Professional Documents

Culture Documents

SIS 103-Safety Standards

Uploaded by

Mahmoud Magdy RizkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIS 103-Safety Standards

Uploaded by

Mahmoud Magdy RizkCopyright:

Available Formats

2005 Emerson Process Management. All rights reserved. View this and other courses online at www.PlantWebUniversity.com.

SIS 103 - Safety Standards

15 minutes

In this course: 1

2 3 4 5 6 7 8 9

Overview

A New Approach From IEC 61508 Came IEC 61511 What About S84? Life-cycle Models Applying the Model in 61511 Resources for Compliance Benefits of Complying Summary

Overview

If your plant or process isn't already using safety standards such as IEC 61508, IEC 61511, and/or ANSI/ISA S84.00.01-2004, chances are you will be in the near future. Although you may initially think of them as sources of paperwork, hassles, and headaches, these standards play a vital role in making and keeping your plant safe. Their disciplined approach can also help ensure that your process control system, operational and maintenance procedures, and safety systems are harmonized in a way that leads to better operational performance. This course introduces the most relevant safety standards IEC 61508, IEC 61511, and ANSI/ISA S84.00.01-2004 and explains why complying with them makes good business sense.

What do all those acronyms stand for? IEC - International Electrotechnical Commission ISA - The Instrumentation, Systems, and Automation Society ANSI - American National Standards Institute

Hint As you go through the topics in this course, pay special attention to the following: How safety standards have changed Which standard is your best choice for new safety applications The benefits of standards-based life-cycle models What kinds of resources are required for compliance The key benefits of compliance

A New Approach In the past, safety standards were developed for a specific application, industry, or country. For example, ANSI P1.1-1969 is an industry consensus standard issued by the American National Standards Institute that defines safety requirements for mills producing pulp, paper, and paperboard. The major problem with this approach is that plants, and even entire industries, have found themselves trying to comply with multiple, overlapping safety standards that were often developed using completely different design and architecture philosophies. Add in the nuances of country or regional standards, and being sure you've achieved compliance becomes nearly impossible. Newer safety standards, however, have been developed using an approach that focuses on reducing risk and establishing a defined degree of operational excellence at each stage of the safety project's life cycle. This performance-based life-cycle approach produces a standard that more easily meshes with other standards, thus creating broader appeal and acceptance. It also makes it easier to produce high-quality results at the least possible cost. For process industries, the relevant safety standards are IEC 61508, IEC 61511, and ANSI/ISA S84.00.01-2004 (S84). These standards each define what is required to attain standard compliance, but in the case of IEC 61511 and S84 they leave the details of how to achieve compliance to plant owners and operators.

From IEC 61508 Came IEC 61511

So why does IEC have two safety standards? IEC 61508 (Parts 1 - 7), titled Functional safety of programmable electronic safety-related systems, is a comprehensive, all-inclusive, performance-based functional safety standard that applies to manufacturers and implementers of functional safety systems in a broad range of industries. In Europe, the seven parts of IEC 61508 are published as EN 61508, and any conflicting national CENELEC or CEN standards were subsequently withdrawn. IEC 61508 was used by some process industry plants to implement compliant safety instrumented systems

(SIS). However, early process-industry adopters noted that the standard was cumbersome and left too much room for interpretation on how to achieve compliance in these industries. After careful consideration, the IEC standards committee extracted, harmonized, and reworded relevant sections of IEC 61508 to form IEC 61511 specifically for process industries. The result is that IEC 61511 provides the process industries guidance and examples of how the standard is implemented -- while still ensuring compliance is achieved within the framework set forth in IEC 61508. This approach has made IEC 61511, Functional safety: Safety instrumented systems for the process industry sector, the safety standard of choice for process industries as witnessed by the growing number of references to it by safety agencies in China, Ireland, Italy, India, Norway, United Kingdom, and the United States; the number of papers being presented by end-users at conferences and symposiums; and the references on control system manufacturers' Web sites. While plants still have the option of applying IEC 61508, its main use is by instrumentation and control system manufacturers developing and selling SIS certified devices for use in IEC 61511-compliant applications.

What About S84?

