owned by one or more parties. TIA makes no search or investigation for IPR. When IPR consisting of patents and published pending patent applications are claimed and called to TIAs attention, a statement from the holder thereof is requested, all in accordance with the Manual. TIA takes no position with reference to, and disclaims any obligation to investigate or inquire into, the scope or validity of any claims of IPR. TIA will neither be a party to discussions of any licensing terms or conditions, which are instead left to the parties involved, nor will TIA opine or judge whether proposed licensing terms or conditions are reasonable or non-discriminatory. TIA does not warrant or represent that procedures or practices suggested or provided in the Manual have been complied with as respects the Document or its contents. If the Document contains one or more Normative References to a document published by another organization (other SSO) engaged in the formulation, development or publication of standards (whether designated as a standard, specification, recommendation or otherwise), whether such reference consists of mandatory, alternate or optional elements (as defined in the TIA Engineering Manual, 4th edition) then (i) TIA disclaims any duty or obligation to search or investigate the records of any other SSO for IPR or letters of assurance relating to any such Normative Reference; (ii) TIAs policy of

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

encouragement of voluntary disclosure (see Engineering Manual Section 6.5.1) of Essential Patent(s) and published pending patent applications shall apply; and (iii) Information as to claims of IPR in the records or publications of the other SSO shall not constitute identification to TIA of a claim of Essential Patent(s) or published pending patent applications. TIA does not enforce or monitor compliance with the contents of the Document. TIA does not certify, inspect, test or otherwise investigate products, designs or services or any claims of compliance with the contents of the Document. ALL WARRANTIES, EXPRESS OR IMPLIED, ARE DISCLAIMED, INCLUDING WITHOUT LIMITATION, ANY AND ALL WARRANTIES CONCERNING THE ACCURACY OF THE CONTENTS, ITS FITNESS OR APPROPRIATENESS FOR A PARTICULAR PURPOSE OR USE, ITS MERCHANTABILITY AND ITS NONINFRINGEMENT OF ANY THIRD PARTYS INTELLECTUAL PROPERTY RIGHTS. TIA EXPRESSLY DISCLAIMS ANY AND ALL RESPONSIBILITIES FOR THE ACCURACY OF THE CONTENTS AND MAKES NO REPRESENTATIONS OR WARRANTIES REGARDING THE CONTENTS COMPLIANCE WITH ANY APPLICABLE STATUTE, RULE OR REGULATION, OR THE SAFETY OR HEALTH EFFECTS OF THE CONTENTS OR ANY PRODUCT OR SERVICE REFERRED TO IN THE DOCUMENT OR PRODUCED OR RENDERED TO COMPLY WITH THE CONTENTS. TIA SHALL NOT BE LIABLE FOR ANY AND ALL DAMAGES, DIRECT OR INDIRECT, ARISING FROM OR RELATING TO ANY USE OF THE CONTENTS CONTAINED HEREIN, INCLUDING WITHOUT LIMITATION ANY AND ALL INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS, LOSS OF PROFITS, LITIGATION, OR THE LIKE), WHETHER BASED UPON BREACH OF CONTRACT, BREACH OF WARRANTY, TORT (INCLUDING NEGLIGENCE), PRODUCT LIABILITY OR OTHERWISE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THE FOREGOING NEGATION OF DAMAGES IS A FUNDAMENTAL ELEMENT OF THE USE OF THE CONTENTS HEREOF, AND THESE CONTENTS WOULD NOT BE PUBLISHED BY TIA WITHOUT SUCH LIMITATIONS.

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

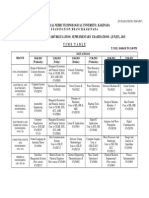

SMALL WIND TURBINE SUPPORT STRUCTURES TABLE OF CONTENTS

OBJECTIVE SCOPE 1.0 GENERAL 2.0 TURBINE MANUFACTURER DATA 3.0 EFFECTIVE PROJECTED AREA 4.0 DRAG FACTORS FOR POLE STRUCTURES 5.0 EXTREME WIND CONDITION 6.0 EXTREME ICE CONDITION 7.0 EXTREME EARTHQUAKE CONDITION 8.0 CRITICAL TURBINE MOMENTS 9.0 SERVICEABILITY REQUIREMENT 10.0 DYNAMIC REQUIREMENTS 11.0 FATIGUE STRENGTH 12.0 OTHER STRUCTURAL MATERIAL 13.0 FOUNDATIONS 14.0 MAINTENANCE AND MATERIAL ASSESSMENT REFERENCE TABLES ANNEX A: REFERENCES (INFORMATIVE) 2 2 2 4 4 5 5 5 5 6 6 6 7 12 12 13 14 17

Note: Informative annexes contain additional information that are not considered part of the standard.

