Professional Documents

Culture Documents

Shipconstruction Iindmate 100211

Shipconstruction Iindmate 100211

Uploaded by

pramodkb_cusatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shipconstruction Iindmate 100211

Shipconstruction Iindmate 100211

Uploaded by

pramodkb_cusatCopyright:

Available Formats

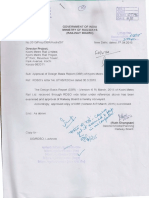

SECOND MATE (FOREIGN GOING) SUBJECT: SHIP CONSTRUCTION

TOPICS Teaching method/hours Lectures Exercise Practicals

Competence 13: Maintain sea-worthiness of the ship 13.1. Ship construction(Including corrosion and maintenance of Hull and fittings) 13.1.1 Ship dimensions and form: Illustrate : Mid-ship section, General cargo ships, Oil, chemical and gas tankers, Bulk carriers, Combination carriers, Container ships, Ro-Ro ships Passenger ships 6 Side elevation and plan layout of: General cargo ships, Oil, chemical and gas tankers, Bulk carriers, Showing holds/ tanks, engine room, hatchways, DB tanks, peak tanks and position of bulkheads Define: Camber, Rise of floor, Flare, Shear, Rake, Parallel middle body, 13.1.2 Ship stresses : Explain: Hogging, Sagging, Racking, Panting, Pounding, Slamming Torsion stresses Localized loading Water pressure loads on ships hull Liguid pressure loads on tank structures Shear Force and Bending moments. Describe Constructional features to compensate for above stresses. 13.1.3 Hull structure : Page 1 of 2

TOPICS Explain: Standard steel sections (flat plate, offset bulb plate, equal angle, unequal angle, channel, tee). Structural components on ship plans. Frames, floors, beams, knees, brackets, shell plating, decks, tank tops, bulkheads Stiffeners, Pillars, Girders, Coamings, Bulwarks and Breast hook. Stress concentration in the deck round hatch opening Loss of strength at hatch opening Why transverse bulkheads have vertical corrugations and longitudinal bulkheads have horizontal corrugations. Bilge keel Sketch and label: Double bottom structure for longitudinal and transverse framing. Combined system of framing on transverse sections of the ship A plane bulkhead showing connections to sides, deck and double bottom. Corrugated bulkhead Duct keel Deck edge, attachment between shear strake and stringer plate Connection of superstructures to the hull at the ship side 13.1.4 Bow and stern : Explain with Sketch Stern frame, Panting and pounding arrangements Transom stern showing connections to the stern frame 13.1.5 Fittings : Sketch and describe: Weather tightness of the hatches, coamings and cross joints including cleating arrangements Transverse section showing arrangement of hatch coamings, and deep webs Hatch corner and structural arrangements in plan view Openings in oil, chemical, gas tankers, Page 2 of 2

Teaching method/hours Lectures Exercise Practicals

TOPICS Chain lockers and attachment of cables, Bilge piping system, strum box Ballast system, sounding and air pipes Deck freeing arrangements, freeing ports, scuppers and open rails Hold drainage systems and related structure Typical mooring / anchoring arrangement in forecastle showing the leads of mooring Fire main arrangement Describe Roller, multi angle, pedestal and panama fair lead Mooring bitts showing their attachment to the decks Cable stopper 13.1.6 Rudders and propellers : Sketch and describe: Rudders: balanced, semi-balanced, Propeller: Boss, Rake, Skew, Face, Back, tip, radius, pitch. Stern tube- oil lubricated only Explain Purpose of rudder carrier and pintles Rudder trunking Arrangement of watertight gland around the rudder stock Controllable pitch propeller. 13.1.7 Load lines and draught marks : Define: Deck line, freeboard, Plimsoll line FP, AP, LBP, LOA, Moulded depth, Breadth, Draft. Sketch Load lines of a vessel. Use of loadline zone chart TOTAL