Many national standards have been superseded by IEC 61508 and 61511. One example is the ANSI/ISA S84.01 safety standard that was widely used in the United States. Several years ago, following a number of unnerving accidents, safety experts within the process industry began a thorough review of existing safety standards.

Incidents leading to improved safety standards 1968 1974 1976 1984 1998 Pernis oil refinery, the Netherlands Flixborough, United Kingdom Seveso, Italy Bhopal, India Piper Alpha, North Sea 2 dead, 85 injured 28 dead, hundreds injured 700 injured 2,500 dead, 100,000 injured 165 dead, 61 injured

Among their conclusions was that existing standards were too industry-specific and limited the ability of safety experts to share best practices. From those findings came the formation of the ISA SP84 committee. Almost immediately, committee members agreed that a more appropriate standards approach would be to use a performance-based lifecycle model. The result of their work was ANSI/ISA S84.01-1996, Application of Safety Instrumented Systems for the Process Industries (S84). More recently, however, the S84 standard has been harmonized with IEC 61511, with one exception: ANSI/ISA S84.00.01-2004 includes a "grandfather" clause allowing installations currently using the 1996 version of S84 to continue doing so provided they determine that the safety equipment is designed, maintained, inspected, tested, and operated in a safe manner. Unless you're already using S84, therefore, your best choice would be to forgo the old ANSI/ISA standard and adopt IEC 61511 which is the same as S84-2004.

Life-cycle Models

A life-cycle model provides a structure for a series of processes to create or update a product or service. Life-cycle models can take many forms, but each provides a structure for approaching the myriad tasks involved in creating and managing a complex product or service.

A major benefit of a life-cycle-based standard is the ease it provides to leverage and integrate other lifecycle-based standards and practices. As the table shows, such models are used or recommended by a number of regulatory agencies and other bodies.

Organizations & agencies recommending use of life-cycle models International Standards Organization (ISO) U.K. Health & Safety Executive U.S. Food & Drug Administration Software Engineering Institute U.S. Occupational Safety & Health Administration U.S. Environmental Protection Agency Product & service quality Safety-related activities New drug approval and production High-availability software Worker safety Environmental protection

For example, the Software Engineering Institute has developed a number of software life-cycle models, several of which are used to create "survivable" software that is, mission-critical application software requiring security, fault tolerance, safety, reliability, reuse, performance, verification, and testing. Similarly, life-cycle-based current Good Manufacturing Practices (cGMPs) are integral to industries where product quality is essential, like those regulated by the U.S. Food & Drug Administration. Besides making it easier to integrate such standards, the discipline provided by the life-cycle approach helps produce high-quality results at the least possible cost.

Applying the Model in 61511

IEC 61511 permits customizing the life cycle model to fit your current practices - as long as you meet the standard's requirements. One approach uses five major life-cycle stages to address these requirements, plus a verification and documentation process throughout the cycle:

Life-cycle stage 1. Front-end engineering and conceptual design

IEC 61511 requirements Hazard and risk assessment (Clause 8) Allocation of safety functions to protection layers (Clause 9) Safety requirements specification for the SIS (Clauses 10 and 11)

2. Detailed design and engineering

SIS design and engineering (Clauses 11 and 12.4) SIS build, integration, and FAT (Clause 13)

3. Installation and startup

SIS installation and commissioning (Clause 14) SIS safety validation (Clauses 12.3, 12.7, and 15)

4. Provision of functional safety 5. Modification and updating - Verification and documentation (included in each stage)

SIS operations and maintenance (Clause 16) SIS modification (Clause 17) Verification (Clauses 7, 12.4, and 12.7) Documentation (Clause 19)

Together, these activities add up to meet the core requirement of IEC 61511:

Management of functional safety

Management of functional safety and functional safety assessment and auditing (Clause 5) Safety life cycle structure (Clause 6.2)

The following diagram shows how these activities fit together.