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

Small Wind Turbine Support Structures

OBJECTIVE The objective of this Design Supplement is to provide recognized literature intended to be used in conjunction with the ANSI/TIA-222-G Standard, Structural Standard for Antenna Supporting Structures and Antennas (TIA) for the design and analysis of structures supporting Small Wind Turbines (SWTs) defined as wind turbines with rotor swept areas less than 2,200 sq. ft. [200 sq. m]. This Design Supplement defines how specific portions of the TIA Standard shall be applied to SWT supporting structures and provides supplementary requirements that pertain specifically to the unique characteristics of SWT supporting structures. The provisions of this Design Supplement are intended to be used for the development of standard designs for SWT supporting structures and for the design and analysis of site-specific structures. SCOPE This Design Supplement is intended to apply to self-supporting or bracketed latticed towers, guyed masts and pole structures that support single or multiple SWTs that may also support antennas and other appurtenances. The design and analysis of turbine components are not included within the scope of this Design Supplement. 1.0 GENERAL 1.1 Design Criteria SWT supporting structures shall be in conformance with the requirements of TIA and the additional supplementary requirements of this Design Supplement. The design parameters used for standard designs for SWT supporting structures developed in accordance with this Design Supplement shall be verified prior to installation. Conformance to this Design Supplement is not required for structures supporting wind turbines with rotor swept areas less than 22 sq. ft. [2 sq. m]. Structures supporting turbines with rotor swept areas less than 22 sq. ft. [2 sq. m] may be designed and/or analyzed in accordance with the TIA Standard with each turbine considered as an appurtenance. The effective projected area of each turbine shall be determined in accordance with TIA Section 3.0. The effective projected area shall be considered to be constant for all wind directions. The wind force based on the effective projected area of each turbine shall be considered as a wind load using a load factor equal to 1.6 and a wake interference factor, Ka, equal to 1.0.

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

1.2 Turbine Model For all loading conditions with the exception of fatigue, a turbine shall be modeled as a mass and an effective projected area. Unless otherwise specified, the center of mass and the centroid of the effective projected area shall be considered to be at the hub height of the turbine and assumed to be distributed symmetrically about the vertical centerline of the turbine base. When a horizontal offset of the center of mass from the vertical centerline of the turbine base is specified by the turbine manufacturer, the additional overturning moment on the supporting structure due to turbine weight shall be considered to occur in the direction which adds to the overturning moment from the horizontal turbine thrust. For fatigue loading, unless otherwise specified, the turbine effective projected area shall be replaced with the equivalent constant range fatigue loads determined in accordance with Section 11.0. For the purpose of determining factored extreme loading conditions, turbine weight shall be considered a dead load and turbine forces and moments shall be considered as wind loads. 1.3 Definitions Equivalent constant range load: a constant amplitude load range intended to represent the fatigue effects of actual variable amplitude loading events. Flange plate: a base, top or intermediate flange welded to a latticed tower leg or pole structure. Hub height above turbine base: the height of the center of the wind turbine rotor above the turbine base. Initial tension condition: the equilibrium position of a guyed mast (with corresponding forces in the components of the mast) with guys at their specified installation tension. Turbine base: the base of the turbine that interfaces with the supporting structure. 1.4 Abbreviations AISC AWEA AWS SWT TIA American Institute of Steel Construction Manual, 13th Edition American Wind Energy Association Standard AWEA 9.1-2009 American Welding Society Standard AWS D1.1/D1.1M:2010 Small Wind Turbine Telecommunications Industry Association Standard ANSI/TIA-222-G