Teaching method/hours Lectures Exercise Practicals

29

Page 3 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mla628 Owner ManualDocument130 pagesMla628 Owner ManualmarianoNo ratings yet

- Mil STD 1797Document717 pagesMil STD 1797DBestel100% (4)

- 14 02 17 Balfour Beatty (BBASJV) Criminally Suppressed Criminal ReportDocument12 pages14 02 17 Balfour Beatty (BBASJV) Criminally Suppressed Criminal ReportTom CahillNo ratings yet

- DHLDocument3 pagesDHLMayilai Kumaran Jeyaratnam33% (3)

- VSP PDFDocument47 pagesVSP PDFVisuNo ratings yet

- Contoh InvoiceDocument2 pagesContoh InvoiceLinda RizkaNo ratings yet

- Report of AS 350 B2 B3 and EC 130 B4 T2 Rev1Document33 pagesReport of AS 350 B2 B3 and EC 130 B4 T2 Rev1EX919No ratings yet

- History of Puerto Galera - Samarita - Sandoval Dianne - Sandoval RecuerdoDocument3 pagesHistory of Puerto Galera - Samarita - Sandoval Dianne - Sandoval RecuerdoSAMARITA, SHAINA MARIE J.No ratings yet

- CarsDocument164 pagesCarsMikey Ciurea100% (4)

- Palm Islands ReportDocument2 pagesPalm Islands ReportRicardoBonoNo ratings yet

- SBB Cargo in 2009.: An Extract From SBB's Annual ReportDocument24 pagesSBB Cargo in 2009.: An Extract From SBB's Annual ReportintensolineNo ratings yet

- !transportationDocument28 pages!transportationКатяNo ratings yet

- Lyrics 2Document106 pagesLyrics 2Neil V. MonteleoneNo ratings yet

- Important Information About Your 140 & 210 Climate Control PanelsDocument4 pagesImportant Information About Your 140 & 210 Climate Control PanelsLesia DeFeliceNo ratings yet

- Table of ContentsDocument68 pagesTable of ContentsvjdjeddyNo ratings yet

- CDI - Harmonized Vessel Particulars Questionnaire (HVPQ) - 6th EditionDocument76 pagesCDI - Harmonized Vessel Particulars Questionnaire (HVPQ) - 6th EditionQuốc Tiến TrịnhNo ratings yet

- PendahuluanDocument6 pagesPendahuluanadiw1072No ratings yet

- SAP MM PresentationDocument157 pagesSAP MM PresentationArvind0% (1)

- DBR KochiDocument22 pagesDBR Kochipmali2No ratings yet

- 8.5 Chute, Charging Hopper Deep Mining General (Steep Formation) Underground Mining LoadingDocument6 pages8.5 Chute, Charging Hopper Deep Mining General (Steep Formation) Underground Mining LoadingJuan MontufarNo ratings yet

- California Bearing Ratio PrintDocument5 pagesCalifornia Bearing Ratio PrintvethamoortyNo ratings yet

- Integrated II Project bekiLASTDocument80 pagesIntegrated II Project bekiLASTkhedira samiNo ratings yet

- Two-Lane Highway Capacity and LOS Analysis Exam 2Document7 pagesTwo-Lane Highway Capacity and LOS Analysis Exam 2Madriaga RayNo ratings yet

- F3000 CFDDocument2 pagesF3000 CFDdhenwikanNo ratings yet

- SHT Question Bank1Document10 pagesSHT Question Bank1Deepak PooranachandranNo ratings yet

- The Weddington EffectDocument140 pagesThe Weddington EffectkittleboyNo ratings yet

- Staircases and BalconiesDocument4 pagesStaircases and Balconieskundanika prasadNo ratings yet

- What Is The Difference Between Dual Fuel and RCCIDocument2 pagesWhat Is The Difference Between Dual Fuel and RCCIAbdulrahman Al HuribyNo ratings yet

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pages017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- Update BRTC Bus and Route EnglishDocument2 pagesUpdate BRTC Bus and Route EnglishZayaan ShohailNo ratings yet