Front-end engineering & conceptual design Create conceptual process design Identify potential hazards Allocate safety requirements Decide whether an SIS is required Identify levels of tolerable risk and select target SILs Create Safety Requirements Specification Select technology, architecture, and proof test philosophy Calculate SIL for each safety function Provision of functional safety Operate and maintain SIS in accordance with documented procedures Perform proof tests as defined in the design to verify operation of the SIS

Detailed design Detailed design of - SIS field devices installation - SIS logic solvers hardware - SIS software Design verification Logic solver hardware build and verification SIS software configuration and safety function testing Integration of SIS logic solver Verification of integration (FAT) Create installation & commissioning documentation Create operations & maintenance documentation Modification & updating Assess scope of modification If change does not affect safety case then make change, and complete all required verification and change management procedures If change is significant then repeat the Safety Lifecycle

Installation & startup Install SIS field devices Install SIS logic solvers Integrate SIS into BPCS as required Verify installation Commission SIS Validate SIS

Resources for Compliance

Obviously, saying your company is committed to providing a safe working environment isn't enough. Management has to provide the resources needed to fulfill that commitment including appropriate funding, people, and training. That's part of building the environment and culture that must exist before IEC 61511 compliance can be achieved. IEC 61511 requires having persons with demonstrated safety engineering knowledge and experience appropriate for the process and the SIS technologies being used. The standard also says that the people assigned to engineer, design, and implement safety systems must have adequate training, management and leadership skills appropriate to their role in safety life-cycle activities, and knowledge of the applicable legal and safety regulatory requirements. It then becomes the job of these safety professionals to establish documented evidence that conformance to the IEC safety standard has been appropriately defined, achieved, and maintained. If you don't have all the right resources in-house, knowledgeable suppliers and consultants can help. IEC 61511 is an international standard, its life-cycle model is well understood, and it is being applied by a large number of companies. As the groundswell for its use continues, the number of knowledgeable resources will also increase making it ever easier to find qualified assistance. The PlantWeb Advantage

As the provider of the industry's first smart SIS, Emerson also offers a full range of services to help ensure your safety system provides the protection you need...and keeps providing it. These services including analysis and design, implementation, maintenance, and modification -- span the full lifecycle of your system, with TV-certified compliance to IEC 61511 best practices. If you want, we can also train your staff to make the most of your SIS, or provide access to Emerson field safety engineers in your area for ongoing support and maintenance.

Benefits of Complying

Depending on where you're located, compliance with Agencies endorsing IEC 61511 include IEC 61511 or other safety standards may be a legal requirement. Even if it's not, doing so makes good Factory Mutual Insurance Company sense. For one thing, the committee that developed IEC 61511 included globally recognized safety experts who drew on their their combined knowledge and experience to create the standard. The result is a rigorous set of "best practices" for engineering, implementing, verifying, operating, and maintaining robust and reliable safety instrumented systems. In short, it's a good way to help ensure the safety of your plant and community, while also minimizing lifecycle costs. But even when safety incidents do occur, having complied with the standard can help.

U.S. Occupational Health and Safety Administration (OSHA) U.S. Environmental Protection Agency (EPA) Automation, Software and Information Technology ASI of TV Industrial Services GmbH United Kingdom's Health & Safety Executive (HSE)

Investigations that follow an accident or environmental release often involve government agencies that have the authority to levy fines, send people to jail, close down a facility or all three. Among the questions they're likely to ask are Has this sort of incident occurred within this company or facility previously? What proactive processes were used to identify risks? What methods were used to quantify risks? What actions were taken to mitigate risks? What process was followed to ensure the mitigation was properly deployed? What processes are in place to ensure the mitigation solution continues to perform as expected over time? Answers to those sorts of questions are exactly what is produced by using IEC 61511. You may still face a tough investigation, but if you can prove that conformance to the IEC safety standard was appropriately defined, achieved, and maintained, you'll also reduce the risk of the investigating agency's sending anyone to jail or closing down the plant.

Summary

In this course you've learned that: For the process industries, key safety standards are IEC 61508, IEC 61511, and ANSI/ISA S84.00.01-2004. Today, in the process industries IEC 61511 or the new S84 is the best choice for end-users implementing a safety project or operating and maintaining a safety system. All three standards use a performance-based life-cycle model, which makes it easier to integrate them with other standards and to produce high-quality results at the least possible cost. IEC 61511 allows you some freedom to customize the life-cycle model to meet your needs, as long as you meet the standard's requirements. Doing so requires providing adequate funding, people, and training. Besides helping you keep your plant, personnel, and community safe, standards compliance can make it easier to deal with investigations after a safety incident.