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

2.0 TURBINE MANUFACTURER DATA The following turbine data shall be provided by the turbine manufacturer: 1. 2. 3. 4. 5. 6. Type of turbine: horizontal or vertical axis machine Rotor diameter, ft [m] Rotational Rotor Speed at electrical power rating of turbine, RPM Hub height above turbine base, ft [m] Maximum turbine horizontal thrust (unfactored), Lb [N] Wind speed at hub height associated with the specified maximum turbine horizontal thrust, mph [m/s] 7. Weight of turbine, Lb [N] 8. Horizontal offset of turbine weight from vertical centerline of turbine base, ft [m] 9. Weight of rotor (blades and hub), Lb [N] 10. Distance from center of rotor mass to vertical centerline of turbine base, ft [m] 11. Clearance requirements of turbine blades to the supporting structure (considering deflected shape of blades under wind loading) 12. Connection details for the turbine base 13. Natural frequency limitations of the supporting structure, Hertz EFFECTIVE PROJECTED AREA

3.0

The effective projected area of a turbine shall be calculated in accordance with this Section unless the effective projected area of the turbine is specified by the turbine manufacturer. The effective projected area of a turbine shall be considered to be constant for all wind directions with a wake interference factor, Ka, equal to 1.0. Unless otherwise specified by the turbine manufacturer, the effective projected area of the turbine, (EPA)T, shall be calculated in accordance with the following equation n: (EPA)T = Fmaxt (ft)2 0.00256(Vmax)2 Fmaxt (m)2 2 0.613(Vmax)

(EPA)T = where:

Fmaxt = maximum unfactored horizontal turbine thrust, lbs [N] Vht = wind speed at hub height associated with the specified maximum turbine horizontal thrust, mph [m/s]

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

4.0 DRAG FACTORS FOR POLE STRUCUTRES The TIA drag factors for pole structures consider a minimum level of roughness due to attachments common to communication structures. For SWT supporting pole structures without appurtenances attached along their height, the drag factors specified in Table 2.0 may be used in place of the TIA drag factors. 5.0 EXTREME WIND CONDITION The TIA basic wind speed (50-year return, 3-second gust at 10 m height) used for investigating the TIA extreme wind condition shall be the larger of the basic wind speed specified by the turbine manufacture, the basic wind speed for the site and 110 mph [50 m/s]. Note: The fatigue investigation criteria specified in Section 11.0 is based on the supporting structure satisfying a minimum strength requirements equivalent to a 110 mph [50 m/s] design basic wind speed, exposure category C. Lower strength requirements would require extensive fatigue investigations of the supporting structure that are not within the scope of this Design Supplement. 6.0 EXTREME ICE CONDITION The design ice thickness and corresponding basic wind speed shall be determined from the TIA Standard when a specific site location is specified. The default design ice thickness for standard designs shall be 1 inch [25 mm] occurring simultaneously with a 40 mph [18 m/s] basic wind speed. Unless more accurate data is provided for the turbine, the weight of the turbine shall be increased 25% and the calculated (EPA)T of the turbine shall be increased 15% from the no-ice condition. 7.0 EXTREME EARTHQUAKE CONDITION The operational loads of the turbine shall be considered insignificant compared to earthquake loading due to the mass of the turbine and the supporting structure. Operational loading need not be considered to occur simultaneously with earthquake loading. The masses of the turbine, the structure and all appurtenances shall be included in the determination of earthquake loading. The default spectral response at short periods (Ss) shall be considered as 0.60. Earthquake analysis in accordance with TIA shall be required for SWT supporting structures located in areas with Ss values greater than 0.60. Note: SWT supporting structures have a lower Ss threshold value compared to antenna supporting structures.