You might also like

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Functional Safety Certified Expert IEC 61508 & IEC61511Document2 pagesFunctional Safety Certified Expert IEC 61508 & IEC61511scribd0423No ratings yet

- Xvi Paper 52Document16 pagesXvi Paper 52Abdeldjalil AchourNo ratings yet

- Safebook 1 - Functional Safety in The Process IndustryDocument170 pagesSafebook 1 - Functional Safety in The Process Industrykamy001100% (1)

- ISA Fire Gas Detection Process Industries: ScopeDocument4 pagesISA Fire Gas Detection Process Industries: ScopeAdolfo Eyzaguirre100% (1)

- Iec 61508Document10 pagesIec 61508mikestone32100% (2)

- Burner Managment SystemDocument46 pagesBurner Managment SystemAlejandra Arias100% (1)

- Paper Rockwell SISDocument6 pagesPaper Rockwell SISIsaac MendibleNo ratings yet

- Understanding ISA 84 ISADocument5 pagesUnderstanding ISA 84 ISAdavid_diaz_sNo ratings yet

- 3BUS095609 en Whitepaper - Is Your SIS CompliantDocument7 pages3BUS095609 en Whitepaper - Is Your SIS CompliantamjadnawazNo ratings yet

- A Primer On Sis Understanding Process Safety Systems Design DataDocument2 pagesA Primer On Sis Understanding Process Safety Systems Design DataAkoKhaledi100% (1)

- IEC61511-2017 2nd Edition PDFDocument61 pagesIEC61511-2017 2nd Edition PDFAmirNo ratings yet

- Investigation On Safety Related StandardDocument6 pagesInvestigation On Safety Related StandardCh Mansoor Anwar AttariNo ratings yet

- Safety Instrumented Systems SummersDocument19 pagesSafety Instrumented Systems SummersCh Husnain BasraNo ratings yet

- SIS DesignBasisRevalidationDocument13 pagesSIS DesignBasisRevalidationjoesuhreNo ratings yet

- ANSIISA 84.00.01-2004 and Existing Safety Instrumented SystemsDocument6 pagesANSIISA 84.00.01-2004 and Existing Safety Instrumented Systemsiman562No ratings yet

- The Long Awaited IEC 61511 Edition 2 and What It Means For The Process IndustryDocument10 pagesThe Long Awaited IEC 61511 Edition 2 and What It Means For The Process IndustryWalid IbrahimNo ratings yet

- RockWell Automation (2013) - Process Safebook 1 - Functional Safety in The Prcess Industry (Principles, Standards and Implementation)Document170 pagesRockWell Automation (2013) - Process Safebook 1 - Functional Safety in The Prcess Industry (Principles, Standards and Implementation)Georges Kouroussis100% (1)

- Que Es El SIL?Document2 pagesQue Es El SIL?marilu_valdez3553No ratings yet

- Functional Safety The Next Edition of IEC 61511 PDFDocument11 pagesFunctional Safety The Next Edition of IEC 61511 PDFweberyosNo ratings yet

- Industry Update SIS BMSDocument11 pagesIndustry Update SIS BMSthotalnNo ratings yet

- Safety Integrity LevelDocument2 pagesSafety Integrity Levelhorry andresNo ratings yet

- IEC 61511 Implementation - The Execution ChallengeDocument7 pagesIEC 61511 Implementation - The Execution Challengehmatora72_905124701No ratings yet

- A Burner Management System Is A Safety Instrumented System!Document2 pagesA Burner Management System Is A Safety Instrumented System!nootyinotNo ratings yet

- Es Hazop PPDocument39 pagesEs Hazop PPAmir AkhlaghiNo ratings yet

- Index: CIA Guidance For The Location and Design of Occupied Building On Chemical Manufacturing SitesDocument16 pagesIndex: CIA Guidance For The Location and Design of Occupied Building On Chemical Manufacturing SitesMr NU KHANNo ratings yet

- Differences Between IEC 61511 and ISA 84Document6 pagesDifferences Between IEC 61511 and ISA 84Arif MohamedNo ratings yet

- SAFA Presentation-IEC61511 Overview-A KneiselDocument40 pagesSAFA Presentation-IEC61511 Overview-A KneiselRiksa Wisudya Achmadsyah SugandaNo ratings yet

- Cyber SecurityDocument6 pagesCyber SecurityIman AtapoorNo ratings yet

- Compliant Standards?: Is Your Safety System With Today's SafetyDocument23 pagesCompliant Standards?: Is Your Safety System With Today's Safetyinglufer100% (1)

- Functional Safety For Mine Hoist-From Lilly To SIL3 Hoist ProtectorDocument20 pagesFunctional Safety For Mine Hoist-From Lilly To SIL3 Hoist ProtectorAndrew PeterNo ratings yet

- The Introduction of Iec 61511 in Norwegian Offshore IndustryDocument9 pagesThe Introduction of Iec 61511 in Norwegian Offshore IndustrymahshidNo ratings yet

- Overview of Safety InstrumentedDocument2 pagesOverview of Safety InstrumentedAceng PikriNo ratings yet

- Safety Instrumented Systems SummersDocument19 pagesSafety Instrumented Systems SummersOussama AbderrahimNo ratings yet

- Ansi Isa S84.01Document8 pagesAnsi Isa S84.01xochihua4986No ratings yet

- Cookbook Versus Performance SIS Practices: A B A BDocument5 pagesCookbook Versus Performance SIS Practices: A B A BjackrzysNo ratings yet

- ISO 26262 OverviewDocument19 pagesISO 26262 OverviewSrinivasan VenkatNo ratings yet

- Applying The Process Safety StandardsDocument125 pagesApplying The Process Safety Standardsdangvh78100% (3)

- The Principles of IEC 61508 and IEC 61511 Day 1Document147 pagesThe Principles of IEC 61508 and IEC 61511 Day 1rameeshamaheen92No ratings yet

- Safety Instrumented SystemDocument19 pagesSafety Instrumented SystemK_S_Krishna0001No ratings yet

- (Mahatir) Trend of International Safety StandardsDocument5 pages(Mahatir) Trend of International Safety StandardsAndiHilmySyahirNo ratings yet

- Safety Instrumented Systems: Angela E. Summers, PH.D., P.E. SIS-TECH Solutions, LLCDocument19 pagesSafety Instrumented Systems: Angela E. Summers, PH.D., P.E. SIS-TECH Solutions, LLCsayedNo ratings yet

- SIL Safety Integrity Level: Tools & ReferencesDocument13 pagesSIL Safety Integrity Level: Tools & ReferencesSteve Forster100% (1)

- SilDocument16 pagesSilRail_RajuNo ratings yet

- Functional Safety of Safety Instrumented SystemsDocument2 pagesFunctional Safety of Safety Instrumented SystemsSteve Forster100% (1)

- SIL 105 Article - Selection and Application of SIL Suitable Fire and Gas DetectorsDocument3 pagesSIL 105 Article - Selection and Application of SIL Suitable Fire and Gas DetectorsCezar DumitriuNo ratings yet

- Accelerating Motor Control Design For Functional Safety PDFDocument11 pagesAccelerating Motor Control Design For Functional Safety PDFLuu TinhNo ratings yet

- NHP Whitepaper - The Impacts and Applications of Functional MSSDocument7 pagesNHP Whitepaper - The Impacts and Applications of Functional MSSNiall BegleyNo ratings yet

- Design of Micro Controllers For SafetyDocument50 pagesDesign of Micro Controllers For SafetyLuca BeniniNo ratings yet

- CDOIF Guideline Demonstrating Prior Use v7 FinalDocument34 pagesCDOIF Guideline Demonstrating Prior Use v7 Finaldwi rakhmatullahNo ratings yet

- IEc 61508 CerftificationDocument6 pagesIEc 61508 CerftificationAnonymous NcB95G6XwNo ratings yet

- Safety Standards and Scrum - May2013Document13 pagesSafety Standards and Scrum - May2013Federico ViterboNo ratings yet