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

8.0 CRITICAL TURBINE MOMENTS Unless otherwise specified by the turbine manufacturer, the extreme wind condition shall be assumed to govern over other turbine operational loading conditions that subject the supporting structure to an overturning or twisting moment. These conditions include braking, shorts, shut down, maximum rotational speed condition, extreme yawing, etc. When a critical turbine moment is specified by the turbine manufacturer, the moment shall be investigated by considering an additional extreme wind loading condition without ice. Unless otherwise specified, the specified moment shall be considered to occur simultaneously with a 25 mph [11 m/s] basic wind speed with the calculated effective projected area of the turbine (EPA)T and the TIA importance factor, I, for wind load without ice, based on the structure classification. Unless otherwise specified, a load factor of 1.6 shall be applied to the specified moment. A specified overturning moment shall be considered to occur at the top of the structure in the same direction as the wind. A specified twisting (yaw) moment shall be considered to act about the vertical centerline of the turbine base in a counterclockwise direction in the plan view. 9.0 SERVICEABILITY REQUIREMENT Unless otherwise specified, the stiffness of the supporting structure shall result in a tip deflection no greater than 1% of the structure height for the TIA service loading condition (60 mph [27 m/s] basic wind speed without ice) with the calculated effective projected area of the turbine (EPA)T. 10.0 DYNAMIC REQUIREMENTS The natural frequency modes involving single, double and triple curvature of the supporting structure shall be determined for a no-ice condition when natural frequencies of the support structure to be avoided are specified by the turbine manufacturer. One of the elastic three-dimensional models specified in TIA shall be used to determine the fundamental frequency modes. The simplified TIA fundamental frequency equations shall not be used for SWT supporting structures. The masses of the turbine, the structure and all appurtenances shall be included in the structural model at the proper locations. Unless a detailed analysis is undertaken to determine an appropriate foundation spring constant to be used in the determination of natural frequencies, the calculated natural frequencies of the structure shall be adjusted +/- 10% for comparison to the turbine manufacturers specified natural frequencies. When frequency ranges or min/max frequencies are provided by the turbine manufacturer, no adjustments to the calculated natural frequencies of the supporting structure are required. Note: Natural frequency modes involving torsion may require investigation for vertical axis turbines when specified by the turbine manufacturer.

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

11.0 FATIGUE STRENGTH 11.1 Equivalent Constant Range Wind Loading on Supporting Structure Unless otherwise specified, fatigue wind loading on the supporting structure and supported appurtenances (excluding the turbine) shall be considered as an additional service loading combination (Kfd = 0.85 for all structures) using a 30 mph [13 m/s] uniform wind speed (Kz, Kzt and Gh equal to 1.0) and the importance factor for fatigue loading specified in Table 11-1 based on the TIA structure classification for the supporting structure. The fatigue loading on the supporting structure shall be considered to occur simultaneously with the equivalent constant range turbine loads specified in Section 11.2. 11.2 Equivalent Constant Range Turbine Loads Equivalent constant range fatigue loads for horizontal axis turbines shall be calculated from the following equations: Fxt = equivalent constant range turbine horizontal force, lbs [N] = (Kfd)(If)(Cfxt)(Dr)2 Mty = equivalent constant range turbine overturning moment, ft-lbs [N-m] = (Kfd)[2(Wtr)(Lrc) + (Dr)(Fxt) / 12] Mtx = equivalent constant range turbine shaft torsion, ft-lbs, [N-m] = (Kfd)[(If)(Cmtx)(Dr)2 / Nr + 0.005(Wtr)(Dr)] where: Kfd If Cfxt Dr Wtr Lrc Cmtx Nr = 0.85 = importance factor for fatigue from Table 11-1 = 1.0 [48] = rotor diameter, ft [m] = weight of rotor (hub and blades), lbs [N] = distance between center of gravity of rotor and centerline of the supporting structure, ft [m] = 275 [4000] = rotor rotational speed, rpm

Note: Kfd accounts for the probability of the applied load range occurring form a direction that creates a response in any one given support structure component. The horizontal force, Fxt, shall be applied concentrically in the direction of the wind at the hub height of the turbine. The overturning moment, Mty, shall be applied at the top of the supporting structure in a vertical plane in the direction which adds to the overturning moment resulting from Fxt. The moment, Mtx, shall be applied at the top of the supporting structure in a vertical plane normal to the wind direction (shaft torsion).