- Overview SiraDocument2 pagesOverview SiraIndranil HatuaNo ratings yet

- Ljungquist-Thelin2005 Chapter AnIEC62061CompliantSafetySysteDocument15 pagesLjungquist-Thelin2005 Chapter AnIEC62061CompliantSafetySysteNguyễn Thái BảoNo ratings yet

- Mastering Functional Safety and ISO-26262Document41 pagesMastering Functional Safety and ISO-26262v5350% (2)

- Safety Integrity LevelDocument5 pagesSafety Integrity Levelonafets100% (1)

- Reliability of Safety-Critical Systems: Theory and ApplicationsFrom EverandReliability of Safety-Critical Systems: Theory and ApplicationsNo ratings yet

- Industrial Network Security, Second EditionFrom EverandIndustrial Network Security, Second EditionRating: 3 out of 5 stars3/5 (2)

- Eb Converged It and OtDocument14 pagesEb Converged It and OtmykillerdroneNo ratings yet

- Digital ElectronicsDocument27 pagesDigital ElectronicsmykillerdroneNo ratings yet

- Digital and Analog Operation of A TKR-750/850 RepeaterDocument2 pagesDigital and Analog Operation of A TKR-750/850 RepeatermykillerdroneNo ratings yet

- Important Reminders: Step 1Document4 pagesImportant Reminders: Step 1mykillerdroneNo ratings yet

- Pretreatments To Prevent Darkening of Fruits Prior To Canning orDocument2 pagesPretreatments To Prevent Darkening of Fruits Prior To Canning ormykillerdroneNo ratings yet

- Haiwell PLC CatalogueDocument62 pagesHaiwell PLC CataloguemykillerdroneNo ratings yet

- Object Database Tutorial: Rick CattellDocument48 pagesObject Database Tutorial: Rick CattellmykillerdroneNo ratings yet

- Nanovna: Very Tiny Handheld Vector Network Analyzer User GuideDocument12 pagesNanovna: Very Tiny Handheld Vector Network Analyzer User GuidemykillerdroneNo ratings yet

- 0 RPEXPRESS 16 Port LT1310F5Document2 pages0 RPEXPRESS 16 Port LT1310F5mykillerdroneNo ratings yet

- Network Solutions For Tunnel Automation 1614004261Document77 pagesNetwork Solutions For Tunnel Automation 1614004261mykillerdroneNo ratings yet

- Automation IntegratedDocument11 pagesAutomation IntegratedcmduranNo ratings yet

- CS DeltaV Security Manual-Introduction OnlyDocument5 pagesCS DeltaV Security Manual-Introduction Onlymykillerdrone0% (1)

- PDS: Rev:S STATUS:Released Printed: Dec 10, 2014Document2 pagesPDS: Rev:S STATUS:Released Printed: Dec 10, 2014mykillerdroneNo ratings yet

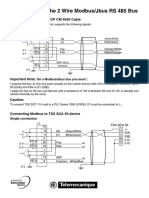

- FA11881-Connection To The 2 Wire Modbus-Jbus RS 485 Bus-EN PDFDocument2 pagesFA11881-Connection To The 2 Wire Modbus-Jbus RS 485 Bus-EN PDFmykillerdroneNo ratings yet

- P091 eDocument142 pagesP091 emykillerdroneNo ratings yet

- DeltaV v13 FlyerDocument4 pagesDeltaV v13 FlyermykillerdroneNo ratings yet

- S7komm eDocument228 pagesS7komm emykillerdroneNo ratings yet

- Bayley Scales of Infant Development IIDocument2 pagesBayley Scales of Infant Development IIbutterflybaby04No ratings yet

- Nursing Care Plan: Her Last Menstrual Period Was May 28 of The Year WithDocument2 pagesNursing Care Plan: Her Last Menstrual Period Was May 28 of The Year WithMiguel VismonteNo ratings yet

- Stem Cells and The Regenerative Therapy Following Lameness Resulting From Equine Tendon InjuryDocument15 pagesStem Cells and The Regenerative Therapy Following Lameness Resulting From Equine Tendon InjuryCharlotte ButlerNo ratings yet