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

The unit direction vector for Mtx shall be in the direction of the wind. Alternately, the moments Mty and Mtx may be combined into a resultant overturning moment and applied in the direction which adds to the overturning moment resulting from Fxt. Note: Turbine weight shall be included in the fatigue investigation analysis. The equivalent constant range fatigue load Fxt includes wind loading on the turbine; therefore, the effective projected area of the turbine is not included in the fatigue investigation analysis. Equivalent constant range fatigue loads for vertical axis turbines shall be provided by the turbine manufacturer. The equivalent constant range fatigue loads shall be based on the turbine cycling between 50% and 150% of the rated power at a 30 mph wind speed. Fatigue loads shall include the effects of eccentric wind loading on the turbine and the effects of eccentric rotor mass. 11.3 Fatigue Analysis An analysis of the supporting structure shall be performed using the equivalent constant range loads from Sections 11.1 and 11.2. The resulting member stresses shall be considered as equivalent fatigue damage stress ranges. Equivalent fatigue damage stress ranges shall not exceed the design stress ranges specified in Section 11.4 for the indentified components. Other components of SWT supporting structures shall be considered to have adequate fatigue strength when properly sized for the extreme wind loading condition specified in Section 5.0. Note: The design stress ranges specified in Section 11.4 are considered as threshold fatigue stress ranges (indefinite number of cycles); therefore, the number of cycles based on the design life of the structure is not required for a fatigue analysis performed in accordance with this Design Supplement. 11.3.1 Self-Supporting or Bracketed Structures Analysis of pole and latticed self-supporting or bracketed structures shall be performed using a load factor of zero for dead load and a load factor of 1.0 for all other loads. The stress range in each component shall be considered to equal the absolute value of the stress in the component. 11.3.2 Cantilever Portions of Guyed Masts The cantilever portion of a guyed mast shall be modeled as a self-supporting structure in accordance with Section 11.3.1. 11.3.3 Guyed Masts below the Cantilever 11.3.3.1 Latticed Masts

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

The full height of the mast with the cantilever shall be analyzed using a load factor equal to 1.0 for all loads. The results of the initial tension condition and the results of the fatigue analysis shall be used to determine the stress ranges in the mast. Leg members below the cantilever that are subjected solely to axial compression from the fatigue analysis need not be investigated for fatigue. The stress range in leg members below the cantilever subjected to axial tension from the fatigue analysis shall be considered equal to the sum of the leg tension stress from the fatigue loading condition and the absolute value of the leg stress from the initial tension condition. The stress range in bracing members shall be equal to the absolute value of the stress form the fatigue analysis. 11.3.3.2 Tubular Pole Masts The full height of the mast with the cantilever shall be analyzed using a load factor equal to 1.0 for all loads. The results of the initial tension condition and the results of the fatigue analysis shall be used to determine the stress ranges in the mast. Tubular mast components below the cantilever with cross sections that are subjected solely to compression stresses (due to combined axial load and bending) from the fatigue analysis need not be investigated for fatigue. The stress ranges in a tubular mast component below the cantilever subjected to tension stresses from the fatigue analysis shall be considered equal to the sum of the maximum tensile stress in the component from the fatigue analysis and the absolute value of the maximum stress in the component from the initial tension condition. 11.4 Design Stress Ranges The stresses calculated form the fatigue analysis shall be considered as equivalent fatigue damage stress ranges and shall not exceed the values specified in Sections 11.4.1 and 11.4.2 unless otherwise specified. 11.4.1 Category A Components (limited to a stress range of 4.5 ksi [31 MPa]): 1. Pole structures at ports or welded attachments. 2. Pole flanges connected with a full penetration weld without a backer 3. Pole flanges connected with a full penetration weld with a backer connected to the flange with a full penetration or continuous fillet weld. 4. Pole flanges or latticed tower legs, with stiffeners connected to a continuous top annular ring plate. 5. Legs in latticed structures with welded connection plates, flanges or other welded attachments.

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

11.4.2 Category B Components (limited to a stress range of 2.6 ksi [18 MPa]): 1. Pole flanges connected with a full penetration weld with a backer connected to the flange without a full penetration or continuous fillet weld. 2. Pole socketed flanges connected with double fillet welds. 3. Latticed structure legs and pole flanges with stiffeners. 4. Main load carrying bracing members in latticed structures with effective slenderness ratios less than 60 that have welded end connections or welded gusset plates for use with a bolted connection. 5. Tension only bracing members with welded end connections or welded gusset plates 11.4.3 Anchor Rods (limited to a combined stress range of 7.0 ksi [48 MPa] The stress range shall be calculated by combining stresses due to axial loads and bending on the individual anchor rods regardless of whether grout is utilized and regardless of the distance between the bottom of the leveling nut and top of concrete. Axial anchor rod forces from a moment reaction shall be determined from an elastic distribution of anchor rod forces. The distance between the top of concrete and the bottom of the leveling nut shall be used to determine anchor rod bending moments based on assuming an inflection point equal to 0.65 times the gap dimension. Anchor rod bending stresses shall be determined using the anchor rod elastic section modulus. For anchor rods arranged in a round pattern, the following equations apply (other arrangements shall follow an equivalent methodology): dn = d - 0.9743 / nt inches = d - 0.9382(p) mm = [(dn)3] / 32

Fa1 = anchor rod axial load due to an applied vertical reaction = Pa / nar Fa2 = anchor rod axial load due to an applied resultant overturning moment reaction = 4(Ma) / [nar(Dp)] Va1 = anchor rod shear load due to an applied resultant shear reaction = 2(Va) / nar Va2 = anchor rod shear force due to an applied torsional moment reaction = 2(Ta) / [nar(Dp)] Mb = anchor rod bending due to an applied shear reaction = (Va1 + Va2)(0.65)(Iar) Ffar = stress range in anchor rod = (Fa1 + Fa2) / (An) + Mb / S

10

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

where: dn d nt p S Pa = tensile root diameter of anchor rod = nominal diameter of anchor rod = number of threads per inch = pitch of threads, mm = section modulus of anchor rod = applied vertical reaction (larger of tension or compression reaction) on anchor rod group nar = number of anchor rods Ma = applied resultant overturning moment reaction on anchor rod group Dp = anchor rod bolt circle Va = applied resultant shear reaction on anchor rod group Ta = applied torsional moment reaction on anchor rod group Iar = length form top of concrete to bottom of leveling nut An = net area of anchor rod through the treaded portion 11.5 Miscellaneous Requirements for Fatigue Strength 11.5.1 Latticed Structures The maximum effective slenderness ratios for members and the minimum gusset plate thicknesses for member connections shall be determined form Table 11-2 unless otherwise specified. 11.5.2 Guy Anchorages Guy connection plates for guyed mast anchor rods shall be limited to designs using pinned connection plates. 11.5.3 Connection Bolts for Turbine Bases Bolted connections shall be fully tensioned in accordance with the AISC Standard. The number, size, arrangement and grade of turbine base connection bolts shall be specified by the turbine manufacturer. 11.5.4 Complete Penetration Flange Plate Welds for Pole Structures A reinforcing outer fillet weld shall be provided for all complete penetration welds. The size of the weld reinforcement shall be no smaller than 25% of the pole wall but need not be greater than 0.375 inches [10 mm]. Complete penetration welds made without backers shall have an inner fillet weld size equal to the size of the reinforcing outer fillet weld. Backer bars, when used in complete penetration welds, shall be continuous for their full length with all backer bar joints made with complete penetration groove weld butt joints

11

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

in accordance with AWS. Backer bars shall not exceed 0.375 inches [10 mm] when a fillet weld is used to attach the backer bar to the flange plate. 11.5.5 Socketed Flange Plate Welds for Pole Structures The inner fillet weld shall be an equal leg fillet weld with the weld size not less than the pole wall thickness minus 1/16 inch [2 mm]. The outer fillet weld shall be an unequal leg fillet weld with the long leg of the fillet weld along the pole wall with an approximately 30 degree angle between the fillet weld and the pole wall. 12.0 OTHER STRUCTURAL MATERIALS This Design Supplement has been developed primarily for steel SWT supporting structures but may also be applied to other materials using appropriate resistance factors to result in an equivalent level of reliability. 12.1 Extreme Loading Conditions The nominal strengths for extreme loading conditions for material other than steel shall be based on the minimum strengths guaranteed by the manufacturer of the material or alternately, based on tests to determine strengths of 95% survival probability with a 95% confidence limit. Resistance factors applied to nominal strengths shall be in accordance with Table 12-1. 12.2 Fatigue Loading Condition The design stress range values indicted in Section 11.4 include appropriate resistance factors applied to the nominal stress ranges for steel components manufactured in accordance with TIA. Appropriate resistance factors for other materials shall be applied to the nominal fatigue stress ranges in accordance with the Table 12-2. For materials that do not display a fatigue threshold limit, the number of cycles used to determine the nominal stress range for use with this Design Supplement shall be based on 5 million cycles. 13.0 FOUNDATIONS Mat foundations for self-supporting structures shall be sized so that the reactions form the serviceability loading combination result in compressive soil bearing stress over the full plan dimension of the mat. Drilled shaft or pile foundations subjected to lateral load shall be designed considering repetitive loading soil conditions.