- The Bold and The Beautiful. Influence of Body Size of Televised Media Models On Body Dissatisfaction and Actual Food IntakeDocument8 pagesThe Bold and The Beautiful. Influence of Body Size of Televised Media Models On Body Dissatisfaction and Actual Food IntakeKATALINA IGNACIA AZÓCARNo ratings yet

- Meghan Baxendell Resume January 2017 OnlineDocument3 pagesMeghan Baxendell Resume January 2017 Onlineapi-323081470No ratings yet

- Facilities ManagementDocument21 pagesFacilities ManagementEduardo Viana100% (1)

- Discrimination in Different FormsDocument2 pagesDiscrimination in Different FormsPillow ChanNo ratings yet

- Attending Physicians Statement - Form CDocument1 pageAttending Physicians Statement - Form CPritam sarkarNo ratings yet

- Aurora Juliana Ariel - The QuestDocument215 pagesAurora Juliana Ariel - The QuestCristian Catalina100% (3)

- Spine Care Technologies Inc. and Zober Industries Inc. Announce Strategic AllianceDocument3 pagesSpine Care Technologies Inc. and Zober Industries Inc. Announce Strategic AlliancePR.comNo ratings yet

- Jurnal PsikiatriDocument4 pagesJurnal PsikiatriSri SiswatiNo ratings yet

- Health & Safety Topic: HairDocument15 pagesHealth & Safety Topic: HairdyanNo ratings yet

- The Tactical Combat Casualty Care Casualty Card - TCCC Guidelines - Proposed Change 1301Document9 pagesThe Tactical Combat Casualty Care Casualty Card - TCCC Guidelines - Proposed Change 1301Paschalis DevranisNo ratings yet

- Jumpstart: Name: Angel E. PicazoDocument2 pagesJumpstart: Name: Angel E. PicazoAngel PicazoNo ratings yet

- Slu Brochure Ay 2014-2015Document2 pagesSlu Brochure Ay 2014-2015Michael BermudoNo ratings yet

- Ankylosing Spondylitis Disease Activity ScoreDocument2 pagesAnkylosing Spondylitis Disease Activity ScoreDebarshi DasNo ratings yet

- Case Study Keme 1Document9 pagesCase Study Keme 1JhovelNo ratings yet

- Material Safety Data Sheet: Section I - Chemical Product and Company IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - Chemical Product and Company IdentificationMu ClasNo ratings yet

- NCP Acute Pain Related To Tissue Ischemia As Manifested by Changes in Level of Consciousness PDFDocument3 pagesNCP Acute Pain Related To Tissue Ischemia As Manifested by Changes in Level of Consciousness PDFOGNTVNo ratings yet

- Conflict or Consensus - An Investigation of Stakeholder Concerns DuringDocument10 pagesConflict or Consensus - An Investigation of Stakeholder Concerns DuringhohoexeNo ratings yet

- Health and Wellness Programs For CVommercial Truck Drivers 144 PagesDocument91 pagesHealth and Wellness Programs For CVommercial Truck Drivers 144 PagesDenise Mathre100% (1)

- Recruit HandbookDocument72 pagesRecruit HandbookJUAN RAMON0% (1)

- Chest Drains Al-WPS OfficeDocument16 pagesChest Drains Al-WPS OfficeisnainiviaNo ratings yet

- CertificateDocument3 pagesCertificateRathnayaka NewilNo ratings yet

- Turner 1st SEM at FinalDocument102 pagesTurner 1st SEM at FinalSashikant Sharma100% (1)

- The Amazing DeclineDocument26 pagesThe Amazing DeclineSuzanne HumphriesNo ratings yet

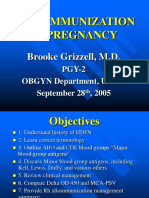

- Alloimmunization in Pregnancy: Brooke Grizzell, M.DDocument40 pagesAlloimmunization in Pregnancy: Brooke Grizzell, M.DhectorNo ratings yet

- Boq Lahan Parkir Hotel BogorDocument2 pagesBoq Lahan Parkir Hotel BogorFariz MemetNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument8 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary LevelKelvin SerimweNo ratings yet

- REPORTDocument1 pageREPORTFoamy Cloth BlueNo ratings yet