12

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

14.0 MAINTENANCE AND CONDITION ASSESMENT The maintenance and condition assessment of SWT supporting structure shall be in accordance with TIA except the recommended interval period is 6 months for all supporting structure types.

13

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

REFERENCE TABLES

Table 4-1 Force Coefficients (CF) for Pole Structures without Attachments (Refer to TIA for Pole Structures with Attachments) C Mph-ft [m/s-m] < 32 [4.4] (Subcritical) 32 to 64 [4.4 to 8.7] (Transitional) > 64 [8.7] (Supercritical)

Round 1.2 162/(C)1.42 [9.64/(C)1.42] 0.45

18-Sided 1.2 59.3/(C)1.13 [6.29/(C)1.13] 0.55

16-Sided 1.2 25.7/(C)0.884 [4.41/(C)0.884] 0.65

12-Sided 1.2 5.06/(C)0.415 [2.21/(C)0.415] 0.90

8-Sided 1.2 1.2 [1.2] 1.2

C = (I Kzt Kz)0.5 (V)(D) for D in ft [m], V in mph [m/s] I = TIA importance factor for wind loading Kzt = TIA topographic factor Kz = TIA velocity pressure coefficient V is the 50-year, 3-second gust basic wind speed for the loading condition under investigation. D is the pole outside diameter for rounds or the outside point-to-point diameter for polygons.

14

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

REFERENCE TABLES

Table 11-1 Fatigue Importance Factors, If TIA Structure Classification I II III Fatigue Importance Factor, If 0.70 1.00 1.35

Table 11-2 Latticed Structure Limitations Maximum Effective Slenderness of Members 200 185 175 Minimum Gusset Plate Thickness 3/16 [5 mm] 1/4 [6 mm] 3/8 [10 mm]

AWEA Turbine Power Rating Up to 10 kW Over 10 kW to 25 kW Over 25 kW

15

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

REFERENCE TABLES

Table 12-1 Resistance Factors for Extreme Loadings (Other Structural Materials) Type of Failure Yielding of ductile material Local or global buckling Fracture of brittle or ductile material Resistance Factor 0.90 0.85 0.75

Table 12-2 Resistance Factors for Fatigue Loading (Other Structural Materials) Basis of Nominal Stress Range 50% survival probability with coefficient of variation 15% 50% survival probability with coefficient of variation < 15% Test data with basis of 95% survival probability with a 95% confidence level Resistance Factor 0.60 0.67 0.85

16

ANSI/TIA-222-G-DS1-2011 DRAFT 3-29-2011 Rev 0

ANNEX A: REFERENCES (Informative) AASHTO, Standard Specifications for Structural Supports for Highway Signs, Luminaires, and Traffic Signals, 5th Edition, American Association of State Highway and Transportation Officials, 2009. AISC, Steel Construction Manual, 13th Edition, American Institute of Steel Construction, Inc., 2005. ASCE, Minimum Design Loads for Buildings and Other Structures, ASCE/SEI 7-05, American Society of Civil Engineers, 2005. AWEA, AWEA Small Wind Turbine Performance and Safety Standard, AWEA 9.12009, American Wind Energy Association, 2009 AWS, Structural Welding Code - Steel, AWS D1.1/D1.1M:2010, American Welding Society, 2010. IEC, Wind Turbine-Part 1: Design Requirements, IEC 61400-1, International Electrotechnical Commission, Third Edition 2005-08. IEC, Wind Turbine-Part 2: Design Requirements for Small Wind Turbines, IEC 614002, International Electrotechnical Commission, Second Edition 2006-03. TIA, Structural Standard for Antenna Supporting Structures and Antennas, ANSI/TIA222-G, Telecommunications Industry Association, 2005.

17

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Test Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDocument24 pagesTest Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDavidLarsonDDSfgaq100% (43)

- Roland KC-350 Parts List DespieceDocument31 pagesRoland KC-350 Parts List Despiecelperez_110824No ratings yet

- Gi-0007 021Document4 pagesGi-0007 021malika_00No ratings yet

- CA Inter GST Smart Summary Notes For Nov 23 May 24 & OnwardsDocument107 pagesCA Inter GST Smart Summary Notes For Nov 23 May 24 & OnwardsPriyanshu tripathi100% (4)

- Wind Energy Conversion Systems PDFDocument268 pagesWind Energy Conversion Systems PDFfotopredicNo ratings yet

- Diseño de Estanques - Javeed A. Munshi.Document59 pagesDiseño de Estanques - Javeed A. Munshi.Anonymous JcgSiw2jMb100% (2)

- AEC Militant MkIII Recovery User Manual V1Document78 pagesAEC Militant MkIII Recovery User Manual V1David Kelly100% (3)

- TCS BaNCS Service Repository Document - ReverseUUIDDocument9 pagesTCS BaNCS Service Repository Document - ReverseUUIDMohit GuptaNo ratings yet

- Honeywell UOP Gas Processing Brochure v2Document6 pagesHoneywell UOP Gas Processing Brochure v2Satria 'igin' Girindra Nugraha100% (1)

- Development of Job Recommender For Alumni Information SystemDocument6 pagesDevelopment of Job Recommender For Alumni Information SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- LPPEH Standard GuidelinesDocument27 pagesLPPEH Standard GuidelinesEncik Syafix57% (7)

- Research PDFDocument117 pagesResearch PDFSebas SilvaNo ratings yet

- Wind Loading On Base Stationantennas White PaperDocument11 pagesWind Loading On Base Stationantennas White PaperAnonymous JcgSiw2jMbNo ratings yet

- Manual IchaDocument21 pagesManual IchaAnonymous JcgSiw2jMbNo ratings yet

- Calico - Google's New Project To Solve Death - TIMEDocument2 pagesCalico - Google's New Project To Solve Death - TIMEEmerson DiegoNo ratings yet

- 2PAF Flight Plan 2028 Brochure PDFDocument2 pages2PAF Flight Plan 2028 Brochure PDFAir Force SMONo ratings yet

- Vocabulary B1 EnglishDocument10 pagesVocabulary B1 EnglishMaríaNo ratings yet

- Phrasal VerbsDocument81 pagesPhrasal VerbsDien HamNo ratings yet

- Vista Safire e IV LHDDocument504 pagesVista Safire e IV LHDSesar Sehat SantosoNo ratings yet

- The Evolution of Glass Façades - Aleksander T. ŚwiątekDocument10 pagesThe Evolution of Glass Façades - Aleksander T. ŚwiątekAlexSaszaNo ratings yet

- Cocamide DEADocument1 pageCocamide DEADyah Putri Ayu DinastyarNo ratings yet

- Criminology The Essentials 3rd Edition Walsh Test Bank DownloadDocument35 pagesCriminology The Essentials 3rd Edition Walsh Test Bank DownloadJohn Adamson100% (26)

- Cagayan State University - AndrewsDocument4 pagesCagayan State University - AndrewsWynie AreolaNo ratings yet

- ST Lucia March 2022 TBDocument26 pagesST Lucia March 2022 TBAries BautistaNo ratings yet

- Canon Ts5000 (Impressora) MANUALDocument441 pagesCanon Ts5000 (Impressora) MANUALMiguel DinisNo ratings yet

- Research Group 1 10 Zeus AutosavedDocument11 pagesResearch Group 1 10 Zeus AutosavedJudilyn MateoNo ratings yet

- Tubos para Intercambiadores. Principales Medidas BWG.: ASTM Heat Exchanger Tube - Principal BWG SizesDocument1 pageTubos para Intercambiadores. Principales Medidas BWG.: ASTM Heat Exchanger Tube - Principal BWG SizesSaraMendozaNo ratings yet

- Informe Milka Case StudyDocument5 pagesInforme Milka Case StudyCesar D. VillanuevaNo ratings yet

- Article On Effects of Tehri DamDocument10 pagesArticle On Effects of Tehri DamVinayakJindalNo ratings yet

- RLS 160 M MXDocument24 pagesRLS 160 M MXDamian OvidiuNo ratings yet

- Jawaharlal Nehru Technological University:: KakinadaDocument6 pagesJawaharlal Nehru Technological University:: KakinadaSai Ranganath BNo ratings yet

- RanitidineDocument14 pagesRanitidinePapaindoNo ratings yet

- NetcraftDocument9 pagesNetcraftapi-238604507No ratings yet

- Taxable Income and Tax DueDocument13 pagesTaxable Income and Tax DueSheena Gane Esteves100% (1)